Through hole assemblies you can trust for sturdy builds

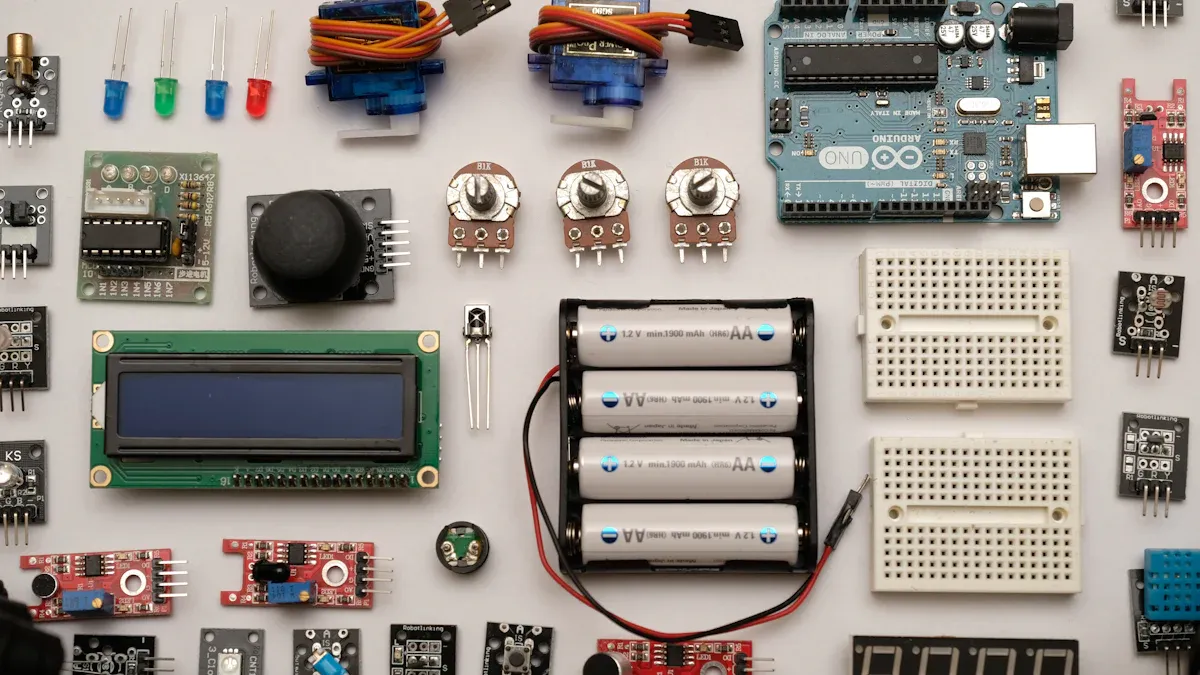

You see through hole assemblies with important parts like resistors, capacitors, diodes, transistors, integrated circuits, connectors, switches, relays, and fuses. These components, featuring axial or radial leads, make through hole assemblies easy to assemble and highly durable. Through hole assemblies create strong mechanical bonds, making them ideal for demanding environments. At LTPCBA, every through hole assembly is thoroughly inspected to meet strict quality standards, ensuring you receive reliable through hole assemblies tailored to your requirements.

Key Takeaways

Through-hole assemblies make strong and long-lasting connections. They do not break easily from shaking, heat, or stress. This makes them great for cars, planes, and factories.

These assemblies use parts with leads that go through the circuit board. This makes it easy to fix or change parts. It also helps your projects last a long time.

LTPCBA makes sure through-hole assemblies are high quality. They follow strict rules and check their work carefully. You can trust them to make reliable and sturdy builds.

Through Hole Assemblies Overview

Key Component Types

Through hole assemblies have many important parts. These include resistors, capacitors, diodes, transistors, integrated circuits, connectors, switches, relays, and fuses. Each part has a job in your printed circuit boards.

Resistors control how much current and voltage move in your circuits.

Capacitors keep and let out energy, so they help with filtering and timing.

Diodes let current go one way and keep your circuits safe.

Transistors work as switches or make signals stronger.

Integrated circuits put many jobs into one part.

Connectors and switches give strong links and let you control things.

Relays and fuses keep your printed circuit board safe from too much power.

There are two main lead types in through hole technology. Axial leads go from one end of the part to the other. Radial leads stick out from the same side. Knowing this helps you pick the right layout for your assembly.

