The role of X-ray in the surface mount technology (SMT) processing

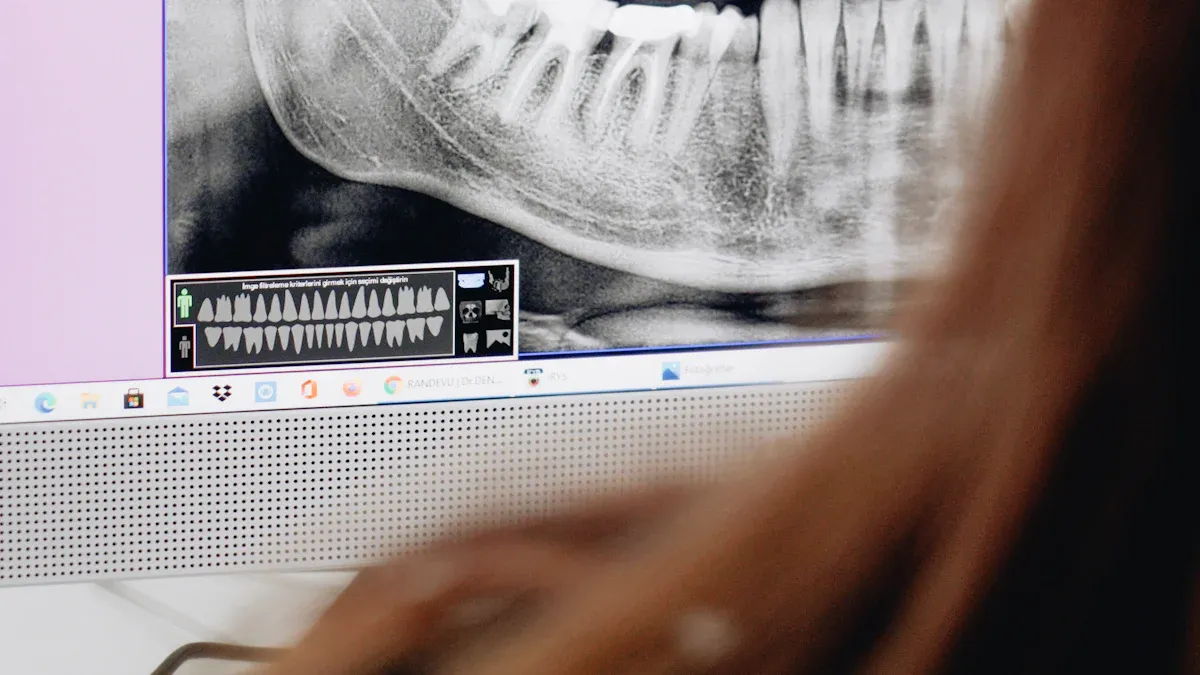

Surface mount technology (SMT) requires precision and accuracy to function effectively. X-ray in SMT plays a crucial role by identifying issues such as gaps or misplaced components. These machines utilize black-and-white images and advanced software to perform inspections. This process helps minimize hidden errors, enhance product quality, and boost production success.

Key Takeaways

X-ray checks are important in SMT to find hidden problems like trapped air or wrongly placed parts, helping make better electronics.

Spotting problems early with X-ray saves money and cuts waste, making production faster and creating more good products.

Modern X-ray tools make products more reliable for key industries, gaining customer trust by providing strong and good-quality items.

Understanding X-ray in SMT Processing

The Importance of X-ray in SMT

X-ray is very important in SMT for checking electronic parts. It helps inspect solder joints and inside parts without breaking them. This is called non-destructive testing. In SMT, parts are packed tightly, and many solder joints are hidden.

With x-ray, you can find hidden problems like air pockets or misplaced parts. These issues cannot be seen with your eyes. X-ray ensures solder joints are in the right place and have enough solder. This keeps electrical connections strong and reliable. Finding problems early with x-ray stops failures and improves product quality.

Industries like aerospace and medical electronics depend on x-ray in SMT. These industries need very reliable products. X-ray finds short circuits, open circuits, and unwanted objects. This ensures products meet strict quality rules. X-ray is a must-have tool for checking modern PCBs.

How X-ray Inspection Machines Work

X-ray machines send x-rays through a printed circuit board (PCB). These x-rays make clear images of hidden parts. Moving from 2D to 3D x-ray has made this process even better. It gives clearer pictures and separates layers for easier checks.

X-ray machines check solder joints, even in tricky parts like BGA chips. They find problems like not enough solder, air pockets, or misplaced parts. Special software highlights problem areas. This ensures all parts are assembled correctly and meet quality standards.

X-ray machines are great for finding defects. They show the exact spot and type of problem. Fixing these issues early makes products more reliable. It also saves money by avoiding rework or recalls.

Common Defects Detected by X-ray

X-ray is great at finding many problems during SMT. Some common issues it detects are:

Voids in Solder Joints: Air bubbles in solder can weaken joints and cause failures.

Misaligned Components: X-ray shows parts that are not placed correctly.

