Rapid SMT Assembly Services: Meeting Tight Production Deadlines Without Sacrificing Quality

You must make electronics fast. Rapid SMT Assembly helps with this. It uses machines and new inspection tools. Studies say machines can make work 30% faster. Special cameras and X-rays check the work. This lets you finish quickly and keep good quality.

Key Takeaways

Rapid SMT Assembly uses smart machines to build circuit boards fast.

These machines check the boards to keep quality high.

This helps you finish your project on time.

Special cameras, X-rays, and AI find mistakes early.

This means your boards work well and cost less to fix.

Pick a company with good skills and certifications.

Make sure they can change plans if needed.

This helps your project go quickly and easily.

Rapid SMT Assembly Overview

What Is Rapid SMT Assembly

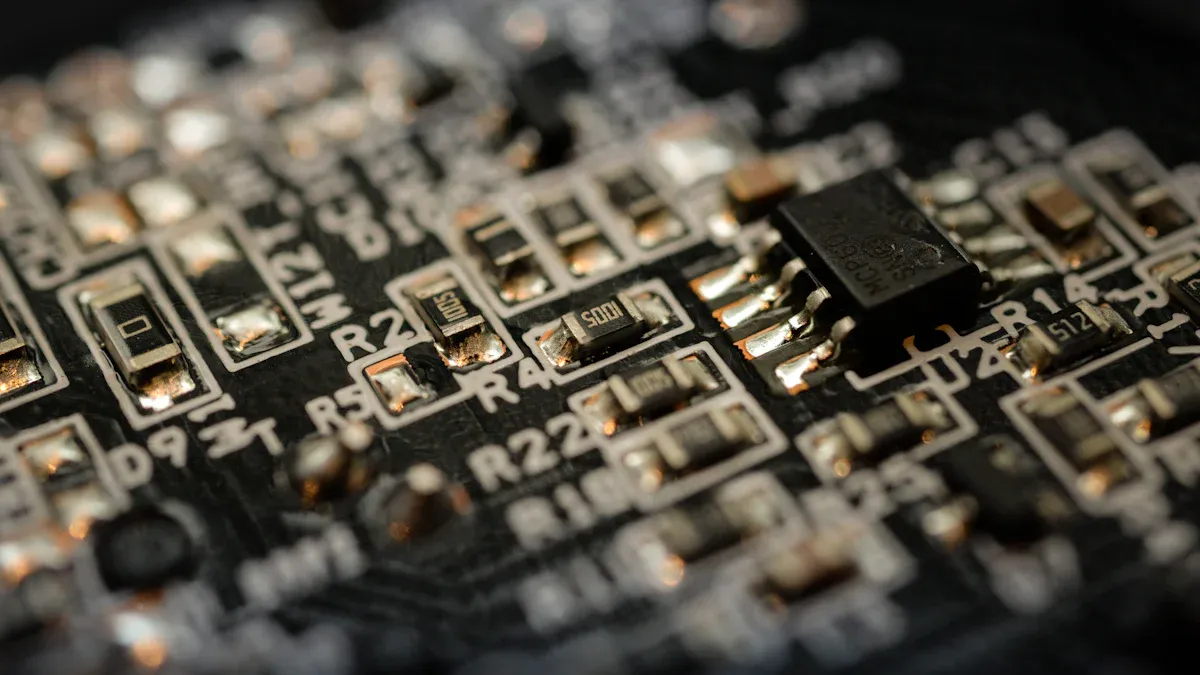

Rapid SMT Assembly helps make circuit boards fast and right. Machines do most of the work. They put tiny parts on boards. Robots add solder paste and place each part. Cameras and X-rays check the boards for mistakes. The main ideas are speed, accuracy, and good quality.

Description | |

|---|---|

Small Parts | Uses tiny parts to make better and smaller circuits. |

Laser tools help put the right amount of paste in the right spot. | |

Controlled Heating | Ovens with special controls melt solder just right for strong joints. |

Fast Part Placement | Machines quickly and carefully put parts in the right place. |

Automatic Checks | Cameras and X-rays find problems early to keep boards good. |

Boards are designed to be simple to build and need less hand work. | |

Better Process | Settings are changed to make work faster and more reliable. |

Careful checks help catch mistakes and save money. |

When Speed Matters

Rapid SMT Assembly is needed when you have little time. It helps you test ideas fast. You can fix problems before making many boards. Machines can make hundreds or thousands of boards quickly. This is good for urgent jobs and new products. It also helps when you need to change designs fast.

Tip: You can get a sample board in one day. Big orders can be ready in ten days or less. Local shops are faster, but faraway ones are better for big jobs.

Typical Use Cases

Many businesses use Rapid SMT Assembly when they need things fast and good. Hospitals need quick boards for medical tools. Car makers use it for new car electronics. Tech companies use it to sell new gadgets first. New wearable tech companies use it to test and fix their ideas fast.

Medical: Fast boards for important tools.

Cars: Quick changes for new models.

Gadgets: Fast launches and feedback.

Wearables: Shorter testing and faster sales.

These examples show how Rapid SMT Assembly helps you win in a fast world.

Quality at Speed

Quality Assurance Measures

You want every board to be good, even if you work fast. Rapid SMT Assembly uses many checks to keep boards strong. Machines look for problems early. This helps you fix mistakes before they get worse.

Solder Paste Inspection (SPI) uses 3D cameras. It checks if there is too much or too little paste. Bad paste can make weak joints.

