Through-Hole Technology vs. SMT: When Through-Hole Technology Is the Right Choice for Your Electronics Manufacturing

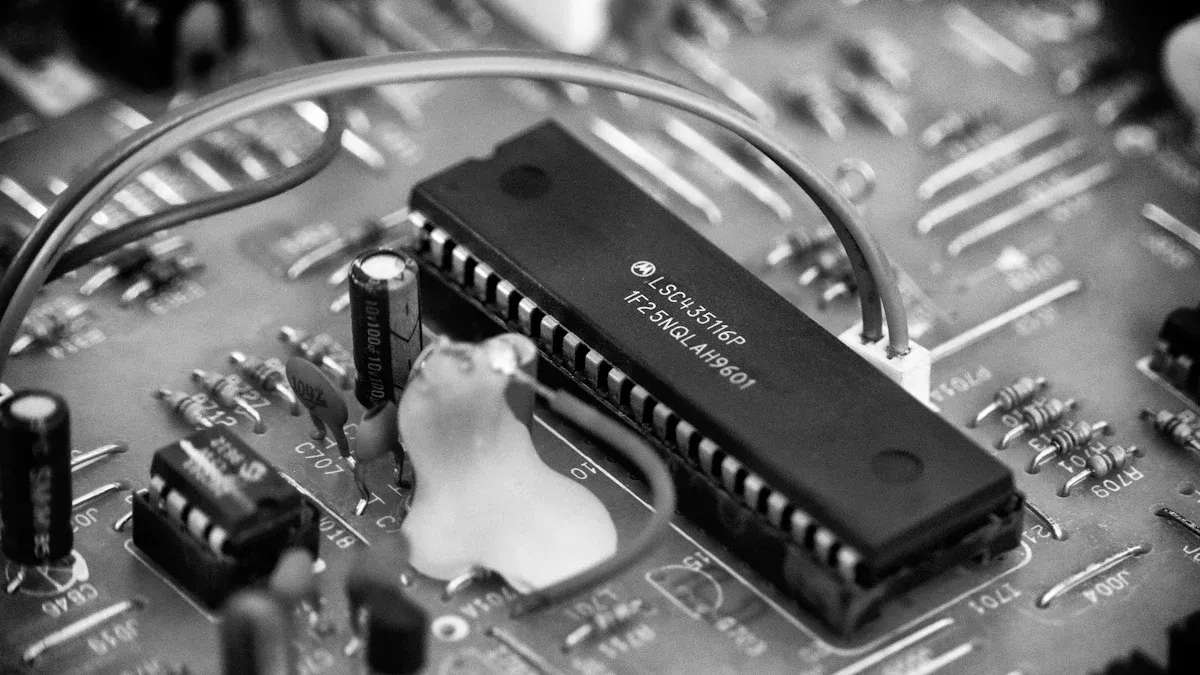

If you want strong and tough parts, pick through-hole technology.

Research shows through-hole boards handle shaking and hard hits better than surface-mount boards.

Tests show through-hole assemblies last longer when stressed or heated and cooled.

Through-hole leads go through the PCB and make strong, steady bonds.

Surface Mount Technology | Through-Hole Technology | |

|---|---|---|

Mechanical connection | Solder joints on top | Leads go through PCB for stronger bonds |

Resistance to stress | Easier to damage | Much better resistance |

Key Takeaways

Pick through-hole technology if your project needs tough parts. These parts can handle shaking, heat, and rough use. This is good for cars, planes, and big machines.

Through-hole mounting helps with repairs and testing. You can add or take out parts by hand. You only need simple tools. This saves time and money when building or fixing things.

Use through-hole technology for small batches or special projects. It is best when you need things to work well and be easy to fix. This matters more than making things fast, small, or cheap.

Through-Hole Technology vs. Surface-Mount Technology

Mounting Differences

There are big differences between through-hole mounting and surface-mount technology. Through-hole mounting means you push component leads through holes in the PCB. You then solder them on the other side. This makes a strong connection. It is best for parts that face shaking, stress, or rough use. Surface-mount technology puts surface mount devices right on the board. These parts are smaller. You can fit more of them on the board. Surface-mount technology is not as strong as through-hole mounting. But it is great for small designs and high-frequency circuits. Through-hole mounting holds bigger and stronger parts. This makes it good for tough jobs.

