Through Hole PCB Assembly vs. SMT: When Traditional Technology Outperforms Modern Alternatives

Through Hole PCB Assembly works well when strength and trust matter. It is often used in tough places with heavy wear. Picking the right PCB assembly method is very important. The worldwide PCB market was worth $80 billion in 2023. It is expected to grow to $120 billion by 2028.

Key Takeaways

Through-hole PCB assembly works well when strength and reliability matter. It is often used in aerospace and military industries.

Surface mount technology (SMT) is great for smaller, efficient designs. It is best for gadgets and making many products quickly.

Picking the right PCB method depends on your project’s needs. Think about strength, reliability, and how much you need to produce.

What is Through Hole PCB Assembly (THT)?

Definition of Through-Hole Technology

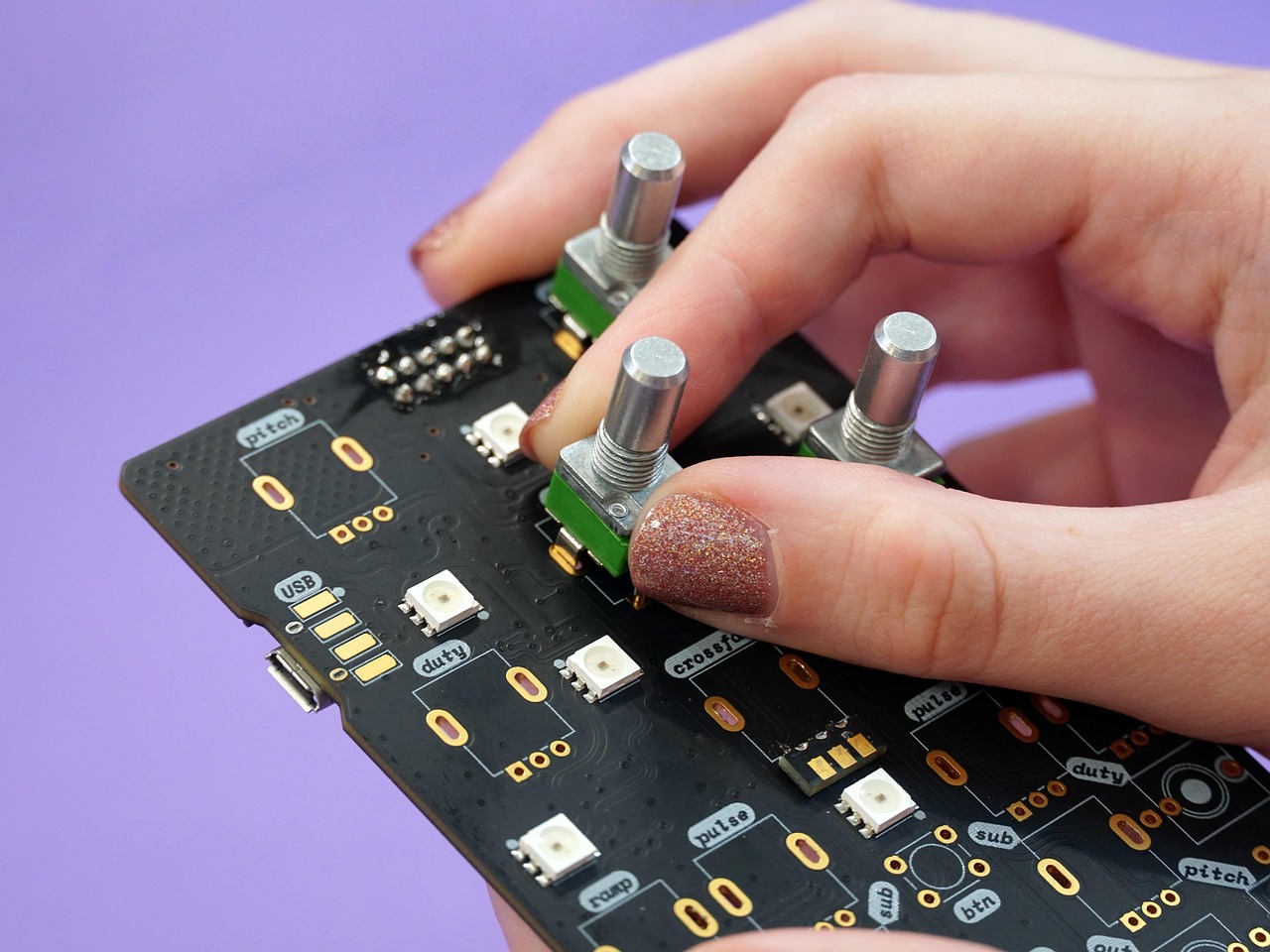

Through-hole technology builds circuits by placing parts with leads into drilled holes on a PCB. The leads are soldered on the back of the board for a strong connection. This method is basic to PCB assembly and works well for parts like resistors, capacitors, and transformers. Unlike SMT, through-hole offers better strength, making it great for tough and reliable uses.

The Process of Through Hole PCB Assembly

The through-hole PCB assembly process has several steps to ensure quality:

Component Preparation: Check and get parts like resistors ready for use.

Component Insertion: Place parts into the PCB by hand or machine.

Soldering: Attach the leads using wave or hand soldering.

Cleaning and Inspection: Clean the board and check for any problems.

This process ensures parts stay firmly in place, making the board good for tough conditions. Through-hole is also helpful for testing since parts can be swapped easily during design.

Key Characteristics of Through-Hole Components

Through-hole parts have unique benefits:

They handle higher voltage and current, great for powerful devices.

Strong connections make them resist shaking and stress.

Perfect for big parts like capacitors and transformers where size isn’t key.

Longer leads can cause issues in fast-speed uses.

These features make through-hole technology a top pick for industries like aerospace, military, and power electronics, where strength and trust are vital.

What is Surface Mount Technology (SMT)?

