What PCBA Stands for in Electronics

PCBA stands for printed circuit board assembly. It helps make electronic designs work. By adding parts to a board, it turns a simple circuit into a working device. The need for smaller and smarter gadgets makes it very important. For example:

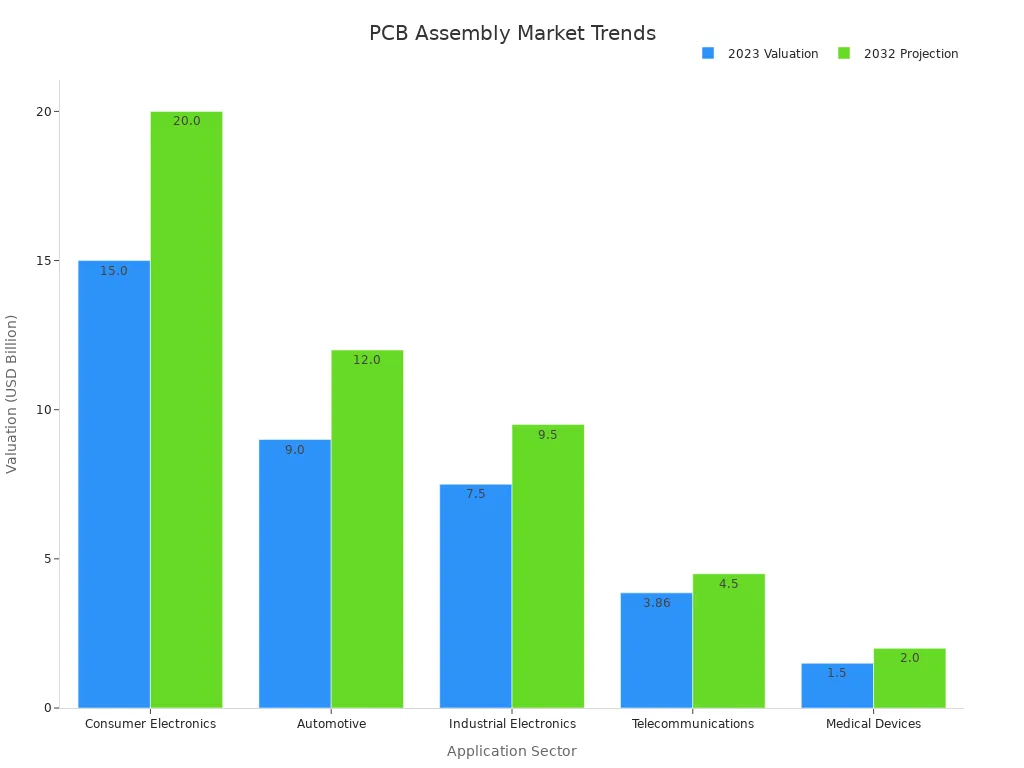

The world PCB market may grow from $78.5 billion in 2023 to $120 billion by 2032.

New materials and designs are helping this growth happen.

Electric cars and the car industry are big reasons for this growth.

PCBA is a key part of today’s electronics.

Key Takeaways

PCBA means printed circuit board assembly. It helps make electronic designs work.

Knowing PCB and PCBA differences is important. A PCB is just a board, but a PCBA is fully assembled and ready to use.

PCBA improves how fast things are made, makes them reliable, and saves money. It is important in cars, healthcare, and gadgets.

