How Accurate Temperature Profiling Impacts SMT Reflow Soldering Quality

Accurate reflow oven temperature profiling in reflow soldering is essential for creating strong solder joints. It reduces errors and maintains a consistent process. Engineers achieve clear results by precisely controlling the reflow oven temperature. For example:

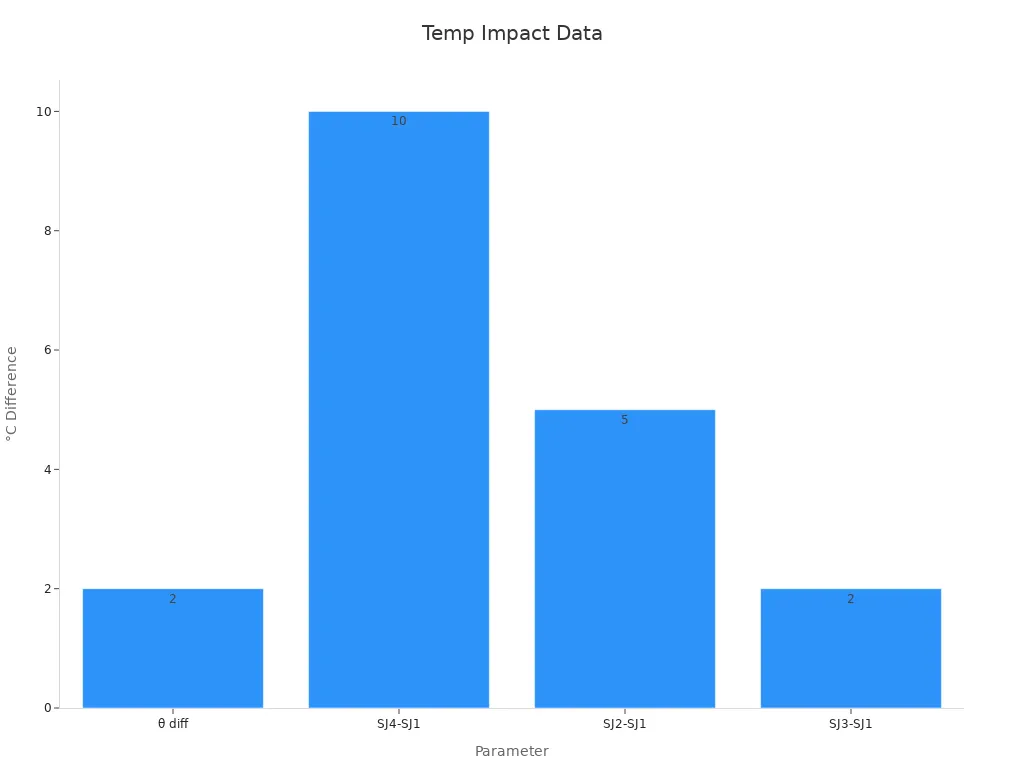

Parameter / Condition | Numerical Evidence / Result | Impact on Solder Joint Quality and Defect Rates |

|---|---|---|

Time-averaged excess temperature difference (θ¯) | Minimum difference > 2°C between good and defective joints | Helps determine if a solder joint is good or bad |

Temperature difference between most severe defect (SJ4) and good joint (SJ1) | ~10°C (ΔθSJ4→SJ1) | Larger temperature difference indicates more severe defects |

Temperature difference between other defective joints and good joint | SJ2→SJ1 ~5°C, SJ3→SJ1 ~2°C | The severity of defects is reflected in the temperature difference |

Monitoring reflow oven temperature in real time helps track the entire soldering process.

Automated systems save time, reduce waste, and lower labor costs.

Highly accurate and repeatable reflow oven temperature profiling simplifies quality checks.

Companies like LTPCBA leverage advanced technology to achieve stable reflow oven temperature control. This enables them to produce higher-quality solder joints and increase production efficiency.

Key Takeaways

Accurate temperature profiling makes solder joints strong and reliable by controlling heat at every reflow step. - Sensors and data loggers watch the temperature in real time. This helps find problems early and keeps soldering the same each time. - Doing careful quality checks and changing oven settings often lowers mistakes and makes production work better.

Temperature Profiling Basics

What Is Temperature Profiling

Temperature profiling means checking and recording the temperature of a printed circuit board as it goes through the reflow oven. Engineers use a thermal profiler to get temperature data from different spots on the board. This information makes a temperature profile. The profile shows how the board heats up and cools down during soldering.