Definition of Surface Mount Technology

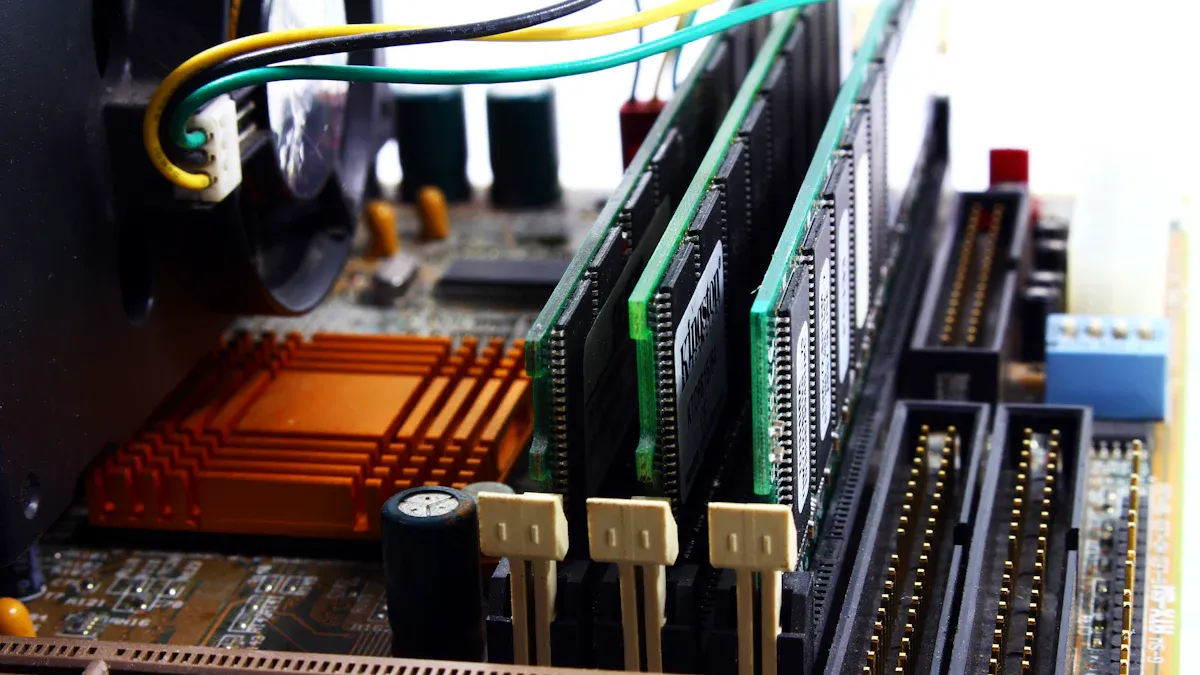

Surface mount technology connects parts directly to a PCB's surface. Unlike through-hole, it skips drilling holes into the board. Parts stick using solder paste and heat, making designs smaller and more efficient.

Definition | Description |

|---|---|

A way to attach parts on PCBs without drilling holes. | |

SMT Process | Uses solder paste, part placement, and heat to connect parts. |

Smaller boards, lighter products, easier making, and cheaper for big batches. |

The Process of SMT PCB Assembly

The SMT process has steps to make sure it works well:

Solder Paste Application: Solder paste goes on PCB pads. It cleans and sticks parts.

Component Placement: Machines place parts on the paste very accurately.

Reflow Soldering: Heat melts the paste, creating strong connections.

Inspection and Quality Control: Tools like AOI and X-rays check for mistakes like bad soldering.

This method is fast and makes sure your PCB works reliably.

Key Characteristics of SMT Components

SMT parts are small and efficient. They have:

Tiny sizes, perfect for crowded designs.

Work with machines, cutting down on handwork.

Great for high-speed electronics.

Many shapes, fitting different designs easily.

Testing checks if parts work right and finds any problems. This step is key for making sure your product is high-quality and dependable.

Key Differences Between THT and SMT

Component Size and Design Flexibility

Through-hole technology uses bigger parts, limiting smaller designs. These parts are great for machines where size doesn’t matter, like factory equipment or power devices. Surface mount technology uses tiny parts, allowing smaller and more packed layouts. SMT also lets you design on both sides of the board, giving more options.

Size | Design Flexibility | |

|---|---|---|

THT | Bigger | Less flexible (hard to shrink) |

SMT | Smaller | More flexible (double-sided use) |

