How X-Ray Inspection Enhances Quality Control in PCBA Manufacturing

X-ray inspection improves PCBA manufacturing by finding hidden problems. It creates a dependable process to keep electronic assemblies high quality.

Before using X-ray, manufacturing had a 97% success rate.

After using X-ray, the rate went up to 98%.

This change lowers failures and saves a lot of money.

X-ray testing checks products without harming any parts, making them more reliable.

Key Takeaways

X-Ray Inspection boosts PCBA success from 97% to 98%. It cuts failures and saves money.

This method spots hidden issues like solder gaps or misplaced parts. It does this without harming the components, ensuring great quality.

Automated X-Ray Inspection (AXI) makes production faster and reduces mistakes. It is very important for fields like aerospace and medical devices.

The Role of X-Ray Inspection in PCBA Manufacturing

Understanding X-Ray Inspection Technology

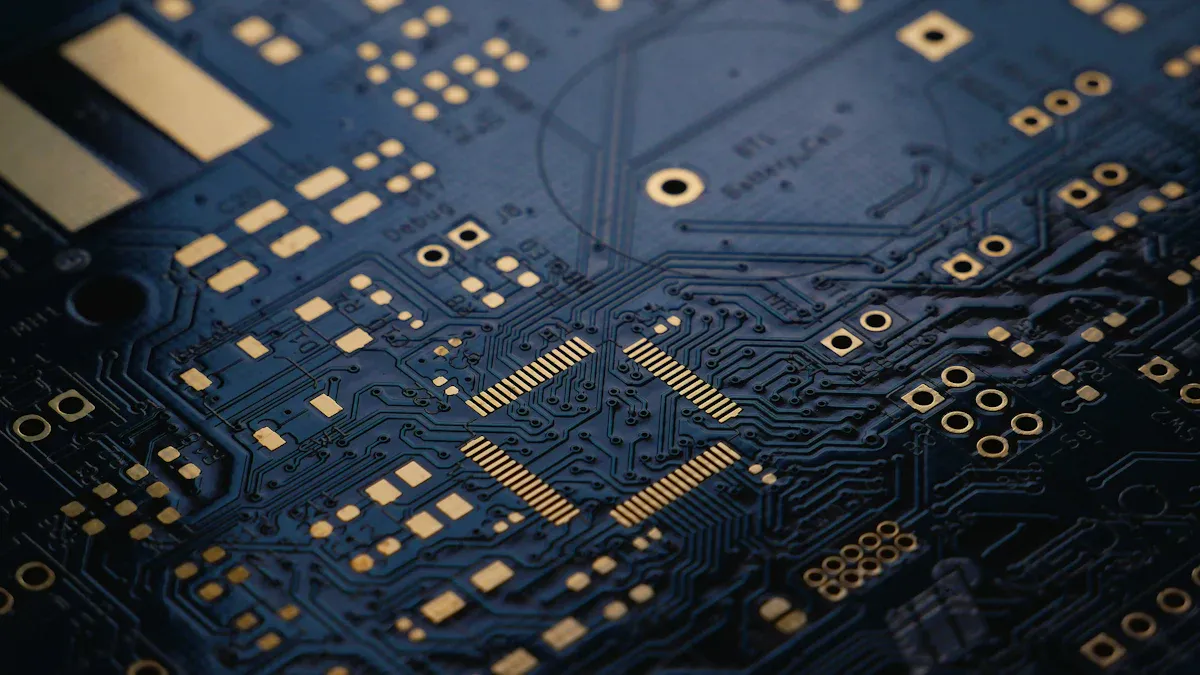

X-Ray Inspection changes how we check PCBA quality. It uses special imaging to find hidden problems that other methods miss. This is very important for keeping products safe and working well, especially in electronics, cars, and airplanes.

The system takes clear pictures of parts inside the PCB. This helps find issues like bad solder joints, gaps, or parts not lined up right. Unlike looking at parts by eye, X-Ray Inspection checks inside without breaking anything. It makes sure every part meets strict quality rules.

Key features of X-Ray Inspection systems include:

Clear images to spot even tiny problems.

Fast testing that doesn’t harm parts.

Works with tricky parts like BGAs and QFNs.

More companies are using X-Ray Inspection because it’s so useful. New technology and research make these systems better all the time. They are now a must-have for making high-quality products.

