Testing methods and steps for the real-time temperature curve of reflow soldering during the manufacturing process of PCBA products

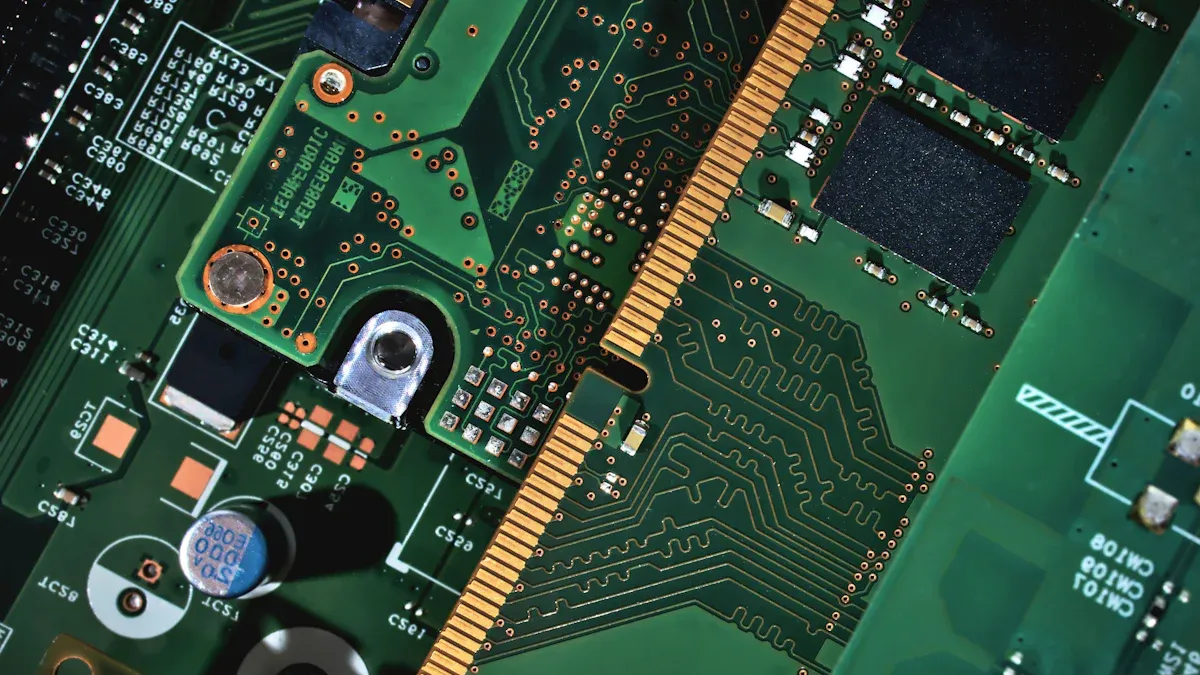

You must watch the real-time temperature curve during reflow soldering. This helps you get strong soldering results in pcba production. Accurate temperature profiling lets you stop defects and make soldering better. LTPCBA uses advanced systems and strict rules in pcba manufacturing. This makes sure every soldering process is very reliable.

Key Takeaways

Watch the real-time temperature curve during reflow soldering. This helps make strong solder joints without problems. It also makes the PCBA better.

Use sensors that are set up right. Put thermocouples at important spots on the board. Hold them tight with clamps to get correct temperature data.

Look at the temperature data often. Change the oven settings using important numbers. This keeps the soldering process steady and the same each time.

Importance of Real-Time Temperature Curve

Solder Joint Quality

Watching the real-time temperature curve during soldering is important for good quality. Each part of the curve—preheating, soaking, reflow, and cooling—changes how solder joints form. If you control the temperature at each stage, you can stop problems like voiding, bridging, and solder balls.

Adjusting the temperature for each part helps make better solder joints.

Putting thermocouples on parts with voids gives better data.

Spreading thermocouples across the board makes results more accurate.

The right tools help you find the best temperature curve faster.

A good reflow profile lowers voiding and makes joints stronger.

Statistical Process Control methods, like control charts, help you watch temperature and other important things. Using SPC and checking often means you get fewer soldering problems and better quality. Good temperature profiling makes sure the solder gets hot enough, which is needed for strong joints.

Process Reliability

You can make the process more reliable by watching the temperature curve as it happens. When you check the temperature closely, you can find problems before they get worse. In one study, engineers used real-time temperature data with a model that predicts problems. This system was 94% accurate and 99% precise at finding issues, so fixes were fast and the process stayed steady.

