Solder paste classification and component differences in Surface Mount Technology assembly

Solder paste classification determines the type and performance of solder paste used in surface mount technology. Proper classification affects SMT results, as stencil printing quality and paste consistency impact joint reliability. LTPCBA applies advanced smt practices, ensuring the right solder paste classification meets each assembly’s needs for high-quality outcomes.

Key Takeaways

Choosing the right solder paste type, based on particle size, flux, and alloy, ensures strong and reliable solder joints in SMT assembly.

Smaller components and tighter pitches need finer solder paste particles and precise printing to avoid defects and improve assembly quality.

LTPCBA’s careful selection and process control of solder paste reduce defects and boost reliability across various industries, from automotive to medical devices.

Solder Paste Classification

Classification of Solder Paste

Solder paste classification helps engineers and manufacturers choose the right material for each job. The classification of solder paste depends on three main aspects: particle size, flux type, and alloy composition. Each aspect affects how the paste works in different applications and how it performs during the reflow soldering process or wave soldering.

Classification Aspect | Categories / Types | Technical/Industry Support Details |

|---|---|---|

Particle Size | Type 3, Type 4, Type 5, Type 6 | Particle size classification balances printability and slump resistance, addressing fine-pitch SMT demands and manual rework needs. Powder production uses advanced atomization for consistent size distribution. |

Flux Type | No Clean, RMA (Rosin Mildly Activated), Water Soluble | Flux chemistry influences residue management and post-process cleanliness, critical for sensitive applications like medical devices. Proprietary flux technologies improve wetting and reduce voids. |

Alloy Composition | Tin-Bismuth-Copper, Tin-Bismuth-Nickel, Tin-Bismuth-Silver | Alloy variations tailor mechanical strength, thermal characteristics, wetting, and electrical conductivity to application needs (e.g., aerospace, automotive, consumer electronics). Copper enhances joint strength; nickel and silver optimize wetting and conductivity. |

Technical studies and industry reports confirm that this classification system matches the needs of modern SMT and general smt applications. LTPCBA uses advanced solder paste classification methods to ensure high-quality assembly for every project.

Solder Paste Types and Properties

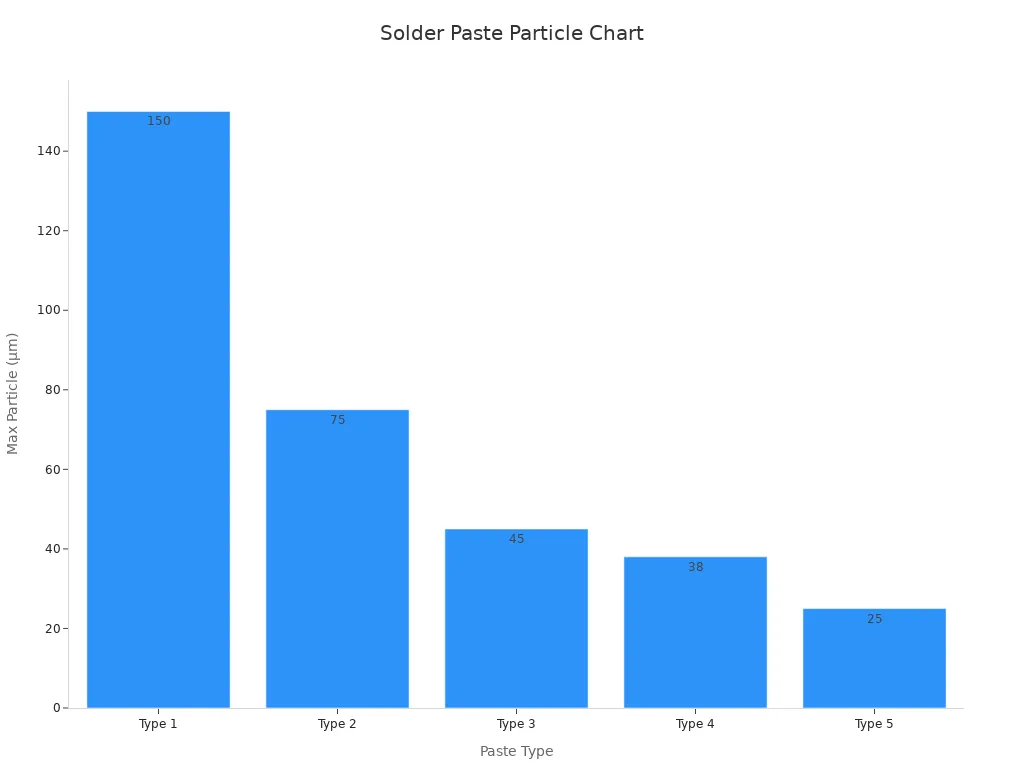

Solder paste comes in many types, each with unique properties and characteristics. The main types are based on particle size, which affects printability and suitability for fine-pitch components. For example, Type 3 and Type 4 solder pastes are common in general smt applications, while Type 5 and smaller are used for very fine features.