Why Choose Through Hole Technology

Through hole technology gives you strong and steady builds. The leads go through the printed circuit board and get soldered on the back. This makes a tough bond that can handle shaking and stress. You will see through hole assemblies in places like factories, cars, and airplanes where things need to last.

Through hole technology fits many sizes and types of parts. It makes it easier to solder by hand and fix things. You can test and check your assembly without much trouble. The solder joints in through hole assembly can take heat and force. This helps your assemblies last longer, even when things get rough.

At LTPCBA, you get great quality checks. The team does design reviews, uses machines to test, and follows strict rules. Every through-hole assembly meets big standards like IPC-A-610 and ISO 9001. You can count on LTPCBA to give you reliable through hole assemblies for your hardest jobs.

Resistors in Through-Hole Assembly

Axial and Radial Types

There are two main resistor types in through-hole assembly: axial and radial. Axial leaded resistors have leads on both ends. You put these standing up from the PCB surface. This type is strong but uses more space on your board. Radial leaded resistors have both leads on one side. You lay these flat on the PCB surface. This saves space and is good for small designs.

Aspect | Axial Leaded Resistors | Radial Leaded Resistors |

|---|---|---|

Construction | Leads come out from both ends of the part | Leads come out from the same side of the part |

Mounting Orientation | Stands up from the PCB surface | Lays flat on the PCB surface |

Space Occupied | Uses more space, bigger size | Saves space, fits small or crowded boards |

Mechanical Stability | Very strong and tough | Not as strong as axial leads |

Suitability for Automation | Not as good for machines to assemble | Works better with machines in factories |

Typical Applications | Good when you need strength and toughness | Great for small designs and new PCB builds |

You pick which type to use by thinking about space and strength.

Reliability and Applications

Through-hole resistors make strong and steady connections. The leads go through the PCB and get soldered tight. This helps parts handle shaking, bumps, and heat. You find these resistors in cars, planes, and big machines where they must work well.

Soldering the leads through the board keeps them in place.

These parts work in places with lots of power and heat.

In tough places, they can last ten years with very few problems.

You can fix or swap these parts easily when needed.

At LTPCBA, experts put resistors together with care. The team solders carefully and checks quality every time. Each assembly meets high standards, so your projects stay safe and work well.

Capacitors for Through Hole Technology

Electrolytic, Ceramic, Film

There are three main capacitor types in through hole technology: electrolytic, ceramic, and film. Each type has special features for your assemblies. Electrolytic capacitors hold a lot of charge and work well in power supply circuits. You must watch their polarity when putting them in. Ceramic capacitors do not have polarity and are very reliable. These parts can handle voltage changes and fit many designs. Film capacitors last a long time and work well for filtering and timing.

The way the leads are set up changes how you place them on your board. Radial lead capacitors have both leads on one side, so they save space and stand up straight. Axial lead capacitors have leads on both ends, giving you more ways to arrange them. You need to think about where and how to put each one to get the best results.

Tip: Always look at the lead direction before you solder. This step helps stop mistakes and keeps your parts safe.

Mechanical Strength

Through hole technology makes your assemblies strong. The leads go through the PCB and get soldered on the other side. This makes a tight bond that can take shaking, bumps, and heat changes. Through hole parts are tougher than surface-mount ones. Tests show through hole technology can handle over 1,000 hot and cold cycles before wearing out. These parts do not break easily, so they are good for cars, planes, and factories.

You will see through hole technology helps your assemblies in hard places. Soldering these parts gives a tight fit and long life. You can count on through hole technology to keep your circuits working, even when things get rough.

Inductors and Coils

Common Types

You can find many kinds of inductors and coils in through-hole assemblies. These parts help your circuits work well and stay steady. Here are some types you might use:

Air core inductors have a ceramic or no core. You see these in high-frequency circuits and radios.

Laminated core inductors use steel layers to stop extra currents. These are good for transformers and noise filters.

Ferrite core inductors have a special iron core. You use them in power electronics and radio circuits.

Bobbin-based inductors have wire wrapped on a bobbin. These fit in power adapters and power supplies.

Axial fixed inductors have a coil around a small ferrite bobbin. You find these in high-frequency circuits and filters.

Multilayer chip inductors have many ceramic and metal layers. These work in communication gear and motherboards.

