How Turnkey PCBA Services in Texas Streamline Your Projects

Turnkey PCBA services Texas, such as those offered by LTPCBA, streamline every phase of electronics manufacturing for you. By choosing turnkey PCBA services Texas, you benefit from significantly faster project completion, with lead times often 20% shorter than traditional methods. These services help you reduce costs by eliminating hidden expenses like rework and unexpected delays. With turnkey PCBA services Texas, you enjoy strict quality assurance and simplified project management, all under one roof. Local Texas providers ensure stable supply chains and fast shipping, making your experience with turnkey PCBA services Texas even more dependable.

Benefit | Turnkey PCBA Services Texas | Traditional Methods |

|---|---|---|

Delivery Speed | 5–15 days | 75–80 days |

Cost Efficiency | Lower hidden costs | Higher hidden costs |

Quality Assurance | Single-source oversight | Higher defect rates |

Key Takeaways

Turnkey PCBA services in Texas speed up your project by handling all steps from design to delivery under one roof, cutting lead times by up to 20%.

You save money with turnkey services because they reduce hidden costs like rework and shipping fees through bundled pricing and efficient sourcing.

Quality is guaranteed with advanced testing methods and strict standards, ensuring your PCBs work right the first time and arrive on schedule.

Working with a single provider simplifies communication and project management, reducing errors and freeing you to focus on your core business.

Local Texas providers offer fast support, reliable supply chains, and strong certifications, giving you confidence and a competitive edge.

Turnkey PCBA Services Texas

What Is Turnkey PCBA?

Turnkey PCBA means you hand over your entire printed circuit board assembly project to a single provider. You do not need to manage multiple vendors or coordinate between suppliers, assemblers, and testers. Providers like LTPCBA offer a comprehensive solution that covers every stage, from sourcing components to final delivery. This approach ensures you receive a fully assembled, tested, and ready-to-use product without the hassle of managing each step yourself.

With turnkey pcba services texas, you gain access to expert teams who handle production planning, procurement, assembly, and quality control. You benefit from advanced technology, such as automated optical inspection and X-ray systems, which guarantee high reliability and a 99.5% pass rate. This all-in-one service model streamlines your workflow and reduces the risk of errors or delays.

How the Process Works

You can expect a clear, step-by-step process when you choose turnkey pcba services texas. Here is how most Texas-based providers, including LTPCBA, structure their service:

Design Review: You submit your design files and bill of materials. The provider reviews and prepares them for production.

Component Sourcing: The provider selects and purchases all components from trusted suppliers, managing inventory internally.

Assembly: Skilled technicians use advanced machinery for surface mount and through-hole assembly.

Inspection and Testing: Automated optical inspection, X-ray, and other tests ensure your boards meet strict quality standards.

Finishing: Processes like coating and cleaning prepare your boards for use.

Packaging and Delivery: The provider securely packages and ships your finished PCBs directly to you.

By consolidating all steps under one roof, turnkey pcba services texas simplify your project management. You avoid miscommunication, reduce errors, and enjoy faster turnaround times. Local supply chain management in Texas further improves reliability and responsiveness, making your experience smoother from start to finish.

Time and Cost Benefits

Faster Delivery

You want your electronics project to move quickly from concept to completion. Turnkey PCBA services Texas help you achieve this goal by managing every step under one roof. You do not need to wait for separate vendors to finish their tasks. Instead, you benefit from a streamlined process that eliminates unnecessary delays.

When you work with a provider like LTPCBA, you submit your design and requirements once. The team handles procurement, assembly, and testing in a coordinated workflow. This approach reduces lead times and helps you launch your product faster. Automated assembly lines and integrated testing further speed up production. You receive your finished boards in days, not months.

Tip: Faster delivery means you can respond to market changes quickly and stay ahead of competitors.

Cost Savings

Managing costs is critical for any business. Turnkey PCBA services Texas offer bundled pricing that covers all stages of production. You avoid the hidden expenses that often come with traditional methods, such as rework, miscommunication, and unexpected shipping fees.

You receive a single, transparent quote for the entire project.

Providers like LTPCBA use their supply chain networks to source components at lower prices.

Early design reviews catch errors before production, saving you from costly changes later.

Inventory and shipping management are included, reducing your overhead and manpower needs.

By combining orders from multiple clients, providers achieve economies of scale that lower your per-unit cost.

You can plan your budget with confidence, knowing there will be no surprise charges down the line.

Efficiency for Small Businesses

If you run a small business, you may not have the resources to manage multiple vendors or oversee complex supply chains. Turnkey PCBA services Texas simplify your workload by acting as your single point of contact. You do not need to coordinate between designers, suppliers, and assemblers.

