How US-Based Turnkey PCBA Services Reduce Supply Chain Risks for Electronics Manufacturers

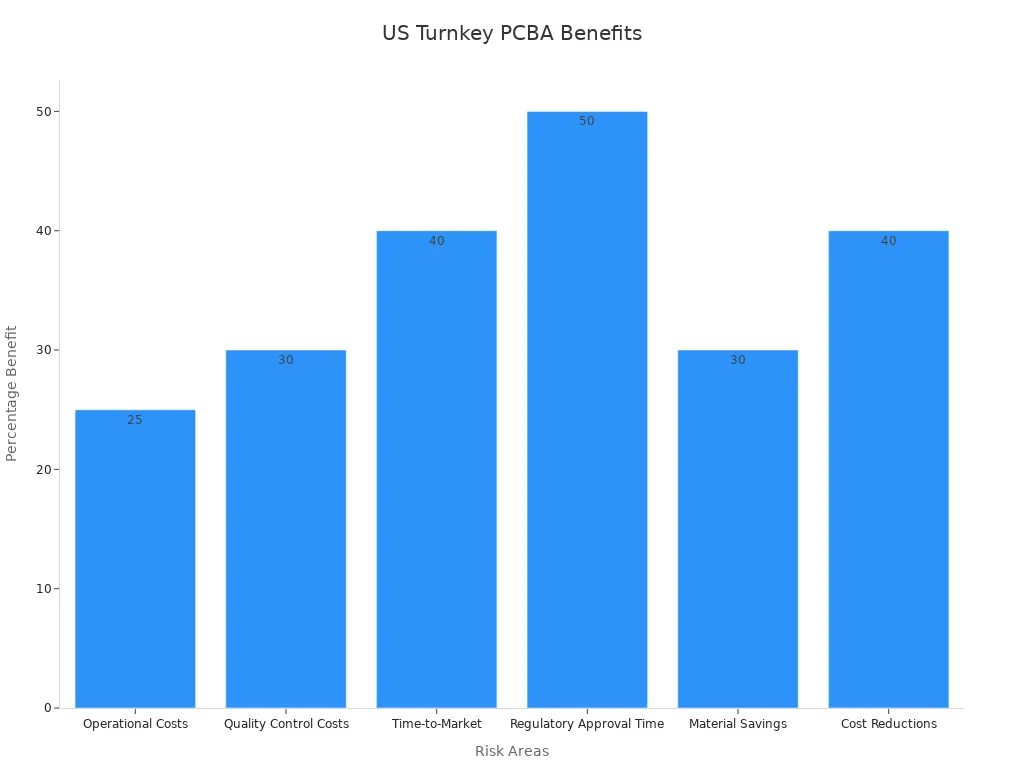

US-based Turnkey PCBA Services help electronics makers handle big supply chain risks. These risks are delays in getting parts, problems with quality, shipping issues, rules that are hard to follow, and trouble talking with others. Companies can lose money from delays, not having enough parts, and things going wrong, as you can see in the chart below.

Picking the right partner helps you get answers faster and manage risks better.

Key Takeaways

US-based turnkey PCBA services make delivery faster and cut down on delays. They do this by working with local suppliers and using quick shipping.

Good quality checks and certifications help make better products. This means there are fewer mistakes, so risks and costs go down.

Picking the right PCBA partner is important. They should talk clearly, have good quality, and give fast help. This helps companies stay away from expensive problems.

Turnkey PCBA Services Overview

What Are Turnkey PCBA Services

Turnkey PCBA Services put all steps together with one company. This includes help with design, getting parts, making the PCB, putting it together, and testing. Companies like having one partner for the whole job. This way, there are fewer mistakes, things move faster, and quality gets better. Providers use special machines to build and test the boards. They do careful checks, like Automated Optical Inspection and other tests.

Simple supply chains mean less money spent on shipping and storage.

The provider handles inventory, so the manufacturer has less work.

One supplier checks quality better and finds fewer problems.

One team in charge makes products more dependable.

Benefit Category | Metric / Statistic | Impact Description |

|---|---|---|

Cost Savings | Buying in bulk and working smart saves money | |

Quality Improvement | Defect rate reduced from 3.5% to <0.5% | Fewer problems and better products |

Lead Time Reduction | Lead time shortened from 10-12 weeks to 4-5 weeks | Products get made and shipped much faster |

Scalability | 300% increase in production capacity | Making more products is easier and faster |

Time-to-Market | 40% faster launch of new product variations | New products reach customers sooner |

LTPCBA is in Shenzhen, China, and does all these jobs. They buy parts, put boards together, and test them. They care about good quality and making customers happy.

US-Based Advantages

US-based Turnkey PCBA Services have special ways to lower risks. Getting parts from the US means no long waits for shipping. These companies can fix problems or changes quickly. Local teams make talking and solving issues easier. US rules make sure products are safe and high quality, which helps everyone.

US-based companies find and fix rule problems fast, so costs and risks stay low.

A US partner also helps keep your ideas safe and stops fake parts from being used. These reasons make US-based Turnkey PCBA Services a smart pick for companies that want less risk and better products.

