Understanding Turnkey PCBA Quotes: Key Factors That Influence Pricing and Turnaround Time

Knowing what affects Turnkey PCBA Quotes helps you plan better. It also helps you set your budget for your electronics project. Important things like getting parts, making the PCB, putting it together, and testing all change the price and time needed.

Impact on Your Project Planning | |

|---|---|

Component Procurement | Changes your budget, risk, and if parts are there |

PCB Fabrication | Changes your design and how you control costs |

Assembly Process | Changes how much you pay for work and tools |

Testing & Quality | Lowers mistakes and the chance of fixing things |

Key Takeaways

Understanding what changes Turnkey PCBA quotes helps you plan your money and time better, so you do not get unexpected costs. - Make your PCB design simple and use parts that are easy to find to save money and get your boards sooner. - Give LTPCBA clear and full documents to get fast and correct quotes and to keep your project moving well.

Turnkey PCBA Quotes: Main Cost Drivers

When you ask for Turnkey PCBA Quotes, many things affect the price and how fast you get your boards. Knowing these things helps you plan and stops surprises.

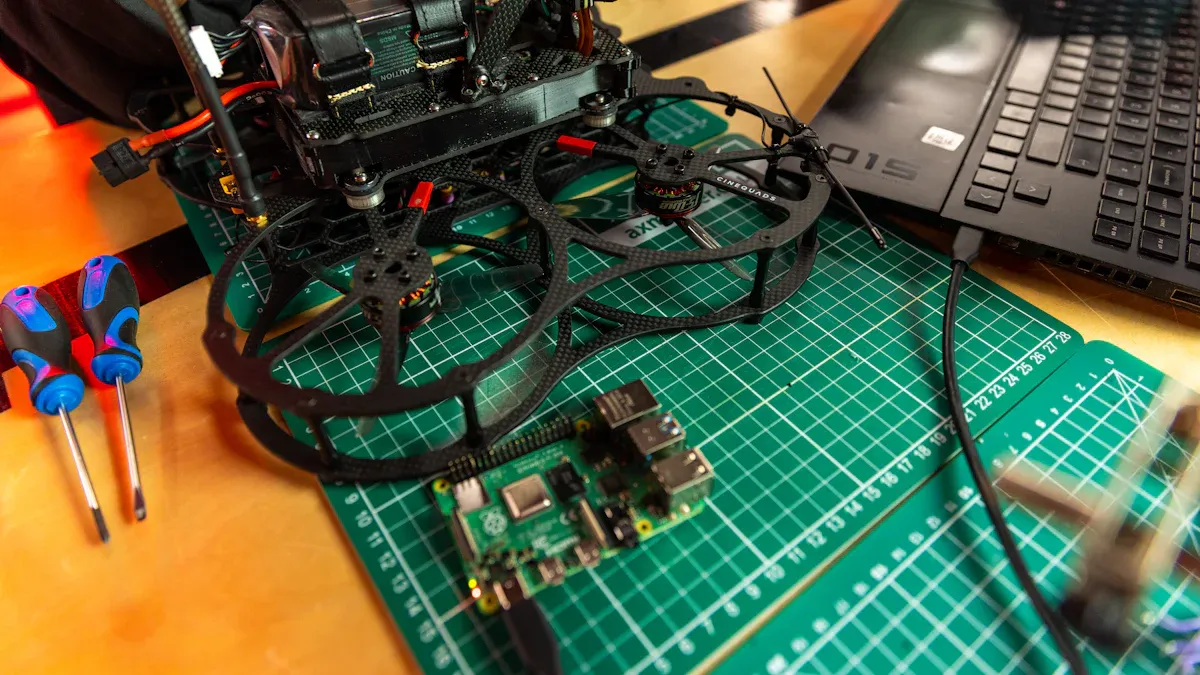

BOM and Component Sourcing

The Bill of Materials (BOM) is a list of every part your board needs. How you get these parts changes the cost and delivery time. If you use a turnkey service, they get all the parts for you. This saves you time and helps stop mistakes.