All project steps, from design to delivery, are handled by one provider.

You save time by avoiding back-and-forth communication with different companies.

The provider manages procurement, manufacturing, assembly, and testing, freeing you to focus on your core business.

Automated processes and professional quality assurance ensure reliable results.

Early identification of design issues during prototyping helps you avoid delays and extra costs.

You gain operational efficiency and peace of mind, knowing your project is in expert hands.

Quality Assurance

Integrated Testing

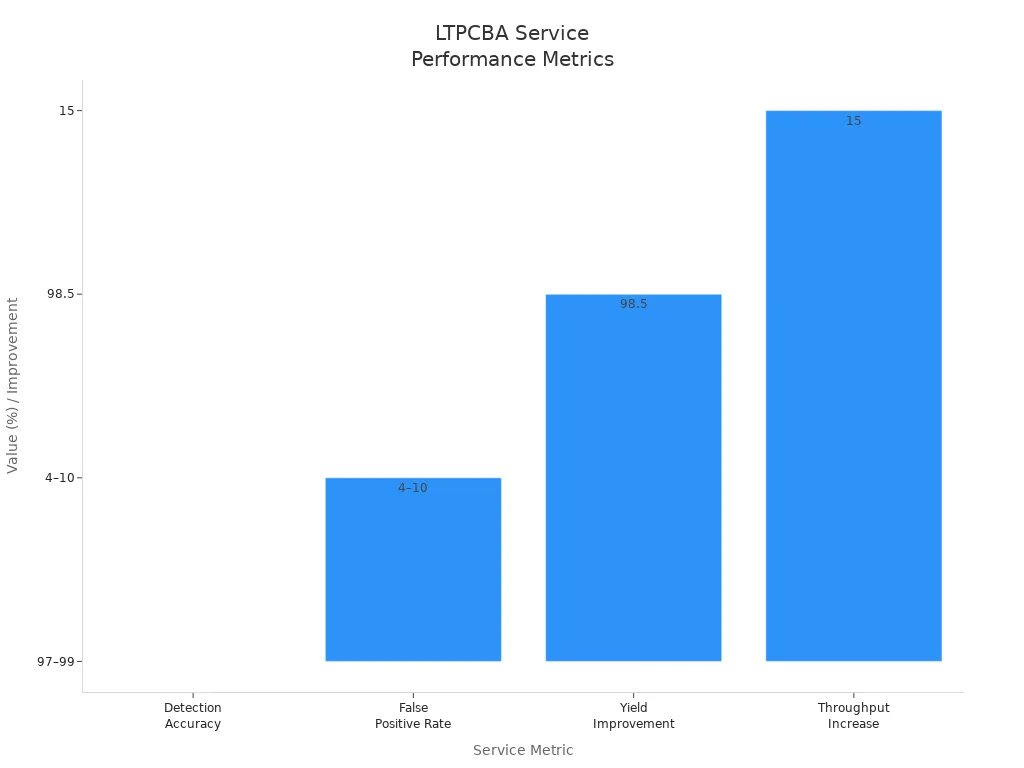

You want your electronics to work right the first time. Integrated testing at every stage of the PCBA process helps you reach that goal. LTPCBA uses a combination of advanced inspection tools and proven testing protocols to catch problems before your boards leave the factory.

Failure Modes and Effects Analysis (FMEA) helps you identify and address possible failure points early in the process.

Statistical Process Control (SPC) and Design for Manufacturability (DFM) analysis allow you to spot and fix defects before they become costly.

Automated Optical Inspection (AOI) and X-ray inspection give you a close look at every solder joint and component placement.

Design for Test (DFT) reviews make sure your boards are easy to test, improving defect detection.

In-Circuit Test (ICT) checks for missing or incorrect parts, while Functional Test simulates real-world use to verify performance.

Continuous improvement through Value Analysis and Value Engineering (VA/VE) helps you optimize your design for quality and reliability.

With these integrated protocols, you reduce the risk of field failures, lower your costs, and deliver more robust products to your customers.

Standards Compliance

You need confidence that your PCBA provider meets the highest industry standards. LTPCBA holds certifications that match or exceed what you find with top Texas manufacturers. These certifications prove that your boards are built to last and meet strict quality requirements.

