Through Hole Assembly Services for Industrial Control Applications

Through Hole Assembly uses parts with leads that go through holes in a printed circuit board. Industrial control systems need this method for strong connections. It also helps the parts last a long time. This method keeps parts safe from shaking or changes in temperature.

Many industries, like aerospace and defense, want assemblies that work well for a long time.

LTPCBA gives trusted solutions. They focus on quality and making customers happy.

Key Takeaways

Through Hole Assembly makes strong and lasting connections. These connections can handle shaking and changes in heat. This method holds big and heavy parts well. It can also carry more power. This is good for control systems in factories, planes, and cars. LTPCBA gives fast and high-quality through hole assembly. They have experts to help and check the work. They use strict checks and have certifications. This makes sure the results are dependable.

Through Hole Assembly Overview

What It Is

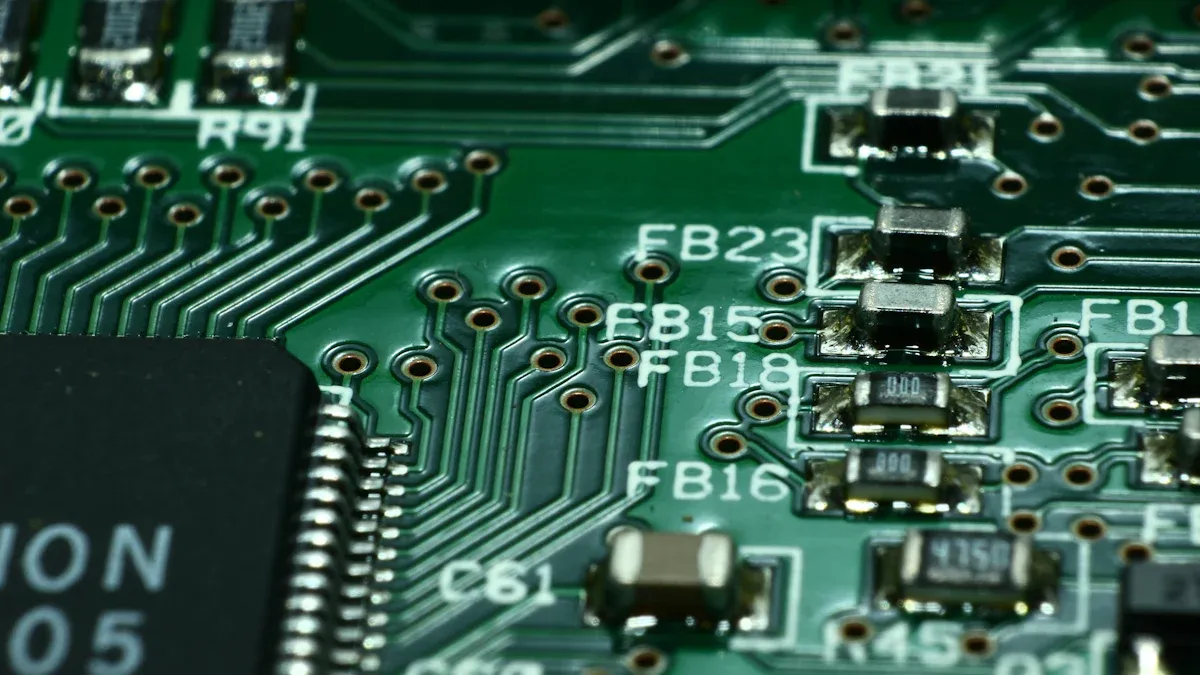

Through Hole Assembly is a way to put electronic parts on a printed circuit board. Technicians push the leads of each part into holes drilled in the board. They then solder the leads to pads on the other side. This makes strong electrical and mechanical connections. There are two main kinds of holes used. Plated Through Holes (PTH) have a layer that lets electricity move between layers of the board. Non-Plated Through Holes (NPTH) do not have this layer. NPTH are often used for mounting or for single-sided parts.

Parts used in this process can be passive, like resistors or capacitors. They can also be active, like integrated circuits or transistors. Axial leads go from one end of the part to the other. Radial leads come out from one side, which saves space on the board. The assembly process follows strict rules to make sure it is good and reliable.

