Comprehensive Guide to Through Hole PCB Assembly

Through Hole PCB Assembly involves inserting component leads into drilled holes, which are then soldered to pads on the opposite side of the board. This method creates robust connections, making it ideal for demanding conditions.

Through-hole passive parts are projected to grow from $39.68 billion in 2024 to over $101.6 billion by 2037, with a growth rate of 7.5% each year.

PCB assembly services, valued at $32.8 billion in 2023, are expected to reach $54.6 billion by 2032, growing at a rate of 6.1% annually.

These statistics highlight the continued significance of through hole technology in today's market.

Key Takeaways

Through-hole PCB assembly makes strong links, perfect for tough uses like planes and military tools.

This method is expected to grow a lot, showing its value in electronics.

Picking through-hole tech is wise for projects needing strength, heat safety, and simple part changes.

Understanding Through Hole PCB Assembly

What is Through Hole PCB Assembly?

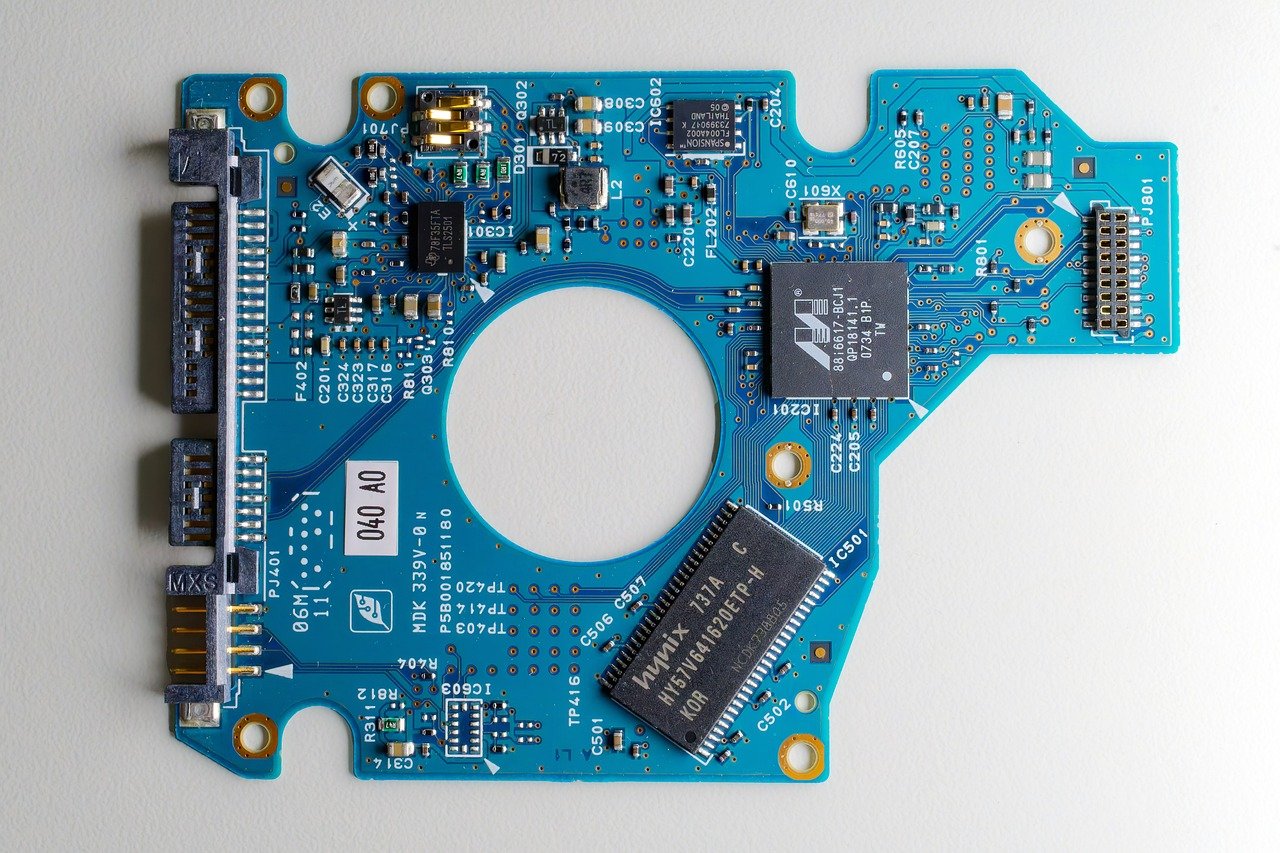

Through-hole PCB assembly is when parts with leads go into drilled holes on a PCB. The leads are soldered to pads on the other side, making strong connections. This method is tough and works well for reliable uses.

