How to Streamline Hardware Assembly for Better Results

Putting hardware assembly together is important in making products. Using smooth steps helps save money and create high-quality items. Making these steps easier reduces mistakes and saves time. New ideas can solve common problems, helping you work faster and achieve your goals.

Key Takeaways

Making hardware assembly simpler lowers costs and boosts quality. Use better workflows to save time and avoid mistakes.

Using machines and new tech, like robots, speeds up work. These tools help get more done and improve accuracy.

Teaching workers is key to doing well. Trained workers make fewer errors and help keep the process safe and smooth.

Challenges in Hardware Assembly

Workflow inefficiencies and production bottlenecks

Hardware assembly often gets delayed by slow workflows. Poor teamwork and old methods can cause these delays. These problems raise costs and lower productivity. Studies show better workflows can improve productivity by up to 18.8% and cut costs by nearly 20%. Predictive analytics also work better, beating older methods by over 37%.

Evidence Type | Improvement Metrics |

|---|---|

Productivity Improvement | 15.81-18.8% |

Cost Reduction | 19.73% |

Overall Equipment Effectiveness Gain | 30% |

Predictive Analytics Accuracy | 62.53% vs 24.69% |

Data-Driven Approach Advantage | 37.84% over observation |

Using data-driven methods can fix delays and make work smoother.

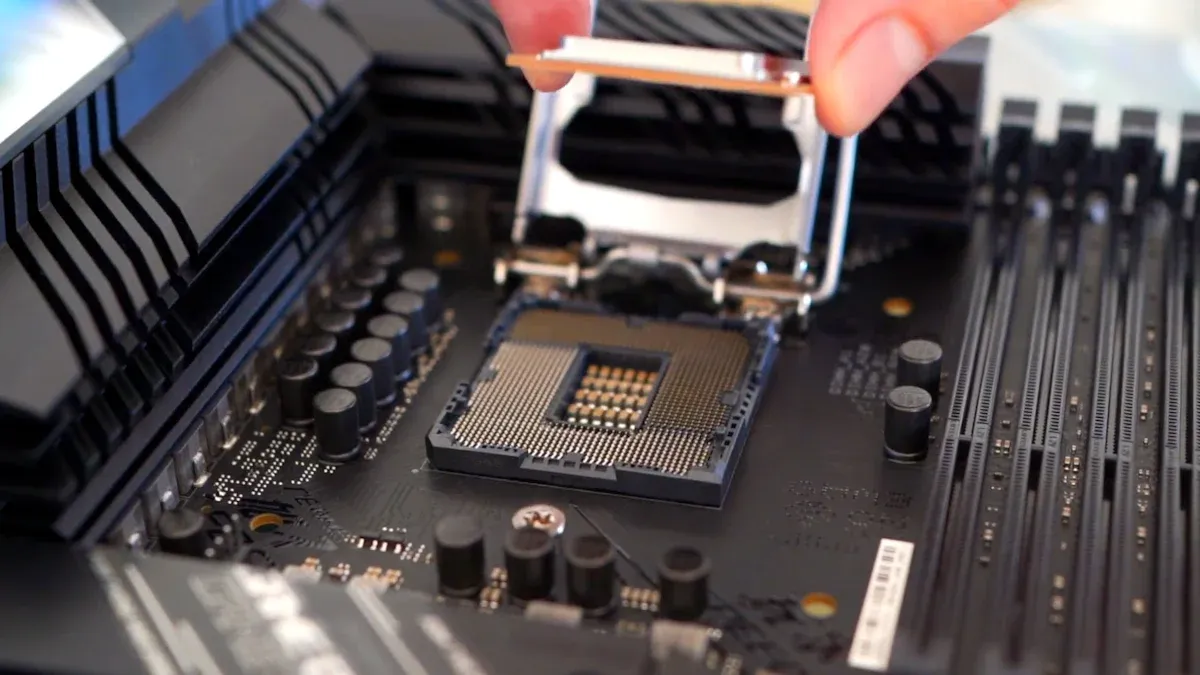

High labor costs and manual assembly errors

Manual assembly needs a lot of workers, which costs more money. Workers can also make mistakes that hurt product quality. Fixing these mistakes takes time and slows things down. Automating tasks lowers labor costs and reduces errors. For example, robots can do hard tasks with great accuracy. Training workers to use new tools makes work even better.

Limited adoption of automation and advanced technologies

Many companies avoid automation because it costs too much or doesn’t fit their needs. From 2016 to 2018, only 3.2% of companies used AI, and 2% used robots. Almost half of the companies didn’t use advanced tools at all. Older companies often stick to old ways instead of trying new ones.

Only 3.2% of companies used AI, and 2% used robots from 2016 to 2018.

9.6% of companies used special equipment, 40.2% used special software, and 34% used cloud computing during this time.

High costs and lack of fit stop companies from using new tools.

Using automation can make hardware assembly faster and more dependable.