Short Circuits and Open Circuits: These serious problems can stop electronics from working. X-ray helps find and fix them.

Insufficient Solder: Not enough solder can make weak connections and harm the assembly.

Foreign Object Debris (FOD): X-ray finds unwanted materials that can cause damage or problems.

Fixing these problems early improves product quality and reliability. This makes customers happy and lowers the chance of product failures.

Benefits of X-ray Inspection in SMT

Enhancing Quality Control with X-ray

X-ray inspection helps improve quality control in SMT. It finds hidden problems that other methods might miss. Non-destructive testing checks solder joints and parts without damage. This ensures products meet high standards before reaching customers.

Advanced x-ray tools give detailed defect data. This helps manufacturers improve processes. For example:

Automated x-ray inspection (AXI) is popular for zero-defect goals.

AXI systems lower defect rates and boost production success.

These tools provide clear data to refine manufacturing steps.

Adding x-ray machines to production ensures products meet strict rules. This is especially important in fields like aerospace and medical electronics.

Cost Savings Through Early Defect Detection

Finding defects early saves money during production. X-ray systems spot issues like air pockets or misplaced parts. Fixing these early avoids rework, reduces waste, and improves output.

Studies show the cost benefits of early defect detection:

Fixing defects can raise yield to 85%, saving $538,000 yearly.

Stopping PCB waste can save $546,000 in one year.

For complex PCBs, x-ray can save up to $1,006,885 annually.

Catching problems early saves money and boosts efficiency. X-ray inspection is a smart way to keep production costs low.

Improving Reliability of Electronic Assemblies

Reliability is key for electronic products, especially in critical industries. X-ray ensures all parts and solder joints are correct. This lowers the chance of product failures.

X-ray is great for finding problems like short circuits or debris. Fixing these during production makes products more reliable. They perform well in different conditions.

Industries like automotive and medical devices need reliable products. X-ray helps meet these tough demands. It builds customer trust by delivering dependable, high-quality items.

LTPCBA’s Skill in X-ray Inspection

Modern X-ray Machines at LTPCBA

At LTPCBA, advanced x-ray machines help check SMT products. These machines use non-destructive testing to inspect solder joints and parts. They do this without harming the circuit board. High-resolution detectors find tiny problems like cracks or air pockets. This ensures all parts are placed correctly, making products more reliable.

Automated x-ray systems at LTPCBA reduce human errors. They improve accuracy and speed during inspections. With this technology, products are checked thoroughly. This lowers defect risks and meets industry rules.

Keeping High SMT Standards

LTPCBA uses strong quality control to keep high SMT standards. Their quality checks ensure products are good at every step. They use two x-ray systems to check for problems and measure quality. A skilled team fixes issues and prevents future ones.

This focus on quality ensures products meet strict industry needs. Whether for aerospace, medical, or automotive use, LTPCBA guarantees reliable electronic products.

Why Pick LTPCBA for X-ray in SMT

Choosing LTPCBA means getting expert help and great tools. Their x-ray machines find problems like misaligned parts or weak solder. These issues can cause devices to fail if not fixed. The machines also confirm parts are placed properly, making products strong and long-lasting.

Using automated x-ray checks, LTPCBA improves product reliability and cuts costs. Their dedication to innovation and customer happiness makes them a trusted choice for SMT inspections.

X-ray is very important in SMT processing. It helps check parts carefully to improve quality and save money. As electronics get more complex, better tools are needed. Real-time X-ray systems find problems fast, make production smoother, and cut costs by fixing issues early.

Did you know? The global X-ray inspection market is worth $780 million. It is growing at 8.2% each year until 2030.

Company | What They Offer | Speed/Accuracy | Market Value | Growth Rate |

|---|---|---|---|---|

North Star Imaging | Special X-ray systems | 2-5x faster checks | N/A | N/A |

VJ Group | Strong X-ray systems | 99.97% defect detection | N/A | N/A |

Global X-ray Market | N/A | N/A | $780 million | 8.2% CAGR |

Nordson Corporation | 3D X-ray systems | N/A | ~22% of electronics market | N/A |

Using advanced X-ray tools, companies like LTPCBA make sure products are high-quality, cost-effective, and reliable. This technology meets industry rules and builds trust by making dependable items.

FAQ

Why is x-ray inspection important in SMT?

X-ray finds hidden problems like air gaps or misplaced parts. It checks quality and keeps products reliable without causing damage.

Can x-ray check tricky parts like BGAs?

Yes, x-ray looks at solder joints in BGAs. It spots issues like not enough solder or air bubbles, making sure everything works well.

How does x-ray help production?

X-ray finds problems early, cutting down on waste and fixes. This saves money and makes production run better.

See Also

A Comprehensive Guide to SMT and DIP Assembly Techniques

Essential Guidelines for Wave Soldering in DIP Assembly

Importance of Nitrogen Reflow Soldering in Automotive PCBA

Evaluating Advantages and Disadvantages of SMD and Through-Hole