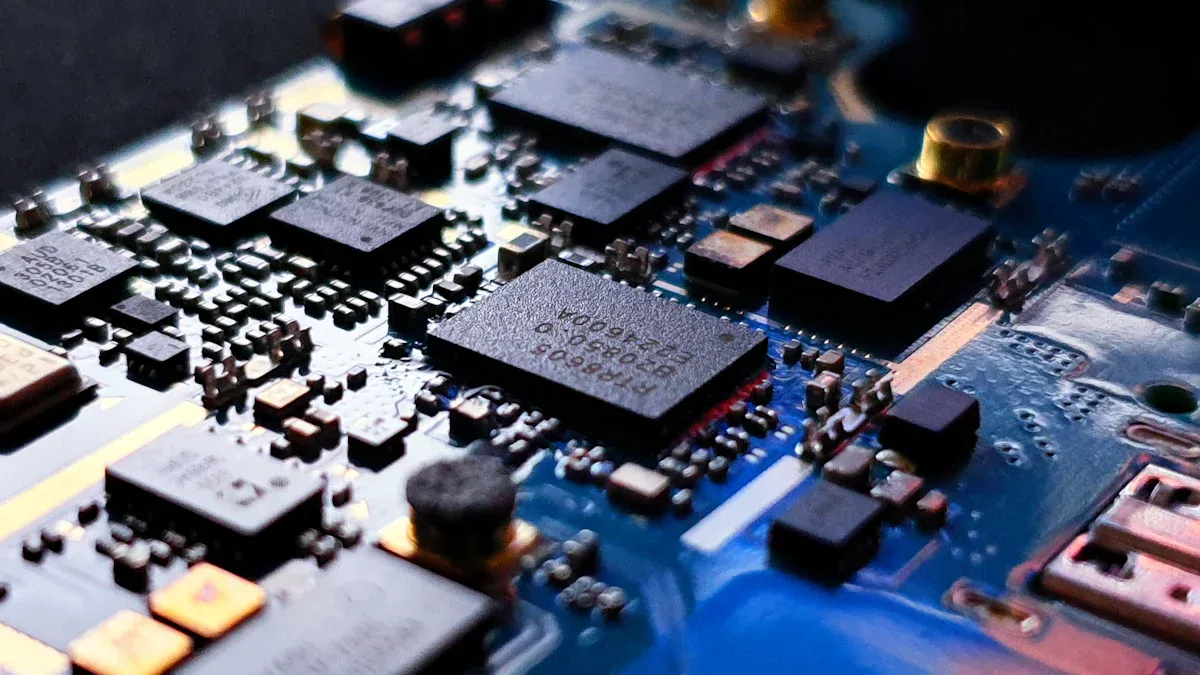

Why PCBA products need to undergo aging tests

PCBA products must undergo aging tests to ensure stability and reliability. Manufacturers use aging tests to detect failures before pcba products reach customers. These tests improve quality and confirm the long-term reliability of pcba products. The importance of pcba testing reflects best practices for pcb aging testing and supports high quality.

Key Takeaways

PCBA aging tests find weak points early to ensure products work well over time and meet high quality standards.

Advanced testing methods and automated systems help detect defects quickly, reduce failures, and improve product reliability.

Following strict industry standards and thorough inspections guarantees safe, durable, and compliant PCBA products.

PCBA Aging Test Overview

What Is PCBA Aging Testing

PCBA aging testing refers to a series of procedures that evaluate how a pcb or pcba performs over time under different stress conditions. These tests help manufacturers understand how devices will behave after long periods of use. The process includes several types of pcb aging test, each designed to simulate real-world environments and stresses. The table below shows common aging test types, their descriptions, and the industry standards that guide them:

Aging Test Type | Description | Relevant Industry Standards |

|---|---|---|

Thermal Aging | Exposure to elevated temperatures or thermal cycling to accelerate material degradation. | IPC-TM-650, JEDEC JESD22-A104 |

Humidity & Temperature | Tests under high humidity and temperature to simulate moisture-induced failures. | JEDEC JESD22-A101, IPC-TM-650 2.6.3 |