Case studies from car and airplane industries show that careful temperature checks make products more reliable. For example, car ECUs and satellite transmitters use strict temperature rules and tests. These steps help the products work well even in tough places. Finite Element Analysis also shows that controlling the temperature curve puts less stress on solder joints, so there are fewer failures later. By focusing on the real-time temperature curve, you make soldering more reliable and your products last longer.

Preparation

Equipment Setup

You need the right tools to measure well. At LTPCBA, you use advanced reflow soldering machines and automated systems. These machines follow strict rules and meet standards like ISO, IATF, and UL. Always check if the reflow soldering machine is clean and works right before you use it.

Follow the instructions from the manufacturer for safety and use.

Wear safety gear and keep your workspace tidy.

Make sure the machine has good airflow.

Do regular checks and look at electrical safety.

Using equipment that meets IPC standards, like IPC-TM-650 and IPC J-STD-001, helps you get results you can trust every time. These standards show you how to set up the reflow soldering machine for real temperature checks and process tests.

Sensor Calibration

You must set up your sensors before you start any test. Calibration makes sure your temperature readings are correct for the PCBA.

Pick a reference standard that is more accurate than your sensor.

Let both the sensor and the reference get to the same temperature so you do not get mistakes.

Write down what the sensor shows at different temperatures.

Compare the sensor’s numbers with the reference and use math to find what needs to change.

Change the sensor using these numbers, either with software or hardware.

Always set up your sensors again after some time.

Use labs with special approval to make sure your calibration matches big standards.

Keep good records, like certificates and dates for calibration.

Good sensor calibration helps you trust your data and makes sure you follow all the process rules.

Probe Placement on PCBA

Critical Points Selection

You have to pick the best spots for probes on your pcba. This helps you check the temperature in each zone. Every part of the reflow oven heats the board in a different way. You should put probes close to parts that are sensitive to heat, connectors, and big ground planes. These places often show the biggest temperature changes.

Criterion | Description | Impact |

|---|---|---|

Put probes near hot spots to watch heat in each zone | Stops parts from getting too hot or breaking | |

Signal Integrity | Check important signal paths in every zone | Helps keep signals clear and strong |

Proximity Rules | Do not put probes near the edge in any zone | Makes the board work better and stops shorts |

Test Point Accessibility | Pick easy-to-reach spots in every zone | Makes testing and fixing problems faster |

Component Orientation | Line up probes with the signal path in each zone | Makes building and testing easier |

Use test points with big pads and gold or tin on them for good contact in each zone.

Do not cover test points with solder mask so you get clear readings in every zone.

Make sure test points are in the same place for all temperature zone checks.

You can use digital or wireless sensors to get more details in each zone. Some people use infrared thermography when designing, but it is not good for always checking temperature zones.

Securing Thermocouples

You need to hold thermocouples tight to get steady readings in every zone. Clamping is the best way to keep thermocouples in place. This keeps the probe touching the board in all zones. If you use tape or glue, it can block heat and give wrong data.

Experts say clamping is best because it gives the same results every time in each zone. This method follows rules like J-STD-075 and helps control the process well. When you clamp thermocouples, you stop the curve from moving and keep your data right. Good thermocouple placement helps you find problems in any zone and keeps solder joints strong on your pcba.

Running Reflow Soldering Test

SMT Reflow Soldering Process

First, you put the PCBA into the reflow oven. The oven moves the board through different temperature zones. Each zone does something special. The first zone heats the board slowly. This stops thermal shock and dries the solder paste. The next zone is called the soak zone. It keeps the board warm for a while. This lets the flux work and cleans the leads and pads.

When the board goes into the reflow zone, the heat goes up fast. The solder paste melts and sticks parts to the board. You need to watch the real-time temperature curve now. If the heat is too low, the solder will not melt right. If it is too high, parts can get hurt or you can get solder balls or bridges. The last zone cools the board slowly. This makes the solder joints hard and stops cracks.

Always use the right profile for your solder paste and parts. Every SMT reflow soldering process might need changes. This depends on board size, how many parts there are, and the oven type. You can use a temperature curve test to check if the board gets hot enough at each step. This test helps you stop common problems and get good results.

You can check your data with special math methods. For example, you can use ANOVA to compare different solder pastes or settings. You can also use a weighted matrix to put many test results together. A special FMEA with weights helps you look at risks and how well things work. These tools let you measure things like solder balling, slump, printability, voiding, wetting, solder joint quality, and cleanliness. By using these math tools, you can see how your process works in different cases. This helps you pick the best solder paste and settings for your SMT reflow soldering process. It also shows that your test data is strong and can be trusted.

