Mastering Through Hole PCB Assembly from Design to Production

You must learn every step in through hole PCB assembly. This helps your boards work well every time. Industry data says through hole methods make up about 30% of all boards made. Some common problems are soldering mistakes and putting parts in the wrong place. LTPCBA’s through hole pcb assembly service helps you stop these problems.

Key Takeaways

Through hole PCB assembly makes strong and lasting connections. These connections work well in hard conditions. They are easy to fix. This makes them good for important and high-power projects.

Good design and careful steps are important. You need to pick the right parts. The hole sizes must match the parts. You should use the right soldering methods. These steps help your boards work well. They also help you avoid common mistakes.

LTPCBA uses new technology and quality checks. This helps make boards faster. It also lowers mistakes. You get quick help and support. This helps you get good boards on time.

Through-Hole PCB Assembly Basics

What Is Through Hole Assembly

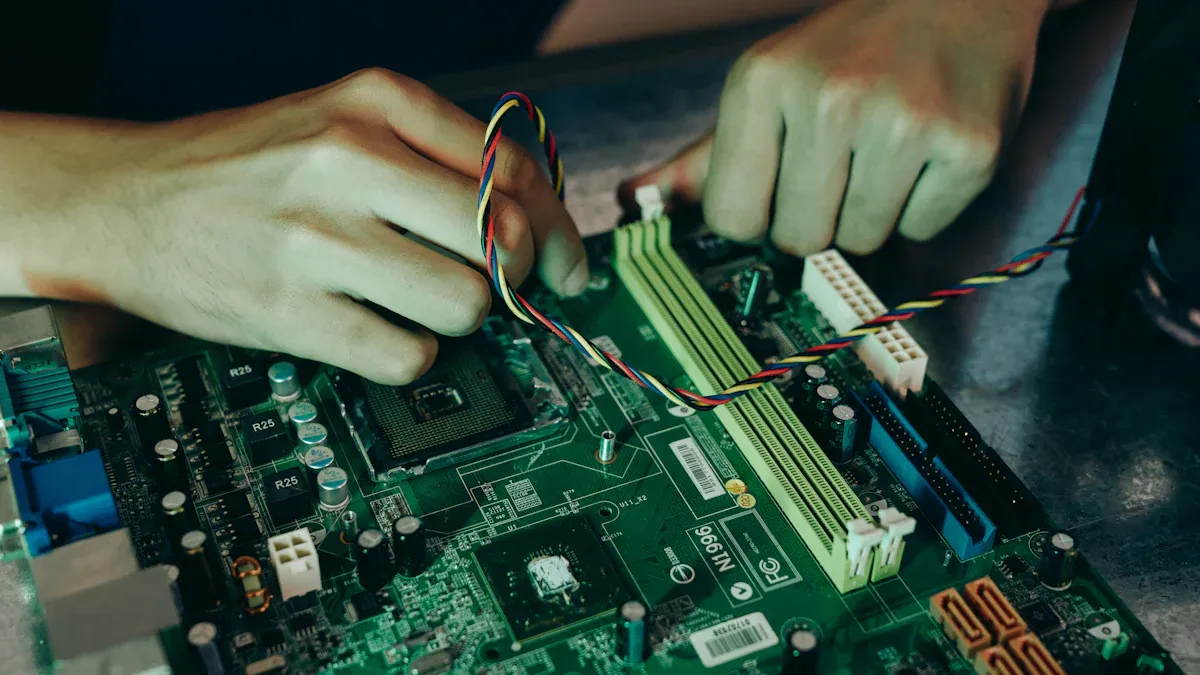

Through hole assembly makes strong and steady connections. You push component leads into holes in the board. The leads stick out the other side. You solder them there to hold them tight. This way, the parts stay in place even if the board shakes or gets hot. Many engineers use through hole assembly for military and space boards. It is also good for prototypes. If a part breaks, you can fix or swap it more easily. The steps are drilling holes, putting in parts, and soldering. Boards made this way last longer and can take more stress.

Tip: Choose through hole pcb assembly if you want your board to be tough and easy to fix.

Through-Hole vs SMT

You might ask how through hole pcb assembly is different from SMT. The big difference is how you put on the parts. Through hole pcb assembly needs you to push leads through holes. SMT puts parts right on top of the board. Through hole assembly uses bigger parts and takes longer. SMT uses tiny parts and is much faster with machines. Through hole pcb assembly makes stronger connections. SMT helps make smaller and lighter gadgets. Use through hole pcb assembly for boards that need to be strong or handle lots of power. SMT is better for small and many-at-once products.

