Comparing Through Hole PCB Assembly and SMT for Reliability

Reliability is very important in making PCBs. Reliable parts help devices work properly, even in tough conditions. Through Hole PCB Assembly and Surface Mount Technology (SMT) have their own benefits. But which one is more reliable? Knowing when one works better helps you choose wisely.

Key Takeaways

Through Hole PCB Assembly creates strong and lasting connections. It works well for powerful devices and harsh environments.

Surface Mount Technology (SMT) is faster and supports smaller designs. It is great for tiny gadgets like smartphones.

Pick the right method based on your project needs. Think about strength, size, and where it will be used.

Understanding Through Hole PCB Assembly

Definition and Process of Through Hole PCB Assembly

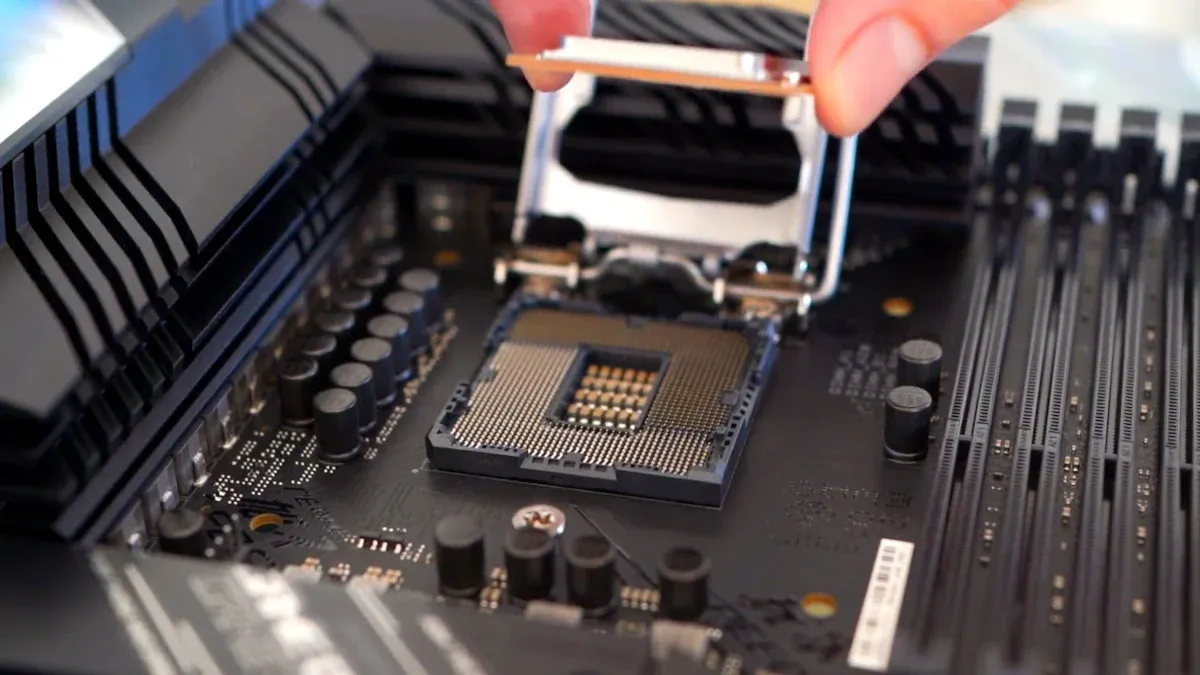

Through hole PCB assembly means putting parts into drilled holes. This can be done by hand or with machines. Hand assembly needs workers to place parts carefully. Machines do it faster and more accurately. After placing the parts, soldering holds them tightly to the board. This makes strong connections and keeps parts from moving. Pictures often show how resistors and capacitors fit on the board. This method works well for projects needing strength and durability.

Key Characteristics of Through-hole Technology

Through-hole technology has special benefits. Parts are attached by leads going through the board. This makes them very stable, even for big or heavy parts. It’s great for high-power uses because it handles more current. But it takes up more space, so it’s not ideal for small designs. You’ll see this used in machines and airplanes where strength and reliability matter most.