The process has a few steps:

Drill exact holes in the PCB.

Put component leads into these holes.

Solder the parts using methods like hand, wave, or selective soldering.

Through-hole technology (THT) is great for parts like connectors, transformers, and high-power devices. Its strong bonds make it popular in industries like aerospace and military electronics, where reliability matters most.

Did you know? Even with surface mount technology (SMT) being common, through-hole PCB assembly is still important. It handles tough conditions, keeping it useful today.

Key Features of Through-Hole Technology

Through-hole technology has unique features that make it stand out. These include:

Strong Mechanical Connections: Leads go through the PCB, creating a secure hold.

Versatility in Assembly: Parts can be placed by hand or machines, based on needs.

Soldering Requirements: Soldering ensures parts stay firmly attached to the PCB.

High-Reliability Applications: Perfect for tough jobs like industrial machines and aerospace systems.

Feature | Through-Hole Technology (THT) | Surface Mount Technology (SMT) |

|---|---|---|

Mounting Method | Leads go into drilled holes | Parts sit on the PCB surface |

Mechanical Connection | Strong and durable | Usually less strong |

Assembly Process | Manual or machine insertion, needs soldering | Automated, often no soldering |

Common Applications | Connectors, transformers, high-power parts | Small parts, dense designs |

These features make through-hole technology a trusted choice for jobs needing strength and reliability.

Applications of Through-Hole PCB Assembly

Through-hole PCB assembly is used in many areas, especially where strength and dependability are key. Common uses include:

Industrial Equipment: Heavy machines use through-hole parts for strong connections.

Aerospace and Military Electronics: These fields need parts that survive tough conditions.

Power Electronics: Transformers and power supplies benefit from strong through-hole bonds.

Prototyping and Testing: Engineers like through-hole for easy assembly and changes in prototypes.

Research shows challenges like needing skilled workers and high costs for manual work. But new tools like visual object detection are making through-hole assembly faster, cheaper, and better.

Tip: If your project needs strong parts or extra durability, through-hole PCB assembly is a smart pick.

