Top Tips for Managing High Volume Quick Turn PCBA Projects

You can efficiently manage high volume quick turn PCBA projects by emphasizing early planning, clear communication, and leveraging advanced technology. LTPCBA specializes in high volume quick turn PCBA, utilizing automated assembly lines and rigorous quality control measures such as AOI and X-ray inspection. Their rapid response times, impressive pass rate, and dedicated customer support ensure you achieve reliable results with every project.

Key Takeaways

Early planning and clear communication are essential for meeting tight deadlines in quick turn PCBA projects.

Utilize a strong supplier network to manage supply chain risks and ensure timely access to components.

Implement automated assembly and digital tracking to enhance efficiency and maintain high quality throughout the production process.

Project Challenges

Tight Deadlines

You often face tight deadlines in high volume quick turn pcba projects. Customers expect fast delivery and short lead times. Quick turn pcb assembly requires you to plan every step carefully. If you miss a deadline, your time to market suffers. Many companies struggle to balance speed with quality. LTPCBA helps you meet these demands by using automated assembly lines and digital tracking. Their quick response service gives you fast quotations and support, which keeps your project on schedule.

Tip: Map out your delivery cycle early and communicate changes quickly to avoid delays.

Supply Chain Issues

Supply chain disruptions can slow down quick turn pcb assembly. Raw material shortages, such as copper or epoxy resin, often extend lead times from two weeks to eight weeks. Price spikes, like the 40% increase in copper costs in 2024, can also affect your budget. Some companies avoid delays by switching to alternative materials. For example, a medical device client saved six weeks by using a bio-based resin during a shortage. LTPCBA’s strong supplier network and flexible sourcing strategies help you manage these risks and keep high-volume production moving.

Common supply chain challenges:

Material shortages

Price fluctuations

Shipping delays

Quality Demands

Maintaining quality in quick turn pcb assembly is critical. Even small errors can lead to many defective boards. Industry benchmarks show that design errors in traditional PCBs reach 5–6%, but quick turn projects lower this to 1–2%. LTPCBA uses strict quality control, including AOI and X-ray inspection, to achieve a 99.5% pass rate. They follow international standards, so you can trust the reliability of your boards.

Challenge | Description |

|---|---|

Cost control | Balancing high upfront investments with later returns is a significant issue for enterprises. |

Quality control | Strict quality control is essential as small errors can lead to many defective products. |

Environmental pressure | Companies must address the environmental impact of PCB manufacturing and strive for green production. |

Technological innovation | Keeping up with rapid technological changes is crucial to meet market demands and avoid obsolescence. |

Market adaptability | Quick adjustments to production plans are necessary to respond to changing market trends. |

Planning for Success

Clear Goals

You set the stage for a successful high volume quick turn PCBA project by defining clear goals from the start. When you outline your targets for quality, budget, and resources, you help your team stay focused. Clear goals make it easier to meet customer requirements and launch products on time. Assigning specific stakeholders to each task increases accountability and prevents duplicated work.

Benefits of setting clear goals:

You ensure project execution stays on track.

You address customer needs quickly.

You reduce confusion and wasted effort.

Early and frequent communication with all stakeholders supports these goals. You can use LTPCBA’s quick response service to get fast quotations and technical support, which helps you make decisions without delay.

Timeline Mapping

Effective planning means you map out every step of your project timeline. You should prepare your design files carefully and check that all information is complete. This prevents delays during production. Creating a detailed schedule helps you align PCB delivery with your overall project needs.

Strategy | Description |

|---|---|

Submit clear and complete design files to avoid production delays. | |

Timeline Planning | Plan each phase to match your delivery goals. |

Communication Protocols | Set up fast update systems for quick decisions. |

Contingency Planning | Prepare backup plans to handle unexpected problems. |

You can also use proven planning methods to reduce delays. For example, process parallelization lets you overlap steps to save time. Inspection optimization focuses on checking critical components, which speeds up the process. LTPCBA’s team supports you at every stage, making sure your project stays on schedule.

Design Optimization

Manufacturability

You can improve manufacturability by following best practices in pcb design for manufacturing. Start by selecting components that meet industry standards. This step ensures you have parts that are easy to source and compatible with automated assembly. Standardizing your components and board sizes reduces procurement challenges and lowers costs.