Electrical Aging | Power cycling and bias testing to simulate electrical stress and detect electrochemical migration. | IPC-9701, JEDEC JESD22-A104 |

Mechanical Aging | Vibration and bend/flex testing to assess physical wear and solder joint reliability. | IPC-9701, MIL-STD-810 |

Chemical Exposure Aging | Exposure to chemicals like solvents and fluxes to test corrosion resistance. | IPC-TM-650 2.3.28 |

LTPCBA follows these standards closely. The company uses advanced equipment and automated systems to ensure every pcba aging test meets strict quality requirements.

Purpose of PCB Aging Test

The main goal of a pcb aging test is to make sure every pcb and pcba can handle real-world conditions. Manufacturers use pcba aging testing to find weak points in devices before they reach customers. The following points highlight the key purposes of these tests:

Burn-in testing exposes pcb assemblies to high temperature and voltage to catch early failures.

These tests improve reliability by finding weak components and connections.

They help reduce warranty costs by detecting defects early.

Aging tests boost product quality and customer satisfaction.

They are essential for critical applications that demand high reliability.

Tests simulate harsh environments to check long-term durability.

The process ensures the operational life of pcb and pcba under stress.

LTPCBA integrates an effective pcb aging test programme into its manufacturing process. The company uses a long-term working test to guarantee that every device meets high standards for aging and reliability. This commitment ensures that each pcb and pcba can perform well throughout its lifespan.

Benefits of PCBA Testing

Reliability for PCBA Products

PCBA testing plays a vital role in ensuring the reliability of pcba products. Manufacturers use a variety of tests to check how each pcb and pcba will perform under real-world conditions. These tests help confirm stable and reliable performance, which is essential for products used in critical applications. LTPCBA uses several advanced testing methods, such as Functional Test (FCT), Burn In Test, and In-Circuit Test (ICT). The Burn In Test simulates long-term user input and output, verifying durability and soldering reliability. LTPCBA also uses X-ray, AOI, and UV testing benches to check for hidden defects.

LTPCBA’s systematic approach includes:

Multiple testing methods for thorough inspection

Advanced equipment for accurate detection

Error-proof design and data analysis to prevent recurring failures

Problem-solving teams that improve technologies and standards

These steps help reduce field failures and address potential aging problems before products reach customers. As a result, LTPCBA achieves enhanced product reliability and long-term working test success for every pcb and pcba.

Early Failure Detection

Early detection of failures is one of the most important benefits of pcba testing. Modern inspection methods, such as automated optical inspection (AOI), allow manufacturers to find defects quickly and accurately. AOI provides non-destructive testing, which means the pcb remains intact during inspection. This technology supports early identification of failures during production, reducing the risk of defective products moving forward in the process.

A predictive maintenance system using advanced algorithms, like XGBoost, can identify temperature curve deviations during the SMT reflow process. This system enables timely interventions and rechecks of high-risk pcb assemblies. Early detection of failures helps reduce field failures and lowers production costs by removing defective items before they reach later stages. Studies show that dedicating more time to early inspection increases defect detection rates and improves overall performance. This approach ensures that pcba products meet high standards for reliability and quality.

Compliance and Quality at LTPCBA

LTPCBA demonstrates a strong commitment to compliance and quality in every step of its manufacturing process. The company follows internationally recognized standards, including IPC-A-600, IPC-6012, ISO 9001:2015, and UL 796. These standards guide the inspection and testing of every pcb and pcba, ensuring safe and reliable products.

LTPCBA’s multi-layered quality control system includes incoming, in-process, and outgoing inspections. The company uses AOI for surface defects, X-ray for internal issues, and functional testing to verify operational integrity.