Reliability Factors in Through-hole Applications

Through-hole technology is very reliable. Its soldered parts stay strong under stress, like shaking or movement. It also works well in tough places, like hot or wet areas. The parts don’t easily break or fall off over time. This makes it a top choice for devices that need to work well in hard conditions.

Exploring Surface Mount Technology (SMT)

Definition and Process of SMT

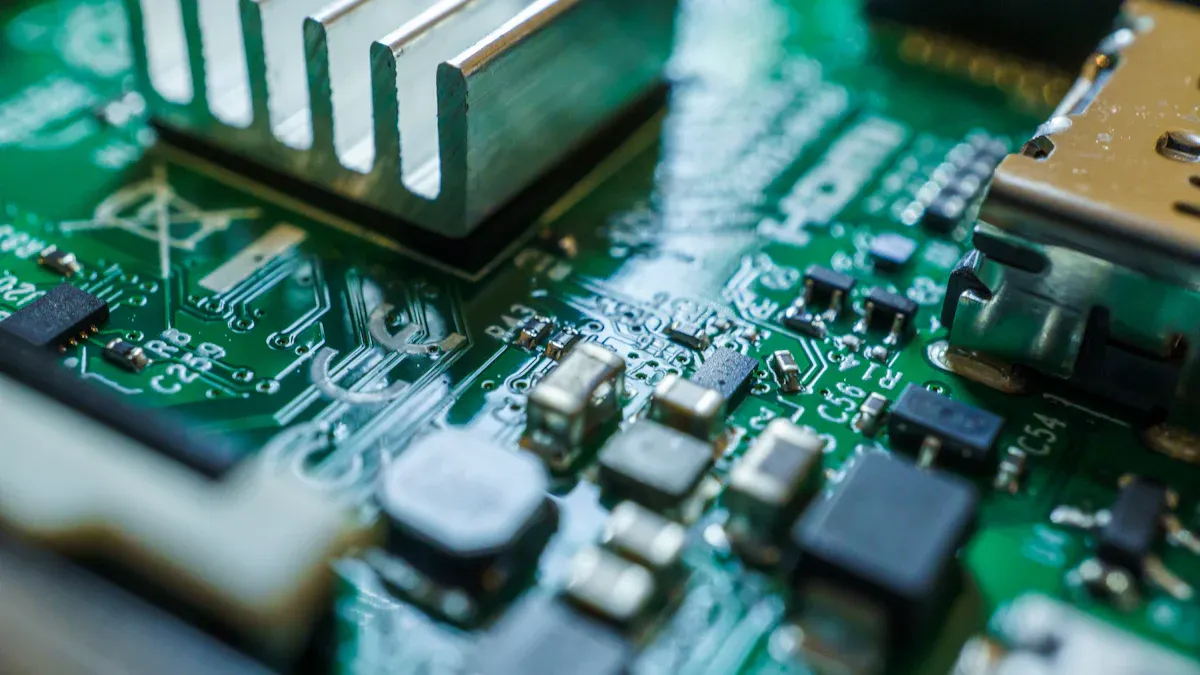

Surface mount technology (SMT) attaches parts directly to a circuit board. Unlike through-hole methods, it doesn’t need drilled holes. Instead, parts are placed on the board’s surface. This makes the process quicker and more efficient.

The SMT process has several steps. First, solder paste is spread on the board. This paste sticks parts in place and conducts electricity. Next, machines carefully place parts onto the paste. Then, the board is heated to melt the paste and secure the parts. Finally, the board is checked and tested to ensure it works properly.

Key Characteristics of SMT

SMT has some special features. It uses smaller, lighter parts, which save space. This makes it great for tiny designs. Machines can assemble these parts quickly, speeding up production. Parts can also go on both sides of the board, using space wisely. But, SMT parts are more fragile and may not last as long in tough conditions.

