Typical SMT assembly methods and process flows

Surface-mount technology (SMT assembly methods) are crucial in today's electronics landscape. They enable the creation of small, powerful devices by placing components on circuit boards. Approximately 90% of large factories utilize robots for SMT assembly methods, which accelerates production, reduces errors, and fulfills the demand for superior electronics. Mastering SMT assembly methods allows you to work more efficiently, cut costs, and enhance product quality.

Key Takeaways

Learning SMT assembly methods helps work faster and save money.

Picking manual, semi-automatic, or automatic methods depends on size and design.

Taking care of SMT machines stops problems and keeps work on time.

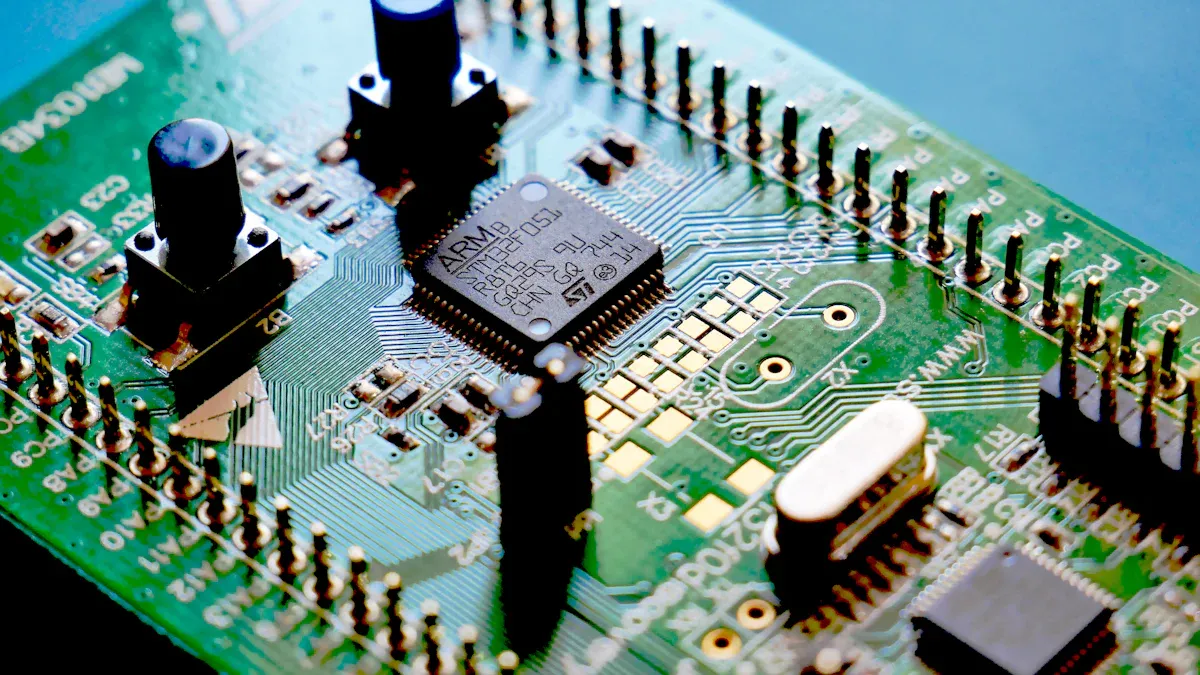

Overview of SMT Assembly Methods

Surface mount technology (SMT) assembly has changed a lot over time. These methods are grouped into three types: manual, semi-automated, and fully automated. Each type has its own benefits and works best for different needs and production sizes.

Manual SMT Assembly Methods

Manual SMT assembly is done by people placing parts on a circuit board by hand. It works well for small projects or testing new designs. This method is good when accuracy and flexibility matter more than speed. Skilled workers are needed to avoid mistakes and ensure everything is correct.

Some advantages of manual SMT assembly are:

Low cost for starting equipment.

Great for custom or tricky designs.