Data Capture

You need to collect data at every step of the SMT reflow soldering process. Real-time monitoring systems help you get and study this data. These systems watch the temperature at each probe spot and save the whole temperature curve. You can use this data to see patterns, find problems early, and make quick changes.

Data capture means getting system numbers like CPU use, memory use, disk work, and network traffic.

Pipeline numbers include how much data, how fast it moves, and error rate.

Data quality numbers are accuracy, completeness, timeliness, validity, consistency, and uniqueness.

Data is collected from logs, numbers, and traces, often with software agents; some tools check data at the agent for faster results.

Performance tests look at bandwidth, delay, errors, response times, CPU use, and network traffic.

These tests help set alerts for strange things, so you find and fix problems faster.

Real-time monitoring systems are checked for how much data they can handle, how fast, and how many errors, to make sure they work well.

Watching data quality and changes keeps the data safe and working.

Linking with incident, ticket, and service systems makes things work better.

Dashboards help you see patterns, trends, and odd things quickly.

Checking and updating monitoring rules and alerts keeps the system working well.

You can use dashboards to see the temperature curve test results. These tools help you check if the SMT reflow soldering process stays in the right range. If you see something strange, you can fix it fast. Automatic alerts tell you if the temperature is wrong or if the process slows down. This keeps your pcba production working well and helps you get good soldering quality.

Curve Analysis

Reflow Zones Overview

It is important to know about each temperature zone in smt reflow soldering. The temperature curve shows how heat moves through the board in every zone. Each zone does something special. You must keep the temperature right in every zone. This helps make strong solder joints and stops problems.

Preheating Zone: This is the first zone. It warms the board slowly. This stops thermal shock and starts the flux. The temperature curve should go up slowly here.

Soaking Zone: In this zone, the board stays at one heat. This dries the solder paste and removes oxides. Watch the temperature curve to keep the board at the right heat.

Reflow Zone: This is where the solder melts. The temperature curve is highest here. You must control the top temperature. This helps the solder flow but does not hurt parts.

Cooling Zone: This is the last zone. It cools the board down. The temperature curve should drop slowly. This makes the solder joints strong and stops cracks.

You can use a temperature control table to set the best values for each zone. The table helps you check if the temperature curve is right for your process. If you see a problem in any zone, you can change the settings to fix it.

Tip: Always look at the temperature control table before you start smt reflow soldering. This helps you avoid mistakes and keeps your process steady.

Key Parameters

You need to watch key parameters to control the smt reflow soldering process. These numbers help you keep the temperature curve safe in every zone. If you control these numbers, you get better solder joints and fewer problems.

Here is a temperature control table with important numbers and their targets:

Parameter / Measure | Threshold / Target Value | Description / Role in Optimization |

|---|---|---|

Peak Temperature | ~210°C | Target peak temperature for optimal soldering |

Preheating Slope | ~3.0 °C/s | Heating rate during preheating zone |

Soaking Temperature | ~160°C | Temperature during soaking zone |

Process Capability Index (Cpk) | > 1.43 | Shows process capability and quality |

Process Window Indices (PWI) | Used for evaluation | Measures process robustness and window for acceptable parameters |

Defects Per Million Opportunities (DPMO) | Used for evaluation | Defect rate metric for quality assessment |

Model Adequacy (R^2) | > 0.90 | Indicates model fit and quality |

Influential Variables | Conveyor speed, exhaust rate, board gap, heater temperature settings | Key factors affecting thermal profile and soldering quality |

You should use the temperature control table to check your real-time data against these targets. If the temperature curve goes outside the safe range in any zone, you need to change the process. You can use math tools like Process Window Index (PWI) and Cpk to see how well you control the process. These tools help you find weak spots in your smt reflow soldering process.

Control the conveyor speed so the board stays in each zone long enough.

Change the exhaust rate to remove fumes and keep the temperature curve steady.

Set the board gap and heater temperature to match your temperature control table.

Note: You can use advanced methods like Response Surface Methodology or hybrid AI models to make your smt reflow soldering process better. These methods help you find the best settings for each zone and improve your temperature curve.

If you follow these steps and use the temperature control table, you will control the smt reflow soldering process better. You will see fewer problems and higher quality in your PCBA products.