Aspect | Through-Hole Assembly | Surface Mount Technology (SMT) |

|---|---|---|

Component Mounting | Leads go through drilled holes | Parts sit on the board surface |

Strength | Strong mechanical bond | Less strong, but improving |

Size | Larger components | Smaller, compact designs |

Speed | Slower, more manual | Faster, automated |

Repair | Easier to repair | Needs special tools |

Best Use | High-reliability, high-power boards | Small, high-volume electronics |

Pick the method that matches your project best. Through hole pcb assembly is still used a lot when you need your board to be strong and last a long time.

Design for Through Hole PCB Assembly

Component Selection

You need to pick the right parts for your printed circuit board. Good choices help your pcb manufacturing process run smoothly. Here are the most important things to check:

Know what your board needs, like voltage, current, and where it will be used.

Decide if you need through-hole or surface mount parts for strength and flexibility.

Make sure parts are easy to find and order.

Check that each part can handle the power and heat on your board.

Pick parts that meet safety rules, like RoHS or UL.

Choose the right size so everything fits during pcb fabrication.

Use trusted brands for better reliability and longer life.

Tip: Use design tools and libraries to help you manage your parts list and avoid mistakes.

Hole Size and Pad Design

You must match hole sizes to the leads of your components. This step is key for strong solder joints and a reliable printed circuit board. Follow these steps:

Find the biggest lead size from the datasheet.

Add a margin to the lead size: +0.25 mm for low-density, +0.20 mm for medium, +0.15 mm for high-density boards.

Calculate the pad size by adding the hole size, twice the annular ring, and a small extra for fabrication.

Make sure the annular ring is at least 0.13 mm wide for strength.

These rules follow IPC-2221 standards and help your pcb manufacturing process stay on track.

Layout and Spacing

You should plan your layout to make assembly and repair easy. Place through-hole parts on the top layer. Keep at least 10mm between parts for easy soldering and fixing. For wave soldering, use a 2.0mm pitch and 1.0mm pad edge spacing. Do not put heavy parts in the center of the board. Leave at least 10mm from parts to the board edge. This helps your pcb fabrication avoid damage and keeps your board strong.

Note: Good spacing stops solder bridges and makes your printed circuit board last longer.

Through Hole PCB Assembly Process

Preparation Steps

You begin by getting everything ready for through hole pcb assembly. This makes the whole process go smoothly and helps stop mistakes. The IPC standards say you should do these things:

Collect all your parts and check if they match your plan.

Put the parts into any machines you will use.

Get your soldering stations ready, no matter which type you use.

Make sure your work meets IPC-A-610 rules for good solder joints.

Teach your team and keep the area clean and dry.

LTPCBA uses smart ways to get ready. Their team checks every part and uses machines to load parts fast. They also keep their work areas clean and train workers to follow strict rules. This careful start helps you get good results every time.

Tip: Getting ready the right way stops mistakes and keeps pcb manufacturing on track.

Component Insertion

Putting in parts is a key step in through hole pcb assembly. You push each part’s leads into the right holes. To do this well, follow these steps:

Work in a clean, bright place and wear safety glasses.

Put each lead into its matching hole.

Bend the leads a little to keep the part in place.

Clean the leads and pads with flux to help solder flow.

Use tools to shape the leads so they fit better.

You can put in parts by hand or use machines. Machines like axial and radial inserters make this step faster and cut down on mistakes. LTPCBA uses robots with AI to place parts very accurately. These robots can put in up to 50,000 parts every hour and are very precise. This helps you get perfect placement, even on crowded boards.

Note: Good part placement keeps things steady during soldering and makes the board better.

