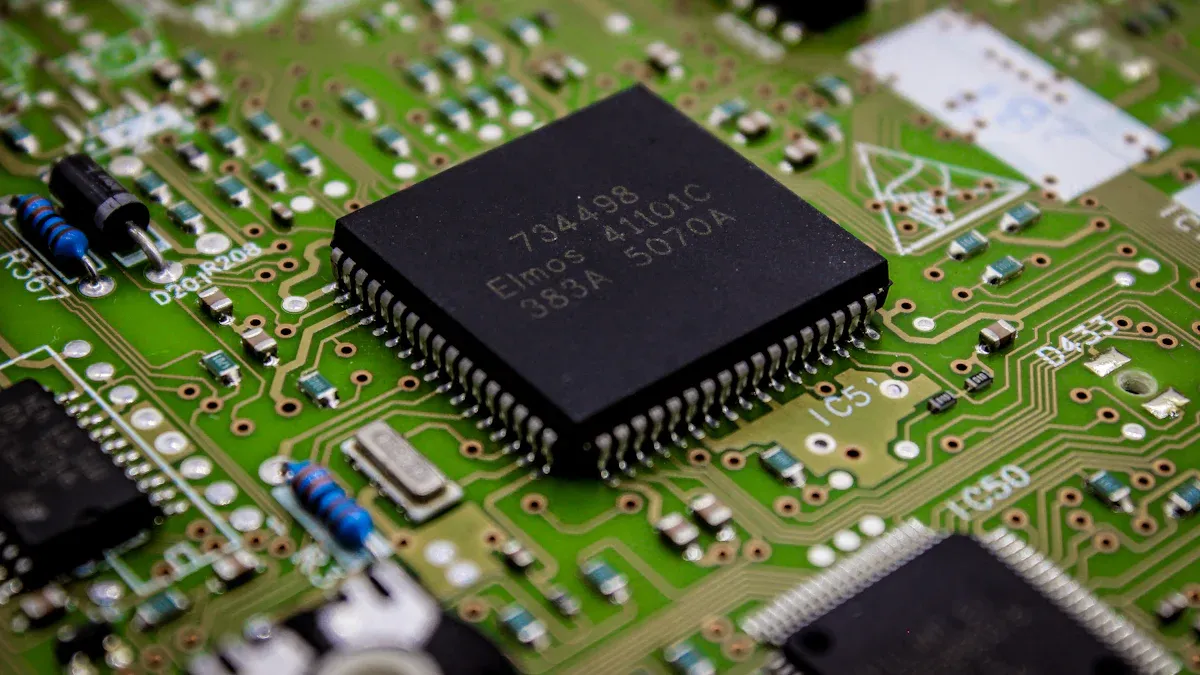

Through-Hole DIP PCBA: Manufacturing Process, Quality Control, and Industry Applications

Through-Hole DIP PCBA is important in today’s electronics, particularly in the manufacturing process. It provides strong reliability and lasts a long time, making it useful in places needing high performance. Its tough design handles shaking, impacts, and very hot or cold temperatures, ensuring it keeps working without stopping. This technology is used in key areas like airplanes and defense, where safety and working well are of utmost importance.

Key Takeaways

Through-Hole DIP PCBA is strong and long-lasting, perfect for tough jobs in fields like airplanes and cars.

Making it involves drilling holes, placing parts carefully, and soldering well to build good products.

Quality checks include detailed tests to find problems early, making sure the products follow strict rules.

Manufacturing Process of Through-Hole Assembly at LTPCBA

Precision Drilling for Through-Hole Components

Drilling holes is the first step in through-hole assembly. At LTPCBA, advanced tools make sure every hole fits perfectly. The process follows strict rules to ensure accuracy.

Important measurements for drilling include:

Hole Position Accuracy: Makes sure the hole is in the right spot, with a tolerance of ±0.05 mm.

Hole Diameter: Checks that the hole size is correct, with a tolerance of ±0.025 mm.

Circularity: Ensures the hole is round for a proper fit.

Barrel Hole Wall: Looks at the shape of the plated hole, which affects electricity flow.

Hole Breakout: Makes sure the hole exits cleanly for strong connections.

Drill Smear: Removes leftover resin to improve stickiness and conductivity.

These careful drilling steps make the design strong and dependable, even in tough conditions.

Component Insertion Techniques

Placing through-hole parts needs to be exact and steady. LTPCBA uses both hand and machine methods for this. Hand placement works best for small projects, while machines handle bigger jobs.

Studies show peg-in-hole methods are widely used in factories. Over 35% of assembly tasks depend on this method. At LTPCBA, robots with special hands place parts accurately. This reduces mistakes and improves the assembly's quality.

Soldering Methods for Through-Hole Assembly

Soldering attaches through-hole parts to the board, creating strong connections. LTPCBA uses two main soldering methods:

Wave Soldering: Good for large batches, this method passes the board over melted solder for even connections.

Selective Soldering: Best for tricky designs, this method focuses on specific areas to avoid heat damage.

Both methods follow strict rules to ensure strong and lasting connections.

Inspection and Testing in the Manufacturing Process

Checking and testing are key to keeping through-hole assembly high-quality. LTPCBA uses several steps to meet industry standards.