Automated Optical Inspection (AOI) checks if parts are in the right spot. It finds missing or wrong parts fast.

X-ray inspection looks inside the board. It finds hidden problems under chips.

Functional circuit testing turns on the board. This makes sure it works right.

Real-time monitoring watches numbers like defect rates. You can see problems and fix them quickly.

Statistical Process Control (SPC) uses data to keep things steady. It helps you get better over time.

Note: These checks are very fast. They do not slow down your work. You get more good boards and fewer mistakes.

Here is a table to show how these checks help:

Quality Control Method | What It Does | Why It Matters |

|---|---|---|

SPI | Checks solder paste | Stops weak joints |

AOI | Finds wrong or missing parts | Less fixing needed |

X-ray | Looks for hidden problems | Makes sure joints are good |

Functional Test | Turns on board | Checks if it works |

SPC | Watches data | Helps you improve |

Real-time checks and smart computers help you find problems early. Over 78% of PCB lines use AOI. New 3D AOI finds 65% more problems than old 2D ones. AI helps in over 60% of checks. It finds almost 50% more mistakes. These tools let you work fast and still make good boards.

Advanced Equipment

You need great machines to work fast and well. Modern SMT lines use fast robots, smart ovens, and good inspection tools. Companies like Panasonic, Fuji, Yamaha, and Juki make machines that place up to 45,000 parts each hour. These machines use AI to find problems, fix placement, and know when they need care.

AI in SMT machines finds problems right away. It helps you fix them fast.

3D vision systems check every part and joint for mistakes.

Modular machines let you change jobs quickly.

New soldering, like laser and vacuum, works with tiny parts safely.

Modern SMT lines also control heat, humidity, and static. This keeps boards safe from harm. It helps you finish work on time. Fast checks and flexible machines let you switch jobs without losing time or quality.

Compliance and Standards

You must follow rules to keep boards safe and strong. Rules like IPC-A-610 Class 3, ISO9001, and ISO 26262 set high standards. These rules cover how you place parts and check your work.

You must wear safety gear and keep your area safe.

Check and care for machines often to stop breakdowns.

Handle chemicals safely and keep your space clean.

Training helps your team do things the right way.

Here is a table to show how rules help you:

Standard / Method | What It Needs | How It Helps You |

|---|---|---|

IPC-A-610 Class 3 | Very good assembly | Makes boards safe for important jobs |

ISO9001 | Written, controlled steps | Fewer mistakes, more trust |

Safety for car electronics | Safer boards in cars | |

AOI and X-ray Inspection | Needed by rules | Finds problems early |

Compliance Reporting | Good records and checks | Shows you follow the rules |

Tip: Certifications like SMTA, ITAR, and UL show you meet world rules. Few engineers have SMTA, so it means you are skilled and trusted.

By following rules and using smart tools, you keep boards safe and ready for any job. New factories use strict controls and smart checks. They do better than old ways. You get faster, safer boards and happy customers.

Choosing a Provider

Key Capabilities

Pick a partner with good skills and tools. They train workers well and use smart machines. Good companies follow rules like IPC-A-610 and ISO 9001. Their machines can do many jobs at once. They use AI to check boards and share data fast. Teams with over 25 years of work help you avoid mistakes. They also help you finish faster. Look for fast service, easy quotes, and help with shipping.

Tip: Companies that always try to get better make fewer mistakes. They also teach workers to work safely and well.

Selection Criteria

Check these things before you pick a company. Use this table to help:

What to Look For | |

|---|---|

Capabilities | Fast jobs, BGA, small parts, and different amounts |

Certifications | ISO 9001, IPC-A-610, ISO 13485, ITAR |

Testing & Inspection | AOI, X-ray, working and in-circuit tests |

Customer Support | Help from engineers, clear papers, quick answers |

Volume Flexibility | Small or big orders |

Design for Assembly | Help with design, parts, and testing |

Companies like Profab Electronics and Suntronic Inc. show that experience and good checks make boards you can trust.

Overcoming Challenges

Pick a company that can handle problems. They should fix supply issues, design changes, and order size changes. The best ones use data and AI to plan work and fix problems. They check parts, find new ones if needed, and keep machines working. Local shops are fast and easy to talk to. Faraway shops may be cheaper for big jobs. Choose what fits your project best.

You can make products faster, better, and cheaper with advanced SMT assembly. Smart machines, AI tools, and smooth processes ensure steady results. Reports and industry trends show using these tools helps you stay quick and strong in electronics production.

FAQ

How fast can you get boards with rapid SMT assembly?

You can get prototype boards in as little as 24 hours. Large orders often ship within 10 days. Speed depends on your design and part availability.

What quality checks do you get with rapid SMT assembly?

You get automated optical inspection, X-ray checks, and real-time monitoring. These tools catch mistakes early and help you get reliable boards every time.

Can you use rapid SMT assembly for both small and large orders?

Yes! You can order just one board or thousands. Many providers offer flexible volume options to fit your project needs.

Tip: Always ask your provider about their minimum and maximum order sizes.

See Also

Meeting SMT Assembly Standards For Automotive Product Success

Fast PCB Prototype Assembly Boosts Overall Project Productivity

Maximizing SMT PCB Assembly Efficiency And Yield Optimization

Improving Hardware Assembly Processes To Achieve Superior Results

Advanced BGA Assembly Methods For Reliable Electronics Production