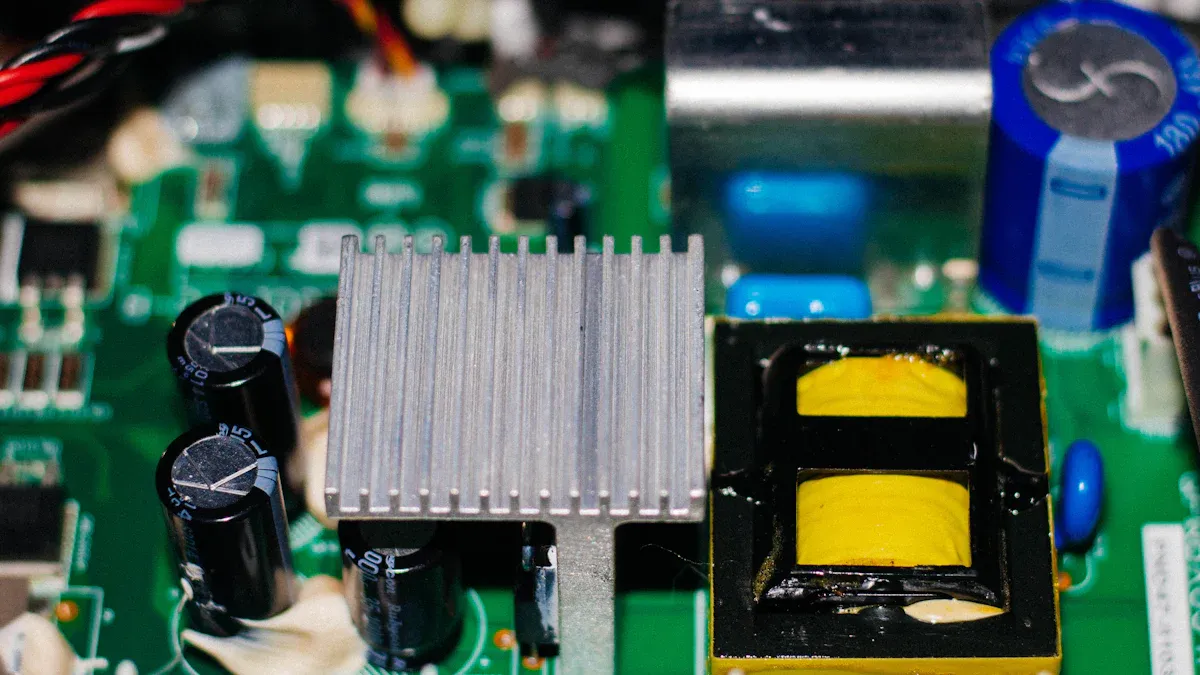

Soldering Methods

Soldering connects the leads to the board and makes the circuit work. There are three main ways to solder in through hole assembly: manual, wave, and selective soldering. Each way is good for different jobs.

Method | Advantages | Disadvantages | Typical Use Cases |

|---|---|---|---|

Flexible, good for prototypes and repairs | Slow, less consistent, needs skill | Small runs, repairs, manual through hole assembly | |

Fast, great for high-volume production | Not for mixed boards, less precise on dense PCBs | Large batches, simple through-hole pcb assembly | |

Selective Soldering | Precise, programmable, handles complex layouts | Slower, higher cost per board | Mixed-technology, dense or tall components |

Manual soldering lets you control each joint but takes longer. Wave soldering moves the board over melted solder and joins all leads at once. This is best for making lots of boards. Selective soldering uses a nozzle to put solder only where it is needed. It works well for boards with both through-hole and surface-mount parts.

LTPCBA uses all three soldering ways. Their smart soldering machines, like nitrogen and vacuum ovens, make solder joints strong. These machines stop oxidation and help every joint look shiny and last longer.