The properties of solder paste also depend on the flux and alloy. Flux types include rosin-based, water-soluble, and no-clean. Each type has different cleaning needs and residue characteristics. Rosin-based fluxes may need solvent cleaning, water-soluble fluxes clean with water, and no-clean fluxes often leave little residue.

Paste Type | Approximate Max Particle Size (µm) | Mesh Size Range |

|---|---|---|

Type 1 | ~150 | -150/+325 |

Type 2 | ~75 | -200/+325 |

Type 3 | ~45 | -325/+500 |

Type 4 | ~38 | -400/+635 |

Type 5 | ~25 | -500/+635 |

Alloy composition changes the melting point and strength of the solder joint. Lead-free alloys, such as Sn-Ag-Cu, are popular for their safety and performance in reflow soldering and wave soldering. These alloys meet environmental rules and work well in many applications of solder paste.

The properties of solder paste, such as viscosity, tack, and slump, affect how the paste prints and holds components before reflow soldering. Mechanical, electrical, and thermal testing help engineers compare the characteristics of different pastes. For example:

Electrical resistance tests check conductivity.

Thermal tests show how well the joint handles heat.

Microstructural analysis reveals how the solder bonds to the board.

These tests help LTPCBA select the best solder paste for each application, ensuring strong, reliable joints.

Role in Surface Mount Technology

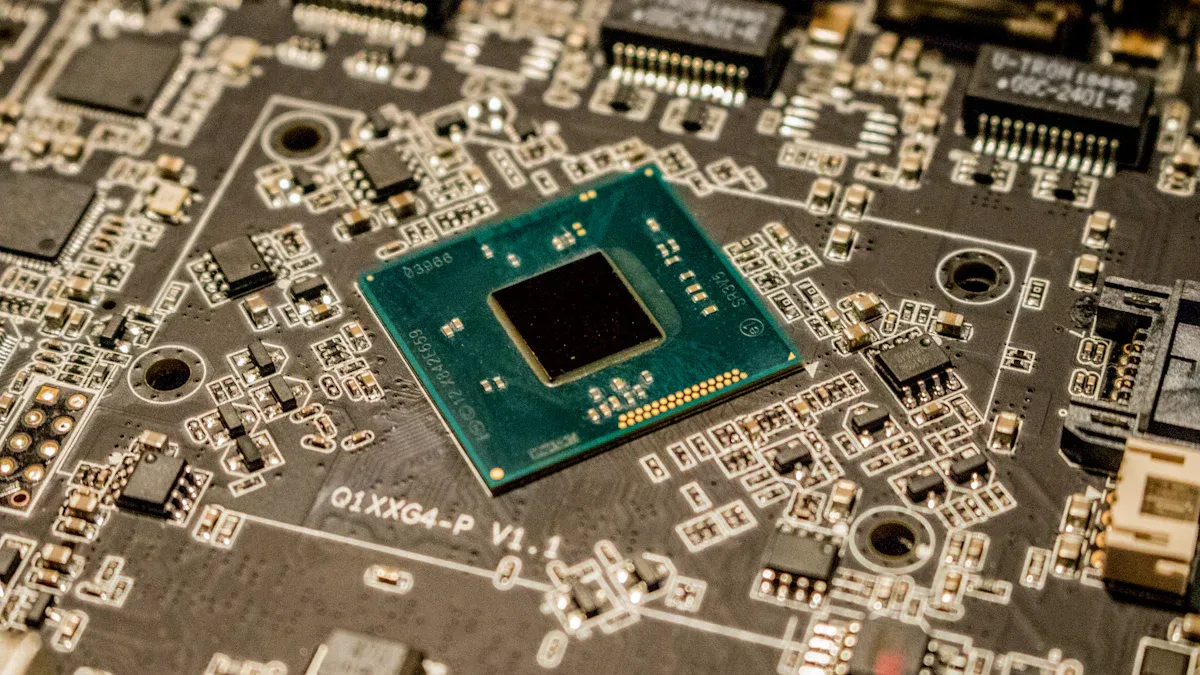

Solder paste plays a key role in surface mount technology. It acts as both an adhesive and a source of metal for solder joints. The quality of solder paste printing affects more than half of all soldering defects in SMT assembly. Good printability ensures that the right amount of paste goes on each pad, which is vital for reliable reflow soldering and wave soldering.