A normal reflow thermal profile has a few main steps:

Preheat (ramp): The temperature goes up slowly, about 0.5–2.0°C per second. This helps stop thermal shock.

Soak: The board stays at one temperature for a while. This lets the flux work and spreads heat evenly.

Reflow (peak): The temperature gets highest, 15–25°C above the solder’s melting point. The board stays hot for 30–90 seconds so the solder joints form right.

Cooling: The temperature drops at a steady rate, about 4°C per second. This helps make strong solder joints.

Engineers put thermocouples on important parts and use data loggers to record the temperature profile. Software looks at the data to help make the soldering process better.

Why It Matters

A correct reflow thermal profile is very important for soldering. It keeps sensitive parts safe from damage you can’t see. Sometimes, solder joints look fine but bad temperature profiles can cause problems later in things like capacitors, fuses, or inductors. The soldering process must use the right temperature profile to protect every part. Lead-free soldering needs even more careful thermal profiling because it uses higher temperatures that can hurt parts. Engineers use the thermal profiler to make sure each reflow thermal profile fits the assembly. Keeping temperature profiles the same lowers defects, makes solder joints stronger, and helps make good products.

Tip: Always make a starting reflow thermal profile for each new assembly. Change it if parts are sensitive or the layout is different.

Reflow Oven Temperature Zones

Preheat and Soak

The reflow oven starts with preheat and soak steps. In preheat, the oven slowly gets hotter. It uses infrared or convection heat to warm the board. This slow rise stops thermal shock. It also keeps sensitive parts safe. During soak, the oven holds a steady temperature for a short time. This lets the solder paste start working. It also spreads heat evenly across the board. Careful control is very important here. Engineers test the oven to make sure the temperature profile is right for each job. A steady preheat and soak step helps lower the chance of problems.

Reflow Soldering Peak

The hottest part is called the peak stage. The oven gets 20–40°C hotter than the solder’s melting point. Most ovens set the peak between 235°C and 250°C. The exact number depends on the solder paste. For lead-free solder, the peak is usually 240–250°C. The temperature must stay below the limit for the most sensitive part. If it goes over 260°C, parts can get damaged or joints can be weak. Good control at this stage makes strong and reliable connections.

Cooling Stage

After the peak, the oven cools down in the last step. Cooling is just as important as heating. The cooling speed must be controlled. This helps the solder harden the right way. If it cools too fast or too slow, joints can be weak or cracked. Engineers test the oven to watch the cooling curve. They change the profile if needed. The cooling step finishes the process and helps make sure the product is good.

Note: Every step in the oven’s temperature profile is important. Careful checks and tests at each step help make sure the results are always good.

Temperature Monitoring Methods

Thermocouples

Thermocouples are a common tool for checking temperature during reflow soldering. Engineers use them because they last a long time and can handle tough places. These sensors react fast, which helps when watching temperature changes as they happen. The table below shows important features:

Feature | Standard Wire | Specialty Wire |

|---|---|---|

Accuracy (Type K) | ±1.1°C or 0.4% | |

Response Time (0.040") | 1.75 seconds | 1.75 seconds |

Response Time (0.250") | 24 seconds | 24 seconds |

Thermocouples can check temperatures from -270°C up to 2300°C.

They do not break easily from shaking or bumps.

Checking them often is important because they can lose accuracy over time.

Data Loggers

Data loggers are important for watching temperature because they record the whole process. These devices are very accurate and can store lots of information. The table below lists some main details:

Metric | Specification/Value |

|---|---|

Temperature Range | -100°C to 1370°C |

Accuracy | |

Resolution | ±0.1°C |

Sampling Interval | 0.05 seconds to 10 minutes |

Memory Capacity | 50,000 readings/channel |

Channels | 6 or 12 |

Data loggers let engineers get exact temperature numbers. This helps them measure better and make the process work well.

Non-Contact Sensors

Non-contact sensors, like infrared thermography, check temperature without touching anything. These sensors give quick results, but how well they work depends on the room and how they are set up. Research shows:

There is a balance between finding real temperature changes and not getting false alarms.

Things like the room’s temperature can change how well they work.

Most non-contact sensors are right within ±2°C, but if the settings are too low, there can be more mistakes.

Making sure the area is controlled and the sensor is set up right makes it work better.

Non-contact sensors are helpful for checking temperature, especially when you cannot touch the thing you are measuring.

