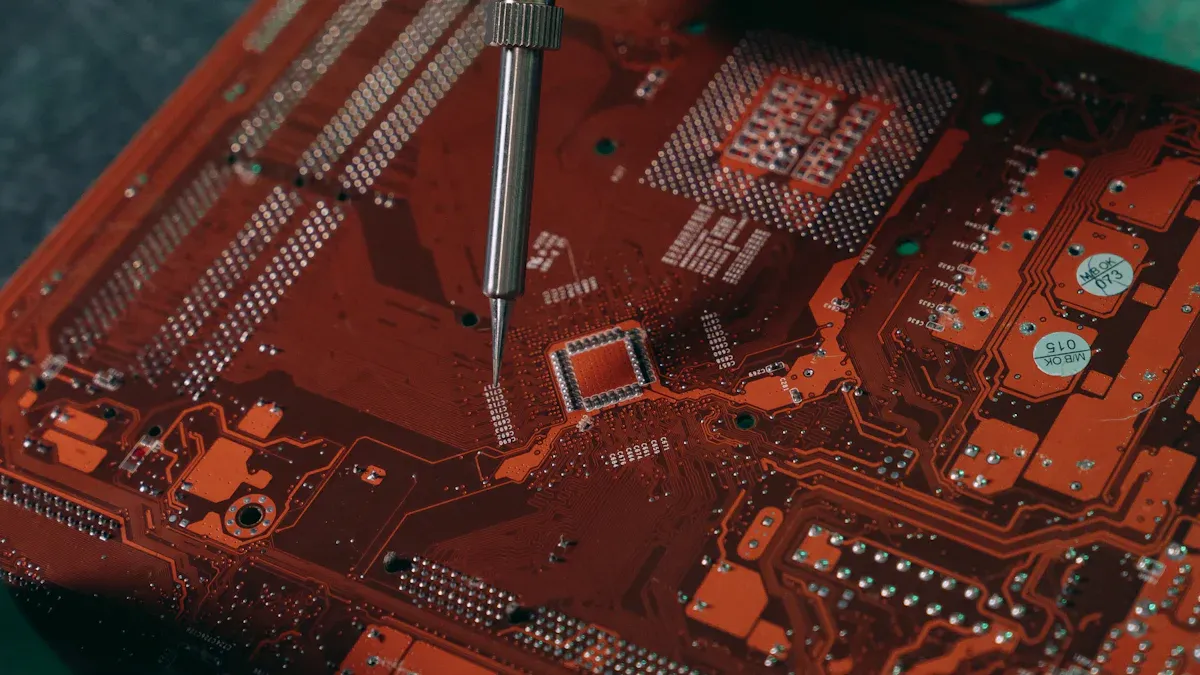

Technical issues that PCB board with VIPPO should pay more attention to during the smt assembly process

When using PCB boards with VIPPO in SMT, technical issues can arise. Solder bridging might create shorts in the circuit. Weak solder joints can cause circuits to stop functioning. Signal issues may reduce performance. Poor heat control can negatively impact the board's quality. Addressing these technical issues ensures the board operates effectively and maintains its durability.

Key Takeaways

Fix solder bridging by spacing pads better and changing oven heat. This stops short circuits and makes the board work better.

Use good flux and keep oven heat right for strong solder joints. This stops breaks and helps devices last longer.

Control heat well to stop problems like tombstoning. Good heat control keeps parts in place and makes the PCB work well.

Understanding VIPPO in SMT Assembly

What is VIPPO in PCB Design?

VIPPO stands for Via-in-Pad Plated Over. It is a special design used in PCBs. Copper is plated over the via to stop solder from flowing into it. This method is important for small and high-speed PCBs.

Here’s a simple look at VIPPO’s meaning, benefits, and problems:

Aspect | Details |

|---|---|

Definition | |

Advantages | - Makes PCBs smaller by saving routing space. |

- Shorter signal paths improve performance.

- Helps with fine-pitch BGA routing.

- Keeps capacitors closer for better heat control.

