How to Select the Right Turnkey PCBA Manufacturing Manufacturer for Your Electronics Project

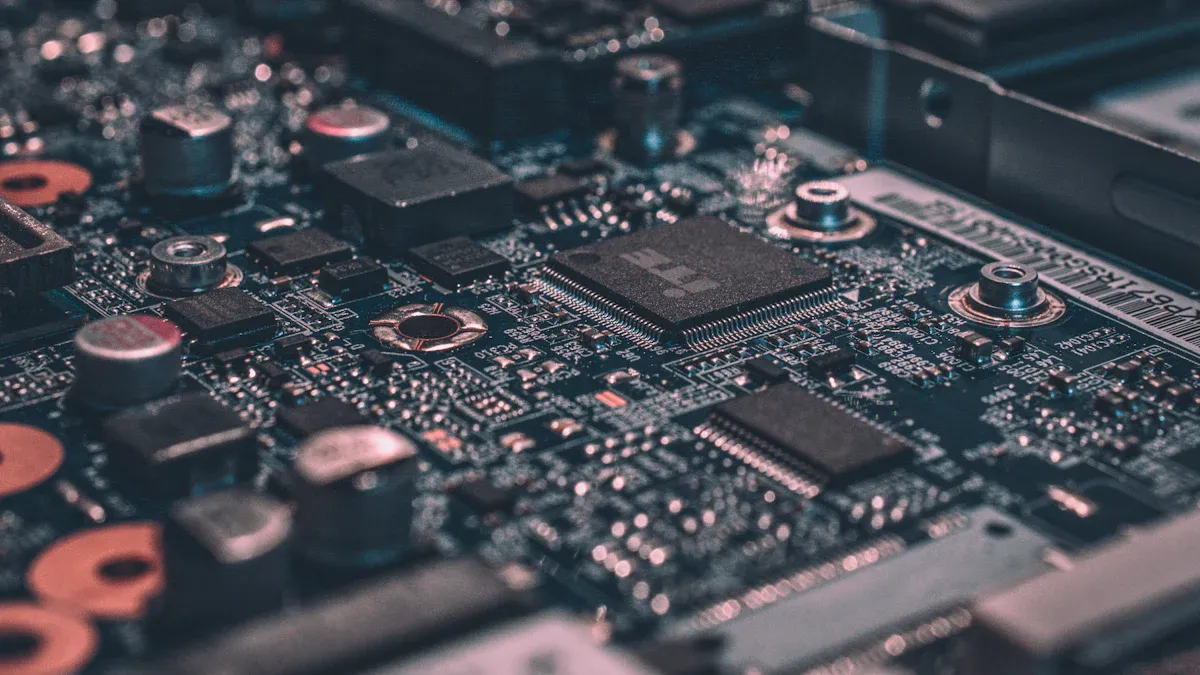

When you pick a turnkey pcba manufacturing partner, you want a manufacturer with strong experience, top certifications, and advanced technology. A trusted turnkey pcb assembly service provider like LTPCBA uses strict quality checks and offers a complete turnkey solution. With great support, you get reliable pcba, pcb, and turnkey manufacturing every time.

Key Takeaways

Choose a turnkey PCBA manufacturer with strong experience and key certifications like ISO and IATF to ensure high quality and reliability in your electronics project.

Look for manufacturers that use advanced technology and thorough quality checks, including automated inspections and early design evaluations, to catch defects and save costs.

Pick a flexible and scalable partner who manages supply chains well, offers fast prototyping, and provides excellent customer support to keep your project on track and ready to grow.

Turnkey PCBA Manufacturing: Key Criteria

When you start looking for the best pcb manufacturer for your electronics project, you want to focus on a few key things. The right turnkey pcb assembly manufacturer will help you avoid costly mistakes, speed up your timeline, and deliver high-quality pcba every time. Let’s break down what you should look for.

Experience and Certifications

You want a turnkey pcb assembly manufacturer with real experience. Years in the industry show that a manufacturer knows how to handle different pcb assembly challenges. When you work with a custom pcba manufacturer like LTPCBA, you get a team that understands both simple and complex printed circuit board assembly projects.

Certifications matter, too. Top manufacturers hold certifications like ISO, IATF, and UL. These prove that the manufacturer follows strict quality rules. Research shows that regulatory standards such as RoHS, IATF 16949, and ISO 13485 require technical expertise and certified quality control systems. These certifications also mean the manufacturer uses advanced inspection tools like AOI and X-ray inspection. This helps catch defects early and keeps your pcba reliable.