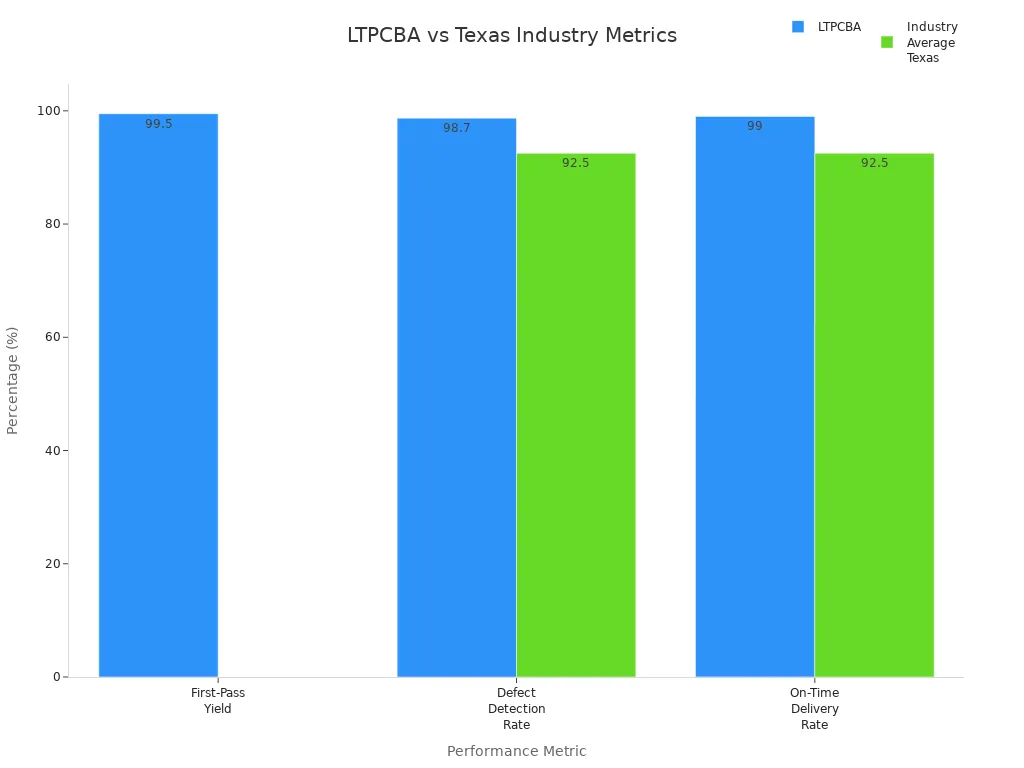

Certification / Metric | LTPCBA Status / Performance | Industry Average in Texas |

|---|---|---|

ISO 9001 | Held | Commonly held |

IATF 16949 | Held | Commonly held in automotive sector |

UL Certification | Held | Commonly held |

IPC-A-610 | Held | Industry standard |

First-Pass Yield | 99.5% | Lower (not specified exactly) |

Defect Detection Rate | 98.7% | 90–95% |

On-Time Delivery Rate | 99% | 90–95% |

You see that LTPCBA not only meets the most important certifications, but also outperforms the industry in first-pass yield, defect detection, and on-time delivery. This means you get boards that meet your requirements and arrive when you need them.

Reliable Results with LTPCBA

You want results you can trust. LTPCBA delivers with a 99.5% first-pass yield and a 98.7% defect detection rate. Automated inspection systems, including AOI and X-ray, check every board for accuracy and quality. Skilled technicians review the results and make sure your boards meet IPC-A-610 standards.

You benefit from:

Fewer defects and less rework, saving you time and money.

Consistent quality across every batch, whether you order prototypes or mid-volume runs.

Fast, on-time delivery so you can keep your project on schedule.

When you choose LTPCBA, you get more than just a PCBA provider. You gain a partner committed to quality, reliability, and your project’s success.

Project Management Made Simple

Single Point of Contact

You gain a major advantage when you choose turnkey pcba services texas. You work with a single point of contact who manages every aspect of your project. This approach simplifies logistics and eliminates the need to coordinate with multiple vendors. You avoid miscommunication and cascading delays that often happen when several suppliers are involved. Your project manager oversees procurement, fabrication, assembly, testing, packaging, and shipping. You receive consistent updates and clear answers, which gives you peace of mind throughout the process.

You save time by not juggling different contacts.

You experience fewer disruptions and faster issue resolution.

You enjoy consistent quality and reliable delivery.

This model works especially well for small businesses and startups. You get flexibility in order quantities and early identification of manufacturing problems, which helps you stay on track.

Streamlined Communication

Clear communication drives project success. With turnkey pcba services texas, you benefit from centralized digital platforms that store all your design files, BOMs, and assembly instructions. Everyone involved accesses the same information, which prevents discrepancies and confusion. Real-time collaboration allows you to solve problems quickly and make decisions without delay.