- No need for plugging vias under parts.

- Great for high-speed grounding. |

| Disadvantages | - Harder to make due to extra steps.

- Can cause air bubbles during soldering.

- Needs full filling to avoid trapped air.

- Must be flat for fine-pitch BGA soldering. |

Knowing these points shows why VIPPO is key for PCB design, especially in SMT.

The Role of VIPPO in SMT Assembly Processes

VIPPO helps make PCBs work better and last longer. It shortens signal paths, which improves performance and reduces issues. This is very useful for high-speed circuits.

In SMT assembly, VIPPO makes routing easier for small parts like BGAs. It also keeps capacitors close, helping with heat control and stopping overheating. But making VIPPO needs care. The via must be fully filled to avoid air pockets and ensure smooth soldering.

New materials and methods help solve VIPPO problems. For example, better via designs can stop BGA failures. These upgrades keep PCB assembly fast and reliable.

Using VIPPO allows for smaller, faster PCBs that meet today’s technology needs.

Common Technical Issues in SMT Assembly for PCB Boards with VIPPO

Solder Bridging: Causes and Solutions

Solder bridging happens when solder connects two pads by mistake. This creates a short circuit and can damage the board. Several reasons cause this problem:

Uneven component weight from poor PCB design.

Misplaced parts during assembly can lead to bridging.

Pads placed too close together make unwanted connections.

Wrong oven settings affect solder flow and cooling.

Too much solder paste increases bridging risks.

High heat during soldering can cause splashing or balling.

To fix solder bridging, try these solutions:

Change PCB design to improve pad spacing.

Adjust oven settings for even heating and cooling.

Use less solder paste to avoid extra connections.

Add solder masks to block unwanted solder flow.

These steps help reduce bridging and make boards more reliable.

Weak Solder Joints: Key Challenges

Weak solder joints can break easily and harm PCB reliability. These joints often fail under stress like shaking or temperature changes. Heat cycles can cause cracks and make joints fail over time.

This is a big problem for important devices like military electronics. Lead-free solder makes it harder because it lacks proven data compared to older materials.

To fix weak joints, improve the soldering process. Use good flux and set oven temperatures carefully. Check and repair joints often to stop problems early.

Signal Problems in PCB Assembly

Signal problems can lower PCB performance. Crosstalk happens when signals interfere with each other. Differential pairs need balance, or they lose signal quality.

Vias also affect signals, especially in fast circuits. Poor via designs can hurt signal strength. Timing issues like delay and jitter can mess up systems.

To fix signal problems, design PCBs with good spacing and shielding. Balance differential pairs and improve via layouts. These fixes improve signal quality and PCB performance.

Heat Control Challenges in SMT Processes

Good heat control is needed for strong PCB assembly. Parts get hot during soldering and need cooling to avoid damage. VIPPO designs help by placing capacitors near heat sources.

Bad heat control can cause parts to lift off the board. This problem, called tombstoning, needs fixing. Too much heat can also cause solder defects like holes.

To solve heat issues, adjust soldering heat profiles. Use better materials to spread heat evenly. Check boards often to find and fix heat problems quickly.

Best Practices for SMT Assembly with VIPPO by LTPCBA

Preparing the PCB Correctly

Getting the PCB ready is key for good SMT assembly. The board must meet standards and be free of defects. This step lowers risks and improves the final product's quality.

Important steps include checking standards, finding defects, and improving processes. These actions make the PCB more reliable, cut costs, and keep customers happy.

Metric/Guideline | Benefit Description |

|---|---|

Makes sure products follow rules, improving safety and reliability. | |

Cost Savings | Finding defects early lowers repair and production costs. |

Customer Trust | Good PCBs make better products, building customer confidence. |

Process Upgrades | Testing data shows ways to improve quality and efficiency. |

Risk Reduction | Fixes problems early to avoid recalls and protect reputation. |

Market Advantage | High-quality checks make products better and more competitive. |

Long-lasting Devices | Reliable boards help devices last longer and need fewer repairs. |

Following these steps gets the PCB ready for SMT assembly. It also helps avoid soldering problems like bridging or tombstoning.