Effective Strategies for Streamlining Hardware Assembly

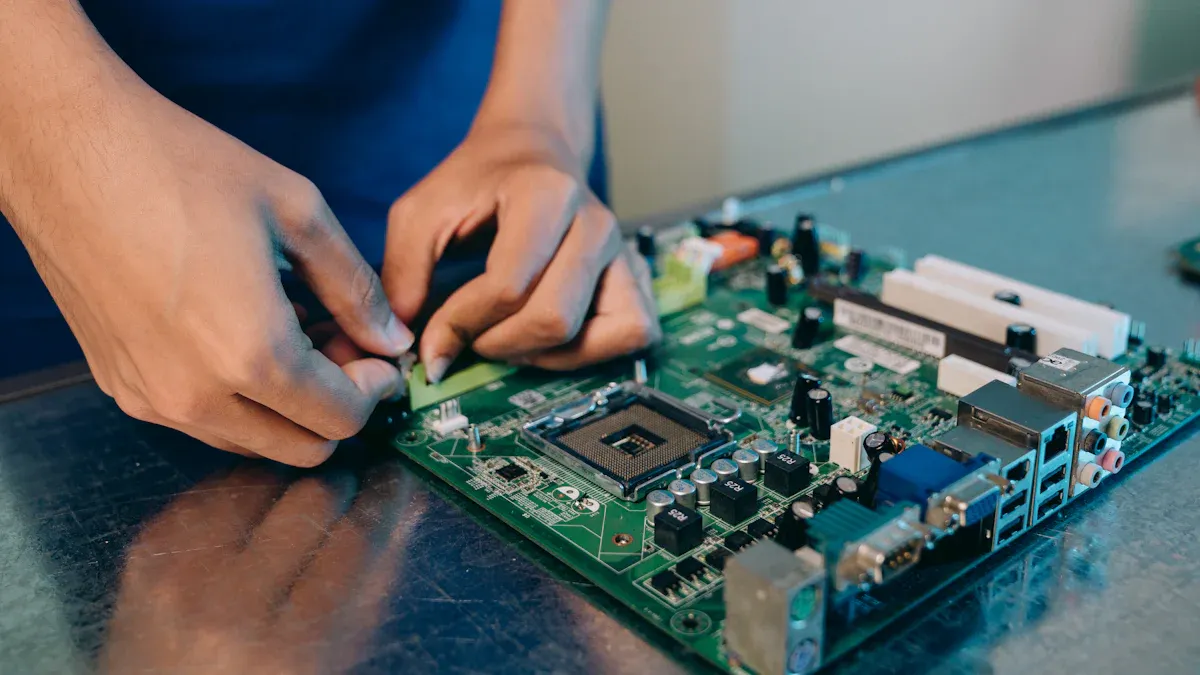

Advanced assembly methods for improved efficiency

Using better assembly methods can make hardware assembly faster. These methods aim to improve steps and reduce mistakes. Important measures, called KPIs, track how well these methods work.

KPI | What It Does |

|---|---|

Keeps products good by testing and following rules. | |

Process Control | Spots problems early so they can be fixed quickly. |

Team Quality Efforts | Involves everyone in making things better and keeping customers happy. |

Automation and Smart Tools | Cuts down mistakes and gives live updates for quick fixes. |

Ongoing Learning | Helps workers get better through training and learning new skills. |

Focusing on these KPIs can improve production results. For instance, keeping machines running 90% of the time and boosting output by 5% are good goals.

