How to Meet the SMT Assembly Requirements for Automotive Products

Building SMT assemblies for automotive products requires accuracy and strict regulations. Today’s cars incorporate numerous electronics, with over 8,000 chips and 100 control units in some models. These components account for 35% of car costs currently and could rise to 50% by 2030. Flawless assembly is crucial for the safety and performance of automotive products.

Key Takeaways

Using good-quality parts in SMT builds makes cars work better.

Following IPC rules keeps quality steady and lowers problems in car electronics, gaining customer trust.

Using smart tests like AOI and X-ray finds problems early, keeping cars safe and reliable.

Ensuring Quality Standards in Automotive Products

Why Good Components Matter

Good components are key to making safe and strong cars. Using better materials helps meet the tough rules of the car industry. These parts make cars work well, last longer, and stay safe, which is very important.

Studies show many benefits of using good parts in SMT assemblies for cars:

Benefit | Description |

|---|---|

High Reliability | Works well even in heat, cold, or shaking. |

Better Electrical Performance | Cuts down noise and boosts efficiency and function. |

Lighter parts save fuel and improve car performance. |

Good parts also allow more features in small spaces. This helps create advanced designs without losing reliability. SMT parts are smaller and lighter than older ones, making them perfect for modern cars.

The car repair market also values quality. Top-grade parts improve things like speed and exhaust sound. They also make driving more enjoyable. By focusing on quality, you meet rules and make customers happy.

Why IPC Standards Are Important

Following IPC standards is vital for keeping quality in SMT assemblies for cars. These global rules ensure products are reliable and work well. IPC certifications show your dedication to making great products.

Here’s how IPC standards help ensure quality:

Source | Description |

|---|---|

IPC Standards | Provide rules for making dependable electronics. |

IPC Certification | Proves manufacturing steps are consistent and high-quality. |

IPC A-610 Standards | Sets rules for checking electronics, accepted worldwide. |

Products made to IPC standards are more reliable. For example, solder joints that meet IPC-A-610 rules are less likely to break. This lowers defects and makes car parts last longer. Reports show problems like bad solder joints and misaligned parts cause many failures. Following IPC rules reduces these issues and improves production.

Meeting IPC standards also makes legal and customer needs easier. It helps you follow laws and stand out in the car market. When you use these standards, clients trust you and your products work well in real life.

Reliability in Tough Automotive Conditions

Handling Heat and Vibrations

Car parts face heat and shaking in tough conditions. To keep them working, use methods to handle heat and vibrations. These steps help parts last longer and avoid breaking.

Here’s a table of ways to manage heat:

Method | What It Does |

|---|---|

Heat Sinks | Pulls heat away to keep parts cool. |

Heat Pipes | Moves heat fast using special liquids. |

Thermal Interface Materials | Fills gaps to help heat move better. |

Liquid Cooling Systems | Uses liquids to cool high-power parts. |

Shaking and bumps can harm small parts in cars. Stronger solder joints and shock-absorbing materials can stop this damage. These fixes keep parts safe and working well.

Fighting Moisture and Rust

Water and rust can ruin car parts. Protecting them is important. For example, storing parts in vacuum bags stops water damage. Finding rust early on parts like power switches avoids bigger problems later.

Car makers test for rust using salt spray chambers. These tests copy harsh weather to pick strong materials. Adding rust-proof coatings makes car parts last longer and work better.

To block water, use special coatings or coverings. These create shields that protect parts from wet or rusty conditions. This keeps car parts working, even in bad weather.

Compliance with Automotive Industry Rules

Important Automotive Standards (e.g., ISO/TS 16949)

Following car industry rules keeps products safe and reliable. ISO/TS 16949 is a key rule for quality in making car parts. It ensures factories make good parts every time. Using this rule lowers mistakes, boosts efficiency, and meets customer needs.

Another important rule is IATF 16949, which improves ISO/TS 16949. It focuses on managing risks, stopping defects, and improving constantly. Following these rules makes better products and builds trust in the car market. It shows you care about making safe and dependable car parts.

Environmental Rules for Car Products

Environmental rules help reduce harm from making cars. To cut pollution, track emissions, make plans, and follow the Clean Air Act. These actions help meet rules and support a greener planet.

