How to do reflow soldering for through-hole components after SMT assembly and processing

You can achieve efficient reflow soldering for through-hole components after SMT pcb assembly. LTPCBA uses advanced process control tools, like the Process Window Index, to ensure high-quality pcb results. Proper through-hole component selection and process control help you reduce defects and improve pcb assembly reliability. Quality assurance matters for every pcb.

Key Takeaways

Prepare your PCB carefully by checking SMT assembly, selecting heat-resistant through-hole components, and using the right solder paste and tools to ensure strong solder joints.

Control the reflow soldering process with precise oven profiles and real-time monitoring to avoid defects and protect sensitive parts, improving overall assembly quality.

Inspect every solder joint using automated tools like AOI and X-ray to catch defects early, apply best practices like cleaning and process control, and maintain high reliability in your PCB assembly.

Preparation

SMT Assembly Check

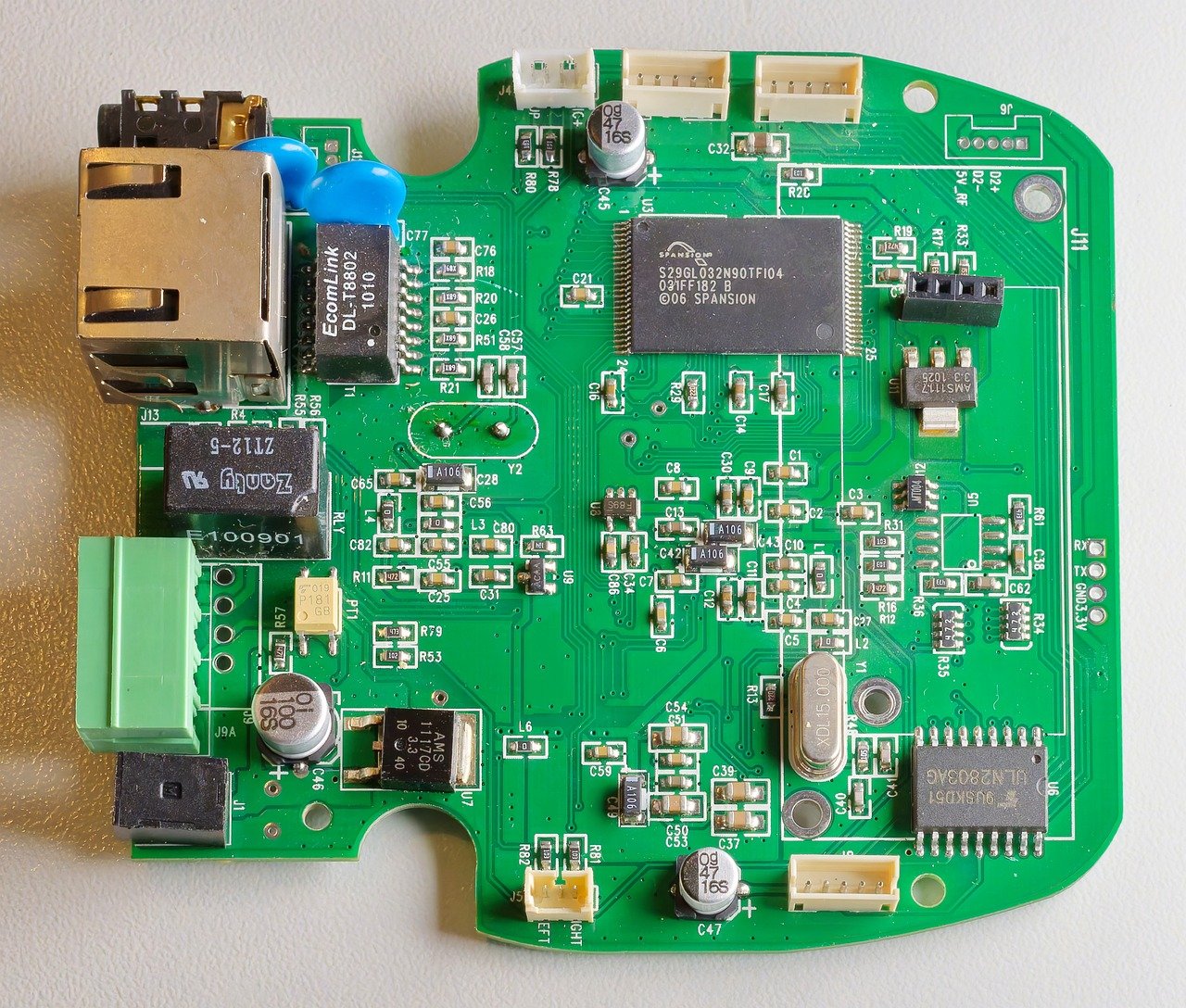

You need to check your SMT assembly before you start with through-hole reflow soldering. LTPCBA uses advanced equipment to make sure every pcb meets high standards. You can follow these steps to confirm your pcb assembly is ready for the next process:

Automated Optical Inspection (AOI) checks solder joints and component placement.

X-Ray Inspection looks at hidden solder joints, especially under BGAs.

In-Circuit Testing (ICT) verifies electrical connections and component installation.

Functional Testing simulates real working conditions to confirm the pcb works as expected.

You should also review your assembly documentation. This includes assembly drawings, placement printouts, and process flowcharts. These steps help you avoid mistakes before you add through-hole components.

Through-Hole Component Selection

Choosing the right through-hole parts is important for successful reflow soldering. You should select plated through-hole components that can handle the heat of the reflow process. The pin-in-paste technique works well for through-hole reflow. This method lets you insert the component pins into solder paste-filled holes before reflow. Make sure your components and pcb materials are compatible with the solder paste and reflow profile. This reduces the risk of defects during soldering.

Tools and Solder Paste

You need the right tools and solder paste for through-hole reflow soldering. LTPCBA uses precise pick-and-place machines and calibrated reflow ovens for reliable results. When you choose solder paste, look at the alloy type, flux activity, and particle size. Type 3 or Type 4 solder paste works well for most pcb assemblies. The paste should have good viscosity and thermal stability. It must match your stencil design and pcb pad layout. Proper solder paste selection and equipment setup help you achieve strong solder joints and reduce reflow defects.