The table below highlights LTPCBA’s compliance and quality measures:

Compliance Aspect | Details |

|---|---|

Certifications | ISO9001, ISO13485, ISO14001, UL, SGS, IPC standards |

Testing Equipment | X-ray, AOI, UV testing benches, FCT equipment |

Quality Control Processes | IQC, IPQC, OQC |

Defect Prevention | Error-proof design, data analysis, preventive measures, problem-solving teams |

Testing Methods | ICT, FCT, Burn In Test, Conformal Coating |

Procurement Quality Control | Experienced team, cooperation with original manufacturers and brand distributors |

Traceability Systems | ERP system, FAI system |

LTPCBA’s adherence to these standards and processes results in a 99.5% pass rate for delivered products. This achievement highlights the importance of pcba testing in delivering high-quality, reliable, and compliant pcb and pcba products.

How PCBA Aging Tests Are Performed

Environmental and Operational Simulations

Manufacturers use scientifically structured aging tests to ensure pcb products can withstand real-world conditions. These tests simulate environmental and operational stresses that devices may face during their lifespan. Common pcb aging testing methods include steady-state testing, thermal cycling, and accelerated aging test procedures. For example, steady-state testing keeps the pcb at a constant temperature and humidity, such as 85°C and 85% relative humidity, for up to 1000 hours. Thermal cycling exposes the pcb to repeated high and low temperatures, which helps reveal solder joint fatigue and delamination.

A data-driven framework uses both empirical and simulated data to predict solder joint life during thermal cycling. This approach achieves high accuracy and confirms that the simulated conditions closely match real operational scenarios. Sensitivity analysis shows how aging duration and temperature range affect reliability, making these aging tests effective for identifying potential failures.

Manufacturers monitor key parameters during aging, such as voltage, current, resistance, and temperature. They record performance data at regular intervals to detect any signs of degradation. After the aging period, engineers perform functional and performance tests to verify the stability of the pcb. These steps help detect issues like electromigration, discoloration, and component degradation before devices reach customers.

Testing Methods at LTPCBA

LTPCBA uses advanced equipment and automated systems to perform thorough aging tests on every pcb. The company combines several testing methods to ensure high product quality and reliability.

In-Circuit Testing (ICT) checks electrical parameters like current and voltage.

Functional Circuit Testing (FCT) verifies that the pcb performs its intended functions.

Fatigue testing subjects the pcb to long-term, high-frequency operation.

Extreme environment testing exposes the pcb to harsh conditions, such as high or low temperatures and physical shocks.

Aging testing powers the pcb continuously to detect failures before shipment.

Technology/Tool | Description | Benefit |

|---|---|---|

Tracks machines and product quality in real time | Enables live monitoring and quality control | |

Big Data Analytics | Analyzes production data for issues | Improves process efficiency and quality |

Automated Optical Inspection | Detects surface defects quickly | Fast error detection and correction |

X-ray Inspection | Finds hidden internal defects | Ensures internal quality and reliability |

High-speed Pick-and-Place Machines | Places thousands of components per hour | Increases speed and reduces errors |

LTPCBA’s use of automated test equipment allows for extensive data collection during each aging test. Statistical process control and Pareto analysis help identify the most frequent defect types. Weibull distribution models and failure logs guide improvements in manufacturing and design. This comprehensive approach ensures that every pcb meets strict reliability standards before delivery.

PCBA aging tests play a key role in product quality. LTPCBA’s advanced testing ensures each device meets strict standards.

Early defect detection reduces recalls.

Design and process improvements boost reliability.

Products meet regulations and last longer, supporting customer satisfaction and long-term reliability.

FAQ

What is the main purpose of PCBA aging tests?

PCBA aging tests help manufacturers find weak points in products. These tests ensure devices work well over time and meet quality standards.

How long does a typical PCBA aging test take?

Aging tests often last from several hours to several days. The exact time depends on product requirements and industry standards.

Why does LTPCBA use automated systems for aging tests?

Automated systems improve accuracy.

They collect data quickly.

LTPCBA uses these systems to ensure every product meets strict reliability standards.

See Also

Essential PCBA Processing Needs For Medical Device Applications

PCBA Services That Manage All Phases From Build To Test

The Importance Of AOI In Ensuring PCBA Manufacturing Quality

X-Ray Inspection Techniques Improving Quality Control In PCBA

Advanced Turnkey PCBA Plants Guarantee High-Quality Production