Formal change management processes communicate design modifications clearly.

Documentation uses concise language to minimize ambiguity.

A dedicated project manager ensures your questions get answered promptly.

You avoid misunderstandings and keep your project moving forward. This streamlined approach fosters continuous improvement and boosts overall efficiency.

Reduced Errors

You reduce errors when you rely on a single provider. Centralized data management and clear communication prevent mistakes that often occur with multi-vendor setups. Your project benefits from formal change management and consistent documentation. You do not depend on individual tribal knowledge, so production disruptions become rare.

Turnkey providers handle procurement, assembly, quality control, and logistics in one place.

You avoid bottlenecks and minimize risks for your team.

Delegating supply chain management lets you focus on design and planning.

You achieve smoother coordination and lower risk, making your project more successful from start to finish.

Local Expertise in Texas

Texas Supply Chain Advantages

You gain a clear edge when you work with Texas-based PCBA providers. Texas stands out for its pro-business environment, low taxes, and minimal regulatory barriers. The state’s central location and robust transportation network give you fast access to both domestic and international markets. Skilled workers from local universities and technical schools keep your projects moving forward with expertise and innovation.

Local sourcing reduces long shipping delays and avoids overseas disruptions.

Proximity to major suppliers, like the new GlobalWafers plant, ensures a steady flow of high-quality materials.

Texas’s strong energy infrastructure supports even the most demanding manufacturing needs.

Government incentives, such as the CHIPS Act, encourage investment and innovation in electronics manufacturing.

You benefit from shorter supply chains, lower logistics risks, and faster delivery. These advantages help you respond quickly to market changes and keep your projects on schedule.

Responsive Support

You need support that matches your pace. Texas-based providers offer quick-turn fabrication and assembly, often with same-day or next-day options for urgent needs. Local teams communicate in your time zone, making it easy to resolve issues fast. You can reach engineers by phone or email, ensuring direct and timely responses.

Metric | Benchmark | LTPCBA Service Feature |

|---|---|---|

Inquiry Response Time | Within 24 hours | 24/7 technical support with rapid responses |

Customer Satisfaction | Above 85% | Friendly, rapid, and continuous support |

LTPCBA stands out by offering 24/7 technical support. You get answers faster than the industry standard, which means less downtime and more confidence in your project’s progress.

LTPCBA Service Highlights

You want a partner who delivers quality and reliability every time. LTPCBA holds top certifications, including ISO, IATF, UL, and IPC standards. The company uses advanced inspection tools like AI-driven AOI and X-ray testing to catch defects early and ensure high product quality. Customers praise LTPCBA for its 99.5% pass rate, fast delivery, and friendly support.

Detailed quality reports help you track performance and drive improvements.

Flexible buying options and strong vendor relationships keep your supply chain resilient.

A 90-day workmanship warranty gives you peace of mind.

You receive not just a product, but a partnership built on trust, expertise, and proven results.

Turnkey PCBA services in Texas, especially those from LTPCBA, help you complete electronics projects faster and with fewer errors. You benefit from:

Time and cost savings through consolidated manufacturing and bulk sourcing

Rigorous quality control and advanced testing for reliable results

Simplified project management with a single point of contact

Local support, fast delivery, and strong intellectual property protection

Choose LTPCBA to streamline your next project and gain a competitive edge with efficient, high-quality PCB assembly.

FAQ

What is included in turnkey PCBA services?

You receive complete project management. This covers component sourcing, PCB fabrication, assembly, testing, and delivery. You do not need to coordinate with multiple vendors. LTPCBA handles every step for you.

How fast can I get my assembled PCBs?

You can expect delivery in as little as 5–15 days. LTPCBA uses efficient processes and local supply chains to reduce lead times. You stay on schedule and launch your product faster.

How does LTPCBA ensure product quality?

LTPCBA uses automated inspection, X-ray testing, and strict quality control. The company holds ISO, IATF, and UL certifications. You receive boards that meet high industry standards and pass rate targets.

Can small businesses benefit from turnkey PCBA?

Absolutely! You save time and resources by working with one provider. LTPCBA manages procurement, assembly, and testing. You focus on your business while experts handle the technical details.

See Also

Choosing The Best Turnkey PCBA Manufacturer For Electronics

Enhancing Business Efficiency Through PCBA Contract Manufacturing

Understanding Complete Turnkey PCB Assembly And Manufacturing

Quick-Turn PCB Prototypes Accelerate Project Completion Speed