Assembly and Cost

The pcb assembly process is different for each method. Through-hole technology needs people to put in and solder parts by hand. This makes manufacturing slower. Surface-mount technology uses machines to place many surface mount devices fast. Here is a quick comparison:

Performance Factor | Through-Hole Technology | Surface Mount Technology |

|---|---|---|

Assembly Time | Slower, manual | Faster, automated |

Labor Intensity | High | Low |

Per-Unit Cost | Lower for big runs |

Surface-mount technology makes assembly about 60% faster. It also lowers mistakes by over 30%. Through-hole mounting costs more for big orders. But it is cheaper for small batches or test builds.

Design Impact

Through-hole mounting changes your board design. You need bigger parts and drilled holes. These take up more space. This means you cannot fit as many parts on the board. Surface-mount technology lets you use smaller parts. You can put them on both sides of the board. This helps you fit more parts and make complex layouts. Surface mount devices give better electrical performance because their leads are shorter. Through-hole mounting gives strong connections. But surface-mount technology makes pcb assembly faster and cheaper for making lots of boards. You should choose the method that matches your needs.

Advantages

Mechanical Strength

Through-hole mounting gives very strong connections. The leads go through the PCB and hold parts tight. This helps the board survive shaking and big temperature changes.

Through-hole solder joints can last over 1,000 hot and cold cycles before getting weak.

When stressed, only about 1% of through-hole parts fail, but up to 8% of surface-mount parts can break.

Through-hole mounting stands up to pulling and keeps parts in place, even in rough places.

Car PCBs with through-hole mounting can work for more than 15 years while driving.

In vibration tests, less than 2% of through-hole parts fail, but over 10% of SMDs can break.

You should use through-hole for jobs that need high reliability, like cars, planes, and factory machines. These strengths make through-hole technology best for tough work.

Reliability

Through-hole mounting works well in hard conditions. These connections stay strong when it gets hot or cold or when used a lot. Engineers test through-hole boards by heating, cooling, and shaking them. They also use glue and potting to make boards stronger. Computer checks look for weak spots before making the boards. You see through-hole mounting in things like medical tools and factory machines. These good and bad points matter most when you need things to work for a long time.

Repair and Prototyping

Through-hole mounting makes fixing and testing easier. You can add or take out parts fast when you change your design. Technicians can solder and unsolder through-hole parts with simple tools. You do not need fancy machines. The strong solder joints help make repairs last longer. These benefits save time and money when building new things. Through-hole mounting also helps test circuits work better, so you can change things if needed. When you look at the good and bad sides, through-hole mounting is best for easy fixes and quick testing.

Limitations

Size and Density

When you use through-hole parts, you need bigger holes and pads. These parts take up more space than surface-mount technology. You must drill a hole for every pin. This means there is less space for other parts. Through-hole parts are bigger, so your board will be larger. If you want to fit lots of parts in a small space, surface-mount technology is better. Some surface-mount parts are as small as 0.4mm by 0.2mm. This helps you add more features to a tiny device. Here is a quick look at how board size changes:

Parameter | Through-Hole Technology | Surface-Mount Technology |

|---|---|---|

Lead diameter + 0.25 mm | Not needed | |

Pad diameter | Hole size + 0.1 mm + 0.6 mm | Much smaller pads |

You can see that through-hole designs limit how many parts fit on a board.

Cost and Speed

Through-hole technology has some clear downsides for cost and speed. You need more people to put in and solder each part. This makes the process slower and costs more, especially for big batches. Surface-mount technology uses machines to place parts fast. This lowers labor costs and makes boards faster. Here is a comparison:

Aspect | Surface Mount Technology | Through-Hole Technology |

|---|---|---|

Fast, automated | Slow, manual | |

Labor Intensity | Low | High |

Material Costs | Lower, smaller parts | Higher, larger parts and holes |

If you want to make lots of boards, surface-mount technology saves time and money. Through-hole works best for small batches or test boards.

Design Flexibility

Through-hole technology has more limits when you design new electronics. Every drilled hole takes up space and blocks paths for signals. This makes it harder to route and stack layers. Surface-mount technology lets you put parts on both sides of the board. You can use more creative layouts. You can make smaller and lighter products with more features. Through-hole designs do not give you this much freedom. When you compare both, surface-mount technology gives you more ways to build advanced devices.

