Why X-Ray Inspection is Essential for High-Reliability Electronics Manufacturing

You need X-Ray Inspection to check the quality of electronics. It helps make sure electronics work well and last long. Only this technology can find hidden problems like cracks or empty spaces. These problems can make products unsafe or not work right. In industries like automotive or aerospace, one hidden problem can cause big failures.

Key Takeaways

X-Ray Inspection looks for hidden problems like cracks and parts that are not lined up. It does not hurt the electronics. This helps make sure products work well and last a long time.

This technology helps find problems early. It lowers costs and makes things safer. It also helps meet strict rules like ISO and IATF.

Picking LTPCBA gives you good quality checks and quick help. You get products that pass hard tests with high accuracy and trust.

Hidden Defects

Solder Joints

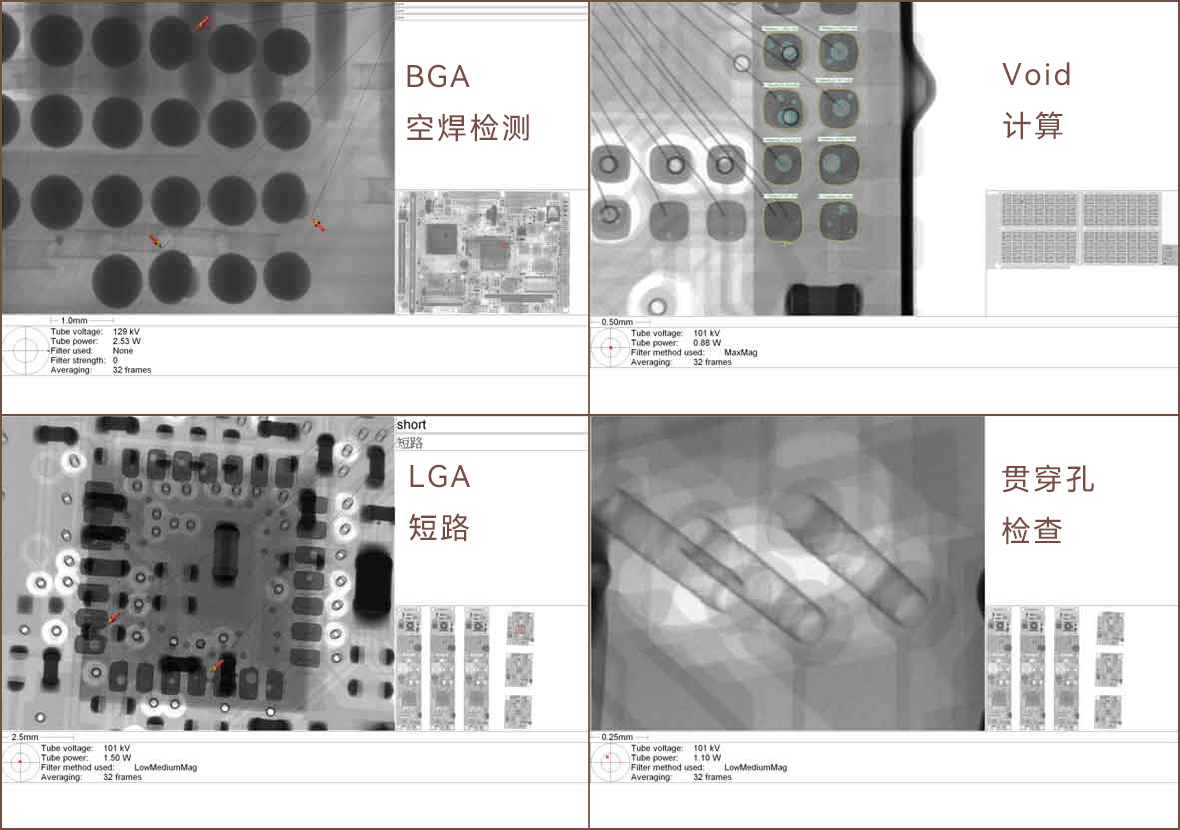

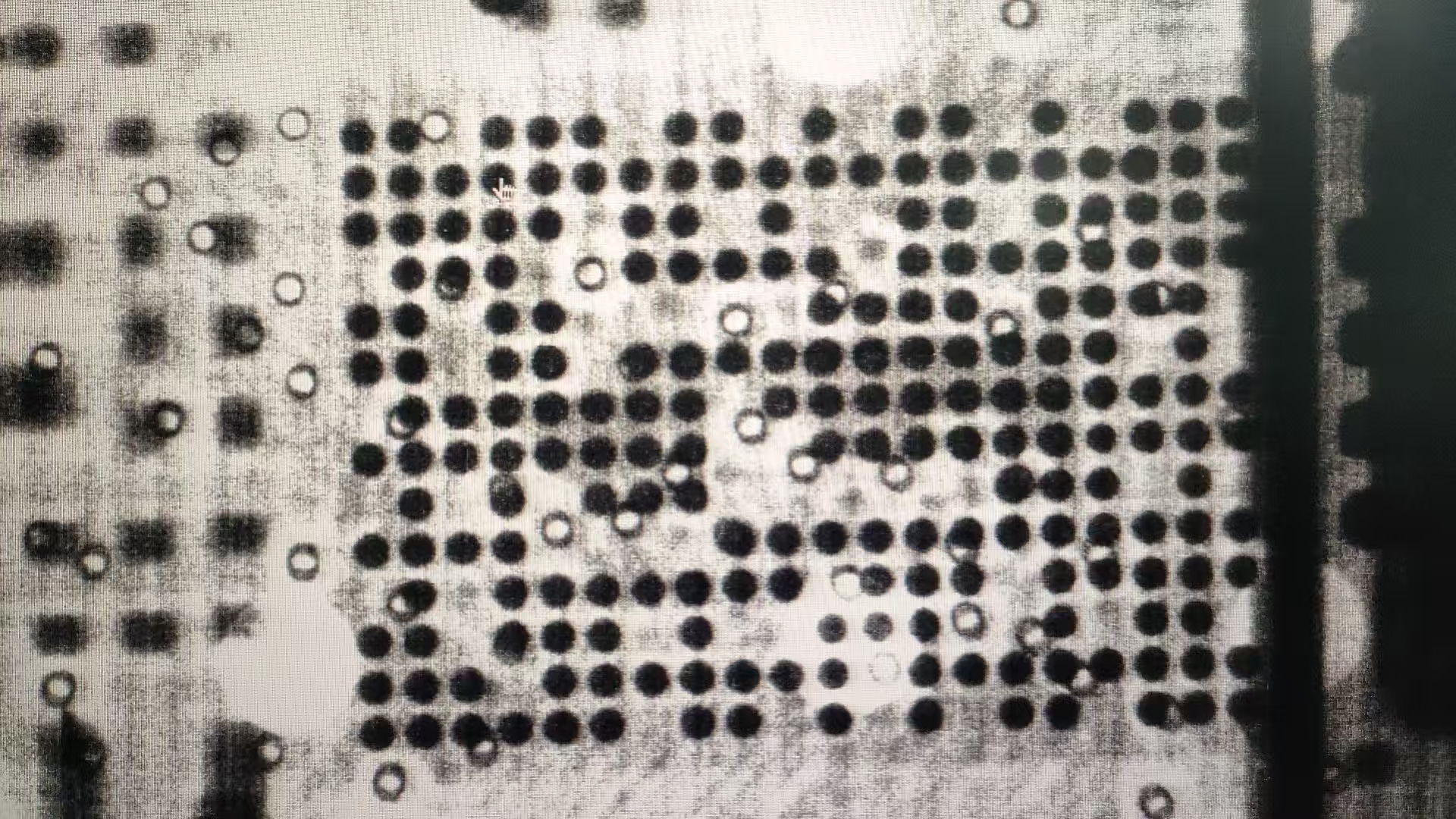

Solder joints hold parts together on a circuit board. They need to be strong and not have any problems. If there are defects, your electronics might not work right. People can look for problems, but they often miss hidden ones. Machines that use cameras help, but they cannot see inside things like BGAs. X-ray inspection lets you see inside and find things like empty spaces, cracks, or parts that do not line up. Other ways cannot find these problems. Studies show 3D X-ray can even watch how these problems get worse when stressed. This tool helps you find issues early, so you can fix them before they cause trouble.

Component Alignment

Parts must be lined up right for electronics to work well. Even a small mistake can cause bad connections or shorts. XCT helps you find these mistakes very well. Experts have shown XCT can spot errors by checking pictures against known good ones. Software can fix these mistakes, making your checks better. This makes sure every part is in the right place. It lowers the chance of having to fix things later or having products fail.

Internal Cracks

Internal cracks are very dangerous because you cannot see them. They can make things break suddenly. Studies show hidden cracks can raise costs by 25%. They can also make equipment work 10-15% worse. X-ray inspection helps you find these cracks before they cause problems. If you catch them early, you keep your products safe and protect your company’s name.