Here is a table to help you compare these parts:

Inductor Type | Construction Highlights | Typical Applications |

|---|---|---|

Air Core Inductor | Ceramic or no core, steady ceramic core | RF/IF tuning, filter circuits |

Laminated Core Inductor | Steel layers, coil on bobbin | Transformers, line filters, noise filters |

Ferrite Core Inductor | Iron oxide core | Power electronics, RF circuits |

Bobbin-Based Inductor | Coil on bobbin, shrink tube for safety | Power adapters, pi filters, power supplies |

Axial Fixed Inductor | Coil on ferrite bobbin, color rings | RF circuits, buck-boost converters, filters |

Multilayer Chip Inductor | Many ceramic and metal layers, small size | Mobile devices, communication gear |

Benefits in Through-Hole Assembly

When you use through-hole inductors and coils, you get strong and steady parts. The leads go through the board and get soldered, so the parts stay put even if the board shakes. These parts can handle more power and heat because of their size and how they are mounted. You can use them in power supplies, car electronics, and factory control systems.

Through-hole mounting lets heat move away better. The parts stay cooler and last longer.

You can fix or swap these parts easily. The pins are easy to reach and solder.

These parts work well in places with lots of power and shaking. You see them in cars, factories, and communication gear.

You get strong connections. The parts resist shaking and bumps.

Note: If you pick through-hole parts, your assemblies will be stronger and easier to fix.

Diodes and LEDs

Standard Diodes

Diodes are important in many through-hole assemblies. They let current move in only one direction. Signal diodes, like the 1N4148, switch fast in small circuits. Power rectifier diodes, such as the 1N4001 to 1N4007, handle more current. They help change AC power to DC power. Schottky diodes have a low forward voltage drop. They also switch very quickly. These are good in power supplies to save energy. Zener diodes keep voltage steady and protect circuits from spikes.

Here is a table with common through-hole diode and LED parts:

Component Type | Common Examples | Key Features and Uses |

|---|---|---|

Signal Diodes | 1N4148 | Fast switching, low capacitance, used in small-signal applications. |

Power Rectifier Diodes | 1N4001 - 1N4007 | 1A current, voltage ratings from 50V to 1000V, used for AC to DC rectification. |

Schottky Diodes | Various 1A 40V types | Low forward voltage drop, very fast switching, used in switching power supplies. |

Zener Diodes | 5.1V, 18V common | Precise reverse breakdown voltage, used for voltage regulation and protection circuits. |

LEDs | 3mm, 5mm, 10mm sizes | Forward voltage varies by color, used for indication, lighting, and optical isolation. |

Through-Hole LEDs

Through-hole LEDs show power, status, or alerts on devices. They come in sizes like 3mm, 5mm, and 10mm. You can get them in red, blue, or green. The cathode has a flat edge or a band on the LED. The forward voltage depends on the color. Red LEDs use about 2.2V. Blue LEDs use about 3.3V.

Through-hole LEDs stay in place very well. They can handle shock, vibration, and heat better than surface-mount LEDs. You can use them in tough places where you need strong parts.

Through-hole LEDs last a long time and do not fall out if the board shakes. You can replace or fix them easily. People use them in control panels, machines, and outdoor gear. When you need strong and reliable parts, through-hole LEDs are a good pick.

Transistors and ICs

DIP Packages

DIP transistors and ICs are common in through-hole assemblies. These parts have two rows of pins. The pins fit into holes on your PCB. You can put these parts in by hand. DIP sockets let you add or take out ICs without soldering. This helps stop damage. It also makes your assemblies easier to fix and more reliable.

DIP packages keep your parts in place. They do not move, even if the board shakes.

You see these parts in microcontroller projects and breadboards.

DIP components are cheap and easy to find.

You can swap or test these parts fast. This makes building and fixing circuits easier.

Here is a table that shows why DIP packages are good:

Feature | Benefit for Your Assembly |

|---|---|

Easy to handle | You can put them in by hand |

Strong connection | They stay in place and do not wiggle |

Serviceable | You can change or fix them easily |

Cost-effective | They do not cost much and are easy to get |

Secure Mounting

Through-hole mounting gives you strong and long-lasting assemblies. The leads go through the PCB and get soldered on the other side. This makes a tight bond that can take shock, shaking, and heat. Your parts will not fall out, even in cars or planes.

Through-hole mounting helps parts handle more heat. The big leads and holes let heat move away. This helps your devices last longer. You also get more room for mistakes when putting parts in. This means your boards work better. If you need to check or fix your parts, through-hole assemblies make it simple.

Tip: For big or heavy parts, secure mounting is very important. It keeps your parts safe and working, even if the board moves.