Picking the Right Flux for SMT Assembly

Choosing the right flux is important for good soldering. Flux helps solder stick, cleans oxides, and strengthens solder joints. Using the wrong flux can leave residue and cause problems.

Rules like IPC 610 and J-STD-001 guide flux choices. These rules are based on tests showing how flux affects solder joints. They also set cleanliness standards for PCB assembly.

IPC 610 and J-STD-001 explain cleanliness rules for solder joints.

These rules use test data to guide flux selection.

Cleanliness standards help decide what flux works best for your PCB.

Using the correct flux makes soldering smoother and reduces defects. It also makes components more reliable during SMT assembly.

Keeping Equipment in Good Shape

Taking care of equipment is crucial for good soldering results. Regular maintenance stops problems like poor heat transfer or dirt buildup. These issues can cause soldering defects.

Different maintenance types can improve equipment performance:

Maintenance Type | Description | Benefits |

|---|---|---|

Preventive Maintenance | Regular checks to stop equipment from breaking. | Extends equipment life and avoids sudden failures. |

Predictive Maintenance | Uses data to predict when repairs are needed. | Fixes problems early, reducing downtime and improving reliability. |

Corrective Maintenance | Fixes equipment after it breaks. | Solves issues quickly but may increase costs if not planned well. |

Cleaning soldering tools often ensures good heat transfer and prevents defects. Predictive maintenance can spot problems early, keeping SMT assembly smooth.

By maintaining equipment, you avoid costly repairs and ensure strong solder joints. This leads to better and more reliable PCB assembly.

Post-Assembly Inspection and Testing for PCB Boards

Why Automated Optical Inspection (AOI) Matters

Automated Optical Inspection (AOI) is important for checking PCB quality. It uses cameras to find problems early, saving time and money. AOI can spot solder mistakes, misaligned parts, and physical damage.

Here are the main benefits of AOI:

Early Fault Detection: Finds problems early to avoid expensive fixes.

High Inspection Speed: Quickly checks PCBs for large-scale production.

Consistent Quality Control: Gives steady results without human mistakes.

Wide Range of Defects: Detects many issues like solder errors or misplaced parts.

Modern AOI systems with 3D imaging give accurate and repeatable results. This helps improve processes and fix defect causes. AI-powered AOI systems also boost production by adjusting automatically during assembly.

Using X-Ray Testing for Better Quality

X-Ray testing is great for finding hidden problems in PCBs. It detects solder issues, short circuits, and material defects early.

This method is especially useful for checking hidden solder joints in BGAs. Automated X-Ray Inspection (AXI) systems are used to ensure ICs and BGAs work properly. By catching these problems early, X-Ray testing avoids costly failures and ensures high-quality products.

Adding X-Ray testing to your SMT process improves quality and makes PCBs more reliable. It is a must-have for precise and high-performing PCB assembly.

PCB boards with VIPPO face many challenges during SMT assembly. Fixing solder bridging, weak joints, signal problems, and heat issues is important. These fixes help the board work well and last longer. Preparing the board properly and doing inspections improve assembly quality. LTPCBA provides expert services for reliable PCB assembly to meet your needs.

FAQ

Why is VIPPO important for fast PCB designs?

VIPPO makes signal paths shorter. This boosts speed and reduces signal mix-ups. It works well with small parts like BGAs. VIPPO is great for tiny, fast circuits.

How do you stop solder bridging in SMT assembly?

Fix pad spacing to keep them apart. Use less solder paste to avoid extra connections. Adjust oven heat settings for better solder flow. Solder masks can block unwanted solder.

Why does heat control matter in SMT processes?

Good heat control stops parts from breaking or solder problems. It helps the PCB last longer and work better.

See Also

Key Considerations for SMT Assembly of Rigid-Flex PCBs

Effective Methods for Cleaning PCB Boards Post-SMT Assembly

Top Strategies for Optimizing SMT Lines in PCBA Production