The Through Hole PCB Assembly Process

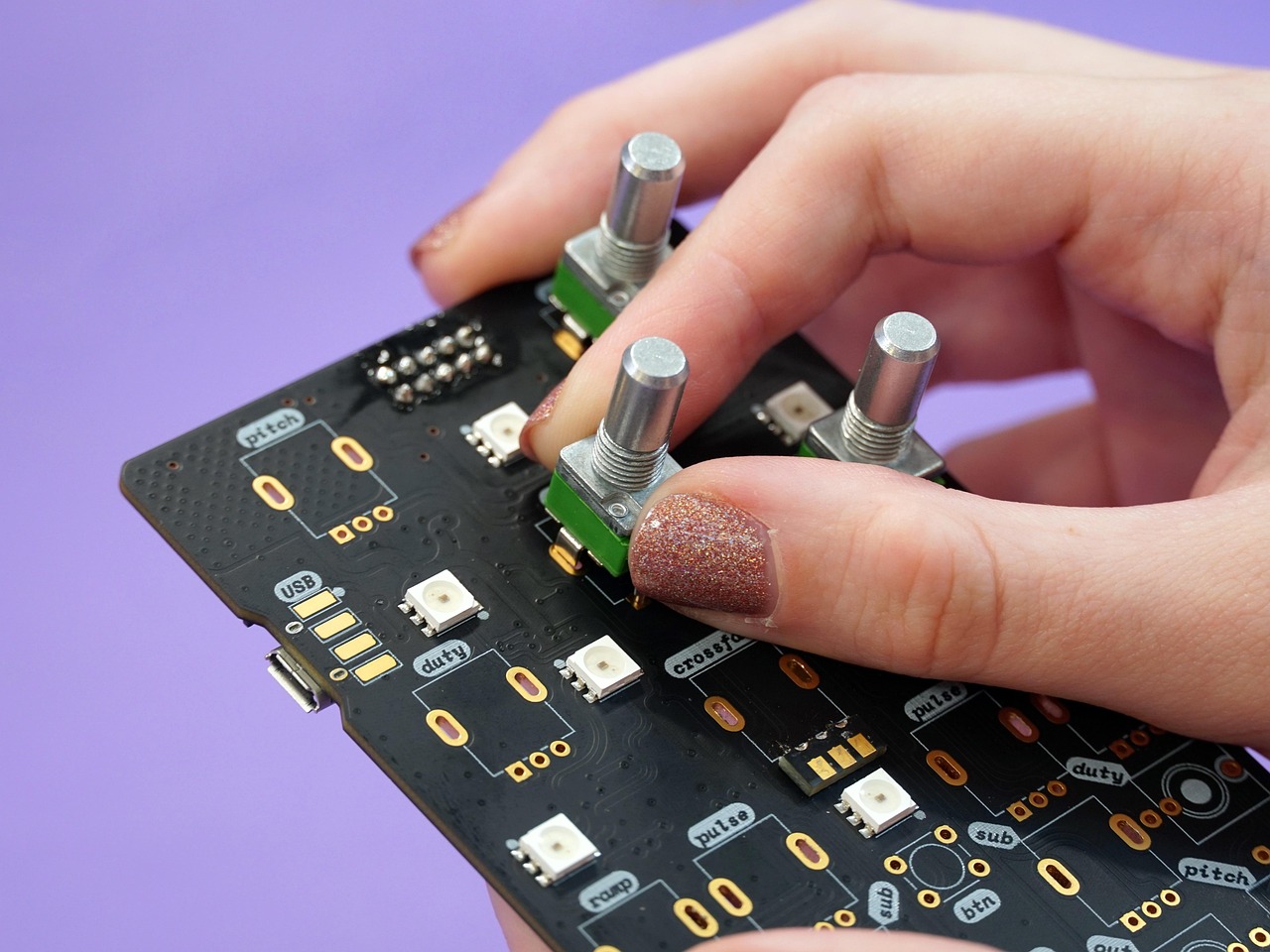

Types of Components Used in Through-Hole Assembly

Through-hole assembly uses parts with leads that go through drilled holes. Axial lead parts are strong and handle heat well, making them great for hot environments. Radial lead parts are smaller and fit tight spaces easily.

These parts are common in aerospace, military, and car industries. They work well in tough conditions because they are stable and reliable. Connectors, transformers, and power parts often use through-hole assembly for strength and durability. Also, these parts are easy to replace, which helps in testing and building prototypes.

Soldering Methods: Manual, Wave, and Selective Soldering

Soldering is an important step in through-hole assembly. There are three main ways to solder:

Manual Soldering: This is cheap and flexible but needs skilled workers. It’s best for small projects or prototypes.

Wave Soldering: The whole board is dipped in melted solder, making it fast for large jobs. But it can cause heat damage on crowded boards.

Selective Soldering: This method solders specific spots, avoiding heat damage. It’s perfect for complex boards needing precise soldering.

Soldering Method | Efficiency and Suitability |

|---|---|

Selective Soldering | Very accurate, good for tricky designs, saves time, and ensures quality. |

Manual Soldering | Flexible but depends on skill, harder to control heat, and may vary in quality. |

Wave Soldering | Covers the whole board, can overheat parts, less useful for crowded boards. |