You can trust through-hole assemblies for jobs that need to be very reliable. Many industries use this way for important parts because it keeps everything safe and steady.

Connectors, Switches, and Electromechanical Parts

Mechanical Stability

You want your assembly to last in hard places. Through hole technology gives you strong builds. When you use through hole connectors, switches, and electromechanical parts, you get tough connections. These parts can handle stress, shaking, and heat. The leads go through the PCB and get soldered on the other side. This makes a tight hold that stays strong. It works even if you plug and unplug cables or press buttons many times.

Many industries use through hole technology for strong builds. You see it in planes, cars, and power systems. These jobs need assemblies that work in tough conditions. Through hole connectors like pin headers, terminal blocks, and JST connectors stay in place even if the board shakes. Switches like toggle, slide, and push buttons keep working after lots of use. Electromechanical parts like relays and potentiometers also stay strong with this mounting.

Tip: Through hole technology helps your assemblies last where surface mount parts might not.

Here are some common parts you will find in these assemblies:

Pin headers and terminal blocks for strong wire links

JST connectors for safe battery and sensor connections

Toggle and push button switches for user control

Electromechanical relays for switching high power

LTPCBA’s Assembly Quality

You need a partner who knows how to build strong assemblies. LTPCBA uses advanced through hole technology to put together connectors, switches, and electromechanical parts with care. The team checks every step to make sure parts are mounted right. Machines look for problems early. Skilled workers solder each lead to make a solid hold.

LTPCBA’s assembly process follows strict rules. You get assemblies that meet ISO and IPC standards. The company’s experience with through hole technology means your connectors and switches will not come loose or break. You can trust LTPCBA to handle heavy or high-voltage parts. The team knows how to place and solder each part for the best strength.

When you pick LTPCBA, you get assemblies that last. Your projects will work in rough places because the parts stay put. You can count on LTPCBA’s quality for every assembly, from first samples to big orders.

Other Notable Components

Relays and Fuses

Relays and fuses are important in through-hole assemblies. Relays use switches with magnets to control big amounts of power. You find them in control panels for things like HVAC systems. They help run motors and compressors. Their radial leads make them stay in place well. This keeps them steady when things shake or get hot. Fuses keep your circuits safe by breaking the flow if too much current passes. If a fuse blows, you need to put in a new one. This protects other parts from getting hurt.

Relays are good when you need to turn circuits on and off many times. They last a long time and you can reset them. Fuses are best for simple, one-time safety. Both relays and fuses stop overloads and short circuits. Through-hole mounting makes them work well in hard places like factories, cars, and planes. You get strong links that can take hits and high heat.

Tip: Pick relays for automatic control. Use fuses for simple, cheap protection.

Specialty Parts

Specialty parts are important in custom assemblies. Sometimes you need parts that handle lots of power or can take shaking and heat. Through-hole mounting puts these parts in the right spot and holds them tight. This matters for cars, planes, and factory electronics. It is easier to fix or swap these parts, so your products last longer.

Specialty parts can be custom connectors, resistors for high heat, or shielded inductors.

Bigger leads make it easy to test and check your assembly.

Through-hole technology works for big jobs and special projects.

New tools and machines help put parts in the right place and stop mistakes.

These parts help your assemblies take stress, shaking, and heat.

You see specialty parts in tough industries. They help your assemblies stay strong and work well, even when things get rough.

You get strong builds when you use through hole technology for resistors, capacitors, diodes, transistors, and connectors.

Through hole technology works well where things shake a lot or need lots of power.

It makes fixing parts easy and gives printed circuit boards tough connections.

Pick LTPCBA if you want through hole technology you can trust for your printed circuit board projects.

FAQ

What makes through-hole assemblies stronger than surface-mount assemblies?

Through-hole assemblies use leads that go through the board. You get a stronger hold. These parts resist shaking and heat better than surface-mount parts.

Can you repair or replace through-hole components easily?

Yes, you can remove and replace through-hole parts with simple tools. This makes fixing your board much easier than with surface-mount parts.

Why should you choose LTPCBA for through-hole assembly?

You get strict quality checks, skilled workers, and fast support. LTPCBA follows ISO and IPC standards. Your assemblies stay reliable and strong for tough jobs.

See Also

Evaluating Reliability Between Through Hole And SMT PCB Assembly

An In-Depth Look At Through Hole PCB Assembly Techniques

Expert Tips For DIP Assembly And Managing Through-Hole Tolerances

Choosing Between SMT And Through-Hole For Your Electronics Build