Tip: Doing X-ray checks often helps you get more good products the first time and keeps your costs down.

X-Ray Inspection Benefits

Non-Destructive Testing

You can check electronics without breaking them. X-Ray Inspection lets you look inside your products. You can find cracks, empty spaces, or parts that are not lined up. Other ways only show the outside, but this one shows the inside. You do not need to cut or damage anything. This saves both time and money.

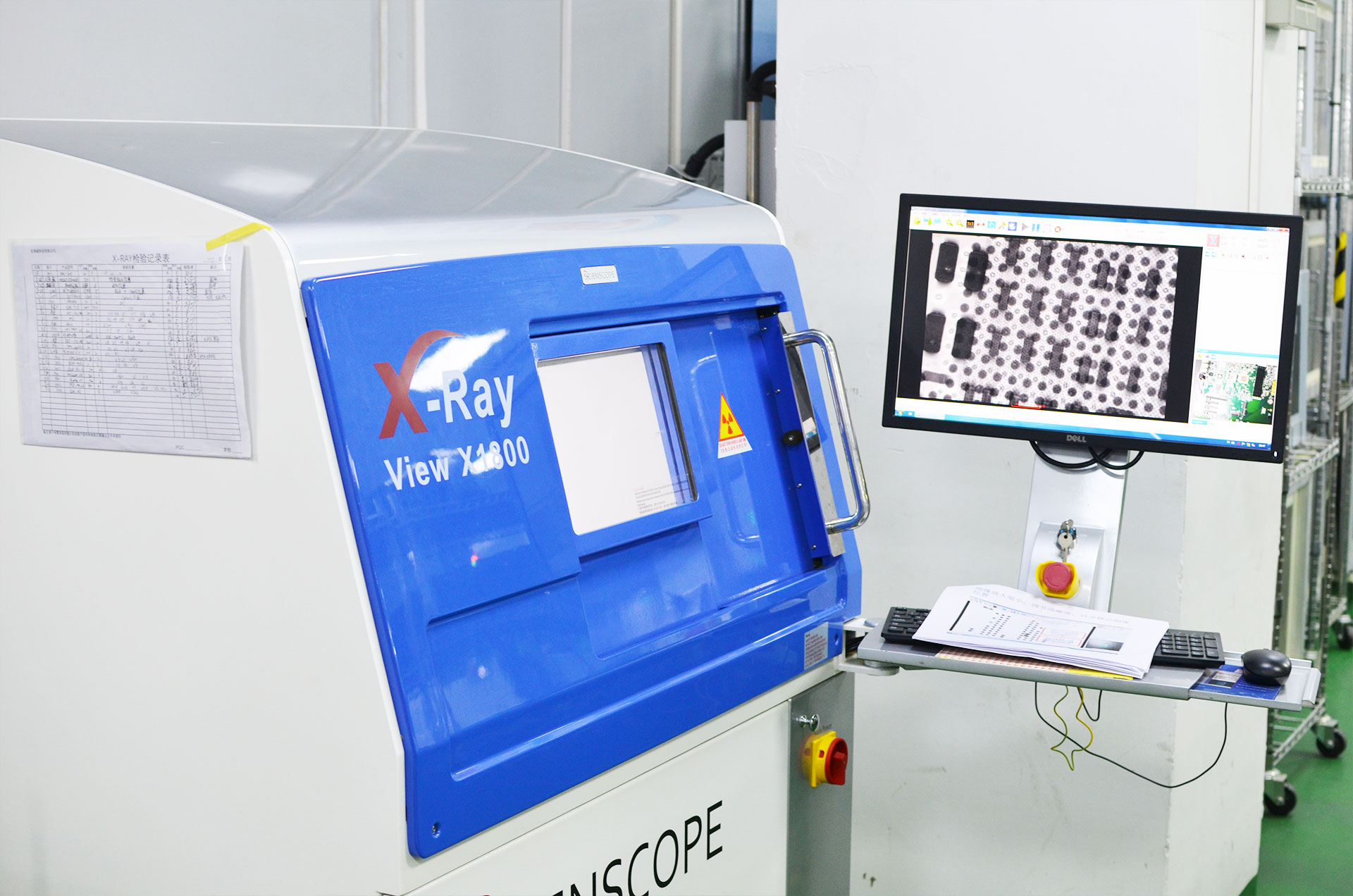

Many companies use X-Ray Inspection because it works well. You get clear pictures of what is inside your parts. This helps you decide if the quality is good. You can also save these pictures for later checks or reviews. Companies like LTPCBA use this technology to meet tough rules like ISO, IATF, and UL. This helps you make safe and good products every time.