What PCBA Stands for and Its Meaning

Definition of Printed Circuit Board Assembly

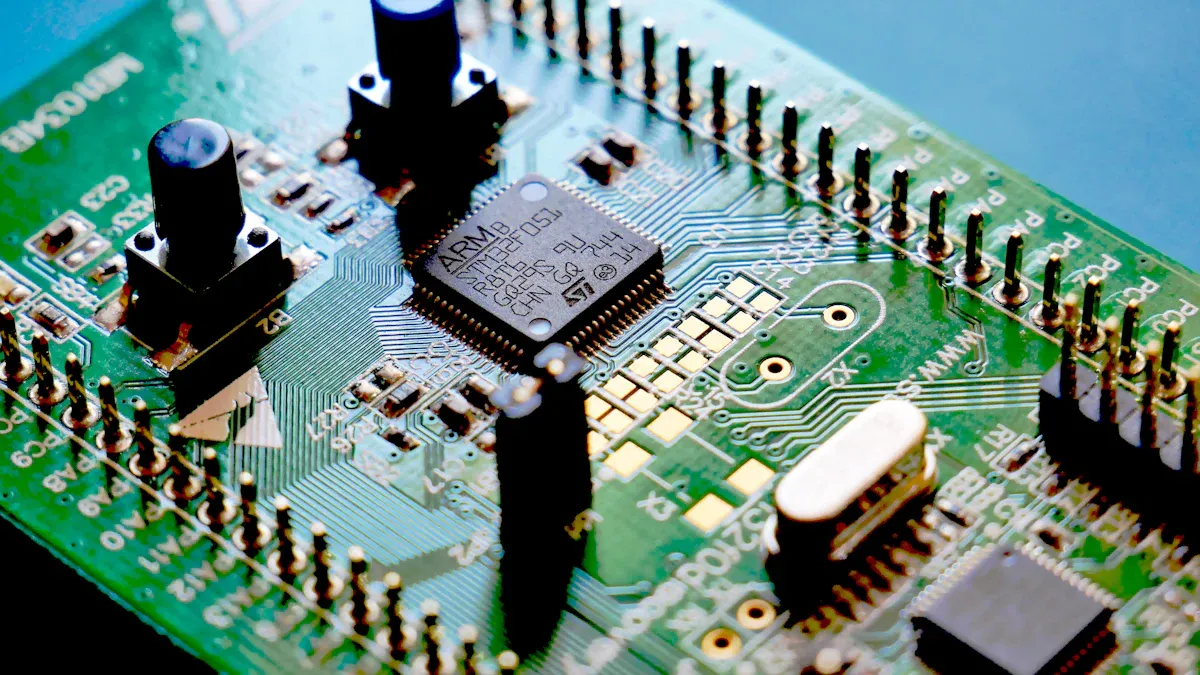

Printed circuit board assembly (PCBA) means adding electronic parts to a printed circuit board (PCB) to make it work. After the parts are soldered on, the PCB becomes a working assembly. It can now do its job as planned. This process uses copper pathways on a non-conductive base to connect components.

Sometimes, people call the whole assembly a "printed circuit board." But really, a PCB becomes a PCBA only after all parts are added. These parts include resistors, capacitors, ICs, and transformers.

Important things to know:

A PCBA is the finished board with all parts added.

It is also called a printed circuit assembly (PCA).

The assembly process makes the PCB ready to work.

The Role of PCBA in Electronics Manufacturing

PCBA is very important in making modern electronics. It is like the backbone of devices, helping them work well. Without PCBA, electronic designs would just stay ideas and not work.

For example, in defense, PCBAs are used in drones, secure systems, and navigation tools. They are made to handle tough conditions like heat and shaking. This makes them reliable for critical tasks.

Besides defense, PCBA is used in cars, healthcare, and gadgets. Electric cars need PCBAs for battery systems. In healthcare, devices like heart monitors depend on them for accuracy and safety.

Did you know?

PCBAs are built to survive tough conditions, making them key in industries needing strong and reliable devices.