Choose surface-mount technology (SMT) for most assemblies. SMT supports automation and speeds up high-volume production.

Use clear silkscreen labels and fiducial marks. These features help machines place parts accurately.

Align components in the same direction. This approach reduces placement errors and makes assembly faster.

Optimize panelization and trace design. Good panelization prevents damage when separating boards.

Tip: Avoid designs that require a lot of manual soldering. Automated processes lower labor costs and reduce mistakes.

You should always apply design for manufacturability principles early in your pcb design for manufacturing process. LTPCBA’s team has deep experience with complex assemblies and can guide you through these steps. Their expertise ensures your boards move smoothly from design to production.

Testability

Testability is just as important as manufacturability in pcb design for manufacturing. You need to make sure your boards are easy to test and diagnose. Place test points at key locations to allow for quick fault detection. Use boundary scan testing to check connections between components. Built-in self-test (BIST) circuits can help your boards find faults on their own.

Partition power and ground networks. This method makes it easier to test different sections.

Design for manufacturability and testability together. This approach lowers defect rates and reduces rework costs.

Following DFM and DFT guidelines in pcb design for manufacturing leads to fewer errors, lower costs, and higher reliability.

LTPCBA uses advanced testing strategies to ensure every board meets strict quality standards. Their team helps you develop a consistent product at the lowest manufacturing cost.

Component Sourcing

Supplier Networks

You need a strong supplier network to succeed in quick turn pcb assembly. Reliable suppliers help you get parts quickly and avoid delays. LTPCBA works with trusted partners to make sure you receive quality components on time. When you use standard components and board sizes, you speed up the sourcing process. This approach also lowers costs and reduces the risk of shortages.

A strong supplier network offers several benefits:

Benefit/Strategy | Description |

|---|---|

Faster sourcing of components | Strong networks enable quicker access to necessary parts, reducing delays in assembly. |

Improved communication | Clear communication with suppliers allows for prioritization of urgent orders. |

Access to a wider range of suppliers | Diverse supplier options help meet urgent demands more effectively. |

Prioritization of orders | Companies can prioritize orders based on urgency, leading to faster processing times. |

Utilization of digital tools | Real-time data tools streamline procurement processes, enhancing overall efficiency. |

Preferred parts libraries | Maintaining libraries of preferred parts simplifies sourcing and reduces lead times. |

Transparency with suppliers | Clear timelines help suppliers prioritize orders and offer tailored solutions. |

LTPCBA uses digital tools and preferred parts libraries to keep your quick turn pcb assembly projects on track. You benefit from their established relationships and transparent communication.

Lead Time Management

Managing lead times is critical in quick turn pcb assembly. Standard components arrive faster than custom parts. For example, you can get 1-10 standard parts in just 1-2 days, while larger orders may take up to 7 days or more.