Note: Studies show that stencil printing accounts for over 50% of soldering defects. Early detection and proper solder paste classification can greatly improve assembly quality.

The applications of solder paste cover a wide range, from consumer electronics to medical devices and automotive systems. Each application may need a different type of solder paste, depending on the size of the components, the pitch, and the required joint strength. The characteristics of the paste, such as melting point and wetting ability, must match the needs of the assembly.

Advancements in solder paste technology, including better fluxes and alloys, have improved SMT performance. These improvements reduce defects like head-on-pillow and non-wet-opens, especially in miniaturized and high-power applications. For example, a study on Sn-Ag-Cu solder paste showed that the right alloy and process settings can lower defect rates and boost reliability in fine-pitch SMT.

LTPCBA’s commitment to quality means using the best solder paste classification for each job. Their expertise ensures that every assembly meets strict standards for reliability and performance, whether for general smt applications or specialized uses.

Component Differences in PCB SMT Assembly

SMD Size and Pitch

Component size and pitch play a major role in pcb smt assembly. Surface-mount devices (SMDs) come in many sizes, from large chips to tiny resistors and capacitors. Pitch refers to the distance between the centers of two adjacent pins or pads. Smaller pitch means components are closer together, which increases the challenge for solder paste printing and placement.

A table below shows how device pitch and solder paste type relate to assembly quality:

Parameter | Typical Value / Setting | Impact on Solder Paste and Assembly Reliability |

|---|---|---|

Device pitch (BGA) | 1.27 mm | Stencil aperture: 0.55–0.65 mm; standard paste |

Device pitch (fine pitch) | 0.8–1.0 mm | Aperture: 0.4–0.5 mm; Type III solder paste needed |

Device pitch (very fine pitch) | 0.5 mm | Aperture: 0.25–0.35 mm; Type IV solder paste needed |

Solder powder particle size | Type 2 to Type 4 | Smaller particles for finer pitch |

Paste transfer efficiency | Type IV: 10–15% higher than Type III | Better printability and fewer defects |

Print efficiency for 0.5-mm pitch | Less than 60% | Indicates difficulty in fine-pitch printing |

Smaller SMDs and tighter pitches require finer solder paste particles and precise stencil apertures. If the solder paste is too coarse, it will not pass through small stencil openings, leading to poor printability and defects. LTPCBA uses advanced equipment and carefully selects solder paste types to match each component’s size and pitch. This approach ensures high-quality results in pcb smt assembly, even for the smallest and most complex devices.

Material and Design Factors

Material and design choices also affect solder paste application and assembly quality. The type of solder paste, the design of the printed circuit boards, and the handling of materials all influence the outcome.

Printing defects, such as unfilled pads or misaligned prints, often result from poor stencil quality, incorrect squeegee pressure, or improper PCB handling.

Proper storage and handling of solder paste, especially those with silver, copper, and tin alloys, improve printability and reduce defects.

High humidity can cause oxidation on PCB pads, which increases the risk of defects. Careful handling and storage prevent this problem.

Temperature during solder paste printing affects viscosity and filling area. Higher temperatures can lower viscosity, making the paste flow too much and causing defects.

Placement methods for mini-scale components matter. Placing components between the solder paste and pads can improve accuracy and reduce misalignment.

A table below highlights how design and material factors influence solder paste performance:

Factor | Effect on Solder Paste Application |

|---|---|

Smaller apertures reduce transfer efficiency | |

Reflow profile | Optimal settings improve solder deposit volume |

Pad geometry | Affects solder paste release and joint quality |

Solder paste alloy/rheology | Determines flow, wetting, and joint strength |

LTPCBA follows strict process controls and uses high-quality materials to minimize defects. Their team optimizes every step, from stencil design to reflow soldering, to ensure reliable pcb smt assembly for all applications.

Solder Paste Selection for Components

Choosing the right solder paste for each component is key to successful pcb smt assembly. Different components need different solder paste properties, depending on their size, pitch, and function.