Key Steps in the PCBA Process

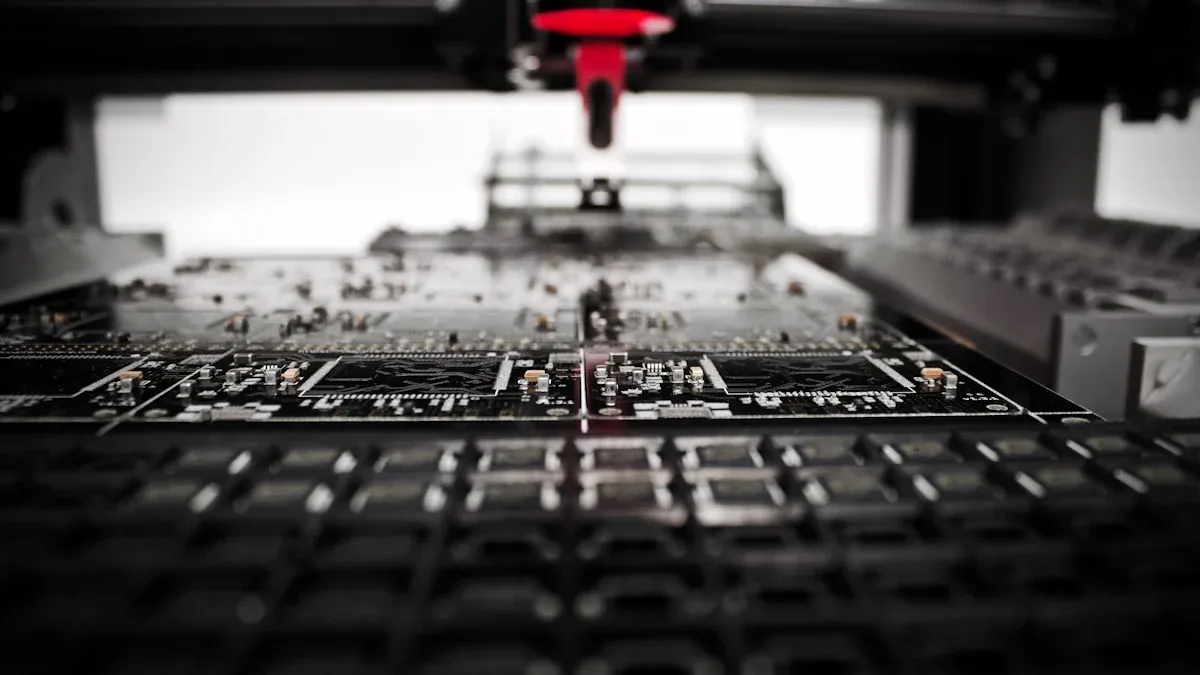

The PCBA process has many steps to make sure it works well. Each step needs care and checks to meet high standards.

Design and Preparation:

Engineers plan the PCB layout and check if it can be made. Parts are then ordered based on the design.Solder Paste Application:

A stencil is used to put solder paste on the PCB. This paste helps hold parts in place.Component Placement:

Machines place small parts on the board. Bigger parts are often placed by hand.Reflow Soldering:

The board goes through an oven. The solder paste melts and hardens, securing the small parts.Wave Soldering:

For bigger parts, molten solder is used to attach them firmly.Inspection and Quality Control:

Tools like cameras, X-rays, and tests check if the assembly works correctly.Conformal Coating (Optional):

A protective layer is added to keep the assembly safe in harsh places.Final Assembly and Packaging:

Extra parts are added, and the product is tested. Then, it is packed for delivery.

Each step helps make a strong and reliable PCBA. By following these steps, manufacturers ensure the product works as it should.