Oven Adjustment

Profile Optimization

You must change oven settings by looking at the real-time temperature curve. Modern reflow ovens have many heating zones. Each zone can get hot or cool at its own speed. You put thermocouples on your PCBA to get temperature data from each zone. This data shows how heat spreads across the board. Studies say using data from many zones helps you control the temperature profile better. You do not need as many test runs and can find the best settings faster. This is very important for lead-free soldering, which needs higher heat and careful control. By checking each zone’s temperature, you make sure every part gets enough heat. This step makes the process more reliable and helps you get strong solder joints.

Tip: Always look at the temperature data after each run. Even small changes in oven speed or zone heat can change how well the soldering works.

LTPCBA Quality Assurance

At LTPCBA, you use smart systems to watch and control every step of reflow. You use real-time temperature curve data to adjust oven settings. This keeps the process steady and the same each time. You check each zone’s temperature and change settings to stop defects. Your team follows strict world standards for high quality. You write down every change and result. This focus on process control helps you make products that pass tests. You can trust that each PCBA is made to meet your quality needs.

Verification and Documentation

Solder Joint Inspection

You have to check every solder joint for quality. There are rules like IPC-A-610 and IPC J-STD-001 that tell you how to do this. You use your eyes, AOI, and X-ray tools to look for problems. Some problems are not enough solder, solder bridges, cold joints, or cracks. Checking the joints makes sure they are strong and work well.

Feature | Requirement Summary |

|---|---|

Solder must cover the lead and pad, making a strong bond. | |

Wetting Evidence | Solder should look smooth and shiny for a good bond. |

Maximum Lead Side Overhang | Overhang must stay small to stop stress and keep it working. |

Minimum End Joint Width | Joint width must be big enough for each class. |

Minimum Side Joint Length | The joint needs to be long enough to hold up. |

Heel Fillet Height | Fillet should not touch the part and must be tall enough. |

You use these rules to see if each joint is good. AOI and X-ray help you find hidden problems and make sure the joints are right.

Data Recording

You must write down inspection data the right way. This helps you track and control quality. Make sure your data comes from safe and trusted places. AOI systems take clear pictures and compare them to good models. Smart computer programs help you find problems and lower mistakes.

Make sure all needed data is there and matches the first records.

Check any changes to the data to keep it right.

Write down what you find so you have a good record.

You can use new tools like AI to find strange things and blockchain to keep records safe. If you follow IPC-1782, you track materials, steps, and test results. This helps you find problems fast and keep getting better. Good data recording keeps your products good and helps customers trust you.

Best Practices

Routine Profiling

You should always do routine profiling. Regular checks help you find changes early. This stops problems before they start. Make a schedule for profiling each line. Always use the same test board and probe spots. This makes your data easy to compare.

Check the temperature zone at the start of every shift.

Write down the results in a logbook or on a computer.

Look at old profiles to see trends or sudden changes.

Tip: If you notice a big change in the temperature zone, stop production and check why. Acting fast can stop defects and save time.

Staff Training

You must teach your staff why temperature profiling matters. Show them how to put probes in the right spot. Teach them how to read the data. Use hands-on lessons and pictures to help them learn. Trained staff can find problems early and keep things working well.

Training Topic | Key Points |

|---|---|

Probe Placement | Right spot in temperature zone |

Data Interpretation | How to read and understand curves |

Safety Procedures | How to use equipment safely |

Update training materials often. Tell your team to ask questions and give feedback. This helps everyone care about quality and pay attention to details.

You make PCBA soldering reliable by doing each step right. First, get ready and set up your tools. Next, put probes in the best places. Then, test the board and look at the results. After that, change settings if you need to. Last, check your work to make sure it is good. Studies using data show that watching the temperature curve closely makes solder joints stronger and more reliable.

LTPCBA uses smart systems and follows strict rules to help you get the same, high-quality results every time. Use these best ways to do your work well.

FAQ

How often should you calibrate temperature sensors in reflow soldering?

You need to calibrate sensors two times a year or after big repairs. Doing this often helps you get the right temperature numbers. This makes sure your soldering works well and is reliable.

What is the best way to secure thermocouples on a PCBA?

The best way is to use clamps. Clamps keep thermocouples tight so they do not move. This way, you get the best temperature data during reflow.

Why does LTPCBA use automated inspection after reflow soldering?

Automated inspection finds problems fast. You get quick results and can fix things right away. This helps you keep your work good and always the same.

Tip: Always check your inspection data. This helps you see patterns and make your process better.

See Also

The Role Of Precise Temperature Profiling In SMT Reflow

Effects Of Temperature Zones On PCB Quality During Reflow

Essential Process Needs For Reflow Soldering In SMT