Tip: Always ask your turnkey pcb assembly manufacturer for proof of certifications and examples of past projects. This gives you confidence in their expertise and quality.

A strong track record also matters. LTPCBA, for example, has a 99.5% pass rate in product delivery. That kind of performance shows you can trust their quality and consistency.

Here’s a quick look at how certifications and quality systems influence your decision:

Criteria | Why It Matters | Impact on Your Project |

|---|---|---|

ISO, IATF, UL Certifications | Proves quality and compliance | Reduces risk, ensures reliability |

AOI & X-ray Inspection | Finds defects early | Improves product quality |

High Pass Rate | Shows consistent results | Gives you peace of mind |

Documented Quality Assurance | Tracks every step | Makes troubleshooting easier |

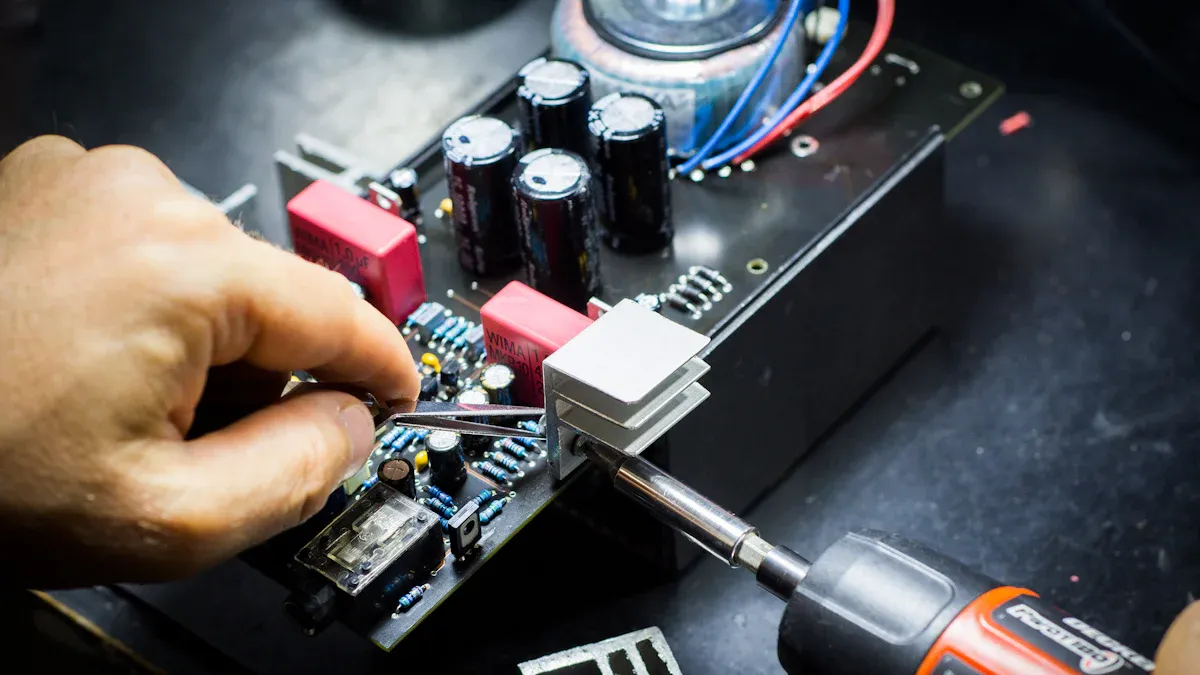

Technology and Quality Assurance

You want a turnkey pcb assembly manufacturer that invests in the latest technology. Advanced machines and digital tools help speed up pcb manufacturing and improve accuracy. LTPCBA uses automated systems for SMT assembly, BGA assembly, and even rigid flex pcb assembly. This means your pcba gets built with precision.

Quality assurance is more than just a buzzword. It’s a promise. The best pcb manufacturer uses multiple inspection steps, including AOI, X-ray, and manual checks. Industry standards like IPC-6012 and IPC-610D require these inspections to catch even the smallest issues. Some manufacturers even use AI-powered AOI systems, which can reduce false defect calls by 22%. That means fewer delays and better results for you.

Pre-production technical evaluation ensures your design is ready for manufacturing.