PCBA vs. PCB and Other Related Terms

Difference Between Printed Circuit Board and Printed Circuit Board Assembly

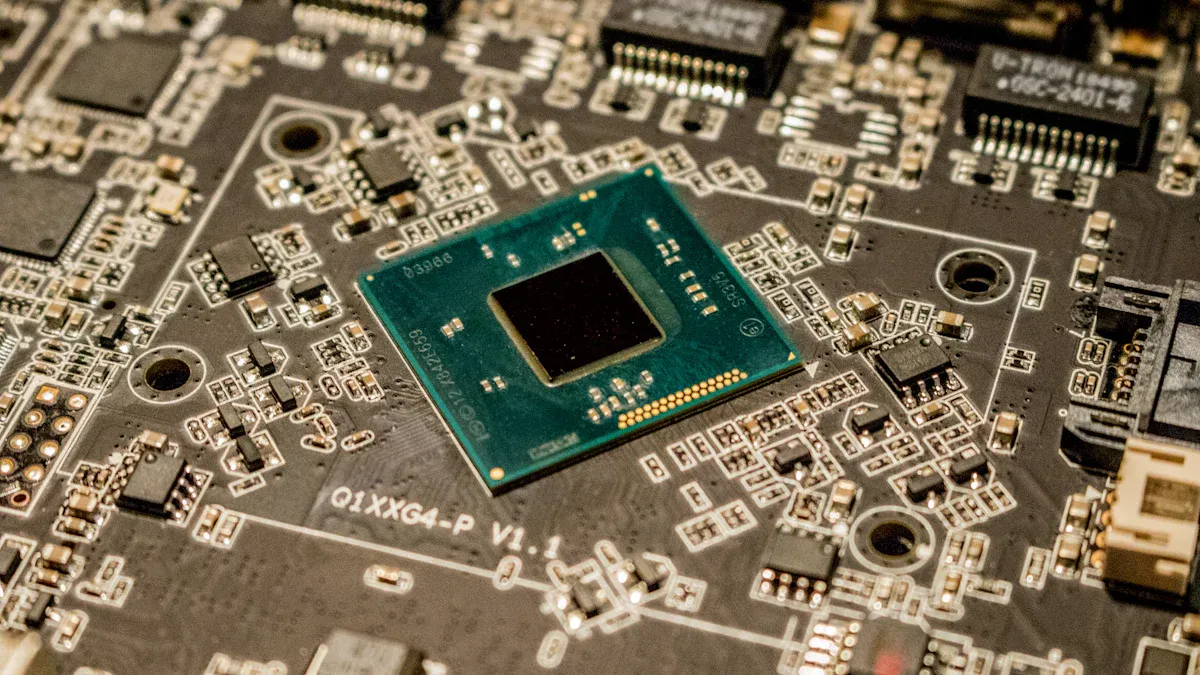

A printed circuit board (PCB) is the base of electronics. It is a flat board made from non-conductive materials like fiberglass. Copper lines on the board let electricity move between parts. But a PCB cannot work until parts like resistors and capacitors are added.

A printed circuit board assembly (PCBA) is a PCB with all parts attached. It is ready to be used in devices. Think of a PCB as an empty board and a PCBA as the finished product. The assembly process makes the board functional.

Key differences include:

A PCB is empty, while a PCBA is complete and working.

Making a PCBA costs more because it includes parts and assembly.

First, the PCB is made, then the PCBA is assembled.

Tip: People often call a PCB a "circuit board." Once parts are added, it becomes a PCBA.

How PCBA Differs from Printed Wiring Board

Printed wiring boards (PWBs) are older versions of PCBs. PWBs are simpler and use basic methods like screen printing. They are made from materials like phenolic paper or epoxy glass.

PCBs are more advanced and use modern techniques like laser imaging. They are made from stronger materials like FR-4 or polyimide. PCBs also perform better, handling heat and signals more efficiently.

Aspect | Printed Wiring Boards (PWB) | Printed Circuit Boards (PCB) |

|---|---|---|

Manufacturing Techniques | Basic methods like screen printing. | Advanced methods like laser imaging. |

Material Selection | Phenolic paper or epoxy glass. | FR-4 or polyimide materials. |

Performance and Reliability | Simple functions. | Better heat and signal handling. |

Industry Standards | Fewer rules to follow. | Strict standards like IPC rules. |

Terminology Use | Rarely used now. | Commonly used today. |

Post-Design Process | Basic manufacturing steps. | Advanced steps like reflow soldering. |

Board Type | Called a "bare board." | Can be part of a PCBA. |

Applications | Used in simple devices like power supplies. | Used in advanced devices like phones and cars. |

Knowing these differences helps you pick the right board. PWBs work for simple gadgets, but PCBs are needed for complex devices.

