Tips for Selecting a Trustworthy PCBA Professional Manufacturer

Selecting the right pcba manufacturer shapes your product’s quality and delivery success. When you choose a pcba professional manufacturer with proven experience, strong certifications, and advanced technology, you gain reliable results and efficient timelines. Trusted suppliers use rigorous testing methods and maintain transparent communication, which minimizes mistakes and ensures consistent outcomes. LTPCBA stands out as a pcba professional manufacturer that meets these high standards, making it a dependable choice for long-term partnerships.

Key Takeaways

Choose a PCBA manufacturer with strong certifications like ISO 9001 and IPC-A-610 to ensure high quality and safety.

Look for advanced technology and experienced teams that can handle complex projects and maintain a high pass rate.

Clear communication and fast customer support help avoid mistakes and keep your project on schedule.

Consider reliable material sourcing and a proven track record of on-time delivery to prevent delays.

Balance cost with value by comparing quality, support, and turnaround time, not just the lowest price.

Experience and Technology

When you select a pcba professional manufacturer, you need to look beyond basic production. Years of experience, advanced technology and expertise, and strong engineering support set apart a reliable custom pcba manufacturer from the rest. Industry experts recommend that you check for specialization areas, quality assurance processes, and the ability to handle complex printed circuit board assembly projects. You should also look for a company that can scale production and maintain a robust supply chain.

LTPCBA’s Technology and Expertise

LTPCBA stands out as a custom pcba manufacturer with a proven track record. The company uses advanced automation, including Automated Optical Inspection (AOI), Statistical Process Control (SPC), and Six Sigma methods. These tools help LTPCBA maintain a 99.5% pass rate, which is a benchmark for any experienced pcba company. LTPCBA’s technology and expertise allow them to assemble complex components like Ball Grid Arrays (BGA) with high precision. Their certifications—ISO 9001, IATF, UL, RoHS, and IPC-A-610—show their commitment to quality and process control. As a custom pcba manufacturer, LTPCBA supports industries that demand the highest standards, such as medical, automotive, and aerospace.

Tip: Always ask your pcb assembly company about their testing protocols and certifications. This ensures your printed circuit board assembly meets industry requirements.

Here is how LTPCBA’s technology and expertise compare to leading industry players:

PCB Manufacturer | Technology and Capabilities |

|---|---|

LTPCBA | AOI, SPC, Six Sigma, BGA assembly, 24/7 support, ISO/IATF/UL/RoHS/IPC-A-610 certifications |

Leading Brands | SMT, THT, BGA, Rigid-Flex, X-ray, rapid prototyping, advanced testing, supply chain control |

Industry Reputation

A custom pcba manufacturer builds its reputation through consistent quality, strong customer service, and advanced process control. Industry analysts look for intelligent manufacturing, full-chain quality management, and rapid delivery capability. They also value a pcb manufacturer that invests in R&D collaboration and laboratory-level quality verification. When you choose a pcba manufacturer with a strong reputation, you benefit from reliable ems services and professional assembly.

Customer satisfaction often reflects a company’s reputation. High ratings usually mean the custom pcba manufacturer delivers on service, quality, and support. LTPCBA’s focus on professional assembly, ems solutions, and customer care makes it a trusted pcb assembly company for both small and large projects.

Quality Assurance and Certifications

Reliable PCBA Supplier Standards

When you evaluate a reliable pcba supplier, you must check their certifications and standards. These certifications, such as ISO 9001, IATF, UL, and IPC-A-610, show that the supplier follows strict quality assurance practices. In regulated industries, reliable pcba suppliers must meet these requirements to ensure product safety and reliability. IPC standards, like IPC-A-610 and IPC-6012, set clear guidelines for electronic assemblies and rigid PCBs. These standards help you reduce defects by improving design accuracy, material selection, and testing protocols.

A reliable pcba supplier uses advanced quality control methods, including Automated Optical Inspection (AOI) and Statistical Process Control (SPC). These tools help catch defects early and maintain high-quality pcba output. You should also look for suppliers who provide traceability, detailed documentation, and regular internal audits. This approach ensures that every step of the process meets international quality benchmarks.