Evidence Type | Description |

|---|---|

Acceptable Quality Levels (AQL) | Sets the highest number of defects allowed in a sample. |

Counts defects per million parts to measure quality. | |

Statistical Quality Control (SQC) | Uses past data to find and fix problems during production. |

LTPCBA also runs tests like ICT, FCT, and Burn-In to check how well the assembly works. These tests make sure the product is reliable in real-world use.

By using advanced tools and strict checks, LTPCBA creates high-quality through-hole PCB assemblies for many uses.

Quality Control Steps for Through-Hole DIP PCBA

Checking Through-Hole Parts by Eye

Looking at parts carefully helps find problems early. You can spot issues like crooked parts or bad soldering. This step stops bigger problems before testing starts. At LTPCBA, workers check parts after important steps to keep quality high.

Inspection Type | What It Does | Why It Matters |

|---|---|---|

Finds clear problems during assembly. | Catches mistakes early, keeping quality high before testing. | |

Automatic Check | Uses tools like cameras and X-rays to find issues. | Covers more ground but may not be as simple as looking by eye. |

Strength Check | Makes sure solder joints stay strong under stress. | Helps the board last longer and work better. |

By mixing hand checks and machine checks, LTPCBA makes sure parts meet strict rules.

Using Machines to Inspect Through-Hole Boards

Special machines help find tiny problems in through-hole boards. These machines use cameras to look for missing parts or bad soldering. They scan the whole board to catch things people might miss.

At LTPCBA, these machines work with hand checks to find all issues. They are great for tricky designs where small mistakes can hide. This makes the final product very reliable.

Testing to Make Sure Boards Work

Testing checks if boards work like they should in real life. LTPCBA tests boards by pretending they are in use. They check how the board works as a whole and fix any problems.

Test Type | What It Does |

|---|---|

Finds assembly mistakes, broken parts, and fixes problems. | |

Assembly Test | Tests the whole board, including software and hardware, for issues. |

PCBA Test | Uses special tools to test one board or part at a time. |

These tests make sure the boards work well and last a long time.

Following Important Rules at LTPCBA

LTPCBA follows strict rules to make safe and good boards. They meet global standards to ensure every product is top quality.

Rule/Standard | What It Covers |

|---|---|

ISO13485 | Medical device quality |

ISO14001 | Environmental safety |

IPC | Electronics manufacturing rules |

UL | Safety checks |

SGS | Testing and certification |

RoHS | Limits harmful materials |

By following these rules, LTPCBA makes boards that are safe, reliable, and eco-friendly. You can trust their products to meet high standards.

Industry Applications of Through-Hole DIP PCBA

Automotive and Transportation Systems

Through-hole assembly is key in cars and transport systems. It is used in engines, brakes, and vehicle communication parts. Its tough design works well with shaking and temperature changes. For example, electric cars use it in battery systems and power inverters. These parts need strong links to handle heat and high currents. The rise of self-driving cars and smart transport shows its growing importance.

Aerospace and Defense Applications

Through-hole assembly is very reliable for planes and defense tools. It works well in tough places like high skies or battle zones. This technology makes strong connections that resist shocks and shaking. For example:

It creates strong links in layered boards.

It handles heat, perfect for military tools.

Pin bending adds strength, making it more reliable.

These features are vital for systems like radar, avionics, and missile controls.

Consumer Electronics and Home Appliances

Through-hole assembly is also used in home gadgets and electronics. TVs, washing machines, and air conditioners depend on it for control boards. It helps these devices work well for a long time. Manual DIP switches, a key part in these gadgets, are in high demand. More smart devices and automation are driving this growth. Through-hole assembly is a cheap and durable choice for making these products.

Industrial and Medical Equipment

Factories and medical tools need reliable parts, so they use through-hole assembly. In factories, DIP switches set up motor controllers and PLCs. Medical tools like monitors and imaging systems use its strong connections.

Factor | What It Means |

|---|---|

Works well in important tasks. | |

Environmental Adaptability | Handles tough places like factories or hospitals. |

Cost-Effectiveness | A low-cost option for older systems in growing areas. |

The rise of smart factories and embedded systems increases its demand. Even with new digital options, through-hole assembly stays useful thanks to innovation.

Through-Hole DIP PCBA is known for its strong build and careful checks. These steps make sure it works well in tough conditions. It is useful in many fields, like airplanes and home gadgets.

Learn about LTPCBA’s skill in Through-Hole Assembly. Using modern tools and following global rules, LTPCBA creates top-quality products just for you.

FAQ

Why is Through-Hole DIP PCBA stronger than SMT?

Through-hole parts go through the PCB, making them stronger. They are great for places with shaking or extreme temperatures.

Can Through-Hole DIP PCBA manage high-current systems?

Yes, it can handle high currents. Strong solder joints and big leads make it work well in power-heavy systems.

Why pick LTPCBA for Through-Hole Assembly?

LTPCBA uses modern tools and strict checks. They follow global rules to make reliable and high-quality through-hole PCB assemblies just for you.

💡 Tip: Check out LTPCBA to learn more about their Through-Hole Assembly and other PCB services.

See Also

An In-Depth Overview of PCBA Manufacturing For All Levels

Understanding SMT and DIP Assembly in PCBA Processes

The Importance of AOI in Ensuring PCBA Quality

Top 5 Testing Techniques for Through Hole PCB Assembly

Complete PCBA Solutions: From Manufacturing to Assembly Testing