Strict raw material control keeps your pcba safe from faulty parts.

100% final inspection by a dedicated team means every pcb meets your standards.

You also want a manufacturer that keeps up with new technology and expertise. LTPCBA’s team uses digital manufacturing tools to optimize your design and cut costs early in the process. Studies show that over 70% of a part’s cost is set during the design phase, so early involvement from your manufacturer can save you money and improve quality.

Scalability and Flexibility

Your project might start small, but it could grow fast. You need a turnkey pcb assembly manufacturer that can handle both prototypes and mid-volume production. Flexibility is key. If you need to make design changes, your manufacturer should adapt quickly.

Empirical research shows that flexible manufacturing operations help companies respond faster to design changes and market demands. LTPCBA uses advanced planning and control technologies, like ERP and MES systems, to keep production smooth and adaptable. This means you can move from prototype to larger runs without switching manufacturers.

Flexible manufacturing systems let you change your design without long delays.

Automated processes make it easy to scale up production when you need more units.

Quick response and 24-hour support from LTPCBA help you solve problems fast.

Note: Choosing a custom pcba manufacturer with strong flexibility and scalability means you won’t outgrow your partner as your business grows.

In today’s fast-moving market, speed and service matter as much as price and quality. Studies show that for innovative products, speed and service are top priorities. For larger orders, price and quality take the lead. The best turnkey pcb assembly manufacturer balances all these needs, giving you the right mix of technology, expertise, and support.

When you choose a turnkey pcba manufacturing partner like LTPCBA, you get a team that delivers quality, adapts to your needs, and supports you every step of the way. That’s how you set your project up for success.

Evaluating a Turnkey PCB Assembly Manufacturer

Supply Chain and Component Sourcing

When you choose a turnkey pcb assembly service provider, you want to know your pcba project will not get stuck because of missing parts or slow suppliers. A strong supply chain keeps your pcb assembly manufacturer on track and helps you avoid delays. You should look for a manufacturer that uses smart tools to track parts, manage suppliers, and predict risks.

Here’s how top manufacturers handle supply chain and component sourcing:

They use spend analysis to find high-cost areas and spot savings.

They check supplier performance for quality, reliability, and price.

They research the market to see trends and risks, and watch supplier inventories in real time.

They build sourcing strategies that match your business goals, using analytics to predict demand and spot problems early.

They pick the right sourcing model—single, dual, or multi-sourcing—to keep your supply steady.

They check new suppliers with research and capability tests.

They negotiate contracts using real-time price and stock data.

You want a turnkey pcb assembly manufacturer that can handle these steps. This approach helps control costs, keeps your project moving, and protects you from shortages.

Challenge | Strategic Countermeasure |

|---|---|

Use dual sourcing, safety stock, and long-term supply deals | |

Component end-of-life risks | Monitor part lifecycles and approve alternates early |

Global shortages of key components | Build strong OEM partnerships and keep extra inventory |

Cost control pressures | Buy in bulk, optimize BOM, and use supplier bidding |

Environmental compliance requirements | Follow RoHS, REACH, ISO standards, and keep material records |

A turnkey pcb assembly service provider like LTPCBA uses these strategies to keep your pcba project safe from supply chain problems. You get better price control, steady supply, and strong quality.

Prototyping and Lead Time

You want easy prototyping with short lead times. Fast prototyping lets you test your pcb design, catch problems, and make changes before full production. A good turnkey pcb assembly manufacturer offers quick-turn prototypes and keeps you updated on progress.

Industry research shows that using a single turnkey pcb assembly service provider speeds up the process. You do not have to juggle multiple suppliers or worry about miscommunication. Everything happens under one roof, so your pcba moves from design to prototype to production without delays.

Benefit Area | Evidence Summary | Supporting Example / Detail |

|---|---|---|

Single-provider turnkey manufacturing reduces vendor management complexity and administrative tasks. | BeBop Sensors accelerated VR glove production by consolidating design, prototyping, manufacturing, and logistics under one roof. | |

Faster Time to Market | Managing all processes internally shortens development cycles and speeds product launch. | BeBop Sensors benefited from faster development cycles and improved integration with turnkey partner RSP Inc. |

A turnkey pcb assembly manufacturer like LTPCBA uses advanced planning and automation to keep lead time short. You get prototype quality and accuracy, and you can move to larger runs without switching partners. This helps you stay ahead of your competition.