Reducing Supply Chain Risks

Component Sourcing

US-based Turnkey PCBA Services help electronics makers get parts from the US. Local suppliers mean parts arrive faster and with fewer problems. If a supplier has trouble, companies can find new parts quickly. This helps keep making products on time. Many US providers use smart systems to watch parts all the time. These systems stop too many or too few parts from piling up. Good relationships with trusted suppliers help keep fake parts out. LTPCBA is known for good quality and finding reliable parts. They show what companies should look for in a provider.

Quality Control

Good quality control is very important in electronics. US-based Turnkey PCBA Services use special checks like AOI, X-Ray, and other tests. These steps make sure every board is made right. Providers have certifications like IPC and UL to show they care about quality. Tracking all materials helps companies follow the rules, like in FinTech. LTPCBA also uses world standards and machines to check every product. This focus on quality means fewer mistakes and better products.

Note: Good quality checks and tracking help stop recalls and unhappy customers.

Logistics and Lead Times

Fast shipping and short wait times are very important. US-based Turnkey PCBA Services use US shipping and smart hubs for quick delivery. Companies do not have to wait for long overseas shipping or customs. The table below shows how US providers do in important shipping areas:

KPI Metric | Industry Standard / Benchmark | Notes on Change or Context |

|---|---|---|

On-time delivery | On-time to appointment with 30-min buffer | |

Primary tender acceptance | 85% acceptance rate | Shifted down from 90% in 2022 due to market conditions |

Lead time for shipments | 2 days minimum lead time | 79% of shippers and 81% of carriers expect at least 2 days |

Payment terms to carriers | 92% paid within 30 days; 66% within 1 week | Critical for small carriers' cash flow |

US shipping companies use smart software and work with many carriers. This helps companies change plans fast when needed. Letting experts handle shipping makes less work for manufacturers and fewer mistakes. LTPCBA is quick and delivers on time, showing what to look for in a partner.

Compliance and Communication

Following rules and talking clearly are key to lowering risk. US-based Turnkey PCBA Services follow strict rules and have certifications like IPC and UL. They use safe systems to protect important data and ideas. Security features and updates help stop data leaks. Cloud tools let teams work together and talk in real time. This makes it easy to fix problems fast.

Turnkey solutions give backup and recovery to keep business running.

Standard steps help lower risks and follow rules.

LTPCBA gives 24-hour tech help and great service. This shows why good support and clear talk matter when picking a provider.

Choosing a Turnkey PCBA Partner

Key Criteria

Picking the best Turnkey PCBA partner takes careful thought. Companies should use a checklist to compare each provider. This helps them avoid big mistakes that cost money. The table below shows what to check and what to watch out for:

Evaluation Criteria | What to Look For | Red Flags |

|---|---|---|

Track Record | Certifications, years in business | Lack of credentials, poor reviews |

Delivery Performance | On-time delivery statistics | Frequent delays |

Engagement | Fast, clear communication | Slow replies, unavailability |

Customer Support | 24/7 support, dedicated teams | Poor service, no follow-up |

Other important things to think about are:

Quality assurance: Look for ISO 9001, IPC-A-610, or UL certifications. These show the provider follows strict rules and industry standards.

Technology and expertise: Tools like AOI and X-ray help find problems early.

Turnaround time: Fast lead times and flexible schedules keep projects moving.

Material sourcing: Good suppliers lower the chance of fake or bad parts.

Communication and support: Quick answers and helpful contacts fix problems fast.

Tip: Ask for proof of certifications. Also, ask about how fast they answer and solve problems.

LTPCBA and Industry Best Practices

Top companies set high rules for quality and trust. LTPCBA, for example, has a 99.5% pass rate for products. They use many checks, like AOI, X-ray, and other tests. The company has certifications like ISO 9001:2015, IPC-A-600, and UL 796. These steps make sure quality control and rules are strong.

Best practices also mean using ERP systems to track parts. Working with trusted suppliers keeps parts good. Providers should talk clearly, answer fast, and help after sales. Companies that do these things lower risks and give better results in Turnkey PCBA Services.

US-based providers help electronics makers lower risks. They also make the supply chain stronger. Some important trends are:

Better supply chain visibility lets companies track parts right away.

Working with local partners helps stop problems and delays.

Using new technology helps companies plan better. Picking a good partner and using a checklist helps companies do well for a long time.

FAQ

What is a turnkey PCBA service?

A turnkey PCBA service does all the work for you. They get the parts, put the boards together, and test them. The provider gives you circuit boards that are ready to use.

How do US-based PCBA providers reduce lead times?

US-based providers use local suppliers and shipping. This means products get to you much faster. They can also fix problems or changes right away.

Why are quality certifications important in PCBA services?

Quality certifications, like ISO and UL, mean the provider follows strict rules. These rules help make sure products are safe and work well.

See Also

Sourcing Electronic Parts For Efficient PCBA Production

Choosing The Best Turnkey PCBA Maker For Your Project

Improving Business Efficiency Through PCBA Contract Manufacturing