Note: Non-destructive testing lets you check your products as many times as you want, even while making them, without slowing things down.

Early Defect Detection

Finding problems early helps your products last longer. X-Ray Inspection lets you see issues before they get worse. You can find solder voids, bridges, open circuits, and small cracks. The machine sends X-rays through your parts. Different things inside block the rays in different ways. This makes pictures that show where the problems are.

Smart software and trained people check these pictures with quality rules. You get quick and correct results. This means fewer problems and lower costs. LTPCBA uses this way to get a 99.5% pass rate for their products. You can trust your electronics will be top quality.

Here is a simple chart of what X-Ray Inspection can find:

Defect Type | What It Means for You |

|---|---|

Solder Voids | Weak joints, possible failures |

Solder Bridges | Short circuits, safety risks |

Open Circuits | Non-working connections |

Misaligned Components | Poor performance, rework needed |

Cracks and Layer Separation | Sudden breakdowns, lower reliability |

3D Visualization

You need to see more than just the outside. 3D visualization with X-Ray Inspection lets you see the whole product. You can find hidden problems in solder joints and inside tricky parts. This way, you get a full model of your product, showing both inside and outside.

3D pictures show more than flat ones. You can spot problems that would stay hidden. This helps you fix things before customers get them. LTPCBA uses 3D X-Ray Inspection to make sure every product is top quality. This technology helps you get safe and reliable products, which is very important in some jobs.

Tip: 3D visualization helps you find rare but serious problems fast, making your checks quicker and better.

By using X-Ray Inspection, you make your products better and keep customers happy. LTPCBA’s focus on quality and new tools makes sure you always get great results.

Quality Assurance with LTPCBA

Industry Standards

You want your electronics to be safe and work well. LTPCBA follows very strict rules for every product. The company has certifications like ISO 9001, IATF 16929, and UL. These show LTPCBA uses strong quality checks in every step. You get advanced testing like flying probe, AOI, and X-Ray Inspection. These tests help find hidden problems early. The table below shows how LTPCBA’s rules and tests help you:

Category | Details |

|---|---|

Certifications | ISO 9001, IATF 16929, UL, RoHS, IPC, ISO 13485, ISO 14001 |

Testing Methods | AOI, X-Ray Inspection, flying probe, in-circuit, and functional testing |

Inspection Accuracy | AOI up to 99% accuracy; X-Ray finds hidden defects |

Quality Practices | Control charts, process traceability, IPC solder training |

Process Control

You need products that work right the first time. LTPCBA uses real-time data and smart machines to keep quality high. The company checks every step with SPC and uses robots for careful work. Pick-and-place machines are 99.95% accurate. First pass yield is 95%, and the pass rate is 99.5%. These numbers mean fewer mistakes and faster delivery for you. AOI, X-Ray Inspection, and flying probe tests happen at every step to catch problems early.

Customer Confidence

You want to trust your supplier. LTPCBA’s 99.5% pass rate shows strong quality. Customers give scores above 85% and a Net Promoter Score over 50. The company answers your questions in 24 hours and gives you technical help. Case studies show wins in car, medical, and industrial projects. For example, LTPCBA made an 8-layer PCB for cars with 99.8% reliability and a 6-layer flex-rigid PCB for hospitals with FDA approval. You get reliable products and quick support every time.

You use X-Ray Inspection to make sure electronics are reliable. It helps you find hidden problems and keeps products safe.

You can spot cracks inside and parts that are not lined up.

You can follow tough industry rules.

Pick LTPCBA for smart checks and quality you can trust.

FAQ

What defects can X-Ray Inspection find in electronics?

You can find solder voids, bridges, and misaligned parts. It also finds internal cracks that are hard to see. X-Ray Inspection shows problems that other ways cannot find.

How does X-Ray Inspection help you meet industry standards?

You use X-Ray Inspection to look for hidden defects. This helps you follow ISO, IATF, and UL rules for safety and quality.

Why should you choose LTPCBA for PCB assembly?

You get careful checks, quick help, and great products. LTPCBA uses X-Ray Inspection and follows strict rules for every order.

See Also

Improving PCBA Quality Control Through X-Ray Inspection Methods

Cutting-Edge BGA Assembly Methods For Reliable Electronics Production

Steps To Conduct Thorough Incoming Inspection For SMC And SMD

Top SMT Assembly Practices To Ensure Quality Electronics Manufacturing

The Importance Of AOI In Maintaining PCBA Manufacturing Quality