Reflow Soldering Process

Placing Through-Hole Components

You start the through-hole reflow process by placing each through-hole component into the prepared pcb. LTPCBA uses automated systems to ensure every component sits at the correct height and position. This step matters because proper placement helps you achieve strong solder joints during reflow soldering.

You can use robotic machines to insert components from tape reels into the holes.

Jigs, including 3D-printed ones, hold the components steady while you move the pcb to the next step.

Automated placement tools cut leads and place parts like LEDs or resistors with high precision.

This method increases your production speed and reduces errors. You get consistent results, which is important for high-quality pcb assembly. Through-hole reflow technology lets you process both SMT and through-hole parts together, making your workflow more efficient.

Tip: Always check that the component pins go fully through the pcb holes before you continue to soldering.

Solder Paste Application

You need to apply solder paste to the through-hole pads before reflow soldering. LTPCBA uses advanced stencils or direct paste deposition to fill the holes with the right amount of solder paste. The quality of this step affects the final solder joint strength and reliability.

Use a stencil to deposit solder paste into each through-hole. Make sure the paste fills the hole but does not overflow.

Choose a solder paste that matches your pcb and component needs. No-clean pastes often work better than water-soluble types for through-hole reflow.

Test the paste for printability, slump resistance, and solder balling. Automated inspection tools help you check the print quality.

Store and handle the solder paste carefully. Keep it at the right temperature and avoid air exposure to maintain its performance.

A good solder paste will give you strong, clean joints after reflow. Studies show that using a robust, well-tested solder paste helps you avoid common problems like voids or poor wetting. You should always select a paste that performs well in all key areas, not just one.

Reflow Oven Profile

You now move the pcb to the reflow oven. Setting the correct reflow profile is critical for through-hole reflow soldering. LTPCBA uses convection reflow ovens with closed-loop temperature control for precise results. The oven heats the pcb so the solder paste melts and forms solid joints around each through-hole pin.