Note: The right hole size, pad size, and soldering method are important for a strong connection. Technicians check solder joints and sometimes use a coating for extra safety.

The table below shows important technical standards and things to think about for through hole assembly:

Aspect | Description / Specification |

|---|---|

Definition | Through-hole assembly means putting leaded parts through drilled holes in a PCB, then soldering them. |

Hole Types | Plated Through Holes (PTH) and Non-Plated Through Holes (NPTH) |

Component Lead Types | Axial leads (leads go in and out opposite ends), Radial leads (leads go out the same side) |

Key Standards | IPC 610 A, J-STD-001 |

Drill Hole Size | Minimum hole size = Maximum lead diameter + 0.25 mm (Density A), +0.20 mm (Density B), +0.15 mm (Density C) |

Annular Ring Size | The ring must be big enough for strong solder joints |

Pad Size Formula | Pad diameter = Minimum hole size + (2 x Minimum annular ring) + extra space (0.6 mm for Density A, 0.5 mm for B, 0.4 mm for C) |

Solder Mask Relief | Standard is 4 mils between solder mask and pads or rings |

Solder Fill | 100% fill is best but 75% is okay for Class 2 and 3 boards |

Clearance | Enough space in holes helps solder flow; tight holes may need soldering on both sides |

Assembly Considerations | Put leads from top to bottom, bend leads above solder, check solder joints, use coating for protection |

Advantages | Strong connection, good for big parts, easy to replace by hand, handles more power |

Key Benefits

Through Hole Assembly gives many good things for industrial control uses:

Strong Mechanical Bonds: This process makes tough connections that can handle shaking and stress. This matters for machines in rough places.

Reliable Electrical Performance: Soldered leads give steady paths for electricity, so parts last longer.

Easy Inspection and Repair: Technicians can look at solder joints and change parts if needed, which helps with fixing things.

Support for Large Components: This way works well for big or heavy parts that need more support.

High Power Handling: Through hole connections can carry more current, so they work for power devices.

New research in smart manufacturing shows that better detection methods help through hole assembly. For example, one study used many PCB images and a better object detection tool. The results showed much better accuracy, even for small or hard-to-see holes. This research proves that through hole assembly works well in real factories.

Tip: Many industries pick through hole assembly because it is reliable and easy to fix, especially in important control systems.

Importance for Industrial Control

Reliability Needs

Industrial control systems must work all the time. Even a short stop can cost money or cause danger. Through-hole assembly is known for being strong and lasting a long time. Solder joints in this method make tight connections. These connections do not break from shaking or heat changes. That is why factories, power plants, and big machines use through-hole technology.

Industries like aerospace and defense trust through-hole assemblies for important equipment. These fields need electronics that work in tough places and never stop. The design process uses careful checks and good materials. Workers get special training to build these assemblies. Quality tests, like in-circuit and functional testing, make sure each board works right. People also look at boards by hand and with machines to find problems early.

People who work in factories like through-hole assemblies. They are simple to fix and keep working. This helps stop long breaks and keeps machines running.

Environmental Demands

Electronics in factories face dust, water, shaking, and hot or cold air. Through-hole assemblies are made to handle these things. They follow strict rules like IPC-A-610 and IPC-J-STD-001. These rules say how to solder, check, and make strong boards.

Assemblies go through many tough tests, such as:

Shaking tests

Hot, cold, and wet air tests

Burn-in and working tests in real life

Makers pick materials that can take heat and chemicals. Some designs use gaskets to keep out water and dust. All these steps help through-hole assemblies last a long time, even in hard places.

Through Hole Assembly vs. SMT

Main Differences

Through Hole Assembly and Surface Mount Technology use different ways to put parts on a printed circuit board. Through Hole Assembly puts leads through holes and solders them on the other side. SMT puts parts right on the board’s surface with solder paste. Machines help SMT work fast.