Easy to make changes during assembly.

But manual assembly is not good for making large amounts of products. It also has a higher chance of mistakes, which can lower the product's quality.

Semi-Automated SMT Assembly

Semi-automated SMT assembly uses both people and machines. Machines do repetitive tasks like applying solder paste and placing parts. Workers watch the process and make changes when needed. This method balances speed and flexibility.

A new optimization system helps improve automated inspections in SMT. It reduces false alarms and finds defects better, improving quality and efficiency.

Semi-automated assembly is great for medium-sized production. Its benefits include:

Faster than manual assembly.

Lower labor costs.

Better accuracy in placing parts and soldering.

However, skilled workers are still needed to check the process and fix problems.

Fully Automated SMT Assembly with LTPCBA

Fully automated SMT assembly is the fastest and most accurate method. Machines handle everything, from applying solder paste to placing parts and soldering. Companies like LTPCBA use advanced machines to produce high-quality results.

Evidence Type | Description | Improvement Percentage |

|---|---|---|

SMT Terminal Blocks | Save space on circuit boards | |

Automation Compatibility | Save time and reduce labor costs | 20-40% |

Fully automated methods are perfect for making large amounts of products. They are very fast and accurate, ensuring all items are the same quality. LTPCBA's systems also save materials and energy, making the process eco-friendly.

The SMT industry is growing because people want smaller and better devices. Automation helps meet this demand by making production faster and cheaper. Choosing a company like LTPCBA gives you access to the best technology and expertise.

Detailed SMT Assembly Process Flow

Solder Paste Application on PCB

The first step is applying solder paste to the PCB. A stencil is used to place paste only on the pads for components. This step is very important because it affects welding quality. Over 70% of welding success depends on this stage.

To do this well, focus on stencil design and paste thickness. Problems like stencil damage can cause bad soldering and fewer good products. Factories aim for a first pass yield of 95% to meet standards. Fast work during this step helps save time and money.

Component Placement Using Pick-and-Place Machines

Next, components are placed on the PCB. Pick-and-place machines do this job with great accuracy. They pick parts from trays and put them on the board based on the design. Top machines can place 35,000 parts per hour with a 99.95% success rate.

These machines make very few mistakes. For example, errors for small parts like resistors can be under 1000 ppm. Some machines have placed 10,000 LEDs without a single mistake. This high accuracy keeps the PCB reliable and well-made.

Reflow Soldering in SMT Assembly

Reflow soldering melts the paste to connect parts to the PCB. The board goes through a reflow oven that heats it to the right temperature. This step ensures the solder flows evenly and sticks properly.

Good soldering needs careful temperature control. Problems like cold joints or overheating can ruin the connections. Automated systems do this step well, making sure every board is consistent. Better soldering improves the PCB’s reliability and lowers failure risks.

Inspection and Quality Control (AOI and ICT)

Inspection checks for mistakes and ensures the PCB works correctly. AOI systems look for problems like misplaced parts or bad soldering. ICT tests the PCB’s electrical functions to confirm it works as planned.

Data from tests can predict future issues and improve processes. Using SPC helps track important steps, set limits, and find trends. Tools like charts and analysis fix repeated problems quickly.

Final Assembly and Testing of PCB

The last step is putting the PCB into its case or system. Then, tests are done to check if the product works well. Tests include checking functions, electrical performance, durability, and strength.

These tests make sure the PCB is ready to use. Function tests check if parts work correctly, while durability tests look at long-term use. Careful testing ensures the product meets industry rules and works as expected.

Best Practices for Optimizing SMT Assembly

Design for Manufacturability (DFM) Guidelines

Using DFM guidelines makes PCB designs easier to assemble. These rules help simplify layouts for better manufacturing. For example, placing parts in the same direction speeds up work and lowers mistakes. Avoid crowding parts together to leave enough space. This reduces problems during assembly and improves success rates.