Set the oven to follow a thermal profile that matches your solder paste and component requirements.

Use automated thermal profiling tools to find the best settings quickly. This reduces setup time and helps you avoid defects.

The oven should heat the pcb evenly. Watch for the right ramp-up, soak, and peak temperatures.

The reflow process must not overheat the pcb or components. Too much heat can damage sensitive parts.

The global market for convection reflow ovens is growing fast. This trend shows that reflow soldering is a trusted method for high-density, reliable pcb assembly in many industries, including automotive and medical devices.

Note: Always check the manufacturer's guidelines for your components and solder paste before setting the oven profile.

Monitoring and Control

You must monitor and control the reflow soldering process to ensure quality. LTPCBA uses real-time thermal management and automated systems to keep the process within safe limits. These controls help you catch problems early and maintain high standards.

Control Metric / Monitoring Report | Description / Function | Quality Control Benefit |

|---|---|---|

Automated Thermal Profiling | Finds optimal thermal profiles quickly, reducing setup time | Ensures precise profiles, minimizing defects and improving solder joint quality |

Real-time Thermal Management System | Monitors oven performance and process parameters | Detects process drift and allows rapid correction |

Alarm Relay System | Shuts off conveyor if process drifts outside set limits | Prevents defective boards by stopping the process before defects occur |

Live Data Output for SPC Data Collection | Provides real-time data for Statistical Process Control | Supports ongoing quality monitoring and process control |

Automated Process Documentation for ISO | Generates process documentation automatically for compliance | Facilitates traceability and audit readiness |

Production Documentation and Traceability | Records thermal process data linked to production batches | Enables root cause analysis and supplier accountability |

Rapid Setup and Changeover | Uses pre-profiled products and automated tools to reduce setup times | Increases production efficiency while maintaining consistent quality |

Continuous Oven Performance Monitoring | Schedules predictive maintenance based on oven condition | Reduces downtime and maintains consistent process quality |

You can use these tools to track every step of the through-hole reflow process. Real-time monitoring lets you fix issues before they affect your pcb. Automated documentation helps you meet industry standards and makes audits easier.

Remember: Careful monitoring and control during reflow soldering lead to fewer defects and higher reliability in your finished pcb assembly.