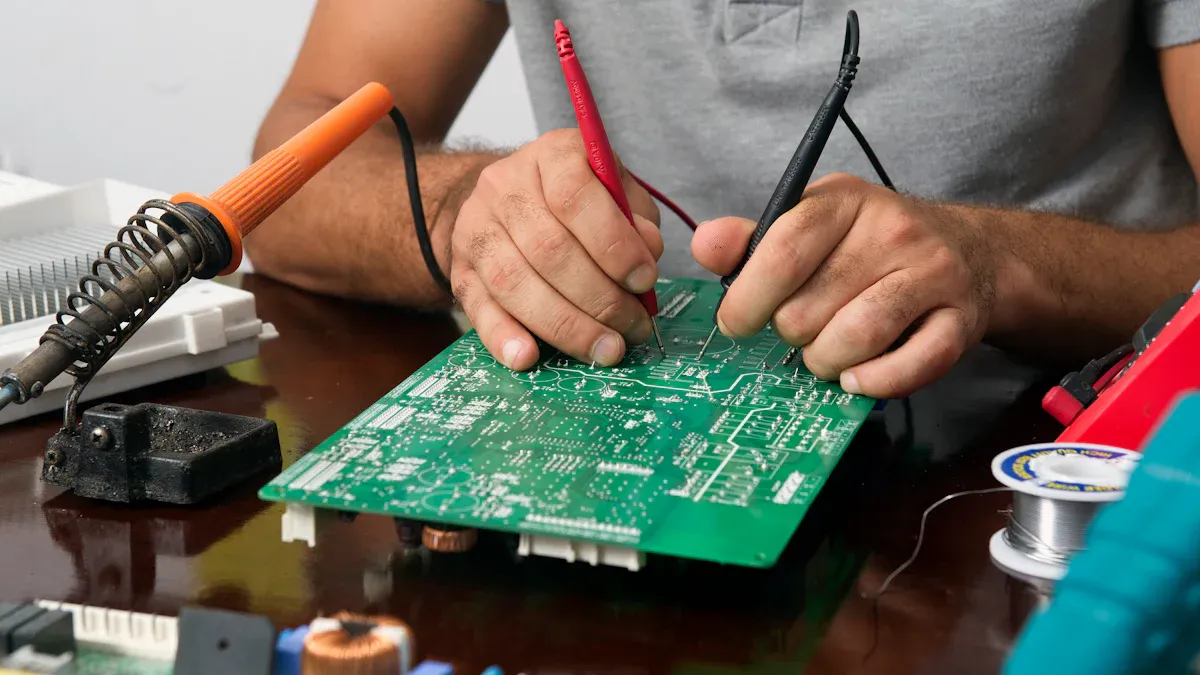

Lead Trimming and Cleaning

After soldering, you need to cut off extra lead pieces. This keeps your board safe and neat. Here are some good steps:

Cut leads close to the solder joint with flush cutters to stop shorts.

Clean the board with special cleaners and brushes to get rid of dirt.

Dry the board with a cloth that does not leave lint.

Check each joint to see if the solder is smooth and shiny.

Bend leads out before soldering to hold parts steady.

LTPCBA uses special cleaning machines that mix cleaners, stirring, and heat. They also put coatings on the board to protect it from water and dust. These steps can help the board last up to 50% longer in tough places.

Callout: Clean boards work better and last longer in real use.

Inspection and Testing

Checking and testing are the last steps in through hole pcb assembly. You must look at every board to make sure it is good. Some common ways to check and test are:

Method | Purpose/Use Case | Benefits | Limitations/Notes |

|---|---|---|---|

Check for visible defects, solder joints, orientation | Simple, no special tools | Human error, only surface defects | |

Automated Optical Inspection (AOI) | Detects visual defects automatically | Fast, consistent, finds many issues | May miss hidden problems |

X-ray Inspection | Finds hidden solder and internal defects | Sees inside joints and layers | Needs special equipment |

In-Circuit Test (ICT) | Tests electrical connections and components | Checks all circuits | Needs test fixtures |

Flying Probe Test | Flexible electrical testing, good for prototypes | No fixtures needed | Slower for big batches |

Functional Test (FCT) | Checks if the board works as designed | Verifies real-world function | Needs custom setup |

Contamination Test | Finds residues that can cause corrosion | Ensures cleanliness | Needs special tools |

Burn-In Test | Stresses the board to find early failures | Improves reliability | Takes more time |

Micro-sectioning Analysis | Looks at cross-sections for detailed analysis | Deep quality check | Destroys the sample |

LTPCBA uses 3D AOI and high-quality X-ray machines to find even hidden problems. Their quality system checks boards many times and uses data to spot issues. They also use in-circuit and functional tests to make sure every board works right. This helps you get more good boards and fewer mistakes.

Tip: Careful checking and testing keep your customers happy and protect your business.

LTPCBA Through Hole PCB Assembly Service

Service Overview

LTPCBA can help you with every step of through hole pcb assembly. Their team finds parts, builds your boards, and checks them at the end. You get help with design, quick samples, and making more boards later. LTPCBA uses smart machines and skilled people to make sure your boards work well. You can order simple or hard boards. This through hole pcb assembly service is used in cars, hospitals, and airplanes. The boards are strong and work in tough places.