Why X-Ray Inspection is Essential for Quality Control

In PCBA manufacturing, quality control makes sure products work well in all conditions. X-Ray Inspection is key because it finds problems with great accuracy. Automated X-Ray Inspection (AXI) systems lower defects and improve production, helping achieve near-perfect results.

Here are some benefits:

Advantage | Description |

|---|---|

Consistent Quality Checks | Gives fair and accurate results, reducing human mistakes. |

High Detail Detection | Spots tiny issues like cracks or gaps that others miss. |

Fast and Safe Testing | Tests quickly without breaking parts, saving time. |

These advantages make X-Ray Inspection vital for industries needing reliable products. For example, airplane and medical device makers depend on it to meet strict safety rules.

LTPCBA’s Commitment to Quality with X-Ray Inspection

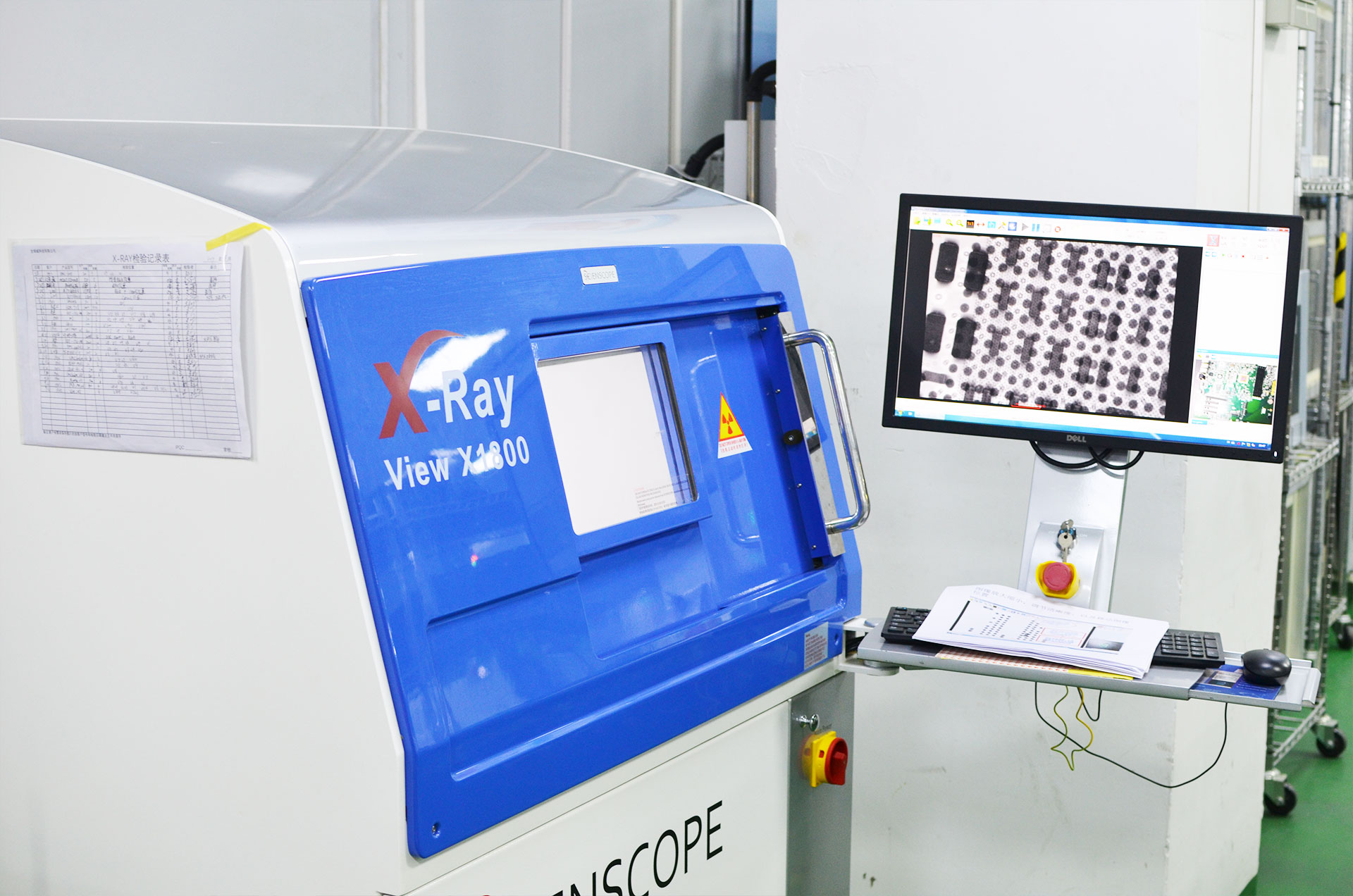

At LTPCBA, X-Ray Inspection is used in every step of making PCBs. This ensures products meet top standards like ISO, IATF, and UL.

