Top Tips for Speeding Up Your PCBA Assembly Orders

Submit accurate files and communicate early with your assembler to speed up your order.

You can achieve faster turnaround when you provide complete documentation and choose components with short lead times.

Select LTPCBA for reliable pcba assembly services and save valuable time.

Key Takeaways

Communicate early with your assembler to identify issues and avoid delays.

Submit complete documentation, including BOM and Gerber files, to ensure a smooth assembly process.

Choose components with short lead times to keep your project on schedule.

Communication

Early Contact

You should reach out to your PCBA assembler as soon as you finalize your design. Early contact gives you a head start on your project. When you start the conversation early, you allow the assembler to review your files and spot any issues before production begins. This step helps you avoid delays and keeps your project on track. If you work with LTPCBA, you can expect a fast response time to your initial inquiries. This quick feedback helps you plan your next steps with confidence.

Clear Expectations

Set clear expectations from the start. Tell your assembler about your required delivery date, preferred shipping method, and any special assembly instructions. When you share your goals and constraints, you help the assembler prioritize your order. You can use a simple checklist to make sure you cover all important points:

Delivery deadline

Quantity needed

Special handling or testing

Packaging requirements

Tip: Write down your requirements and send them with your initial files. This habit saves time and reduces confusion.

Fast Response

You should answer questions from your assembler quickly. Fast replies help maintain momentum and prevent bottlenecks. If you respond within a few hours, you keep the assembly process moving. Quick communication can shave days off your turnaround. LTPCBA values clear and prompt communication, so you can expect updates at every stage of your order.

Documentation

Complete Files

You speed up your PCBA order when you submit complete and accurate files. Always include a Bill of Materials (BOM), Gerber files, and assembly drawings. These documents tell your assembler exactly which parts to use, where to place them, and how to build your board. Missing or unclear files can cause delays. You should double-check that your BOM lists all parts, including reference designators, quantities, and manufacturer part numbers. For small run prototypes, every detail matters because you want to avoid mistakes and wasted time.

Tip: Create a checklist for your files before you send them. This habit helps you catch missing information early.

Standard Formats

You make the process smoother when you use standard file formats. Most assemblers prefer BOMs in Excel or CSV, Gerber files in RS-274X, and assembly drawings in PDF. Standard formats help your assembler load your data into their systems without errors. This step saves time and reduces the risk of confusion about your parts or layout.

File Type | Preferred Format |

|---|---|

BOM | Excel, CSV |

Gerber | RS-274X |

Assembly Drawing |

LTPCBA Support

You can rely on LTPCBA’s 24-hour technical support if you have questions about your documentation. Their team helps you review your files and ensures you include all necessary parts. This support is especially helpful when you work with complex boards or have many parts to track. Fast answers from LTPCBA keep your project moving and improve your turnaround. You get peace of mind knowing your order will not stall because of missing or unclear documentation.

Components

Short Lead Times

You speed up your PCBA assembly when you choose parts with the shortest lead time. Always check the lead times for every part before you place your order. Some parts have long lead times because of high demand or limited supply. You can avoid delays by picking parts that suppliers can ship quickly. Many vendors list lead times on their websites. You should compare these numbers and select parts with the fastest lead time. This step helps you keep your turnaround short and your project on schedule.

Tip: Create a table to track the lead time for each part in your BOM. This habit helps you spot risky parts early.

Approve Substitutes

You can reduce delays by pre-approving substitute parts. Sometimes, a part becomes unavailable after you order. If you approve substitutes in advance, your assembler can use them without waiting for your response. This approach keeps your assembly moving and avoids last-minute sourcing problems. Here are some benefits of pre-approving substitutes:

You maintain your production schedule even if a part is out of stock.

You avoid delays from sourcing issues.

You help your assembler switch parts smoothly during assembly.

You should list acceptable substitutes in your BOM or send a separate list to your assembler.

Monitor Stock

You need to monitor parts availability before and after you place your order. Check the stock status for all parts with your vendors. Some parts may go out of stock quickly, especially those with short lead times. If you see a part with low stock, consider ordering extra or finding another source. You should also ask your assembler to confirm parts availability before starting assembly. This step helps you avoid surprises and keeps your turnaround on track. Time spent checking stock now saves you from bigger delays later.

Design Checks

DFM Tools

You can improve your assembly process by using Design for Manufacturability (DFM) tools. These tools help you spot layout problems before production starts. DFM software checks your PCB design for spacing, pad sizes, and component placement. You save time because you catch errors early. Many engineers use DFM checks to boost the quality of their boards. You should run a DFM check after you finish your layout. This step helps you avoid costly mistakes and keeps your turnaround short.

Tip: Use DFM tools that match your assembler’s capabilities. This habit ensures your design meets their standards for high-quality pcb assembly.