The table below shows how these two methods are not the same:

Factor | Through-Hole Assembly (THT) | Surface Mount Technology (SMT) |

|---|---|---|

Initial Setup Cost | Higher ($50,000 to $500,000+) | |

Component Size | Larger, with leads | Smaller, compact SMDs |

Manufacturing Throughput | Slower, manual steps | Faster, automated lines |

Repair & Maintenance | Easier, uses basic tools | Harder, needs special tools |

Component Density | Lower (10-20 per sq. inch) | |

Mechanical Strength | Stronger, better for vibration | Weaker, can crack under stress |

Power Handling | Handles more current and heat | Suited for low-power, high-speed circuits |

Note: SMT is best for small, fast devices. Through Hole Assembly is better for strong connections in big or powerful parts.

Industrial Use Cases

Many companies use Through Hole Assembly for control systems that need to be strong and last a long time. Aerospace companies like this method because it makes joints that do not break easily. Car makers use through-hole PCBs in control modules for their strength. Factories use through-hole boards in motor controllers, power supplies, and sensors. These boards hold heavy parts and carry lots of current.

Aerospace needs strong, steady connections.

Cars use through-hole for tough control modules.

Factories use through-hole for hot and rough parts.

Power devices like transformers and connectors work best with through-hole boards.

Through Hole Assembly also makes fixing things easier. Technicians can swap out parts fast. This helps control systems work well for many years.

LTPCBA Through Hole Assembly

Service Capabilities

LTPCBA gives advanced help for industrial control jobs. The company uses modern machines and automated tools for accurate Through Hole Assembly. Their team works on every step, from first samples to making many boards. They focus on doing things fast and getting them right.

LTPCBA can handle many types of parts and hard board designs. Their engineers do full tests that copy real factory situations. These tests check power supplies, interfaces, and special functions. This makes sure each PCB can work well in tough places.

The company is known for quick service. LTPCBA sends price quotes in 2-3 days. They also have 24/7 help from a team of 12 experts. This fast service helps customers finish projects on time and fix problems quickly.

LTPCBA’s lines have a 99.5% pass rate and over 98% on-time delivery. Their first-pass yield is over 99%, showing they care about doing a good job.

Metric/Feature | LTPCBA Performance / Description |

|---|---|

Quality Pass Rate | 99.5% quality pass rate showing high trust |

On-Time Delivery Rate | Over 98% on-time deliveries showing fast service |

First-Pass Yield | More than 99% first-pass yield showing great production quality |

Technical Support Team | 12 experts giving 24/7 fast help and answers |

LTPCBA’s work with industrial control means each project gets expert care. Their engineers know what these systems need, like strong bonds and steady electrical work.

Quality Standards

LTPCBA keeps high quality at every step. The company has many world certifications that show they care about safety and quality.

Certification | Significance in Quality Standards |

|---|---|

ISO 9001:2015 | Sets up quality systems for happy customers and steady results. |

ISO 13485:2016 | Focuses on quality and risk for medical device making. |

IATF 16949 | Works to stop mistakes and improve quality in car parts. |

UL Certification | Proves products are safe and meet safety rules. |

These certificates show LTPCBA wants to meet top industry rules. The company also follows IPC-A-610 and RoHS, which helps make every Through Hole Assembly safe and reliable.

LTPCBA uses smart inspection tools, like automated optical inspection and function tests. These steps find problems early and make sure each board works well in hard places.

Customers trust LTPCBA because they have high pass rates and care about quality. Their full support, from design to delivery, makes them a good partner for industrial control jobs.

Choosing a Provider

What to Look For

Picking the best company for industrial control assembly is important. You need to think about many things before you choose.

The company should work with single, double, multi-layer, flexible, and rigid PCBs.

They must know how to do SMT, through-hole, and mixed technology assembly.

Good companies use strong quality checks. They stop mistakes, use good materials, and test with Automated Optical Inspection and functional testing.

Look for industry certifications like ISO 9001, UL, IPC Class 3, AS9100d, and IATF16949.

Compare cost and value. Higher prices should mean better quality and fewer problems.

Think about lead times and where the company is. This helps with shipping and talking to them.

Customer service should answer fast and help after you buy.

The company should test with In-Circuit Testing, flying probe, X-ray, and sample runs before making lots of boards.

Check their reputation. Read case studies and see what other customers say.

Companies should use AOI, X-ray, and ICT to find problems early. Good part sourcing and tracking stop fake parts from getting in. The best companies deliver on time and manage projects well.