LTPCBA uses X-Ray to find hidden problems in tricky parts like BGAs and QFNs. This helps them reach a 99.5% success rate. It also keeps costs low and production high, making LTPCBA a trusted partner for your PCB needs.

With advanced X-Ray systems, LTPCBA delivers high-quality products on time. Whether you need prototypes or medium-sized orders, LTPCBA’s focus on new ideas and efficiency helps your projects succeed.

Benefits of X-Ray Inspection in PCBA Manufacturing

Finding Hidden Problems

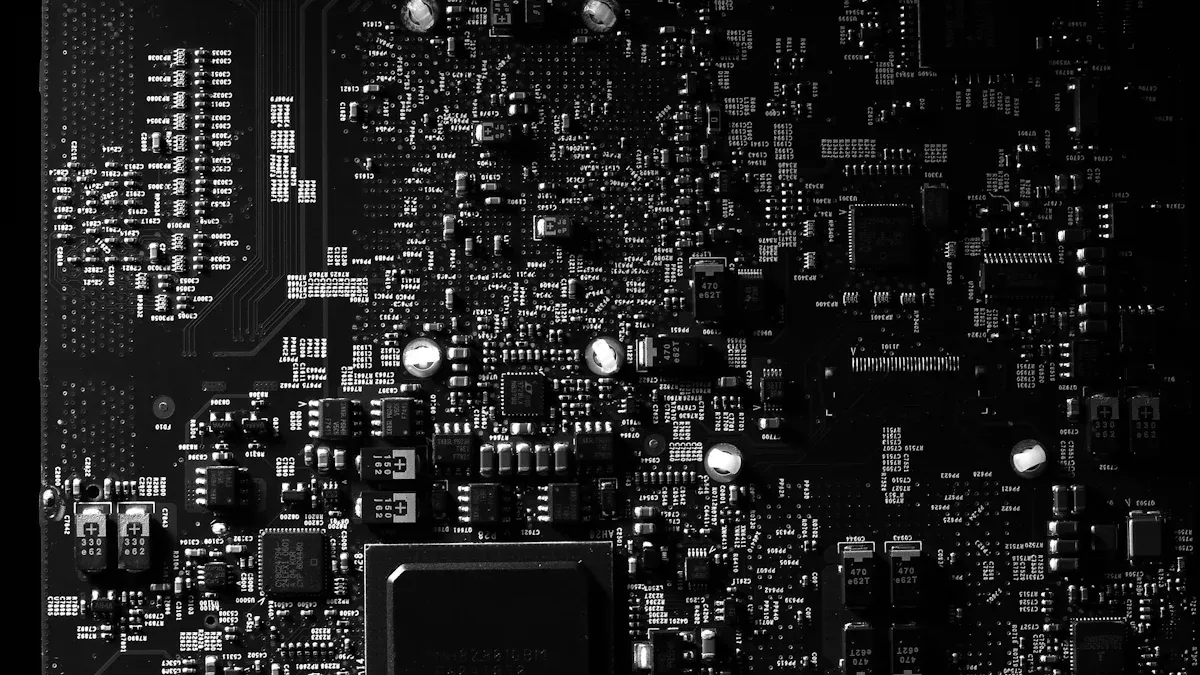

Looking at PCBA parts with your eyes isn’t always enough. Some problems, like gaps in solder or crooked parts, are hard to see. X-Ray Inspection solves this by showing clear images of hidden issues.

It’s the only way to find solder gaps without breaking parts. This helps keep the assembly strong and reliable.

Smart tools, like Viscom’s software, measure gaps and check if they stay under 25%. This is important for meeting quality rules.