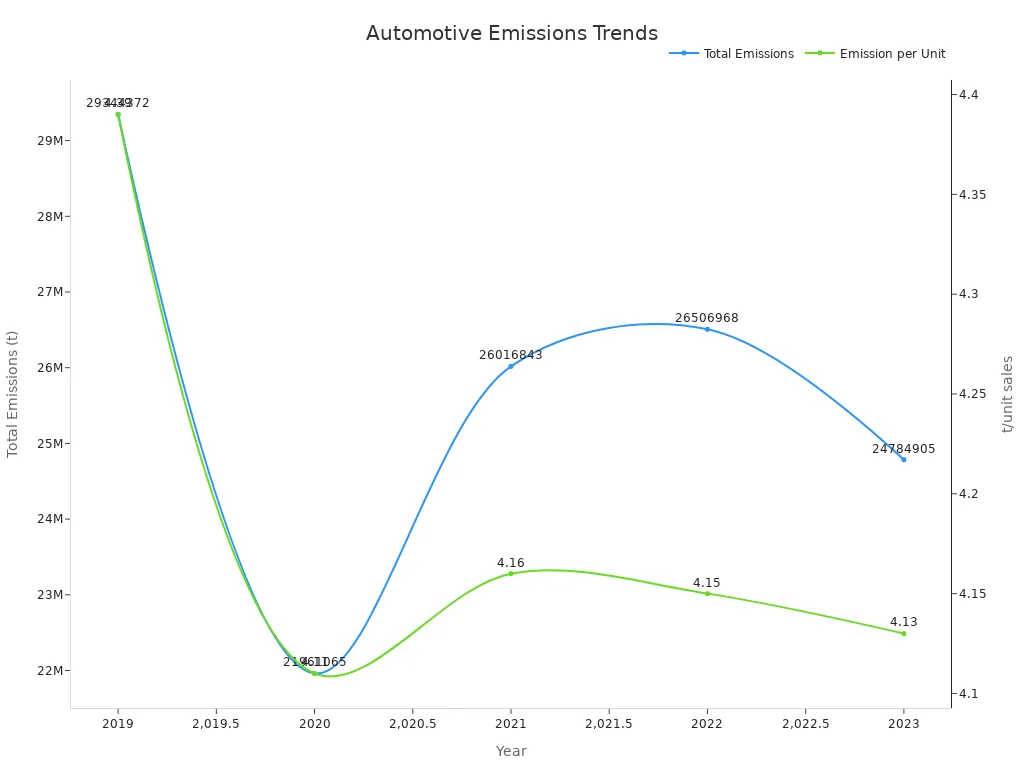

Here’s a table showing car pollution trends in recent years:

Year | Emissions (t) | Emission per unit (t/unit sales) | Reduction Rate (since 2019) |

|---|---|---|---|

2019 | 29,344,372 | 4.39 | N/A |

2020 | 21,961,065 | 4.11 | ▲6.4% |

2021 | 26,016,843 | 4.16 | ▲5.2% |

2022 | 26,506,968 | 4.15 | ▲5.5% |

2023 | 24,784,905 | 4.13 | ▲5.9% |

The EPA checks harmful air pollutants (HAPs) to ensure rules are followed. Reporting pollution and cutting it down helps the environment. These steps protect health and make car products more eco-friendly.

Advanced SMT Technologies for Automotive Products by LTPCBA

Automated SMT Equipment for Precision

Accuracy is very important in making car electronics. Automated SMT machines help ensure parts are placed correctly. These machines make fewer mistakes and improve how fast products are made.

Modern SMT tools include fast pick-and-place systems, stencil printers, and reflow ovens. These tools work together to place and solder parts perfectly. For example, pick-and-place machines can handle tiny parts like 01005 packages with great accuracy. This helps make small and reliable car electronics.

Using machines also reduces human mistakes. Machines can do the same task over and over without errors. This is important for car products because even small problems can cause big safety issues. Automated SMT machines make better products faster, helping meet deadlines while keeping quality high.

Testing and Inspection Methods for Quality Assurance

Testing is key to making sure car electronics work well. Advanced methods like AOI, X-ray inspection, and ICT find problems early. This saves time and money.

Inspection Method | What It Does | How It Helps |

|---|---|---|

Automated Optical Inspection (AOI) | Uses cameras to find surface problems like missing parts or bad solder. | Great for spotting visible issues but not hidden ones. |

Looks inside solder joints to find hidden problems. | Finds cracks or voids, especially in hard-to-see parts like BGAs. | |

In-Circuit Testing (ICT) | Checks if the PCB works and connects properly. | Finds shorts, opens, and makes sure circuits work. |

AOI is good for finding surface problems like crooked parts or solder bridges. Cameras scan the board and compare it to a standard. This catches visible mistakes before moving forward.

For hidden problems, X-ray inspection is very helpful. It shows the inside of solder joints to find cracks or voids. This is important for parts like BGAs, where you can’t see problems easily.

ICT checks if the board works as it should. It looks for broken connections or other issues to make sure everything runs smoothly. By using all these tests, you can make sure car electronics are safe and reliable.

At LTPCBA, we use these advanced tests in our process. This focus on quality ensures your car products are dependable and meet high standards.

Meeting SMT assembly needs for cars requires care and new ideas. Focus on making parts high-quality, reliable, and following rules. Tools like automated optical inspection find problems, such as weak solder or broken joints. Using these methods improves safety and performance. This helps your products shine in the busy car market.

FAQ

1. Why is SMT assembly good for car electronics?

SMT assembly uses small parts that save space and work well. It stays strong in tough conditions, making it great for car electronics.

2. How does LTPCBA make sure SMT assembly is high quality?

LTPCBA uses machines, follows IPC rules, and tests with AOI and X-rays. These steps make sure car electronics are accurate and reliable.

3. Why is following car industry rules important?

Following rules keeps products safe, reliable, and eco-friendly. It builds customer trust and meets standards like ISO/TS 16949 and IATF 16949.

See Also

Common Techniques And Workflows For SMT Assembly

Key Specifications For Wave Soldering In DIP Assembly

Understanding SMT And DIP Assembly For PCBA Uses