Part prices can change fast and make your total cost go up. If a part is hard to find or costs more, your quote will be higher.

Good supply chains help keep prices steady. LTPCBA uses its network to find good prices and avoid delays.

Using common parts and letting the BOM have substitutes can make things cheaper and faster.

Buying in big amounts and working with trusted suppliers can get you discounts.

Tip: You can save money on your BOM by adding other part numbers, using common parts, and not picking parts that are too fancy.

Here are some ways to save money on your BOM: 1. Make sure every part in your BOM is needed. 2. Add substitute parts for each item. 3. Get prices from different distributors. 4. Work with your contract manufacturer to use their buying power. 5. Check part prices often to see if they drop. 6. Use good forecasts to plan your orders. 7. Pick RoHS-compliant and reel-packaged parts for better results.

LTPCBA’s smart way of getting parts means you do not need to talk to many suppliers. This saves you time and helps stop mistakes. They answer fast and give you quotes in 2-3 days, so your project keeps moving.

PCB Design Complexity

How your PCB is designed changes the cost and how long it takes. Harder designs need more steps and special skills.

Factor | Impact on Cost and Turnaround Time |

|---|---|

More layers cost more and take longer to make | |

Board size | Bigger boards use more material and take more time |

Component density | Tighter layouts need careful work, which costs more |

Urgency (turnaround) | Faster delivery costs extra and needs more resources |

Simple boards with fewer layers and normal parts cost less and are quicker to build.

Hard boards with tiny parts, BGAs, or special materials need special tools and skilled workers, so they cost more and take longer.

LTPCBA uses machines and skilled engineers to make hard designs with high accuracy, so there are fewer mistakes and less fixing.

Note: If you make your design simpler—like using fewer layers or normal parts—you can save money and get your boards faster.

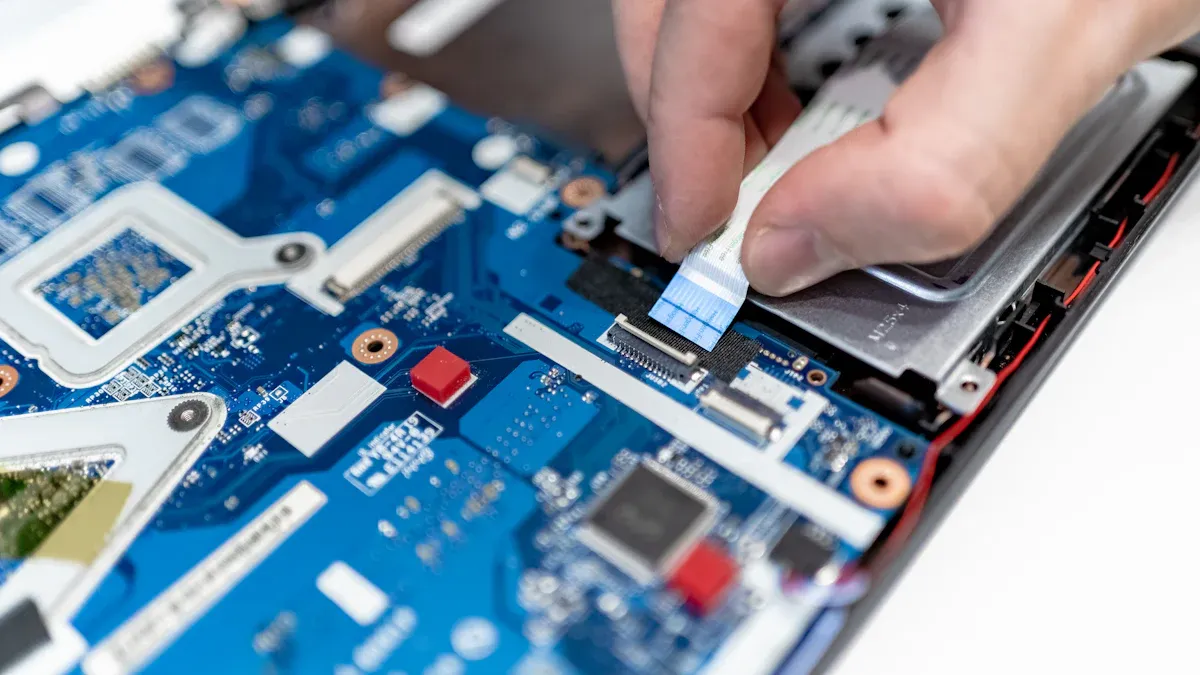

Assembly and Testing

Assembly and testing are important steps in the PCBA process. They make sure your boards work right.