Tip: LTPCBA’s through hole pcb assembly service lets you do small or big jobs.

Quality Assurance

You want your boards to work right the first time. LTPCBA’s through hole pcb assembly service checks quality at every step. The team looks at your design with computer tools and DFM checks. They use machines to test each part for problems. Robots put parts in the right place. Soldering is done in a safe area to stop mistakes. After building, your boards get AOI, X-ray, and working tests. LTPCBA keeps track of every board with digital records. They follow IPC and RoHS rules. Your boards are packed to keep out static and water.

Step | Quality Control Action |

|---|---|

Design Review | CAD checks, DFM analysis |

Component Validation | Automated electrical and mechanical testing |

Assembly | Robotic placement, controlled soldering |

Inspection | AOI, X-ray, functional testing |

Packaging | ESD and moisture-proof materials |

Customer Support

You always get help during your through hole pcb assembly service. LTPCBA lets you contact them by phone, email, or WhatsApp. You get answers to questions in less than 12 hours. If there is a problem, they fix it fast and send back boards in 3 days. You get a 3-year warranty for your orders. The engineering and supply teams help you at every step. You can call or go online for quick help. LTPCBA’s through hole pcb assembly service keeps you updated and helps your project finish on time.

Note: Fast and friendly help lets you finish your projects quickly.

Advantages of Through Hole Assembly

Mechanical Strength

You want your circuit boards to be strong. Through hole assembly makes tight mechanical bonds. Each component lead goes through the board. The lead is soldered on the other side. This keeps parts in place, even if the board shakes. You see this strength in things like industrial machines and cars. These boards must handle shaking and rough use. Through-hole assembly gives better support for big or heavy parts. You can trust these boards for tough jobs.

Tip: Pick through hole assembly if your project needs to survive drops, bumps, or heat.

Reliability

You want your boards to work every time. Through hole assembly helps you get high reliability. Solder joints in this method do not crack or break easily. This means your circuits keep working in harsh places. Many engineers use through hole assembly for important devices. Medical tools, space systems, and power supplies use this method. Through-hole assembly also makes repairs easier. You can fix or swap parts without hurting the board.

Feature | Surface Mount Technology | |

|---|---|---|

Mechanical Bond | Strong | Moderate |

Repairability | Easy | Hard |

Reliability | High | Good |

You feel better when you pick this assembly style for important projects.

When to Use Through Hole PCB Assembly

Best Applications

You should use through hole PCB assembly when your project needs strong and reliable connections. Many products benefit from this method:

Power supplies and converters need stable electrical paths to handle high current.

High-voltage circuits use through-hole parts to prevent short circuits.

Transformers, relays, and connectors require strong solder joints because they get hot and face stress.

Military and aerospace electronics must survive extreme heat, cold, and vibration.

Outdoor automation systems face dust, moisture, and sunlight.

Medical and safety devices demand long-term, reliable performance.

Through-hole components work well in harsh environments. Their leads pass through the board, making a strong bond. This helps your board resist vibration and shock. You can also repair or replace these parts more easily. Many engineers pick through-hole assembly for prototypes and research because it is simple to swap out parts.

Note: Through-hole solder joints can last through over 1,000 temperature cycles, which is twice as many as surface-mount joints.

Mixed Assembly

Sometimes, you need both through-hole and surface-mount parts on the same board. This is called mixed assembly. You might choose mixed assembly when you want the strength of through-hole for big parts and the small size of SMT for other parts. For example, you can use through-hole for connectors and transformers, and SMT for chips and resistors.

Mixed assembly helps you get the best of both worlds. You can make your board strong and compact at the same time. However, mixed assembly brings new challenges. You must plan for two types of soldering. This can make the process more complex and cost more. You also need to think about heat, signal quality, and how easy it is to repair the board.

Many engineers face challenges when they design mixed boards. You must balance the need for strength, size, and speed. You also need to follow rules for safety and reliability, especially in medical or mission-critical devices. If you understand these challenges, you can make better choices for your project.

Tip: Mixed assembly is a smart choice when you want both durability and high part density, but be ready to solve extra challenges during production.