Tip: Always ask for proof of certifications and standards before starting a partnership with a reliable pcba manufacturer. This step protects your project and guarantees consistent quality.

LTPCBA’s Quality Assurance

LTPCBA stands out as a reliable pcba supplier because of its strong commitment to quality assurance. The company holds ISO, IATF, and UL certifications, which means you can trust their processes and results. LTPCBA uses advanced equipment, such as high-speed placement machines and 3D AOI/X-ray inspection, to maintain a 99.5% pass rate. This figure is among the highest in the industry and demonstrates their dedication to quality.

You benefit from LTPCBA’s lean manufacturing practices and continuous improvement culture. Their quality control team performs multiple inspections, including in-circuit and functional testing, to ensure every board meets strict standards. LTPCBA’s focus on assurance, traceability, and process validation gives you confidence in their ability to deliver high-quality pcba products. When you choose LTPCBA, you work with a reliable pcba supplier that values quality at every stage.

Manufacturing Process and Support

Custom PCBA Manufacturer Services

When you choose a custom pcba manufacturer, you want a partner who can handle every step of the production. Turnkey services simplify your project by letting the manufacturer manage component sourcing, BOM procurement, assembly, and testing. This approach saves you time and reduces the risk of errors during the manufacturing process. Leading custom pcba manufacturer teams offer a wide range of electronic manufacturing services, including SMT assembly, BGA assembly, and rigid flex PCB assembly. They also provide box build, cable assembly, and IC programming to support your unique needs.

Service Category | Common Custom Services Offered |

|---|---|

PCB Assembly | SMT Assembly, Through Hole PCB Assembly, BGA Assembly, PCB Prototype Assembly, Quick Turn PCB Assembly, Flex PCB Assembly, Low-cost, Low-Volume, High Volume, Custom PCB Assembly, Lead-Free PCB Assembly |

Electronics Manufacturing | Turnkey PCB Assembly, Consignment PCB Assembly, Box Build Assembly, Electro-mechanical Assembly, PCB Parts Sourcing, PCBA Testing, IC Programming, Wire Bonding, Conformal Coating, Cable Assembly, PCB Design Services |

PCB Manufacturing | Normal PCBs, Rigid PCB, Flex PCB, Rigid Flex PCB, HDI PCB, Aluminum PCB, Multilayer PCB, Microwave & RF PCB, Metal Core PCB, Custom PCB, Gold Finger PCB, Impedance Control PCB |

Efficient communication and support play a key role in the success of your project. When you clearly share your requirements, such as interface protocols or special components, you help the custom pcba manufacturer avoid mistakes and speed up the production. Good communication and support also allow for quick adjustments and better quality control throughout the manufacturing process.

Tip: Close collaboration with your custom pcba manufacturer improves flexibility and helps you resolve issues early in the production cycle.

LTPCBA’s Customer Support

LTPCBA sets a high standard for communication and support. You receive fast answers to your questions, with 24-hour technical support available at every stage of the manufacturing process. The LTPCBA team reviews your requirements quickly and provides detailed quotations within 2-3 working days. This quick response helps you keep your production on schedule and reduces delays.

You can reach LTPCBA through multiple channels, including email and online chat, making it easy to get help when you need it. The support team works closely with you to understand your project goals and timeline. This level of communication and support ensures that your production meets your expectations and industry standards. LTPCBA’s commitment to ems and customer satisfaction makes them a top choice for any custom pcba manufacturer project.