Profiling Optimization with LTPCBA

Best Practices

LTPCBA is a leader in making the reflow soldering process better. They use new technology and follow strict rules. The team checks every step with special machines. Automated Optical Inspection (AOI) finds problems on the board’s surface. Automated X-ray Inspection (AXI) looks inside solder joints for hidden issues. Functional testing makes sure each board works right. These steps help every profile meet high standards.

Engineers at LTPCBA follow important steps to make things better:

They use AOI and AXI to find both easy-to-see and hidden problems, so quality is checked well.

They follow world rules like IPC-A-610, ISO 9001, and UL to keep products safe.

They use Statistical Process Control (SPC) to watch and improve the reflow thermal profile, which lowers mistakes and makes more good boards.

They check solder paste with Solder Paste Inspection (SPI) to stop soldering problems.

They use very accurate pick-and-place machines to put parts in the right spot.

They watch temperature and humidity all the time to keep the best conditions.

They use many ways to check for problems, like AOI, X-ray, and functional tests, to find lots of different mistakes.

They keep good records and use feedback, with a team that solves problems, to keep getting better.

This way of working helps make more good boards the first time and strong solder joints. Using a thermal profiler makes sure each temperature profile fits what is needed, so results stay the same.

Tip: LTPCBA uses many ways to check and strong rules to lower mistakes and waste, making soldering faster and better.

Process Control

Process control is very important for LTPCBA. The company watches every step in real time and uses smart tools to check the reflow soldering process. Engineers change heat settings using live data, so each reflow thermal profile stays just right. Machines check the temperature at important spots, so they can fix problems fast if something is wrong.

Statistical Process Control (SPC) helps the team see patterns and stop problems before they start. By looking at oven data, engineers can change the heat and timing for each job. This careful control works for both small and big batches. The result is a steady soldering process that gives the same good quality each time.

The company helps customers quickly if there is a problem. They answer in 24 hours and can change the temperature profile or settings if needed. This quick help keeps the quality high for printed circuit board assembly.

Quality Assurance

LTPCBA works hard to make sure quality is always high. The company has a 99.5% pass rate for products, showing their methods work well. The team uses AOI, AXI, and In-Circuit Testing (ICT) to check every solder joint and circuit. These tests find both outside and inside problems, so each board meets tough rules.

Quality Assurance Aspect | Evidence Detail |

|---|---|

Pass Rate | LTPCBA keeps a 99.5% pass rate for products, showing they are high quality and reliable. |

Statistical Process Control (SPC) | They use real-time checks and SPC to watch heat profiles during soldering, which lowers mistakes and makes things better. |

Compliance with Standards | Following IPC-A-610 and ISO 9001 rules makes their quality system strong. |

Inspection Technologies | Using AOI, AXI, and ICT helps find problems and check the process. |

Continuous Improvement | They do regular quality checks and have a team to fix problems and stop them from happening again, so there are fewer mistakes. |

The company follows world rules like IPC-A-610 and ISO 9001, which makes their quality system even stronger. They keep getting better by doing checks and listening to feedback, so there are not many mistakes. Customers get good, reliable SMT assembly because LTPCBA is good at controlling temperature, profiles, and reflow.

Note: LTPCBA’s focus on making things better, watching the process, and checking quality makes sure every soldering job gives strong, reliable joints and the same good results.

Profiling Impact on Soldering Quality

Defect Reduction

Accurate temperature profiling helps lower soldering mistakes during reflow soldering. When engineers set the right temperature, each solder joint gets enough heat for the right time. This careful control stops problems like voids, cold joints, and tombstoning. For example, tests show that changing the post-mold curing temperature can shrink warpage in semiconductor packages from about 1519 μm to 486 μm. This big drop in warpage means fewer failures from stress, which makes products more reliable.

Making the reflow soldering process better also keeps sensitive parts safe from heat damage. Keeping the temperature steady across the PCB gives even soldering quality and less need to fix or throw away boards. Using advanced profiling tools, special profiles for each part, and always improving the process all help lower soldering mistakes and make better products.

Tip: Keeping the temperature steady and making profiles better are key to fewer soldering mistakes and strong, reliable joints.

Reliability

Reliability is very important in soldering. Accurate temperature profiling makes sure the solder paste melts all the way and forms a strong metal joint. By controlling how long the solder stays hot and how fast it cools, engineers stop weak or brittle joints. For example, keeping the solder above 183°C for the right time helps make a good alloy layer. Cooling between 1–6°C per second helps the joints get hard without cracks or rust.

New ways to predict results, like using PI-LSTM models, show that good temperature profiling gives reliable data for checking how long solder joints will last. These models use simulation data and match old ways of checking reliability. This shows that accurate temperature profiles are needed to guess how long solder joints will last and work well.