Error Review

You should review your design files for errors before you send them to your assembler. Look for missing footprints, incorrect part numbers, and mismatched layers. A careful review helps you maintain quality and prevents delays. You can use a checklist to track common mistakes:

Check for missing or duplicate reference designators

Confirm part numbers match your BOM

Verify layer stack-up and polarity marks

A thorough error review saves you time and improves the quality of your finished board.

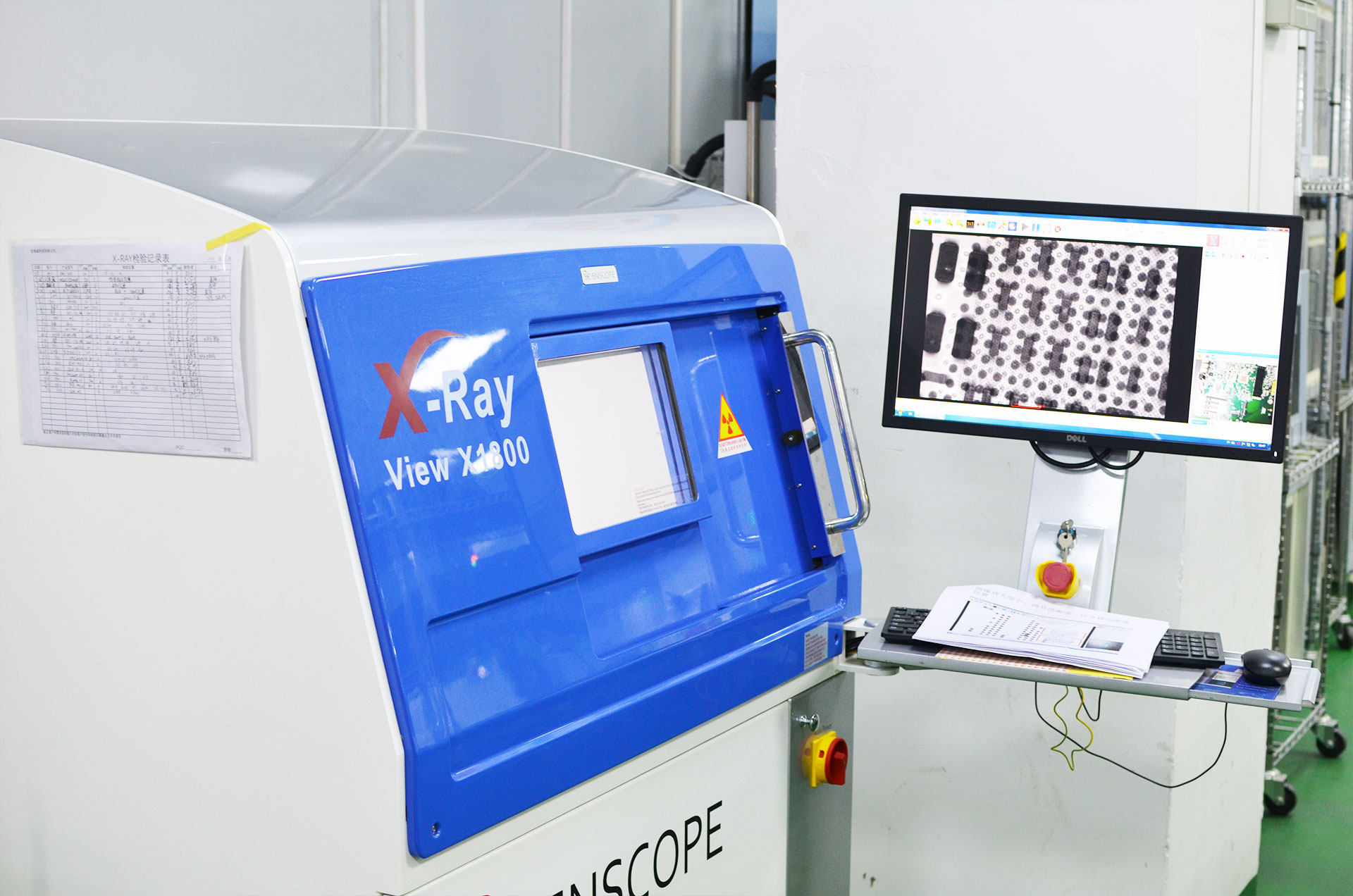

LTPCBA Quality

LTPCBA uses advanced inspection systems to guarantee quality at every stage. Automated Optical Inspection (AOI) and strict process controls help you achieve consistent results. You benefit from a 99.5% pass rate in product delivery. LTPCBA’s team reviews your files and provides feedback to help you reach the highest quality standards. You can trust LTPCBA for reliable, high-quality pcb assembly and fast turnaround every time.