The number of parts, type of assembly (SMT, through-hole, or mixed), and if you need single or double-sided assembly all change the cost.

Special tests like AOI, X-ray, and ICT cost more but help find problems early.

Special needs, like handling BGAs or programming firmware, make things cost more and take longer.

LTPCBA uses machines to put boards together and advanced tools to check them. Their quality pass rate is 99.5%, so you get fewer mistakes and less fixing. They follow strict rules, so your boards are always reliable.

Tip: Using machines for assembly lowers labor costs and mistakes, so your boards are better and cheaper.

Here are common checks in Turnkey PCBA:

Visual inspection

Automated Optical Inspection (AOI)

X-ray checks for hidden joints

In-circuit and functional testing

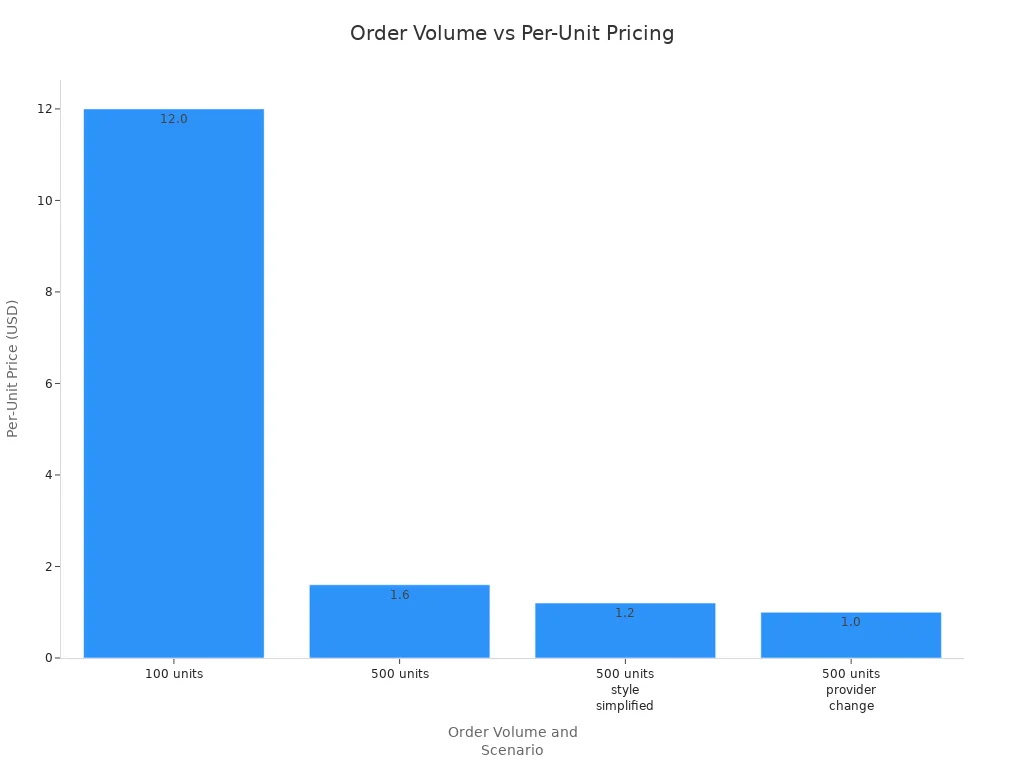

Order Volume and Lead Time

How many boards you order and how fast you need them both change your quote.