Quantity Range | Standard Lead Time (Days) |

|---|---|

1-10 parts | 1-2 days |

1-450 parts | 3-5 days |

451-750 parts | 3-5 days |

751+ parts | 7 days or more |

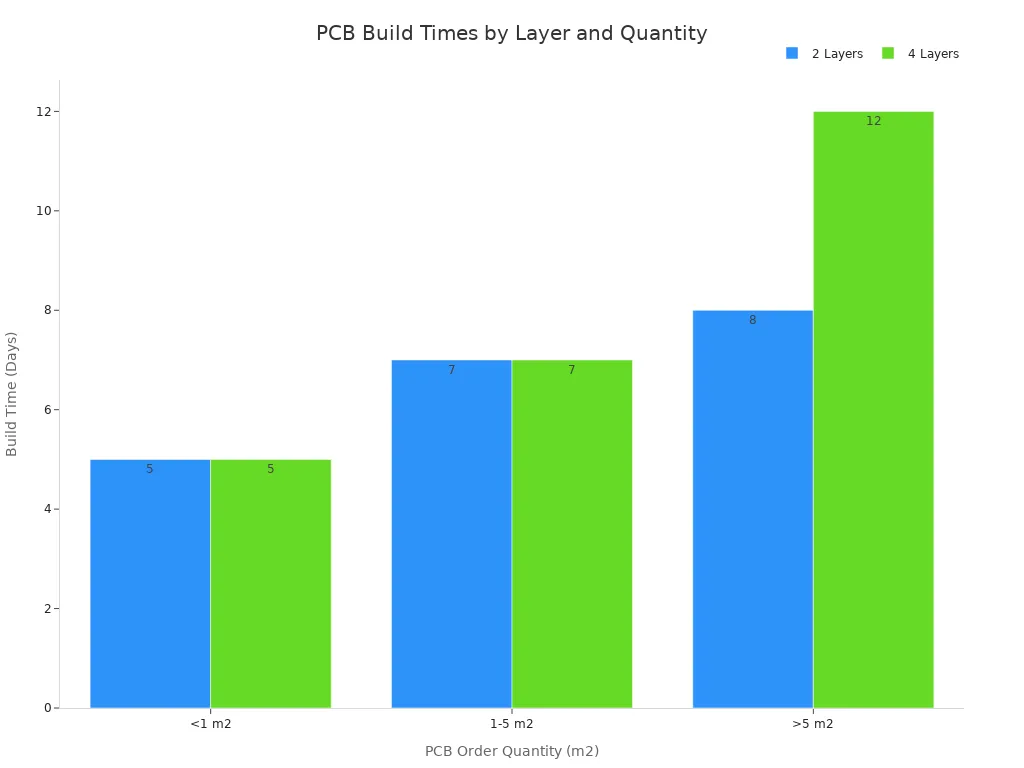

You also need to consider PCB build times. Two-layer boards under 1 m² take about 5 days, while larger or more complex boards may take longer.

Layers | PCB Order Quantity (m2) | Build Time (Days) |

|---|---|---|

2 Layers | <1 m2 | 5 Days |

1-5 m2 | 7 Days | |

>5 m2 | 8 Days | |

4 Layers | <1 m2 | 5 Days |

1-5 m2 | 7 Days | |

>5 m2 | 12 Days |

LTPCBA’s efficient procurement system helps you manage these timelines. Their team tracks every order and works closely with suppliers to avoid delays. When you choose quick turn pcb assembly with LTPCBA, you gain a clear advantage in speed and reliability.

Tip: Always select standard components and board sizes for your quick turn pcb assembly projects. This choice helps you reduce lead times and keep your project on schedule.

Assembly Efficiency

Process Automation

You can boost efficiency in quick turn pcb assembly by using automated assembly lines. Automated assembly lets you produce thousands of boards each day. Machines like high-speed pick-and-place robots place components with great accuracy. Robotic soldering applies solder evenly, which reduces mistakes and improves quality. Automation also controls the reflow soldering process, making sure every solder joint is strong and reliable.

Here is how process automation impacts your results:

Benefit | Description |

|---|---|

Increased Output | Automated systems can operate continuously, producing thousands of boards per day. |

Improved Quality | Error rates often below 0.05%, ensuring consistent results and reducing returns. |

Faster Turnaround | Automation cuts production time by up to 80% compared to manual methods. |

You get faster turnaround and higher quality with automated assembly. LTPCBA uses advanced technology and automated systems to keep error rates low and output high.

Workflow Optimization

You can achieve even greater efficiency by streamlining process steps in quick turn pcb assembly. Digital tracking systems help you monitor every stage of production. These tools give you real-time updates, so you can spot and fix issues quickly. Automation and AI improve inspection, making sure each board meets strict standards.

Automated assembly lines reduce human error and speed up production.

Smart inspection tools check every board for defects, which keeps quality high.

Digital tracking helps you manage orders and delivery times.

LTPCBA’s workflow optimization ensures your quick turn pcb assembly projects stay on schedule. You get reliable results and fast delivery every time.

Quality Control

In-Process Testing

You need strong quality control measures during every stage of high volume quick turn PCBA production. In-process testing helps you catch problems early. Automated Optical Inspection (AOI) checks each board for defects with 100% accuracy. X-ray inspection finds hidden solder issues that you cannot see with the naked eye. In-circuit testing (ICT) detects up to 90% of defects and covers most faults. These quality control measures help you avoid costly rework and keep your project on track.