Following DFM rules helps you make more products with fewer errors. It also saves money and boosts efficiency. Engineers often suggest using standard parts instead of custom ones. Standard parts are easier to use, cost less, and still perform well.

Component Placement and Orientation for PCB Assembly

Placing parts correctly is very important in SMT assembly. Keeping parts in the same direction makes assembly faster and reduces errors. This also helps pick-and-place machines work more accurately.

When designing your PCB, leave enough space between parts. This prevents soldering problems and makes assembly smoother. A neat layout improves both efficiency and product reliability.

Ensuring Accurate Solder Paste Application

Applying solder paste correctly is key for strong connections. The amount and thickness of the paste affect how well parts stick. Too little paste can cause weak connections, while too much can create short circuits.

To avoid these problems, design stencils carefully and check paste thickness. Catching mistakes early during paste inspection saves time and money. This step is vital for making sure your PCB works properly.

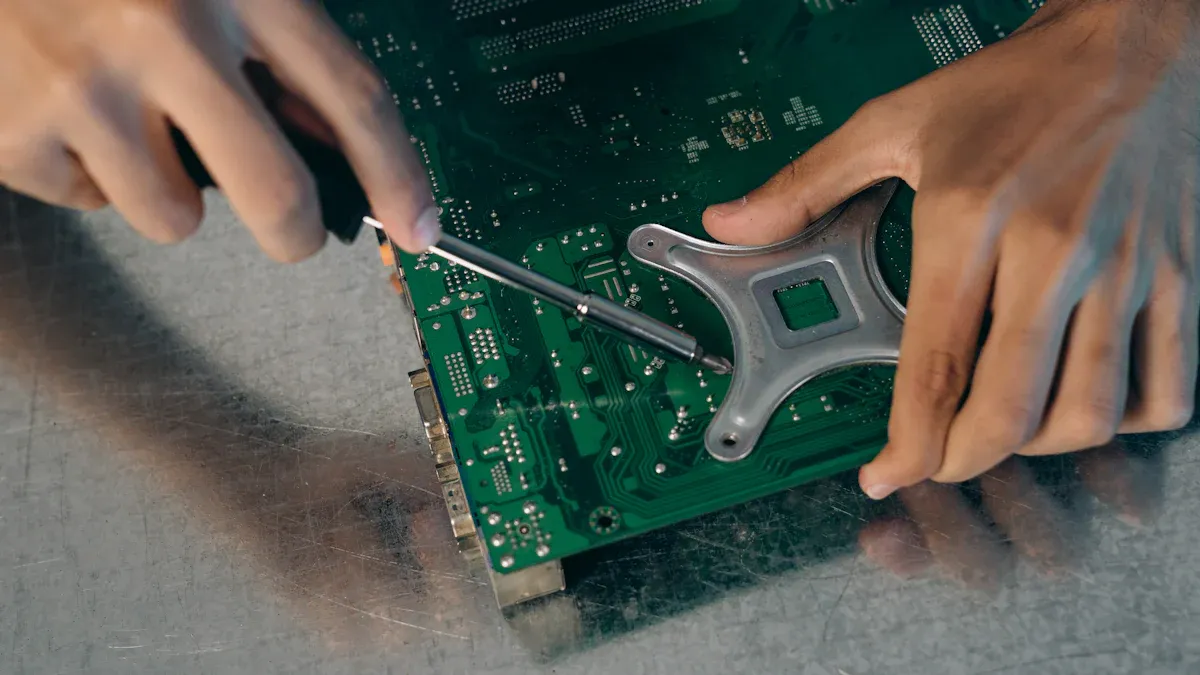

Regular Maintenance of SMT Equipment

Taking care of SMT machines stops unexpected breakdowns. Breakdowns can cause days of delays and waste materials. Regular maintenance costs less and keeps production running smoothly.

Plan routine checkups to keep machines working well. This reduces downtime and helps your equipment last longer. Proper maintenance ensures your SMT assembly process stays efficient and reliable.