Reliability Considerations in SMT Applications

SMT reliability depends on where it’s used. It works well in stable places, like home electronics, where small size matters. But it might not handle shaking or extreme heat as well. Good design, strong materials, and careful testing can make SMT more reliable for different uses.

Reliability Comparison: Through Hole PCB Assembly vs. SMT

Mechanical Stress Performance

Through-hole mounting is great at handling physical stress. Parts are held by leads going through the board and soldered underneath. This creates strong connections that resist pulling, bending, or shaking. It’s perfect for machines or airplanes that face constant movement.

SMT, however, attaches parts directly to the board’s surface. While faster and efficient, it’s not as strong. SMT parts can come loose under heavy stress or impact. But for devices like phones or TVs, which don’t move much, SMT works well.

Environmental Durability (Heat, Vibration, Moisture)

Through-hole technology works well in tough environments. Its soldered parts handle high heat and stay steady during vibrations. The leads also protect against moisture, making it great for outdoor or factory use.

SMT is more delicate with environmental challenges. Heat can weaken its solder, and vibrations may loosen parts over time. Moisture can also damage its smaller solder points. Still, SMT works fine indoors or in calm conditions.

Long-Term Reliability and Maintenance

Through-hole assembly is better for long-term use. Its strong connections keep parts working for years, even in hard conditions. Fixing or replacing parts is easier since the leads are easy to access. This makes it a top choice for products needing lasting performance.

SMT has its own benefits. Its small size allows more parts on one board, improving function. But fixing SMT boards is harder because of tiny, closely packed parts. For projects needing easy maintenance, through-hole is often the better option.

High-Power Application Suitability

Through-hole technology is best for high-power devices. It handles more current and voltage, making it great for power supplies or amplifiers. Its strong solder and lead connections ensure it works well under heavy loads.

SMT is better for low-power devices but struggles with high-power needs. Its small parts and thin solder joints can’t handle big electrical loads. For high-power projects, through-hole mounting is the reliable choice.

Advantages and Disadvantages of Through Hole PCB Assembly and SMT

Pros and Cons of Through Hole PCB Assembly

Through hole PCB assembly is strong and reliable for tough jobs. But it also has some downsides. Let’s look at the good and bad sides:

Disadvantages of Through Hole PCB Assembly | |

|---|---|

Handles big parts well | Takes up more space |

Very strong and durable | Needs more manual work |

Spreads heat better | Slower to assemble |

Good for small batches | Soldering mistakes can cause problems |

Through-hole technology is great for projects needing strength. It works well with big parts, like in amplifiers. The soldered leads help spread heat, keeping parts cool. For small production runs, it can also save money.

However, there are challenges. It uses more space, so fewer parts fit on the board. Manual work takes time and can lead to mistakes. Assembly is slower, which might delay projects. If soldering isn’t done right, parts might not last long.

Pros and Cons of SMT

Surface mount technology (SMT) makes building PCBs faster and smaller. Here are its strengths and weaknesses:

Advantages:

Smaller parts save space, making tiny designs possible. This is perfect for gadgets like phones and smartwatches.

Machines assemble parts quickly, saving time and money for big projects.

Parts can go on both sides of the board, using space wisely.

Disadvantages:

SMT parts are weaker and break easier than through-hole parts. They don’t handle rough conditions well.

Fixing SMT boards is hard because parts are tiny and close together.

It’s not good for high-power devices since small solder joints can’t handle big currents.

SMT is great for fast and compact designs. But it’s not the best for devices in tough conditions or ones that need easy repairs.

Reliability Trade-Offs Between Through-hole and SMT

When choosing between through-hole and SMT, think about reliability. Through-hole is stronger and lasts longer. Its soldered leads keep parts secure, even under stress. This makes it perfect for high-power and industrial uses. It’s also easier to fix, which helps for long-term use.

SMT works well in calm places. Its small size and quick assembly are great for home electronics. But SMT parts are weaker against heat, shaking, and moisture. Careful design can help, but through-hole is better when reliability is a must.

