What Is Through Hole PCB Assembly and Why Is It Important

Through hole pcb assembly involves inserting electronic components into pre-drilled holes on the printed circuit board, ensuring a secure and durable connection. With through hole pcb assembly, you gain exceptional reliability, making it ideal for devices that must perform in harsh or demanding environments. This assembly method also allows for easy replacement and manual adjustment of components when needed. LTPCBA specializes in delivering high-quality through hole pcb assembly services, supporting even the most challenging electronics projects.

Highly reliable through hole pcb assembly for tough conditions

Easy manual adjustments and part replacement

Key Takeaways

Through hole PCB assembly provides strong mechanical bonds, making it ideal for devices in harsh environments.

This assembly method allows for easy manual adjustments and part replacements, enhancing repairability.

LTPCBA ensures high-quality through hole PCB assembly with rigorous inspection and testing, meeting industry standards.

Through Hole PCB Assembly Process

Component Placement

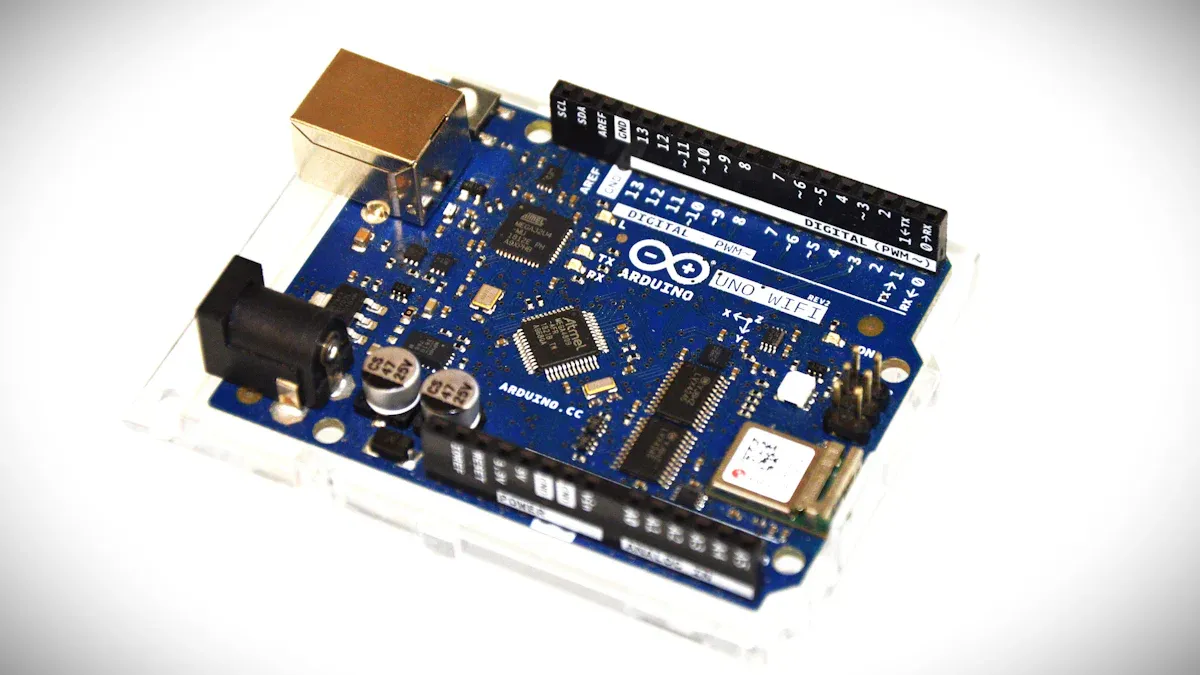

You start the through hole pcb assembly process by placing components onto the printed circuit board. Each component has leads that fit into pre-drilled holes. This step requires accuracy and attention to detail. You must ensure that every part sits in the correct position and orientation. The most common components you will encounter during this stage include:

Resistors

Capacitors

Diodes

Transistors

Integrated Circuits (ICs)

Radial components such as large electrolytic capacitors, switches, and LEDs

Axial lead components like inductors and transformers

Through-hole technology allows you to use components with long leads, which you insert through the board for a secure fit. This method gives you strong mechanical bonds, making it ideal for devices that face vibration or physical stress. LTPCBA uses advanced placement equipment and skilled technicians to guarantee precise component alignment on every printed circuit board.

Soldering Techniques

After you place the components, you move to the through hole soldering stage. This step creates the electrical and mechanical connections that hold your assembly together. Through hole soldering uses two main techniques: manual soldering and wave soldering.

Manual soldering involves a technician using a soldering iron to join each lead to the board. This method works well for prototypes, small batches, or complex assemblies. Wave soldering, on the other hand, uses a machine to pass the board over a wave of molten solder. This process quickly creates consistent, high-quality soldered connections for larger production runs.

Through-hole technology stands out because it produces robust joints that can handle high-stress environments. You benefit from strong, reliable connections that last. LTPCBA’s team uses both manual and automated through hole soldering methods, ensuring each assembly meets strict quality standards.

Tip: Through hole technology remains the best choice for applications that demand durability and long-term reliability.

Inspection and Testing

Once you finish soldering, you must inspect and test the assembly. Inspection checks for proper solder joints, correct component placement, and any possible defects. You can use visual inspection, automated optical inspection (AOI), or even X-ray inspection for complex boards. Testing ensures that the circuit works as intended and meets all performance requirements.