Common Problems in SMT Assembly and How to Fix Them

Fixing Misaligned Parts

Misaligned parts can make your PCB not work right. Fixing these mistakes can cost a lot of money. To avoid this, check machines often to keep them aligned. Automated Optical Inspection (AOI) systems help find problems early. This lowers the chance of misaligned parts. Also, 3D Solder Paste Inspection (SPI) ensures solder paste is applied correctly. This reduces circuit issues caused by misplaced parts.

Problem | Solution |

|---|---|

Machine Alignment | Regular checks stop misalignment during assembly. |

Automated Optical Inspection (AOI) | Finds problems early, lowering risks of misaligned components. |

3D Solder Paste Inspection (SPI) | Makes sure solder paste is applied properly to avoid failures. |

Selective Soldering Equipment | Reduces human mistakes in soldering, cutting misalignment risks. |

Advanced Robotics | Improves accuracy in placing parts, reducing misalignment chances. |

Avoiding Soldering Problems in SMT Assembly

Soldering mistakes can cost a lot and slow production. Fixing mistakes gets more expensive as the process goes on. For example, fixing errors after SPI costs 375% more, and after AOI, it’s 3000% more. To stop these problems, apply solder paste carefully and control reflow oven temperatures. Regular checks and using both AOI and X-ray inspections catch mistakes early.

47 mistakes were found in assembled PCBs, showing the need for checks.

21 PCBs had defects, proving the importance of preventing errors early.

Solving PCB Warping Problems

PCB warping can cause parts to move or soldering issues. Preheating parts before reflow keeps the process steady. Cooling quickly after reflow makes solder joints strong and stops warping. These steps reduce waste and improve the quality of your PCB.

Preheating parts helps make assembly smoother.

Quick cooling stops problems like part misalignment and weak solder joints.

These steps save materials and make your PCB more reliable.

Fixing Slowdowns in SMT Assembly

Slowdowns in SMT assembly can delay production and raise costs. Improving processes and increasing capacity can solve these issues. Using advanced inspection tools like VQI speeds up inspections. Fixing inspection delays makes production run more smoothly.

Solution | How It Helps |

|---|---|

Makes work faster and increases output. | |

Increase Capacity | Allows more production, solving delays. |

Use Advanced Inspection Tools | Tools like VQI make inspections quicker and improve production flow. |

Skilled workers are needed to inspect complex PCBs.

Coatings protect PCBs but can hide problems, making checks harder.

Finding and fixing inspection delays improves production speed.

Learning the main methods and steps in SMT assembly helps improve work quality and speed. Using tips like applying solder paste correctly and keeping machines in good shape makes things run better. Companies such as LTPCBA use smart machines to make inspections faster, lower mistakes, and save money while increasing production.

Metric | Old Method | Automated FAI System |

|---|---|---|

Takes up to 3 hours | Much shorter | |

Error Rate | Higher with manual checks | Lower with automation |

Production Efficiency | Slower due to delays | Faster with better systems |

Cost Savings | Small | Big due to less fixing |

Quality Assurance | Simple visual checks | Full automated checks |

With LTPCBA’s help, you can make SMT assembly faster and create top-quality products for today’s needs.

FAQ

Why is SMT assembly better than older methods?

SMT assembly makes smaller and better devices. It works faster and is more reliable than older through-hole methods.

How does LTPCBA make sure SMT assembly is high quality?

LTPCBA uses smart machines like AOI and X-ray tools. These machines catch mistakes and keep the quality the same for every batch.

Can SMT assembly work with tricky PCB designs?

Yes, SMT assembly is great for hard designs. LTPCBA can handle parts like BGA, Micro-BGA, and QFN with care and accuracy.

See Also

Understanding SMT and DIP Assembly for PCBA Uses

Effective Strategies for Optimizing SMT Production Lines

Challenges to Consider in Rigid-Flex SMT Assembly