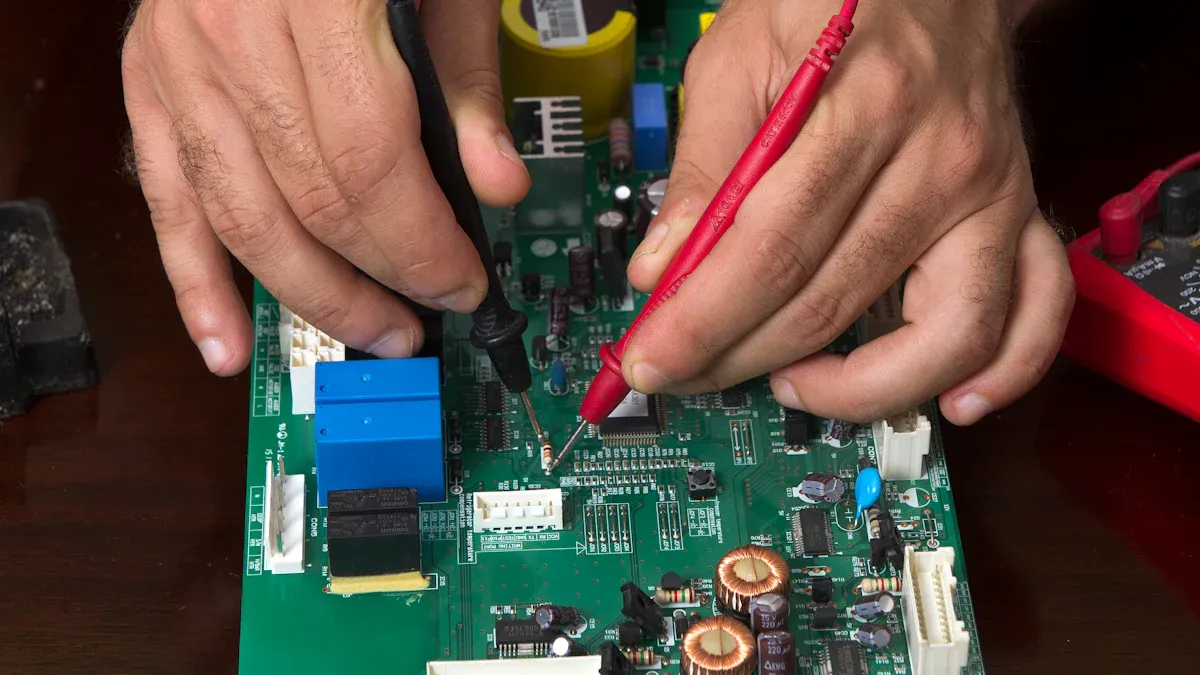

Inspection and Testing Techniques for Through-Hole Assembly

Checking the assembly ensures it works well. Automated Optical Inspection (AOI) is a key tool. It finds problems like bad solder joints and is more accurate than manual checks. AOI is especially helpful for double-sided boards.

Strict testing, including AOI, catches mistakes early in production. This ensures the final product is high quality. Using these methods helps create strong and reliable through-hole assemblies.

Through Hole vs. Surface Mount Technology (SMT)

Advantages of Through-Hole PCB Assembly

Through-hole PCB assembly has many benefits for specific uses. It is strong and reliable, especially in tough environments. Parts attached with through-hole technology stay in place better because of their solid connections. This makes them perfect for industries like aerospace and military, where dependability is key.

Durability: Through-hole parts handle stress, vibrations, and shocks well. Their design, with leads going through holes and soldered, keeps them secure.

Heat Tolerance: These parts manage heat better due to their larger size. This makes them great for hot environments.

High Power Transmission: Strong bonds allow them to carry more power, which is needed for things like power supplies and transformers.

Ease of Replacement: Through-hole parts are simple to swap during testing or repairs, helping engineers make changes easily.

Tip: For projects in tough conditions or heavy-duty tasks, through-hole PCB assembly is a reliable choice.

Comparing Through-Hole and SMT Technologies

Through-hole and SMT technologies each have pros and cons. Knowing these differences helps you pick the best one for your project.

Mechanical Strength: Through-hole is stronger and better for high-stress uses. SMT is weaker because parts sit on the surface.

Component Density: SMT fits more parts in small spaces, like in phones. Through-hole works better for bigger parts.

Heat Tolerance: Through-hole parts resist heat better, while SMT parts can get damaged by heat.

Automation: SMT is faster and cheaper for big jobs because it’s automated. Through-hole often needs manual work, which takes longer.

Application Suitability: Through-hole is best for industries like aerospace and cars. SMT is ideal for small, high-tech devices.

Feature | Surface Mount Technology (SMT) | Through-Hole |

|---|---|---|

Mechanical Strength | Fragile | Strong and durable |

Heat Tolerance | Lower | Higher |

Component Density | High | Lower |

Automation | Highly automated | Primarily manual |

Application Suitability | Compact electronics | High-stress environments |

Note: SMT is great for mass production, but through-hole is better for tough and reliable uses.

When to Choose Through-Hole Over SMT

The choice between through-hole and SMT depends on your project’s needs. Through-hole is best when strength and reliability are most important. Its strong connections make it great for high heat, shocks, or vibrations.

Design Consideration | Surface Mount | Through Hole |

|---|---|---|

Double-sided PCB | ✓ | |

High component density | ✓ | |

Electrical performance priority | ✓ | |

Heavy parts | ✓ | |

Hazardous conditions | ✓ | |

Components only available as through hole | ✓ |

Through-hole is also useful for testing and prototyping. Engineers can easily replace parts to make changes. It’s also preferred for high-power uses like transformers, where strong bonds are needed.

Pro Tip: Use through-hole technology for heavy parts, harsh conditions, or projects needing frequent updates.

Cost Considerations for Through Hole PCB Assembly

Factors Influencing the Cost of Through-Hole Assembly

Many things affect the cost of through-hole assembly. The size of the PCB matters a lot. Bigger boards need more materials and work, which costs more. The type of materials also changes the price. For example, regular FR-4 is cheaper than special materials. Choosing between leaded or lead-free parts can also change costs and reliability.

To save money, think about how complex the assembly is. Using parts that need the same method makes the process easier. Keeping all parts on one side of the board also saves time and money.

Tip: Pick simple parts that don’t need extra steps. This keeps costs low and quality high.