LTPCBA follows rigorous inspection and testing protocols. The company holds several important certifications and quality standards, which guarantee reliable results for your projects:

Certification/Standard | Description |

|---|---|

ISO 9001:2015 | Quality management systems standard |

ISO 13485:2016 | Quality management for medical devices |

MIL-PRF-31032 | Military specification for PCB assembly |

DLA Approval | Defense Logistics Agency approval for quality |

You can trust LTPCBA to deliver through-hole pcb assembly that meets the highest industry standards. The company’s quick response service and commitment to quality help you complete your projects on time and with confidence.

Advantages and Applications of Through-Hole Technology

Benefits of Through-Hole PCB Assembly

You gain several important benefits when you choose through-hole technology for your projects. This method gives you strong mechanical bonds between components and the printed circuit board. The leads of each part pass through the board and receive solder on the opposite side. This process creates a secure connection that stands up to vibration, shock, and physical stress.

Through-hole technology offers excellent durability. You can rely on these assemblies in harsh environments, such as those with high temperatures or frequent movement. The robust nature of through hole technology makes it a top choice for mission-critical devices. You also find that through-hole pcb assembly allows for easy manual adjustments and repairs. You can replace or upgrade components without damaging the board.

Note: Through-hole technology remains the preferred option for prototypes, testing, and products that require long-term reliability.

LTPCBA uses advanced inspection and quality control systems to ensure every through-hole pcb assembly meets strict standards. The company’s experience and technical skill help you achieve consistent results, even in demanding applications.

Applications of Through Hole Technology

You see through-hole technology in many industries that require dependable performance. The unique properties of this assembly method make it suitable for a wide range of uses. Here are some common applications of through hole technology across key sectors:

Industry | Application area |

|---|---|

Automotive industry | Used in vehicle control systems, engine management, and infotainment systems. |

Aerospace industry | Applied in avionics, navigation systems, and communication equipment. |

Industrial machinery | Implemented in industrial automation and control devices, such as PLCs, motor drives, and power supplies. |

You often find through-hole technology in products that must operate without failure. These include automotive electronics, aerospace controls, and industrial automation equipment. The strong connections and high reliability of through hole technology help you meet strict safety and performance requirements.

You also see through-hole technology in power supplies, transformers, and connectors. These components need secure mounting and the ability to handle high currents. Through-hole pcb assembly provides the strength and durability needed for these critical parts.

LTPCBA Industry Solutions

LTPCBA delivers robust solutions for industries that demand the highest quality. The company’s expertise in through-hole technology ensures your assemblies perform well in challenging environments. You benefit from a 99.5% pass rate in product delivery, which shows LTPCBA’s commitment to excellence.

You can trust LTPCBA to handle complex projects, from prototypes to mid-volume production runs. The team uses advanced equipment and follows international standards, such as ISO and UL. You receive quick response service and 24-hour technical support, making your project run smoothly from start to finish.

Tip: When you need reliable through-hole pcb assembly for automotive, aerospace, or industrial applications, LTPCBA stands ready to support your goals.

You gain peace of mind knowing your assemblies meet the highest standards for quality and reliability. LTPCBA’s focus on innovation and customer satisfaction helps you succeed in every project.

Through-Hole vs. SMT Assembly

Key Differences

You often face a choice between through-hole technology and surface mount technology (SMT) when designing electronic assemblies. Through-hole technology uses components with leads that pass through the board, while SMT places components directly onto the board’s surface. Through-hole technology gives you strong mechanical bonds, making it ideal for products that must handle stress or vibration. SMT allows you to fit more components in a smaller space, which helps when you need compact designs.

Through-hole technology supports easy manual adjustments and repairs. You can replace parts without damaging the board. SMT, on the other hand, works best for automated, high-speed production. Through hole technology also uses through hole soldering, which creates robust joints. SMT relies on reflow soldering, which is faster but may not offer the same mechanical strength.

Feature | Through-Hole Technology | Surface Mount Technology (SMT) |

|---|---|---|

Component Mounting | Leads through holes | Mounted on surface |

Mechanical Strength | High | Moderate |

Repair/Replacement | Easy | More difficult |

Assembly Speed | Slower | Faster |

Density | Lower | Higher |

Choosing the Right Technology

You should choose through-hole technology when your project needs durability, reliability, or frequent repairs. Through hole technology works well for prototypes, power supplies, and industrial controls. If you need high-volume production or miniaturized devices, SMT may suit your needs better. Through-hole technology also excels in applications that require through hole soldering for strong connections.

LTPCBA offers both through-hole technology and SMT assembly. You can rely on LTPCBA to match the right method to your project. The team uses advanced equipment and skilled technicians for both through hole technology and SMT. You receive quality results, whether you need through hole soldering or high-density SMT placement.

Tip: Discuss your project requirements with LTPCBA. The experts will help you select the best assembly method for your needs.

You see the lasting value of through-hole pcb assembly in today’s electronics. LTPCBA delivers quality, reliability, and fast support for your projects. When you want dependable results, you can trust LTPCBA to meet your needs and help you succeed.

FAQ

What makes through-hole PCB assembly reliable?

You get strong mechanical bonds with through-hole assembly. This method helps your boards handle vibration, shock, and stress in demanding environments.

Tip: Choose through-hole for projects that need durability.

Can you mix through-hole and SMT components on one board?

Yes, you can use both types on a single board. This approach gives you flexibility for complex designs and different component needs.

How fast can LTPCBA deliver through-hole PCB assemblies?

You receive quick quotes within 2–3 working days. LTPCBA also offers fast production and 24-hour technical support for your urgent projects.

See Also

Ultimate Resource for Understanding Through Hole PCB Assembly

Choosing Between SMT and Through-Hole for Your Project

Evaluating Reliability: Through Hole Assembly Versus SMT

Selecting the Best Through Hole Assembly Service for Industry