Innovations in Through Hole Assembly

Automation Trends

Through hole assembly is changing because of new machines and robots. Factories use robots to put parts into holes quickly and correctly. This helps stop mistakes and makes every board the same. Selective soldering machines heat only the right spots. This keeps the board safe from too much heat and makes strong solder joints. Wave soldering is used for big groups of boards. It joins many parts at once and saves time. Special tools like Automated Optical Inspection and X-ray check for hidden problems. AOI finds most soldering mistakes. X-ray looks inside joints for extra safety. Smaller through-hole parts help you fit more on each board. Hybrid designs use both through hole and surface mount parts. This gives you strong boards that are also small.

Note: Automation gives you better boards, fewer mistakes, and faster work.

LTPCBA Technology

LTPCBA uses the best machines to make through hole assembly fast and correct. You get help from their smart tools and systems. Here is what LTPCBA does for you:

Technology/Equipment | How It Helps You |

|---|---|

Hitachi Laser Drilling | Makes tiny, exact holes for hard boards. |

Vertical Continuous Plating Lines | Adds even copper layers for strong, safe connections. |

Online AOI | Finds problems fast and sorts boards by itself. |

High-speed Flying Probe Testers | Checks circuits quickly and finds issues early. |

Linear Motor Drilling Machines | Drills very small holes with great control for special boards. |

Silkscreen Printer | Prints clear marks for easy part placement. |

Horizontal Electroless Copper Plating | Covers holes with copper evenly, even on tricky materials. |

LDI Exposure Machines | Uses lasers for sharp, clean circuit lines and solder mask. |

Quality Assurance System | Uses smart tests, world rules, and expert checks for over 99.8% accuracy. |

Intelligent Production Scheduling | Speeds up delivery and keeps your project on track. |

LTPCBA’s machines give you strong, clean soldering and quick results. Their systems help you avoid waiting and get boards that work right the first time.

Best Practices for Success

Design Tips

You can make through-hole pcb assembly easier if you plan well. Try to use fewer through-holes on your board. Use surface-mount technology for small parts when you can. This helps save money on drilling and plating. Pick hole sizes that match common drill bits. This way, you do not need special tools and work goes faster. Keep at least 0.5mm space between each hole. This stops the board from breaking and keeps waste low.

Try to use fewer layers in your PCB. Fewer layers mean less drilling and a simpler job. Use good drill bits and group holes of the same size. Automated CNC drilling makes holes more exact and saves on labor. Put parts that work together close to each other and near ports. This makes traces shorter and means less soldering. Always use a clear Bill of Materials and pick standard parts. This helps stop delays and mistakes during through-hole pcb assembly.

Tip: Good paperwork and using machines to place parts help keep your work steady and correct.

Process Optimization

You can make through-hole pcb assembly faster by using smart steps. Start with lean manufacturing ideas like 5S and Kanban. These help you cut waste and keep things moving. Use machines for putting in parts and soldering. Automation means less hand work and fewer mistakes, so things go quicker and better.

Make your work steps the same every time and check quality often. This keeps your boards good and cuts down on errors. Train your team so they know how to use new machines and do things the best way. Check for problems early with automated optical inspection. This finds mistakes before they get worse. Watch your process with data to find slow spots and fix them. Track your materials as they move so you do not run out.

Note: Using lean ideas, machines, and good planning can make through-hole pcb assembly twice as fast and lower mistakes.

You can get really good at through hole PCB assembly if you follow some simple steps. First, always look at the component footprints and read the datasheets. Make sure you mark which way parts go and show their polarity. It helps to work with people who know a lot and use AOI and X-ray testing.

Benefit | How LTPCBA Helps You |

|---|---|

They check quality and test a lot | |

Fast Support | You get help any time, day or night |

Ask LTPCBA for help if you want advice and boards you can trust.

FAQ

What is the main benefit of through hole PCB assembly?

You get very strong connections. The parts stay in place, even if things shake or get hot. This method is best for projects that need to last a long time and use lots of power.

Can you repair through hole PCBs easily?

Yes, you can fix these boards easily. You can take out and put in new parts without hurting the board. This makes fixing and changing parts easy for you.

How does LTPCBA ensure quality in through hole assembly?

LTPCBA checks boards with machines and X-ray tools. They follow strict rules and watch each step closely. You get boards that pass many tests and meet world standards.

See Also

Complete Handbook For Through-Hole Printed Circuit Assembly

Expert Strategies And Tips For Successful BGA Assembly

Essential Techniques For DIP Assembly And Hole Tolerances

Understanding Full Turnkey PCB Production And Assembly Process