Pricing and Delivery

Competitive Pricing

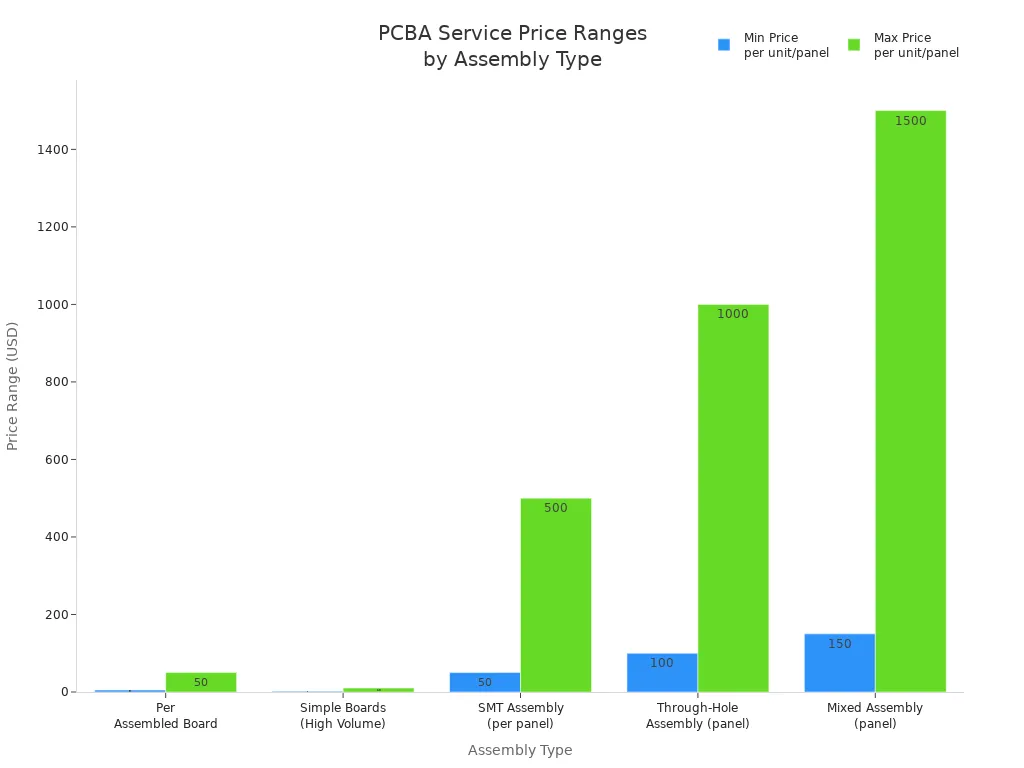

When you select a pcba professional manufacturer, you need to balance cost, service, and reliability. The best pcba supplier does not just offer the lowest price. You should look for value in every step of production. Many factors affect pricing, such as board complexity, order volume, and automation level. You can see typical price ranges for PCBA services in the table below:

Assembly Type | Typical Price Range (per unit or panel) | Influencing Factors |

|---|---|---|

Per Assembled Board | $5 to $50 | Complexity, order volume, automation, labor costs, location |

Simple Boards (High Volume) | $2 to $10 | Volume economies, simpler design |

SMT Assembly (per panel) | $50 to $500 | Component density, board complexity, order quantity |

Through-Hole Assembly (per panel) | $100 to $1,000 | Additional labor, complexity, smaller orders |

Mixed Assembly (per panel) | $150 to $1,500 | Ratio of SMT to through-hole, complexity |

You can lower costs by optimizing your BOM, choosing efficient designs, and ordering in higher volumes. Leading pcba manufacturer teams use lean production and strong supplier partnerships to keep prices competitive. LTPCBA provides fast quotations within 2–3 working days, helping you plan your budget and turnaround time with confidence.

Tip: Always compare total value, not just unit price. Consider quality, support, and turnaround time when choosing your pcb manufacturer.

On-Time Delivery

Reliable turnaround time is critical for your project’s success. Industry leaders maintain on-time delivery rates above 97%. LTPCBA achieves a 99% on-time delivery rate for through-hole assembly, with prototypes ready in 5–7 days and large orders shipped in 2–3 weeks. This performance exceeds most industry standards and ensures your production stays on schedule.