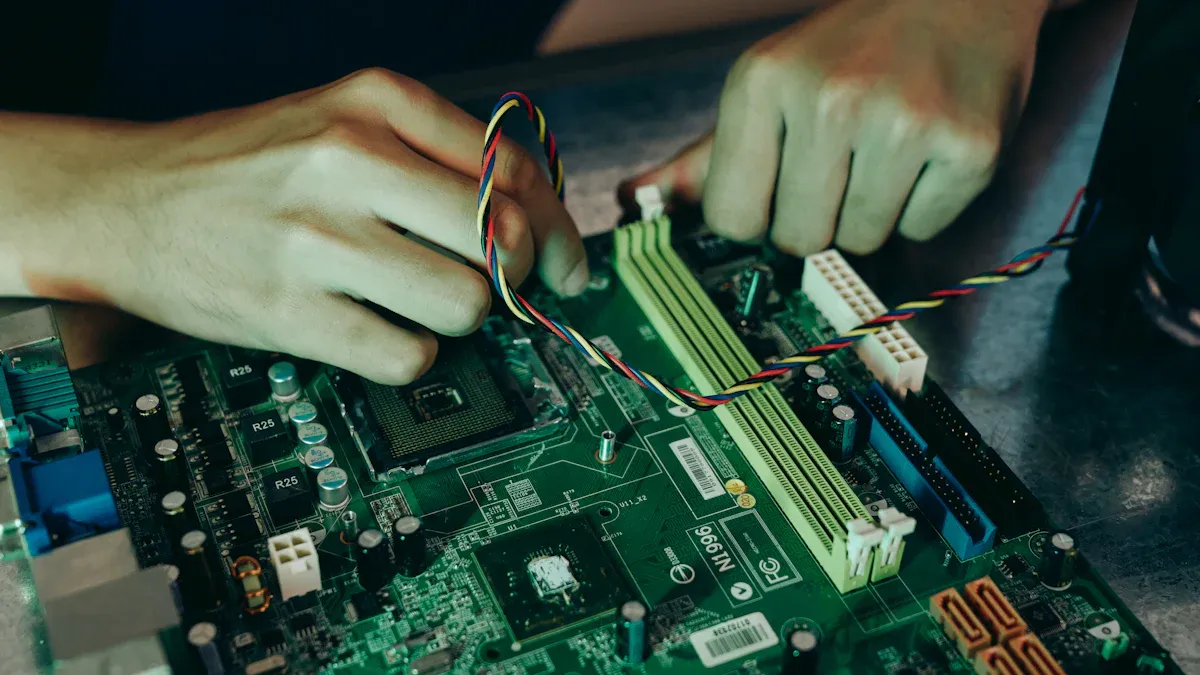

Using automation and robots in hardware assembly

Automation and robots help make hardware assembly easier and faster. They cut down on manual work, reduce mistakes, and increase output. Real-life examples show how automation helps different industries:

Example Type | Main Benefits | Industries That Use It |

|---|---|---|

Stone Cutting Machines | Lowered injury risks, worked faster | Factories |

Vertical Machining Tools | Saved money and worked more efficiently | Factories |

Big improvements in speed and output | Drink-making companies | |

Industrial Robots | Reduced injury risks | Food, machine shops, leather goods, etc. |

For example, drink companies use automated bottling systems to work faster. Adding robots can bring similar benefits to your hardware assembly.

Improving workflows with LTPCBA’s smart solutions

LTPCBA provides advanced tools to make hardware assembly better. These tools focus on working faster and creating high-quality products.

Changes in systems make assembly lines work better.

Teams using Kaizen adjust quickly and find ways to improve.

Automated lines run nonstop, increasing how much they produce.

Automation makes work safer by keeping people away from risky tasks.

Early checks find and fix problems before designs are finished.

Using LTPCBA’s tools can change how you assemble hardware and lead to better results.

Training workers for better assembly processes

Training workers is key to making hardware assembly smoother. Skilled workers do their jobs faster and make fewer mistakes. Benefits of good training include:

Workers are more productive and stay longer in their jobs.

Safety rules are followed better, and mistakes happen less often.

Workers feel more involved and remember what they learn.

Training improves how workers act and perform.

For example, safety and skill training programs lead to happier customers and better worker satisfaction. Spending on training helps your assembly process succeed in the long run.

Benefits of Streamlined Hardware Assembly

Saving money with better processes

Streamlined assembly saves money by improving how work is done. Doing all tasks in one place saves time and cuts costs. This method avoids delays and lowers worker expenses. Mechanical assembly also saves money by avoiding damage during shipping. Robotic assembly lines work faster and cost less, as shown in studies.

Total assembly costs include setup, repairs, and energy use.

Robotic assembly lines shorten work time and save money well.

These methods are better than old ways, helping save more money.

Assembly Method | How It Saves Money |

|---|---|

Full Assembly | Finishes all tasks in one spot, saving time and worker costs. |

Mechanical Assembly | Cuts worker costs and avoids damage during shipping. |

Robotic Assembly Lines | Speeds up work and lowers costs, proven by studies. |

Better product quality and consistency

Streamlined processes make products better by keeping them consistent. Picking good suppliers and setting quality rules help keep standards high. Regular checks and feedback fix problems quickly.

Working closely with suppliers improves product quality over time.

Clear performance tracking helps make smarter choices and happier customers.

Workers feel responsible, which leads to better products.

Faster production with LTPCBA’s smart tools

LTPCBA’s tools make production quicker. Automated systems and live data help make faster choices. Sensors find mistakes early, keeping things running smoothly. These tools help you launch products faster and stay ahead.

Benefit | What It Does |

|---|---|

Data tools help factories work faster and better. | |

Reduces lead times | Better processes make production times shorter. |

Eliminates errors | Live data helps find and fix mistakes during assembly. |

Speeds time to market | Quick decisions help launch products faster. |

Using LTPCBA’s tools can speed up production and keep you competitive.

Making hardware assembly smoother changes how you work. It cuts mistakes, lowers costs, and makes products better. Using automation and fixing workflows helps you work faster and stay ahead.

Tip: Working with LTPCBA gives you top tools and expert help. This makes your assembly process easier and more efficient.

FAQ

What’s the best way to make hardware assembly better?

Find slow spots in your work process. Use smart tools and new methods to work faster and make fewer mistakes.

How does LTPCBA improve hardware assembly?

LTPCBA gives you smart machines, live data tools, and quality checks. These help you work better and make high-quality products every time.

Why is training workers important for hardware assembly?

Training teaches workers key skills. It helps them make fewer mistakes, stay safe, and get more done during assembly.

See Also

Common Techniques and Workflow for SMT Assembly Processes

Effective Strategies for Enhancing SMT Production Lines

The Impact of Rapid PCB Prototypes on Project Success