Performance indicators guide the selection of solder paste formulations:

Performance Indicator | Recommended Setting | Role in Solder Paste Application | Impact on Yield and Component Selection |

|---|---|---|---|

0.00 (on-contact) | Ensures even paste release and uniformity | Prevents bridging, critical for fine-pitch parts | |

Separation Speed | 0.010"–0.020"/s for fine-pitch | Controls squeegee lift-off from stencil | Slower speeds reduce defects in micro-BGA |

Print Speed | 1–8 inches/s, based on viscosity | Matches paste flow to component requirements | High speeds need specialized solder paste |

Squeegee Pressure | 1–1.5 lbs per linear inch | Maintains consistent paste height and coverage | Too much or too little pressure causes defects |

For fine-pitch and micro-BGA components, engineers select solder paste with smaller particle sizes and optimized rheology. This choice improves printability and reduces the risk of defects like bridging or insufficient coverage. LTPCBA uses advanced solder paste formulations and process controls to match each component’s needs. Their expertise ensures high assembly yields and reliable solder joints for all types of applications, from consumer electronics to automotive systems.

Tip: Matching solder paste type to component size and design improves assembly yield and reliability. LTPCBA’s experience with a wide range of components allows them to deliver consistent quality in every pcb smt assembly project.

Modern pcb smt assembly faces challenges from miniaturization, high-mix production, and new packaging technologies. LTPCBA meets these challenges by using the latest solder paste technology, automated inspection, and strict quality assurance. Their approach supports reliable applications across many industries, ensuring that every printed circuit board meets the highest standards.

Solder Paste Comparison and Application

Type 3 vs. Type 4 Solder Paste

Type 3 and Type 4 solder paste serve as the most common choices in SMT assembly. Type 3 solder paste contains larger particles, making it suitable for standard components with wider pad spacing. Type 4 solder paste uses finer particles, which allow for better print definition and less bridging on fine-pitch pads. The table below compares these two types:

Feature | Type 3 Solder Paste | Type 4 Solder Paste |

|---|---|---|

Particle Size (µm) | 25–45 | 20–38 |

Print Definition | Good | Excellent |

Best Use | Standard SMT | Fine-pitch SMT |

Soldering Quality | High | Very High |

LTPCBA selects the right solder paste for each project. This choice ensures soldering quality and maintains solder joint integrity.

Application for Fine-Pitch Components

Fine-pitch components require precise solder paste application. Type 4 solder paste works best for finer-pitch smt applications. Its smaller particles pass through tiny stencil apertures, creating clean deposits. This process reduces defects and improves soldering quality. LTPCBA uses advanced printing techniques and high-quality solder paste to achieve reliable results for all applications.

Tip: Matching solder paste type to component pitch improves long-term circuit integrity and reduces rework.

Quality and Reliability Considerations

Solder paste quality affects both immediate and long-term circuit integrity. LTPCBA evaluates soldering paste quality using several reliability tests:

Print and pause tests measure stencil life and transfer efficiency.

Reflow tests check for solder balling, graping, and voiding.

Heat aging simulates storage at high temperatures to test stability.

Continuous mixing tests assess durability and activity loss.

Water washability tests ensure flux residue removal after multiple cycles.

Comparative studies show that solder paste alloy composition, especially silver content, impacts soldering quality and solder joint integrity. These studies use dynamic tests, thermal shock, and quantitative scoring to select the best solder paste for each application. Proper storage and handling of solder paste also help maintain soldering paste quality and long-term circuit integrity.

LTPCBA’s process ensures high soldering quality and reliable performance for all applications. Their expertise in solder paste selection supports strong solder joints and product integrity.

Selecting the right solder paste for each component ensures strong, reliable SMT assembly. LTPCBA uses advanced inspection and quality control, reducing defect rates by up to 70%.

Sector | Reliability Benefit |

|---|---|

Meets strict safety and durability standards | |

Medical | Maintains device integrity and quality |

Proper matching of solder paste and components supports lasting product performance.

FAQ

What is the main difference between Type 3 and Type 4 solder paste?

Type 3 solder paste uses larger particles for standard components. Type 4 uses finer particles for fine-pitch parts. Type 4 gives better print quality for small pads.

How does LTPCBA ensure reliable SMT assembly?

LTPCBA uses advanced solder paste, precise printing, and strict inspection. Their team follows international standards. This process helps deliver strong, reliable solder joints every time.

Why is solder paste classification important in SMT?

Solder paste classification helps match the right paste to each component. This step reduces defects and improves the strength and reliability of every solder joint.

See Also

Impact Of Solder Paste Quality On SMT PCB Soldering

Best Timing For Selecting Lead-Free Solder Paste In SMT

Essential Quality Control Tips For Solder Paste Screen Printing

Reliability Comparison Between Through-Hole And SMT PCB Assembly

Guide To Reflow Soldering Through-Hole Parts Post SMT Assembly