Using X-Ray Inspection helps keep products safe and lowers the chance of failure. It makes sure every part meets strict standards, which is very important for industries like airplanes, cars, and electronics.

Testing Without Damage

Old testing methods often break parts, making them useless. X-Ray Inspection avoids this by testing parts without harming them. This saves time and keeps products in good shape.

Efficiency Feature | What It Does |

|---|---|

Accuracy | Finds inside problems without breaking anything |

Speed | Quickly takes pictures and gives results |

Costs less than tests that destroy parts |

Non-damaging tests mean you can check parts again without ruining them. This keeps results steady and makes products more dependable. X-Ray Inspection finds problems you can’t see, keeping products safe and high-quality.

Helping Production and Cutting Costs

X-Ray Inspection doesn’t just improve quality; it also helps make more products and spend less money. By using machines to do inspections, you need fewer people and work faster.

New X-Ray systems use AI to sort problems automatically. This lowers mistakes and makes checks more accurate.

Machines follow industry rules better and cost less to run.

Industries like airplanes, cars, and electronics gain a lot from these upgrades. For example:

Industry Type | Money-Saving Benefits |

|---|---|

Airplanes and Defense | Focus on strong materials and safe testing methods |

Cars | Careful checks of parts and welding |

Electronics | Looks at batteries and circuit boards |

Using X-Ray Inspection helps make more products while spending less money. This technology keeps your factory running smoothly and gives you an edge over competitors.

Applications of X-Ray Inspection Across Industries

Consumer Electronics and High-Tech Devices

Precision matters in electronics like phones and laptops. X-ray inspection helps find hidden problems in tiny parts. Defects in solder joints or micro-components are hard to see. X-ray systems make these issues clear. Automated X-ray inspection (AXI) is very helpful for this.

Evidence Description | Key Points |

|---|---|

Importance of AXI in manufacturing | |

Advancements in AXI technology | Fast imaging checks the entire surface for defects. |

Quality assurance | Keeps products safe and meets quality rules for success. |

AI-powered X-ray systems are improving electronics production. These tools help handle complex designs and smaller parts. They also meet the growing need for better PCBs.

Automotive and Aerospace Applications

Safety is critical in cars and airplanes. X-ray inspection checks parts to meet strict safety rules. It finds cracks, gaps, or misaligned pieces in important systems.

Car makers use X-ray to check welds and electronic parts.

Airplane builders inspect lightweight materials for strength and safety.

Automated X-ray systems save time and money while keeping safety high. These industries depend on X-ray technology for reliable production.

Medical Devices and Critical Systems

Medical devices must work perfectly. X-ray inspection ensures tools like pacemakers and imaging machines are free of flaws. It finds even tiny problems to keep patients safe.

X-ray machines improve safety by spotting contaminants and ensuring quality. They work fast and accurately, which is vital in life-saving industries. Though expensive at first, they reduce recalls and improve reliability over time.

X-Ray Inspection helps make sure PCBs are top quality. It finds hidden problems like gaps or broken connections, stopping expensive mistakes. Its smart tools, like fast 3D checks and AI image tools, keep production steady and cut costs. This technology is key for making PCBA manufacturing reliable and efficient.

Feature | Benefit |

|---|---|

Fast 3D checks | Keeps production steady in making tiny chip packages |

AI image tools | Automates tasks, needing fewer skilled workers |

Clean room use | Reduces waste during sudden production changes |

FAQ

What is X-ray inspection in PCBA manufacturing?

X-ray inspection uses pictures to find hidden problems in PCB assemblies. It checks inside parts without breaking them to ensure quality.

Tip: X-ray inspection works best for tricky parts like BGAs and QFNs.

How does X-ray inspection improve production efficiency?

It spots problems early, cutting down on waste and fixes. Automated tools test faster, keeping quality steady while saving money and boosting production.

Why is X-ray inspection essential for industries like aerospace and medical devices?

These industries need perfect products. X-ray inspection finds tiny flaws in important parts, meeting strict safety and performance rules.

Note: Strong PCBs are crucial for life-saving tools and critical systems.

See Also

The Importance of AOI in Ensuring PCBA Quality Control

Understanding SPI Inspection's Role Post-SMT in PCBA Production

Ensuring Quality Production Through Advanced Turnkey PCBA Solutions

Essential PCBA Processing Standards for Medical Equipment Manufacturing