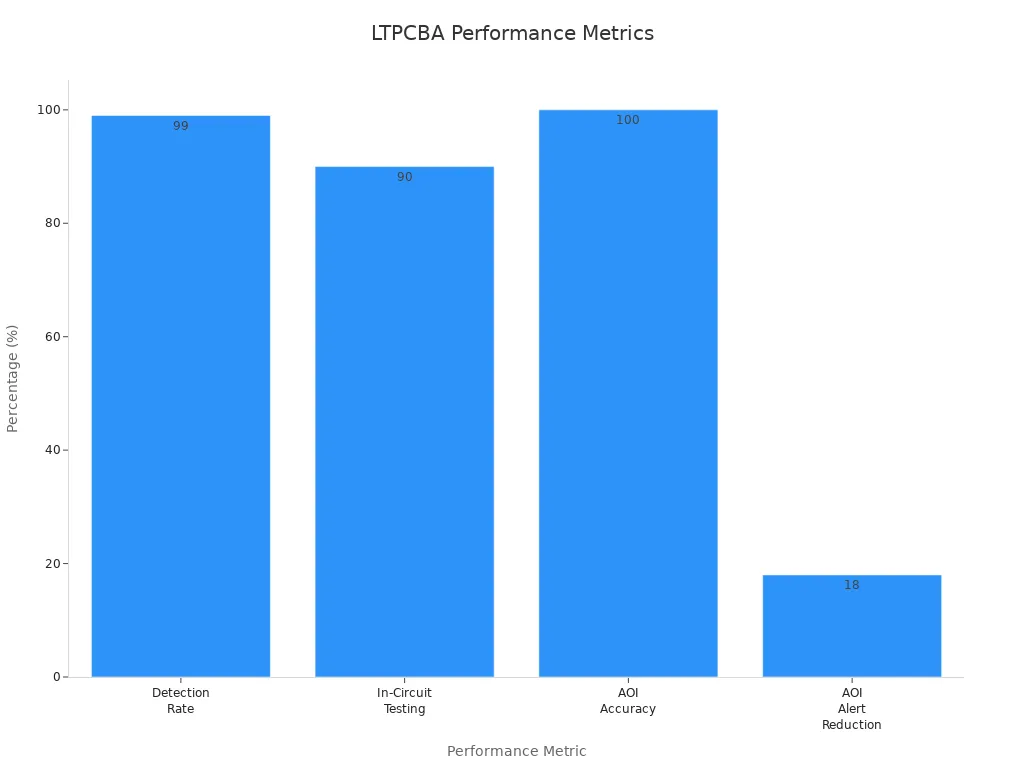

Why Choose LTPCBA

LTPCBA is a top choice for industrial control jobs. They find 99% of problems in manufacturing. They use advanced tests like ICT, AOI, functional, and burn-in testing. These steps make sure the assemblies are high quality and last a long time.

LTPCBA has important certifications like ISO 9001, IATF16949, and UL. Their technical team gives help all day and night and answers quickly. Customers get high pass rates, on-time delivery, and help from start to finish. These things make LTPCBA a smart pick for tough industrial control projects.

Industrial control systems need assemblies that are strong and reliable.

Good soldering helps the parts last a long time.

These assemblies can handle lots of power for tough jobs.

Strong connections help parts stay in place during shaking or bumps.

LTPCBA gives quality you can trust, checks their work carefully, and has experts to help. You can learn more about LTPCBA’s services or ask for a price quote today.

FAQ

What types of components work best with through hole assembly?

Through hole assembly is good for big or heavy parts. It works well for parts that use a lot of power. Some examples are transformers, connectors, and relays. These parts are often used in industrial control systems.

How does LTPCBA ensure quality in through hole assembly?

LTPCBA uses special inspection tools to check their work. They follow strict rules from around the world. Their workers are trained and skilled. The company has a 99.5% pass rate for products they deliver.

Can LTPCBA handle urgent orders for industrial control projects?

Yes. LTPCBA gives fast price quotes in 2-3 days. They also have 24-hour help for urgent project needs.

See Also

Selecting The Best Through-Hole PCB Assembly For Industrial Use

Complete Overview Of Through-Hole PCB Assembly Techniques

Comparing SMT And Through-Hole PCB Assembly For Electronics