Quality Metrics / Benchmarks | |

|---|---|

In-Circuit Testing (ICT) | Detects up to 90% of defects, covers 90% of faults |

Functional Testing | Verifies repeatability, reliability, traceability |

Automated Optical Inspection | 100% accuracy, 18% fewer false alarms, early defect detection |

Uncovers hidden solder defects via 2D/3D analysis | |

Burn-In Testing | Ensures long-term performance under harsh conditions |

Tip: Use strict incoming material checks and optimize soldering parameters to reduce defects like cold joints.

Final Inspection

You must finish with a thorough final inspection to ensure every board meets your standards. Functional testing checks if the board works as designed. Burn-in testing pushes boards to perform under tough conditions, so you know they will last. LTPCBA uses advanced inspection tools and follows strict quality control measures. Their team holds international certifications like ISO, IATF, and UL. With a 99.5% pass rate, you can trust the reliability of your boards.

Automated inspection systems also give you a strong return on investment. You save on labor costs, improve equipment effectiveness, and reduce defect escapes. These savings add up to a 75% ROI each year. When you use LTPCBA’s quality control measures, you get consistent results and peace of mind.

Communication

Real-Time Updates

You need real-time updates to keep your high volume quick turn PCBA projects on track. When you receive instant information, you can react quickly to changes or problems. This approach helps you avoid delays and keeps everyone informed. Real-time updates also improve teamwork and make your project run smoothly.

Contribution to Project Outcomes | |

|---|---|

Enhanced Collaboration | Streamlined communication among stakeholders for faster iterations. |

Reliable Forecasting | Accurate predictions of production needs for smoother operations. |

Proactive Risk Management | Early identification of potential risks to avoid delays and issues. |

You can use digital tracking systems to get these updates. These tools let you see the status of your boards at every stage. LTPCBA provides regular progress reports and fast responses, so you always know what is happening with your order.

Tip: Set up alerts for key milestones. This way, you can solve problems before they grow.

Team Collaboration

Strong team collaboration helps you solve problems faster and avoid mistakes. You can use tools like Slack or Microsoft Teams to share updates, files, and feedback in real time. These platforms support chat, video calls, and document sharing, which makes teamwork easy even if your team works in different locations.

Tool | Overview | Key Features | Benefits |

|---|---|---|---|

Slack | Messaging for real-time communication | Channels, integrations, searchable archives | Reduces email clutter, keeps all info in one place |

Microsoft Teams | Chat and video collaboration | Office 365 integration, screen sharing | Supports real-time teamwork on documents and designs |

You can also use live collaboration tools to track activities, manage files, and compare design versions. These features help you work closely with suppliers and manufacturing experts.

LTPCBA stands out with 24-hour technical support and customer service. Their team answers inquiries within 24 hours, offers design help, and manages urgent updates. Customer satisfaction rates at LTPCBA are above 85%, which is higher than the industry average. You get reliable support whenever you need it, making your project easier to manage.

Regular updates and strong teamwork lead to better results and fewer surprises in your PCBA projects.

You can achieve success in high volume quick turn pcba by focusing on planning, design, sourcing, automation, and communication. Projects in high volume quick turn pcba benefit from these strategies:

Wearable health devices used teamwork for compact designs.

Automotive systems relied on strict testing.

Industrial equipment used modular pcbs for updates.

Telecom projects improved signal integrity.

Metric | Value |

|---|---|

Pass Rate | |

Turnaround Time | 1-5 days |

LTPCBA’s strengths help you deliver high volume quick turn pcba projects with speed and quality.

FAQ

What is the fastest turnaround time for high volume quick turn PCBA at LTPCBA?

You can receive assembled boards in as little as 1-5 days, depending on order size and complexity. LTPCBA’s automated systems speed up every step.

How does LTPCBA ensure quality in quick turn projects?

You benefit from AOI, X-ray, and in-circuit testing.

LTPCBA follows ISO, IATF, and UL standards.

Pass rate reaches 99.5%.

Can I get real-time updates on my PCBA project status?

Feature | Benefit |

|---|---|

Digital Tracking | You see live progress |

24/7 Support | You get quick answers |

You always stay informed with LTPCBA.

See Also

Enhancing Project Efficiency Through Quick-Turn PCB Prototypes

Essential Strategies for Optimizing SMT Lines in PCBA

Crucial Actions to Enhance PCBA Reliability Over Time

Choosing the Ideal Turnkey PCBA Manufacturer for Your Project

Increasing Business Efficiency Through PCBA Contract Manufacturing