Assembly Process and Automation

Through-hole assembly needs parts placed in holes and soldered by hand or wave soldering. This takes more time and effort. SMT uses machines to place parts on the board’s surface, followed by heat soldering. Machines make SMT faster and more consistent.

SMT is quicker because of machines.

Through-hole is better for testing and small projects.

SMT saves money and works well for big batches.

Reliability and Mechanical Strength

Through-hole parts are stronger. They stay in place under stress and shaking, making them perfect for planes, cars, and military tools. SMT parts are efficient but might not last in tough conditions like extreme heat or heavy vibrations.

THT is best for strong and reliable uses, like defense and heavy machines.

Cost and Production Efficiency

Through-hole costs more because it needs more handwork. It’s good for small projects with lower setup costs. SMT is cheaper for big projects because machines make it faster and more efficient.

Technology | Labor Costs | Production Efficiency | Cost-Effectiveness |

|---|---|---|---|

THT | Higher | Lower | Better for small projects |

SMT | Lower | Higher | Cheaper for big projects |

Environmental and Application Suitability

Through-hole works well in tough places. It handles heat, shaking, and stress, making it great for military, space, and factory uses. SMT is better for small, fast electronics but struggles in harsh conditions.

Application Area | Key Features for Performance | Environmental Challenges |

|---|---|---|

Military & Aerospace | Strong, handles shocks well | Heat, heavy vibrations |

Automotive | Safe, stable for systems like airbags | Shaking, heat, physical stress |

Industrial Machinery | Tough for hard jobs | Rough factory conditions |

Medical Devices | Accurate, long-lasting, safe | Cleaning, constant use |

Through-hole PCB assembly is strong and reliable for tough jobs. SMT is fast and great for modern, small electronics.