Why Understanding These Terms Matters in Electronics

Knowing the terms PCBA, PCB, and PWB is important in electronics. Each term refers to a different type or stage of a circuit board. Confusing them can cause mistakes in design or production.

For example, ordering a PCB when you need a PCBA can delay your project. Using a PWB instead of a PCB might lead to poor device performance. Understanding these terms helps you make better choices and meet industry needs.

Did you know? Some people call a PCB or PCBA a "circuit card." This shows why clear communication is key in electronics.

Benefits and Applications of PCBA

Advantages of Printed Circuit Board Assembly in Electronics

Printed circuit board assembly (PCBA) has many benefits for modern electronics. It helps make production faster. Machines work all day without stopping, speeding up the process. This means fewer delays and more products made. The assembly process is also very reliable. Machines place parts with great accuracy, reducing mistakes. This ensures high-quality products every time.

Another big benefit is saving money. Fewer errors mean fewer repairs and warranty claims. This lowers costs and keeps customers happy. Speed, reliability, and cost savings make PCBA very important in electronics.

Advantage Type | Details |

|---|---|

Production Speed | |

Reliability | Parts are placed with accuracy of ±0.05mm, reducing defects. |

Cost Savings | Fewer repairs and returns save money and improve customer trust. |

Applications of PCBA Across Industries

PCBA is used in many industries to make devices work better. In cars, it helps with engine controls and safety systems. These are important as cars rely more on electronics. In healthcare, PCBAs are used in heart monitors and medical tools. These devices need to be accurate and dependable.

Robotics also uses PCBAs for precise machines. Companies like Toyo Electric Corporation use them to make robots work well. PCBAs are also key in IoT gadgets and electric cars. From smart home devices to car batteries, their uses keep growing.

Automotive: Helps with engine controls and safety features.

Healthcare: Used in heart monitors and medical tools.

Robotics: Makes robots accurate and efficient.

Consumer Electronics: Powers IoT gadgets and smart devices.

How LTPCBA Supports Innovation in Circuit Assembly

LTPCBA is a top company in PCBA, known for quality and new ideas. It uses advanced tools to make boards precise and reliable. With strict checks, LTPCBA delivers products with a 99.5% success rate. This makes it trusted by industries needing complex assemblies.

The company also offers flexible services. It can make prototypes or handle larger orders based on your needs. Fast help and 24-hour support keep projects moving smoothly. LTPCBA focuses on customer satisfaction and new technology to help create innovative products.

Did you know? LTPCBA follows global rules like ISO and UL to ensure top-quality assemblies.

PCBA is an important step in making electronics work. It changes a plain board into a working circuit, helping devices run smoothly. Knowing the differences between PCBA, PCB, and PWB helps in making smarter design and production choices.

PCBA is used in many fields like cars, gadgets, and healthcare. For instance, the car industry's value might grow from $9 billion in 2023 to $12 billion by 2032. This shows the rising need for strong and dependable circuit boards.

Companies like LTPCBA help improve technology. They focus on quality and new ideas to make top-notch boards that meet industry rules.

FAQ

What is the difference between prototype and mass production of PCBs?

Prototypes are made in small amounts to test designs. Mass production makes many PCBs for selling and using. Prototypes check if designs work before making lots of them.

How does PCBA improve production efficiency?

PCBA uses machines to put parts on boards fast. This lowers mistakes and speeds up making products. It also keeps the quality the same for every board.

Why is PCBA important for modern electronics?

PCBA turns simple boards into working devices. It helps create strong and useful electronics for cars, healthcare, and gadgets.

See Also

Exploring The Definition And Parts Of PCBA

Essential Materials Required For Effective PCBA Manufacturing

Choosing The Right PCBA Supplier For Your Requirements