Cost Comparison: Through-Hole vs. SMT

Through-hole and SMT have different costs because of their processes. Through-hole often needs manual work, which costs more for big jobs. But wave soldering can make simple through-hole designs cheaper. SMT uses machines, so it’s better for dense or double-sided boards.

Assembly Type | Complexity | Cost Impact |

|---|---|---|

All through hole | Low | |

Through hole with press-fit connectors | Medium | Costs more because of extra steps |

Single-sided surface mount | Medium | Costs a bit more |

Double-sided surface mount | High | Costs much more due to complexity |

Single-sided surface mount with through hole components | Medium | Costs more because of mixed methods |

Double-sided surface mount with through hole components | High | Most expensive due to many steps |

Note: SMT is cheaper for dense designs, but through-hole is better for simple, reliable projects.

Scenarios Where Through-Hole Assembly is Cost-Effective

Through-hole assembly works well for strong and durable projects. It’s cheaper for small batches or prototypes where manual soldering is enough. Industries like aerospace and cars use through-hole because it lasts in tough conditions. Wave soldering can also lower costs for all-through-hole designs, especially if you avoid mixing methods.

To save money, keep the design simple. Put parts on one side of the board and avoid making it too complex. This helps cut down assembly costs.

Pro Tip: Choose through-hole assembly for heavy parts or when strength is more important than small size.

Through Hole PCB Assembly Services by LTPCBA

Turnkey Through-Hole PCB Assembly Services

LTPCBA provides complete turnkey through-hole PCB assembly services, managing everything from start to finish. They handle all steps, including getting parts and assembling the board. This means you don’t need to work with multiple suppliers, saving time and avoiding delays.

One big advantage of LTPCBA's turnkey service is its speed. By running tasks at the same time, they cut lead times by up to 30%. This faster process also keeps quality high with strict checks at every step.

Feature | LTPCBA Full Turnkey | Competitors' Partial Services |

|---|---|---|

Project Control | One vendor handles all | Multiple vendors involved |

Lead Time | Slower due to split workflows | |

Cost Efficiency | Lower costs with bulk work | Higher costs from separate steps |

Quality Consistency | Full quality checks | Mixed standards |

Tip: Using LTPCBA's turnkey service gives you top-quality assembly without extra hassle.

Consigned Through-Hole PCB Assembly Services

If you want to supply your own parts, LTPCBA offers consigned through-hole PCB assembly services. This lets you pick your components while still benefiting from LTPCBA's expert assembly skills.

This option is great for projects needing specific parts. LTPCBA uses advanced methods, like selective wave soldering, to ensure excellent results even with customer-provided materials.

Feature | Full Turnkey | Partial Services |

|---|---|---|

Lead Time | 30% faster | Slower due to split workflows |

Cost Efficiency | Lower costs with bulk work | Higher costs from separate steps |

Quality Consistency | Full quality checks | Mixed standards |

Note: Consigned services work well if you already have parts and need expert assembly.

Why Choose LTPCBA for Through-Hole PCB Assembly?

LTPCBA is a trusted name in through-hole PCB assembly, known for its experience and quality. With over 10 years in the field, they are experts at creating reliable and durable solutions.

Reasons to choose LTPCBA include:

Many services, like hand soldering and selective wave soldering.

A smooth turnkey process for handling through-hole parts.

Strong quality checks to ensure great results.

By working with LTPCBA, you get a team focused on your needs. Whether you pick turnkey or consigned services, LTPCBA delivers on time and with top quality.

Through-hole PCB assembly is great for big parts and tough conditions. It handles vibrations well and gets rid of heat easily. For small production runs, it’s also a budget-friendly choice. Picking a trusted company ensures strong and lasting results. Check out LTPCBA’s expert services for smooth assembly and top-notch quality made just for you.

FAQ

Why is through-hole PCB assembly more dependable than SMT?

Through-hole assembly makes stronger connections. Parts are soldered into drilled holes, which is great for tough jobs like aerospace or factory machines.

Can through-hole PCB assembly work with high-power parts?

Yes, it can handle high-power parts like transformers. Its strong soldering keeps these parts working well in power-heavy tasks.

Is through-hole PCB assembly good for testing new designs?

Yes! Through-hole assembly lets you easily swap parts. This makes it great for testing and trying out new ideas.

Tip: Use through-hole assembly for projects needing strength, heat resistance, or easy changes.

See Also

Essential Insights Into DIP Cable Assembly For PCB Connections

Evaluating Reliability: Through Hole PCB Assembly Versus SMT

Understanding Tolerances In DIP Assembly And Through-Hole Techniques

Seven Key Quality Control Steps For Through Hole PCB Assembly

Selecting The Best Through Hole PCB Assembly For Industrial Needs