Quick Turnaround PCB Assembly

LTPCBA Turnkey Solutions

You can save valuable time by choosing LTPCBA’s turnkey pcba assembly services. With a turnkey approach, you let LTPCBA handle every step of the process. You send your design files, and their team manages sourcing, purchasing, and inspecting all parts. You do not need to worry about missing parts or delays from multiple suppliers. LTPCBA uses advanced systems to track parts and keep your project moving. Their quick turnaround pcb assembly process includes automated checks and real-time updates. You get clear communication at every stage. This method helps you avoid common mistakes and speeds up your order.

Note: Turnkey pcba assembly services from LTPCBA reduce your workload and help you meet tight deadlines.

Local Partners

You can also speed up your quick turnaround pcb assembly by working with local partners. Local suppliers often have parts in stock and can deliver them faster. You avoid long shipping times and customs delays. When you choose a local partner, you get quick support if you need to replace parts or solve problems. However, global providers like LTPCBA offer a wider range of parts and advanced pcba assembly services. They use efficient logistics to keep your quick turnaround pcb assembly on schedule. You should compare both options and pick the one that best fits your project’s needs.

Local partners: Fast parts delivery, easy support

Global providers: More parts choices, advanced pcba assembly services, reliable quick turnaround pcb assembly

Tip: Always check parts availability and delivery times before you place your order. This step helps you avoid delays and keeps your quick turnaround pcb assembly on track.

Logistics

Kitting Best Practices

You can speed up your assembly order by following smart kitting practices. Gather all parts before sending them to your assembler. Label each bag or reel with the correct part number and reference designator. Use a checklist to confirm you have every part needed for your build. Place small parts in anti-static bags to protect them. Group similar parts together, but keep each type separate to avoid mix-ups. Double-check that you include enough parts for the entire order, plus a few extras for possible losses during assembly.

Tip: Accurate kitting reduces errors and helps your assembler start work right away.

Shipping Coordination

You should plan your shipping to avoid delays. Choose a reliable courier that delivers parts on time. Track your shipment and share tracking numbers with your assembler. If you ship parts from different suppliers, tell your assembler what to expect and when. Use a table to keep track of each shipment:

Part Name | Supplier | Tracking Number | Expected Arrival |

|---|---|---|---|

Resistor | Vendor A | 123456789 | June 10 |

IC | Vendor B | 987654321 | June 11 |

This method helps everyone stay organized and keeps your project moving.

Fast Payment

You can help your assembler start work sooner by paying invoices quickly. Fast payment ensures your parts get ordered and your assembly slot is reserved. Some companies will not begin work until they receive payment. Set reminders to pay as soon as you get an invoice. Quick payment shortens your turnaround and helps you receive your finished boards on time.

Testing Needs

Clear Requirements

You should define your testing needs before you send your order. Write down what you want to test on your assembled boards. List the type of tests, such as functional, in-circuit, or visual inspection. Share these details with your assembler. Clear requirements help your assembler prepare the right tools and avoid confusion. When you give exact instructions, you reduce mistakes and save time.

Tip: Use a checklist for your testing needs. This helps you remember every step.

Early Planning

Start planning your testing process as soon as you finish your design. Early planning lets you spot problems before they slow down your project. You can talk with your assembler about test points, fixtures, and any special equipment. If you plan early, you make sure your boards are ready for testing when they arrive. This step keeps your turnaround short and your project on schedule.

Ask your assembler about their testing options.

Check if you need to supply test fixtures.

Plan for extra boards if you expect failures.

Acceptance Criteria

Set clear acceptance criteria for your finished boards. Write down what counts as a pass or fail. You can use a table to list your criteria:

Test Type | Pass Condition | Fail Condition |

|---|---|---|

Visual | No solder bridges | Missing components |

Functional | All outputs correct | Any output wrong |

Share this table with your assembler. When everyone knows the rules, you get boards that meet your needs the first time.

You can achieve a faster turnaround when you communicate early, submit complete files, and select fast components. Use LTPCBA’s turnkey services to save time. Manage logistics and clarify testing needs for every order. Apply these tips to your next order and see real results.

FAQ

How can you check if your files are complete before submitting?

You can use a checklist. Make sure your BOM, Gerber files, and assembly drawings are included. Double-check part numbers and reference designators.

What is the fastest way to get a quote from LTPCBA?

You upload your files on LTPCBA’s website. You receive a quote within 2-3 working days.

Can you track your PCBA order status with LTPCBA?

Step | How to Track |

|---|---|

Quotation | Email updates |

Production | Online dashboard |

Shipping | Tracking number |

You get updates at every stage.

See Also

Enhancing Project Efficiency Through Quick-Turn PCB Prototypes

Maximizing Efficiency and Yield in SMT PCB Assembly

Improving Results by Streamlining Hardware Assembly Processes