Manufacturer | On-Time Delivery Rate |

|---|---|

PROTOPCB | 98.15% |

MCL | 97% |

Best Technology | 97% |

LTPCBA | 99% |

You benefit from LTPCBA’s quick response, strong logistics, and clear communication. Fast turnaround time reduces risk and keeps your production moving. When you work with a supplier who values reliability, you avoid costly delays and meet your market goals.

Customer Feedback and Material Sourcing

Testimonials and Reviews

When you evaluate a custom pcba manufacturer, you should always check customer feedback, testimonials, and referrals. Verified reviews on platforms like ALLPCB and industry forums provide real-world insights into a manufacturer’s reliability and quality. These reviews often highlight key strengths:

Consistent satisfaction with high-quality products and fast manufacturing

On-time delivery and professional customer support

Thorough order validation and attentive service

Long-term cooperation that saves time and cost

You may also find negative reviews that mention lost orders, defects, or pricing issues. These comments help you identify potential risks before you commit. The moderation and verification process for reviews increases their authenticity, making them a reliable indicator of a pcb assembly company’s reputation. By reading both positive and negative feedback, you gain a balanced view of the custom pcba manufacturer’s performance and reliability.

Note: Verified customer reviews on manufacturer websites, forums, and social media give you a clear picture of actual service, prototype quality and accuracy, and after-sales support. Positive reviews build trust, while negative ones reveal areas for caution.

Material Selection

Material sourcing plays a critical role in the success of any custom pcba manufacturer. You need to ensure that your supplier follows strict standards for quality and reliability. Industry experts recommend focusing on several factors during material sourcing:

Application-specific requirements for sectors like automotive or aerospace

Electrical and mechanical properties, such as thermal conductivity and board thickness

Environmental resistance, including moisture and chemical protection

Manufacturing compatibility and material availability

Supply chain disruptions can impact material sourcing reliability. You may face component shortages, long lead times, or price volatility. To address these challenges, top custom pcba manufacturer teams diversify suppliers, maintain inventory buffers, and use advanced forecasting tools. LTPCBA demonstrates strong material sourcing practices by working with trusted suppliers and keeping extra stock to prevent delays. This approach ensures you receive high-quality pcba assemblies on time, even during global disruptions. Reliable material sourcing supports consistent production and helps you achieve the quality standards your projects demand.

Choosing the right PCBA manufacturer shapes your product’s success. Focus on these essentials:

Prioritize quality assurance with certifications like ISO 9001 and IPC-A-610.

Seek advanced technology and skilled engineering teams.

Value clear communication and responsive customer support.

Check for reliable material sourcing and on-time delivery.

LTPCBA sets a strong example with its high standards and proven results. Use these criteria as your checklist to ensure you build lasting partnerships and achieve consistent, high-quality outcomes.

FAQ

What certifications should you check when choosing a PCBA manufacturer?

You should look for ISO 9001, IATF, UL, and IPC-A-610 certifications. These show the manufacturer follows strict quality standards. LTPCBA meets all these requirements, ensuring your products meet industry benchmarks.

How fast can you get a quotation from LTPCBA?

LTPCBA provides quotations within 2–3 working days. You receive clear pricing and detailed information quickly, which helps you plan your project and budget with confidence.

Tip: Fast quotations help you avoid delays and keep your production on schedule.

What types of PCB assembly services does LTPCBA offer?

LTPCBA offers SMT assembly, BGA assembly, through-hole assembly, mixed assembly, and rigid flex PCB assembly. You can choose turnkey solutions for prototypes or mid-volume production runs.

Service Type | Available at LTPCBA |

|---|---|

SMT Assembly | ✅ |

BGA Assembly | ✅ |

Through-Hole | ✅ |

Rigid Flex | ✅ |

How does LTPCBA ensure on-time delivery?

You benefit from LTPCBA’s strong logistics and quick response. The company maintains a 99% on-time delivery rate. You receive prototypes in 5–7 days and large orders in 2–3 weeks.

See Also

Tips For Choosing A PCBA Supplier That Fits

Finding The Ideal Turnkey PCBA Manufacturer For Projects

Ways Modern Turnkey PCBA Plants Guarantee High Quality