When to Choose Through-Hole

High-Power Applications

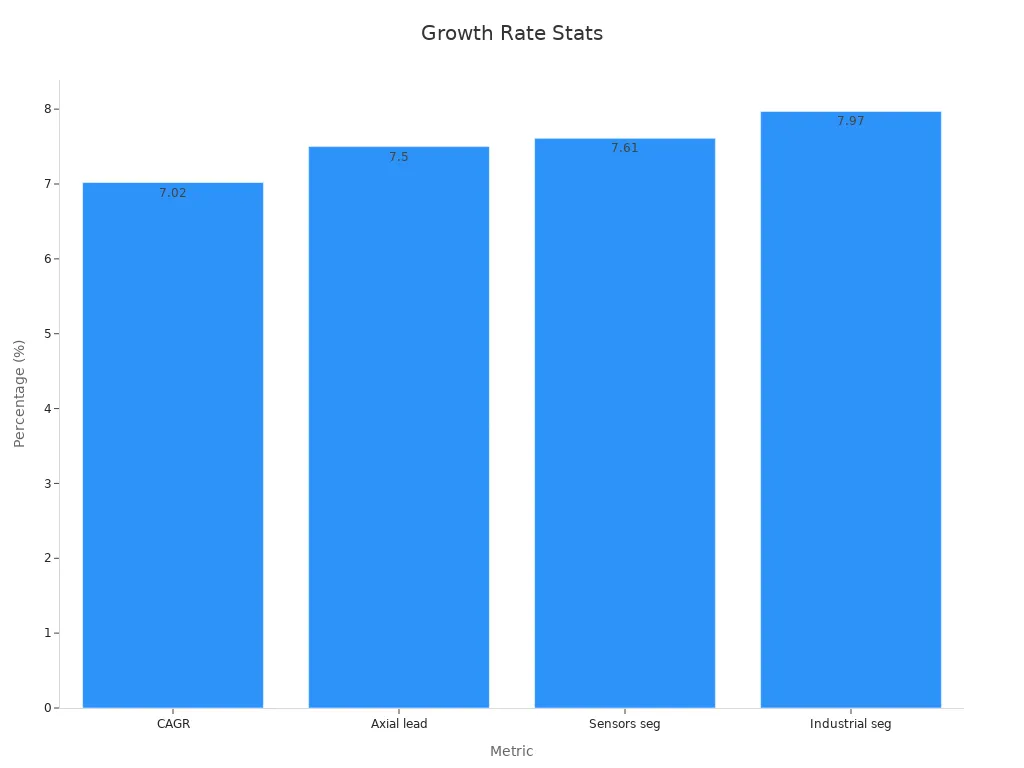

You should pick through-hole for jobs that need strong and tough parts. The leads go through the PCB and make a tight bond. This helps them stand up to shaking, heat, and stress. That is why through-hole is used in aerospace, defense, and cars. These areas need parts that work well in hard places. Through-hole is good because it is strong and easy to fix. You see it in power supplies, big capacitors, and connectors for heavy currents. The use of through-hole in these jobs is growing. In 2023, the market was worth $38 billion. Experts think it will reach almost $70 billion by 2032. People like through-hole because it is reliable, lasts long, and stays strong.

Statistic / Segment | Details / Values |

|---|---|

Market Size (2023) | USD 38 Billion |

Market Size (2032 projected) | USD 69.76 Billion |

CAGR (2024-2032) | 7.02% |

U.S. Production Volume (2023) | Over 1.5 billion units |

Key Application Sectors | Aerospace, Automotive, Industrial Electronics |

Leading Component Segment | Capacitors (44% revenue share in 2023) |

Leading Lead Model Segment | Axial lead (76% revenue share in 2023) |

Key Performance Attributes | Mechanical strength, durability, heat dissipation, suitability for harsh environments |

Market Drivers | Reliability, repairability, long-life performance, mechanical stability |

Industrial and Military

Through-hole is used in many industrial and military products. These places have lots of shaking, dust, heat, and bumps. Through-hole parts stay in place when others might break. Car makers use through-hole for electric and hybrid cars. It works well with high power and rough use. Factories use through-hole for control systems because it is strong and lasts long. Military gear, like radios and plane parts, needs through-hole for strong joints. These joints can handle changes in height and rough use.

Cars use through-hole for jobs with lots of shaking and heat.

Through-hole works with high power, like wirewound resistors and inductors.

Factories need through-hole for strong power and long life.

Airplane parts use through-hole for joints that do not break.

Big power electronics use through-hole for large transformers and heavy currents.