Studies from groups like NASA and NOAA show that strong quality checks and changes are important. These steps keep records reliable and can be used in reflow soldering to make things even more reliable. By using these quality checks, engineers can trust their soldered boards will last a long time.

Repeatability

Repeatability means every batch of PCBs meets the same high standards. Making the reflow profile better makes sure each board gets the same temperature, so soldering quality stays the same. This lowers differences between batches and cuts down on surprise problems.

Some things that help repeatability are:

Using thermocouples and thermal imaging for exact temperature control.

Making sure solder paste and flux are put on right to stop mistakes.

Using robots and machines for steady part placement and reflow.

Checking quality with SPC, looking at boards, X-ray, and AOI.

Using data to fix problems and keep things reliable.

By working on these things, companies get steady results every time they make something. The reflow soldering process becomes easier to predict, and there are fewer soldering mistakes. This way, products are more reliable and customers are happier.

Note: Getting the same soldering quality every time needs always making things better and strict control during reflow soldering.

Data and Process Optimization

Analytics

LTPCBA uses smart analytics to keep making SMT reflow soldering better. They collect and study data as it happens. This helps engineers watch each temperature profile and see patterns fast. Automated tools do the profiling, so engineers do not have to check over and over. This saves up to 20 minutes for each profile. Real-time checks on the oven make startup faster by 10 to 15 minutes. Automated setup tools help new products get ready in just 30 minutes. This makes the reflow process work faster.

Engineers use decision tree models and predictions to find problems early. These models can guess issues with more than 82% accuracy. This lets teams fix things before they hurt quality. By using SPC with AI and machine learning, LTPCBA can look at hundreds of process details at once. This way, they can see yield problems up to 24 hours before they happen. This has made yield go up by 15%. These changes show that analytics and digital tools help keep solder joints strong and reflow results reliable.

Note: Real-time analytics help control the process and also make production faster and profits higher, just like in other industries that use digital tools.

Parameter Adjustment

LTPCBA engineers change important settings to keep reflow soldering working well. They use numbers like Process Window Index (PWI), Defects Per Million Opportunities (DPMO), and Process Capability Index (Cpk) to check if changes work. The table below lists these numbers and what they do:

Metric / Parameter | Description / Role |

|---|---|

Process Window Index (PWI) | Checks if the thermal profile stays in safe limits. |

DPMO | Counts defects, and lower numbers mean better soldering. |

Process Capability Index (Cpk) | Shows if the process is steady and under control. |

Sigma Level | Tells if the process is stable and has fewer mistakes. |

Heating Factor | Changed by adjusting exhaust, board gap, conveyor speed, and heater temperature. |

Thermal Profile Responses | Includes peak temperature, preheating slope, soaking temperature, and time above liquidus. |

Engineers change conveyor speed, heater temperature, and exhaust to fine-tune the process. They use tests like ANOVA and RMSE to make sure results are good. These changes help keep solder joints strong and lower defects in every batch.

Tip: Checking and changing settings often keeps the reflow process steady and makes sure soldering stays high quality.

Accurate temperature profiling makes soldering better, more reliable, and more consistent.

Rules like GLP and ICH Q1A(R2) say you must watch temperature for safety and quality.

New profilers and automated tools help lower mistakes and make soldering better.

Easy steps for good profiling:

Use data loggers to watch temperature as it happens.

Look at the data and change the process if needed.

Trust LTPCBA’s skills to keep things working well.

Make temperature profiling a main part of quality checks to get the best soldering and strong, reliable results.

FAQ

What is the main benefit of accurate profiling in SMT reflow soldering?

Accurate profiling lets engineers find and fix problems early. This means there are fewer mistakes in each batch. It also helps make solder joints stronger and more reliable.

How does LTPCBA ensure high-quality PCB assembly?

LTPCBA uses special inspection machines to check every board. They follow strict rules and world standards. This helps them give every customer the same high quality each time.

Can LTPCBA handle urgent PCB assembly projects?

LTPCBA can help with rush jobs and answers quickly. They give fast price quotes and have tech support all day and night. This helps them finish urgent projects on time.

See Also

Effects Of Temperature Zones On PCB Reflow Soldering Quality

Essential Process Needs For Reflow Soldering In SMT

Influence Of Solder Paste Quality On SMT PCB Soldering

Typical Reflow Soldering Defects In SMT And How To Prevent

Guide To Reflow Soldering Through-Hole Parts Post SMT Assembly