Customer Service and Support (LTPCBA)

Great support makes a huge difference. You want a turnkey pcb assembly service provider that answers your questions fast and helps you solve problems. LTPCBA stands out with 24-hour support and quick response times. This level of service keeps your project on track and gives you peace of mind.

Metric | Benchmark | Impact / Improvement Ideas |

|---|---|---|

Net Promoter Score (NPS) | 50+ | 20-30% more repeat business with high customer service |

Inquiry Response Time | 24 hours max | Faster response boosts satisfaction and repeat orders |

Customer Satisfaction Score | 85%+ | High scores show strong service and support |

You get more than just fast answers. LTPCBA’s team supports you from design to delivery. They offer technical help, training, and even after-sales support. This approach builds trust and helps you succeed.

Experienced engineers offer custom solutions for your needs.

The company provides training and maintenance services.

You always have someone to call if you need help.

Responsive communication practices matter. When you work with a turnkey pcb assembly service provider like LTPCBA, you get clear updates, quick quotes, and real answers. This makes your project smoother and less stressful.

Custom PCBA Manufacturer Capabilities

Every project is different. You need a custom pcba manufacturer that can handle your unique requirements. This means they must understand your industry, protect your intellectual property, and deliver the right solution for your pcb.

Case studies show how custom pcba manufacturers solve tough challenges:

Industry Sector | Challenge | Custom PCBA Solution | Key Metrics & Outcomes |

|---|---|---|---|

PCBs for advanced driver assistance, extreme temps, and vibrations | Custom 8-layer PCB, high-TG materials, automotive-grade parts, conformal coating | Passed tests, 40% smaller, IATF 16949 compliance, 99.8% reliability | |

Medical | Portable respiratory monitor, strict FDA and biocompatibility standards | Custom 6-layer flex-rigid PCB, medical-grade parts, special testing, wireless connectivity | ISO 13485, 72-hour battery, FDA approval, hospital use |

Industrial IoT Gateway | Harsh factory environments, multiple protocols | Custom 10-layer PCB, shielding, industrial-grade parts, redundant power, EMI protection | 99.9% uptime, supports 500+ devices, 30% lower install cost |

A custom pcba manufacturer tracks key metrics like Defective Parts Per Million (DPPM), Defects Per Million Opportunities (DPMO), and First-Pass Yield (FPY). These numbers show how well the manufacturer controls quality and meets your design needs.

DPPM and DPMO help spot and fix defects early.

FPY shows how many pcba units pass the first time, proving process quality.

High Cp and Cpk scores mean the manufacturer can meet tight specs and reduce errors.

You should always ask your turnkey pcb assembly manufacturer for details about design compatibility, testing services, and past projects. Professional testing teams use the latest tools and methods to check your pcb for bugs, security issues, and performance problems. Early testing saves money, improves reliability, and helps your product reach more markets.

Early defect detection keeps your pcba project on track.

Quality assurance ensures your pcb works on all devices and systems.

Security checks protect your product and your customers.

When you pick a custom pcba manufacturer like LTPCBA, you get a partner who values quality, protects your ideas, and supports you from start to finish. This is how you build a successful pcba project with confidence.

When you use a checklist to pick a turnkey manufacturer, you make smarter choices. The best pcb manufacturer like LTPCBA gives you quality products and services, fast support, and strong supply chain control. A custom pcba manufacturer with advanced testing ensures your pcb and pcba meet high quality. Trust a turnkey manufacturer for project success.

FAQ

What is a turnkey pcba manufacturer?

A turnkey pcba manufacturer handles everything for you. They buy parts, assemble your pcba, test it, and ship the finished product to you.

How do you choose the right pcba manufacturer?

You should check the manufacturer’s experience, technology, and service. Ask about their pcba quality, certifications, and how fast they can deliver your order.

Tip: Always ask your manufacturer for sample pcba projects. This helps you see their real work.

Can a pcba manufacturer help with custom designs?

Yes! A good manufacturer works with your custom pcba needs. They help with design, testing, and even changes. You get support from start to finish.

See Also

Tips For Finding A PCBA Supplier That Fits Requirements

Ways Modern Turnkey PCBA Plants Guarantee High Quality Output

How To Pick The Top All-In-One PCB Assembly Provider

Sourcing Electronic Parts For Effective PCBA Production Processes

Understanding Complete Turnkey PCB Production And Assembly Services