Note: New materials and better ways to make things keep making through-hole even more reliable for these hard jobs.

Prototyping Needs

When you build new things or test ideas, through-hole helps a lot. You can put in and take out parts by hand. This lets you try new layouts fast. Through-hole parts fit into breadboards and sockets. You do not need special tools to change your circuit. Engineers like through-hole for testing because it is easy to use and change. You can test, fix, and make your design better before making lots of them.

Through-hole parts fit into breadboards for quick changes.

You can try new layouts without special tools.

Through-hole is simple to use, so it is great for early work.

Through-hole lets you make changes and test by hand. This saves time and helps you find the best design.

Frequent Maintenance

If your product needs repairs or updates often, through-hole is a good pick. The strong pins go through the PCB, so parts are easy to reach and change. You do not need fancy tools to fix or swap parts. This saves money and time, which helps keep things working.

Aspect | Through-Hole Technology (THT) | Surface Mount Technology (SMT) |

|---|---|---|

Repair Cost | Typically under $20 per repair with basic tools | $50-$100 per repair due to specialized equipment |

Mechanical Strength | High, due to pins passing through PCB layers | Lower mechanical robustness |

Repair Complexity | Easier, components accessible and replaceable | Harder, tiny components require special tools |

Suitability for Maintenance | Ideal for frequent repairs and prototyping | Less suitable for frequent manual repairs |

Through-hole parts are very strong. The tight bond lets them take more stress and last longer. You can fix or change parts many times without hurting the board. This makes through-hole great for connectors, big parts, and things that need service often.

Decision Checklist

When you pick the right technology for your pcb assembly, you should look at your project in different ways. Use this checklist to help you decide if through-hole is the best choice.

Project Demands

First, think about what your project needs most. If you want strong parts that can handle shaking, heat, or rough use, through-hole is a good pick. It works well for testing and bigger parts. You can see the main differences in this table:

Surface Mount Technology (SMT) | Through-Hole Technology (THT) | |

|---|---|---|

Project Size | Best for small, compact designs | Good for prototypes, larger parts |

Mechanical Strength | Lower | Higher |

Repairability | Harder | Easier |

Environmental Conditions | Not for harsh places | Great for tough environments |

Tip: If your project will face lots of stress or needs easy repairs, through-hole gives you more strength.

Volume and Cost

Think about how many boards you want to make and how much you can spend. Through-hole is best for small batches or when you are testing ideas. It costs less to set up but takes more time and work. Surface mount is better for making lots of boards because machines can put on parts fast. Here is a quick comparison:

Aspect | Through-Hole Technology | Surface-Mount Technology |

|---|---|---|

Cost for High Volume | Higher | Lower |

Setup Cost | Lower | Higher |

Assembly Speed | Slower, manual | Faster, automated |

Suitability | Low-volume, prototyping | High-volume production |

If you want to save money on small batches or need to test ideas, through-hole is a smart choice for your pcb assembly.

Application Fit

Ask yourself where and how your product will be used. Through-hole technology is great for military, aerospace, and factory electronics. It can handle lots of shaking, heat, and tough places. You can also change parts easily when testing. Some parts only come in through-hole style, which helps with special projects. If your design needs strong bonds, easy repairs, or must work in hard places, through-hole is the right choice.

Use through-hole for:

High stress or tough environments

Testing and easy part swaps

Special parts not found in surface-mount

Small batches or custom builds

Check each point above to see if through-hole fits your project.

You should choose through-hole technology when your project needs strength, reliability, or easy repair.

It works well in tough places like cars, planes, and factories.

You can fix or test boards easily.

Use the checklist above and ask an expert if you feel unsure about your choice.

FAQ

What makes through-hole technology better for repairs?

You can remove and replace through-hole parts with simple tools. This makes repairs faster and easier than with surface-mount parts.

Can you use both through-hole and surface-mount parts on one board?

Yes! Many boards use both types. You can mix them to get strong connections and save space at the same time.

Why do some parts only come in through-hole style?

Some large or high-power parts need strong support. Through-hole mounting gives these parts the strength they need to work safely.

See Also

Choosing Between SMT And Through-Hole For Electronics Projects

Exploring Advantages And Disadvantages Of SMD Versus Through-Hole

When Through-Hole PCB Assembly Beats Modern SMT Methods

Reliability Comparison Between Through-Hole And SMT PCB Assembly

Selecting The Best Through-Hole PCB Service For Industrial Use