When Does Through Hole PCB Assembly Outperform SMT?

High-Reliability Applications in Harsh Environments

Through-hole technology works best where reliability is a must. It is used in aerospace, military, and factories with tough conditions. These include big temperature changes, strong shaking, and even radiation. For example:

Aerospace PCBs face temperatures from −20 °C to +80 °C many times. Through-hole solder joints stay strong under this stress.

Military electronics use through-hole mounting to handle shocks and vibrations during use.

NASA and the Department of Defense found through-hole parts are key for heavy-duty items like power supplies. These parts stay reliable even after 20 years in harsh places.

Evidence Description | |

|---|---|

Through Hole parts are vital for heavy items like power supplies and relays. They resist vibration and shock in tough conditions. | |

Parts built for extreme conditions, lasting up to 20 years, are mostly Through Hole because of their great reliability. | Anthony Upton, Schlumberger UK source |

If your project needs to survive tough environments, through-hole assembly is the most reliable choice.

Mechanical Stress and Durability Requirements

When strength is needed, through-hole mounting beats surface mount technology. Parts like transformers, inductors, and connectors need strong bonds to handle stress. Through-hole technology secures these parts firmly through the PCB.

Performance Aspect | Description |

|---|---|

Strong Mechanical Bonds | Holds parts tightly to handle physical stress. |

High Power Handling | Handles high power or voltage safely. |

Reliability | Used in safety-critical products for steady performance. |

Durability and Strength | Stronger than SMT, perfect for military and aerospace uses. |

For example, heavy parts like transformers use through-hole mounting for strength. This makes it ideal for cars and heavy machines, where stress is constant.

Prototyping and Low-Volume Production

Through-hole assembly is great for testing and small projects. Its process lets you easily swap parts during testing or design changes. This saves time and money compared to SMT.

Key metrics show why through-hole is good for prototypes:

Metric | Description |

|---|---|

Yield rates | Shows how many good units are made. |

Cycle times | Time to finish one production cycle. |

Defect rates | How often problems happen during production. |

Cost per unit | Total cost to make one unit. |

Quality levels | Measures the overall quality of the product. |

If you’re testing or making a small batch, through-hole offers flexibility and quality without high costs.

Mixed Technology Designs for Critical Components

Mixed designs use both through-hole and SMT for the best results. This is useful for important parts needing through-hole strength and SMT’s small size. For example, heavy parts like inductors use through-hole for stability, while smaller parts use SMT to save space.

In these designs, through-hole ensures key parts are reliable. SMT allows faster production for the rest of the board. This mix is popular in telecom and medical devices, where both strength and compactness matter.

Tip: When using mixed technology, think about the stress and conditions each part will face. This helps ensure the best performance and durability.

Applications of Through Hole PCB Assembly and SMT

Industries Benefiting from Through-Hole Technology

Through-hole technology is important for industries needing strong and reliable parts. Aerospace and military sectors use THT because it handles heat and shaking well. Power electronics rely on THT to manage high currents and voltages safely. Factories use THT in machines for its tough connections, which work well in rough conditions.

A report shows THT’s growing value in these industries. It highlights how THT is great for long-lasting and dependable electronics. This makes it the top choice for safety systems like car airbags and medical tools.

Industries Benefiting from Surface Mount Technology

Surface Mount Technology leads the PCB market, with 87% of chip machines using it. Consumer electronics, like phones and smartwatches, benefit from SMT’s small size and fast production. Cars use SMT for advanced features like entertainment and driver-assist systems.

Asia-Pacific is the biggest user of SMT, driven by demand for small, powerful devices. New IoT and 5G tech make SMT even more useful for efficient PCB designs. SMT lowers costs and improves quality, making it key for industries focused on innovation and mass production.