Order Volume Range | Approximate Per-Unit Price (USD) | Notes |

|---|---|---|

$50–$200 | Higher per-unit cost due to setup | |

Bulk Orders (1,000+ units) | $2–$20 | Lower cost from economies of scale |

Bigger orders make each board cost less because setup and programming costs are shared.

Bulk orders also get discounts from suppliers.

Small orders cost more per board, but you get them faster—sometimes in just 24 hours.

Normal lead times for big orders are 2-3 weeks, but LTPCBA can do quick-turn for urgent needs.

Order Volume | Lead Time Range | Notes |

|---|---|---|

Small/Prototype | 1 to 5 working days | Quick turn options as fast as 2-3 days |

Large Production | 14 to 20 working days | Standard production lead time |

Tip: If you combine orders or use panelization, you can make each board even cheaper.

Turnkey PCBA Quotes show all these things. By knowing what changes cost and time, you can make better choices and get more value from your project. LTPCBA is good at getting parts, checking quality, and answering fast, so you can control costs and finish on time.

LTPCBA Quoting Process and Optimization

Required Information for Quotes

You need to get some things ready for a Turnkey PCBA Quote from LTPCBA. These things help them give you the right price and time. Here is what you should have:

A bare board print with all details like size, layers, materials, finishes, hole sizes, and colors.

Gerber files or ODB++ data for your PCB design.

Assembly instructions that show where each part goes and how to pack the boards.

A Bill of Materials (BOM) with part numbers, descriptions, quantities, reference designators, and vendor info.

An Approved Vendor List (AVL) that links your part numbers to trusted suppliers.

Documents that are always updated and have clear revision numbers.

A quote form with details like assembly type, board quantity, unique parts, and special assembly needs.

If you give LTPCBA all the right info, they can give you a fast and correct quote, usually in 2-3 days.

Step-by-Step with LTPCBA

LTPCBA makes getting a quote easy and quick. Here is how it goes:

You send your documents and project details to them.

LTPCBA checks your files and looks for missing info.

Their team uses smart systems to look at your BOM and design.

You get a detailed quote, usually in 2-3 days.

If you have questions, LTPCBA has 24/7 support and account managers to help.

Performance Metric | LTPCBA Performance | Industry Average |

|---|---|---|

Prototype Lead Time | 5-7 days | |

First Pass Yield | 98.7% | 92-95% |

Cost Efficiency | ~30% lower | Standard pricing |

LTPCBA has ISO and UL certifications. They use strong quality checks, so you get good boards every time.

Tips to Reduce Cost and Time

You can save money and get your boards faster if you follow these tips:

Pick partial turnkey service if you can get some parts yourself.

Send your parts to LTPCBA early to make assembly faster.

Keep your BOM simple and use standard parts when you can.

Work with LTPCBA’s team to fix problems quickly.

Use their online portal for updates and fast messages.

Plan your project and update your documents often to stop delays.

LTPCBA’s skilled team, smart machines, and strong supply chain help you finish your project on time and stay on budget.

You can control cost and speed by understanding what affects Turnkey PCBA Quotes. When you give clear files and details, you help LTPCBA give fast, accurate quotes. Use these tips to avoid mistakes and delays. For questions or help, reach out to LTPCBA’s support team any time.

FAQ

What documents do you need for a fast LTPCBA quote?

You need your BOM, Gerber files, assembly instructions, and board details. Clear files help LTPCBA give you a quick and accurate quote.

How can you lower your PCBA costs?

Use standard parts.

Keep your design simple.

Order more boards at once.

Let LTPCBA suggest part substitutes.

How fast can LTPCBA deliver prototype boards?

Service Type | Lead Time |

|---|---|

Prototype | 24–48 hours |

You get your prototype boards quickly with LTPCBA’s fast service.

See Also

Speeding Up Projects With Quick-Turn PCB Assembly Prototypes

Choosing The Best Turnkey PCBA Manufacturer For Electronics

Finding A PCBA Supplier That Perfectly Fits Your Needs

Ensuring High Quality Through Advanced Turnkey PCBA Factories

Boosting Business Efficiency With PCBA Contract Manufacturing