By knowing these differences, you can pick the best option for your project.

Use Cases: Choosing Between Through Hole PCB Assembly and SMT

When Through-hole Technology is the Better Choice

Through-hole technology is great for strong and durable designs. It works well for high-power devices like amplifiers or power supplies. Soldered leads make strong connections that handle heavy loads. This method is perfect for machines or airplanes that face stress and movement.

If your PCB needs to survive tough conditions, choose through-hole. It handles heat, shaking, and moisture without breaking. Fixing through-hole parts is also easier. The leads are simple to reach, making repairs quick and easy.

When SMT Outperforms Through Hole PCB Assembly

SMT is best for small and fast designs. It’s great for gadgets like phones, tablets, or smartwatches. Tiny parts save space, fitting more on one board. This makes SMT ideal for modern electronics needing lots of features in small sizes.

SMT is also good for making many boards quickly. Machines place parts fast, saving time and money. For stable places like homes, SMT works well without needing through-hole strength.

Hybrid Approaches Combining Through-hole and SMT

Some projects use both through-hole and SMT together. Through-hole is used for big, strong parts, while SMT handles smaller ones. This mix gives strength and saves space. It’s common in medical tools or car systems needing both reliability and compact designs.

By knowing what your project needs, you can pick through-hole, SMT, or both.

LTPCBA’s Skills in Through Hole PCB Assembly and SMT

LTPCBA’s Promise for Reliable PCB Assembly

LTPCBA works hard to make reliable circuit boards. They focus on making strong and long-lasting boards. Every step of their process is about quality. They follow strict rules like ISO and UL to ensure great results. Their advanced checks, like Automated Optical Inspection (AOI), find even tiny mistakes. This careful work makes sure your projects are dependable and meet high standards.

LTPCBA’s Expertise in Through-hole and SMT Methods

LTPCBA is skilled in both through-hole and SMT methods. They can handle tricky assemblies with great care. For through-hole, they make strong solder joints that last in tough conditions. Their SMT skills include working with tiny parts like BGA and QFN, which need special tools.

Here’s how LTPCBA stands out from others:

Feature/Benefit | LTPCBA's Offering | Competitors' Offering |

|---|---|---|

Advanced for many BGA types | Limited skills | |

Cost Savings | Lower costs than older methods | Higher costs |

Strong and reliable solder connections | Mixed quality | |

Customer Care | Focused on customer needs | Less attention to customers |

This mix of advanced tools and customer care makes LTPCBA a top choice.

Why Pick LTPCBA for Your PCB Needs

Choosing LTPCBA means picking quality and new ideas. They respond quickly and offer 24-hour support to keep your project moving. Whether you need a sample or a medium-sized order, they deliver on time with great quality. Their skills in both through-hole and SMT give you options for any project. With LTPCBA, you get a partner who cares about your success.

Through Hole PCB Assembly is strong and long-lasting. SMT is better for small, fast designs. Think about your project’s needs to pick the best method. LTPCBA provides reliable results with both technologies. Their skills ensure trustworthy solutions for all kinds of projects.

FAQ

Why is through-hole technology better for tough environments?

Through-hole makes strong connections. Its soldered parts stay firm in heat, moisture, and shaking. This makes it great for outdoor or factory use.

Can SMT work well for high-power devices?

SMT isn’t great for high-power devices. Its small parts and thin solder can’t handle big currents or voltages.

Can you use both through-hole and SMT on one PCB?

Yes, you can use both. Through-hole holds heavy parts, and SMT saves space with smaller ones. This mix makes designs strong and efficient.

See Also

Choosing PCB Materials for Effective SMT Assembly Processes

A Comprehensive Guide to SMT and DIP Assembly Techniques

Key Technical Considerations for VIPPO PCB in SMT Assembly

Evaluating Advantages and Disadvantages of SMD vs. Through-Hole

Designing PCB Boards for Optimal SMT Manufacturing Efficiency