Through-Hole Reflow Soldering: Inspection & Tips

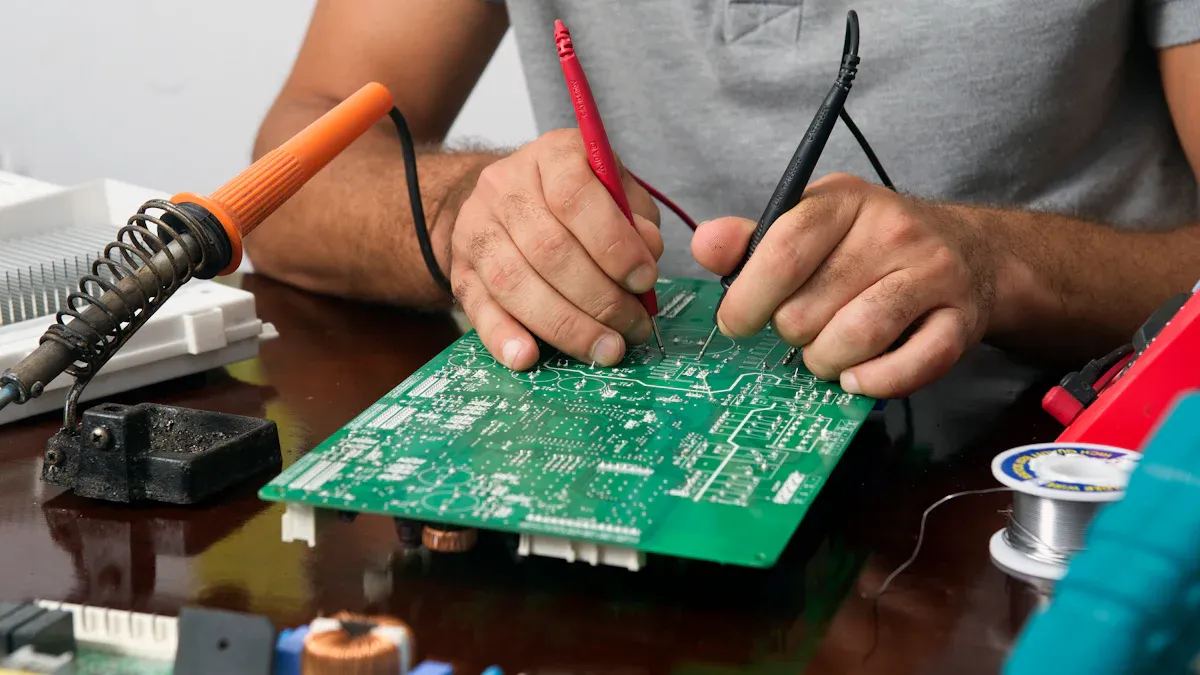

Solder Joint Quality

You need to check every solder joint after through-hole reflow soldering. LTPCBA uses Automated Optical Inspection (AOI) to make this step fast and reliable. AOI gives you real-time process control and helps you find defects that people might miss. You can reach first pass yields as high as 98% when you inspect each board with AOI. This method keeps your through-hole reflow soldering process consistent and tracks every defect for future review. AOI also uses Cp and Cpk indices to measure machine performance, so you know your soldering meets high standards.

Common Issues & Touch-Up

You may see some common problems in through-hole reflow soldering. These include bridging, cold joints, or incomplete solder fill. AOI and X-ray inspection help you spot these issues early. If you find a defect, you can use tools like solder wick or a soldering iron to fix it. LTPCBA uses root cause analysis tools, such as fishbone diagrams, to find out why defects happen. You should always keep your reflow oven and stencils clean to avoid new problems. Regular cleaning helps you keep the reflow process stable and reduces the chance of defects.

Best Practices

You can improve your through-hole reflow soldering results by following best practices:

Use Statistical Process Control (SPC) to watch for trends and keep your process in control.

Clean your stencils and reflow ovens often to prevent solder paste residue.

Set up your reflow profile with the right ramp rates and temperature zones.

Use temporary solder masks for parts that need extra protection during reflow.

Train your team and review inspection data to keep improving your process.

Tip: Always use AOI and SPC together for the best quality in through-hole reflow soldering.

By following these steps, you can avoid defects and make sure your through-hole reflow soldering process gives you strong, reliable joints every time.

You can achieve strong pcb assembly by following key steps: prepare your pcb, control the process, and inspect every solder joint. Thermal profiling helps you avoid defects and protect components. See how different soldering methods compare:

Soldering Method | Advantage |

|---|---|

Enables automated placement, high precision, ideal for high-density and miniaturized electronics | |

Wave soldering for through-hole components | Provides robust mechanical connections, well-established and reliable for high-power applications |

Combination of reflow and wave soldering in mixed technology | Combines precision and efficiency of reflow for SMT with robustness of wave soldering for through-hole, offering design flexibility and compatibility with diverse components |

Choose LTPCBA for efficient, high-quality pcb solutions.

FAQ

What is the pin-in-paste technique?

You fill the through-hole with solder paste, then insert the component pin. The reflow oven melts the paste, creating a strong solder joint.

Can you use standard through-hole parts for reflow soldering?

You should use parts rated for reflow temperatures. Standard parts may not survive the heat. Always check the manufacturer’s datasheet.

How do you check solder joint quality after reflow?

You can use Automated Optical Inspection (AOI) or X-ray inspection. These tools help you find defects quickly and keep your assembly reliable.

See Also

Typical Reflow Soldering Issues In SMT Assembly And Solutions

Importance Of Nitrogen Reflow Soldering For Automotive And PCBA

Effective Methods To Clean PCB Boards After SMT Assembly

The Effect Of Temperature Zones On PCB Quality During Reflow

Essential Wave Soldering Techniques For Successful SMT Assembly