Examples of Products Using THT and SMT

Through-hole technology is used in items like power supplies, transformers, and factory control systems. These need strong bonds and handle high power well. SMT is found in small gadgets like phones, laptops, and IoT devices. Some products, like medical tools and telecom equipment, mix THT and SMT for both strength and small size.

Tip: Think about your project’s needs when choosing a PCB method. Picking the right one ensures the best performance.

Picking the Best PCB Assembly Method with LTPCBA

Choosing the right way to assemble your PCB is very important. LTPCBA knows both through-hole technology (THT) and surface mount technology (SMT). They help you find the best fit for your project. To decide, think about design needs, environment, and your budget.

Things to Think About for Your Project

When picking a PCB method, focus on what your project needs. Each factor affects how well your product works and lasts.

Factor | Why It Matters |

|---|---|

Through-hole parts stay stronger than SMT ones. | |

Reliability | Through-hole PCBs are great for trusted products. |

Heat Tolerance | They handle heat, perfect for tough uses like military. |

Compression Resistance | They survive stress, good for high-power systems. |

Ease of Prototyping | Easy to swap parts, making testing simple. |

Durability | Strong bonds help in rough conditions. |

For example, if your project needs to handle power or tough places, through-hole assembly gives strength and durability. But SMT works better for small designs and big production runs.

Tip: Think about where your product will be used and how strong it needs to be.

Design Complexity and Picking Parts

How tricky your design is and the parts you pick affect the assembly. LTPCBA follows rules like IPC-A-610 and ISO 9001 for top results.

Here’s how to plan your design and pick parts:

Understand Needs: Decide what your product must do.

Pick Parts: Choose parts that work well and last long.

Test Design: Use tools to check if your design works.

Make PCB Layout: Ensure your design is easy to build.

Write Code: Create software for your hardware.

Build Prototype: Test your design with real parts.

For advanced parts like BGA or QFN, LTPCBA ensures careful assembly. Following rules like RoHS Directive (2011/65/EU) also helps meet legal standards.

Note: Keep your design simple to save money and make building easier.

Environment and Durability Needs

Where your product will be used affects how long it lasts. LTPCBA tests products to ensure they work well in tough places.

Test Type | What It Does |

|---|---|

Tests PCBs under stress to find weak spots. | |

Burn-in Testing | Runs PCBs under hard conditions to catch early problems. |

Functional Testing | Checks if PCBs work well in extreme environments. |

Your product might face shaking, heat changes, or chemicals. Through-hole assembly is strong and handles heat well. SMT is fast but may not last as long in tough places.

Stress testing makes sure your PCB can handle moisture, dust, and other challenges.

Budget and Production Size

Your money and how many PCBs you need affect your choice. Through-hole assembly needs more handwork, so it’s better for small projects. SMT uses machines, saving money for big batches.

Technology | Labor Costs | Production Speed | Cost Benefits |

|---|---|---|---|

THT | Higher | Slower | Great for small projects |

SMT | Lower | Faster | Cheaper for big projects |

If you’re testing or making a few items, through-hole assembly is flexible and easy to adjust. For large amounts, SMT is faster and costs less.

Tip: Match your budget to your production needs for the best outcome.

Through Hole PCB Assembly creates stronger connections and handles stress better. This makes it perfect for reliable and tough uses. Surface Mount Technology is faster and saves money for big projects. Picking the right PCB method depends on what your project needs. LTPCBA customizes solutions to fit your goals for the best results.

FAQ

What makes through-hole and surface-mount assembly different?

Through-hole puts parts into holes on the board. Surface-mount sticks parts on top of the board.

Why is through-hole better for tough conditions?

Through-hole parts hold tighter, so they work well in hard environments.

Can one PCB use both through-hole and surface-mount methods?

Yes, using both methods gives strong parts and saves space on the board.

See Also

Evaluating Reliability Between Through Hole and SMT Assembly

Exploring Advantages and Disadvantages of SMD and Through-Hole

Common Methods and Process Flows in SMT Assembly