Rapid Prototype SMT Assembly: How to Get Your Electronics Product to Market Faster

Rapid Prototype SMT Assembly helps you make your electronic ideas fast. When you pick LTPCBA, you get the best machines. They use strong quality checks and have a steady supply chain. You get quick results and help at every step. This lets you reach the market faster and feel sure about your product.

Key Takeaways

Rapid Prototype SMT Assembly lets you make and test boards fast. You can find problems early and fix them. This helps you save time and money.

Pick the right parts and make clear design files. Work with skilled partners like LTPCBA. This makes assembly and testing fast and good quality.

Good quality checks and quick supply chains help a lot. Expert help from LTPCBA lets you go from prototype to production fast and with confidence.

Rapid Prototype SMT Assembly Basics

What It Is

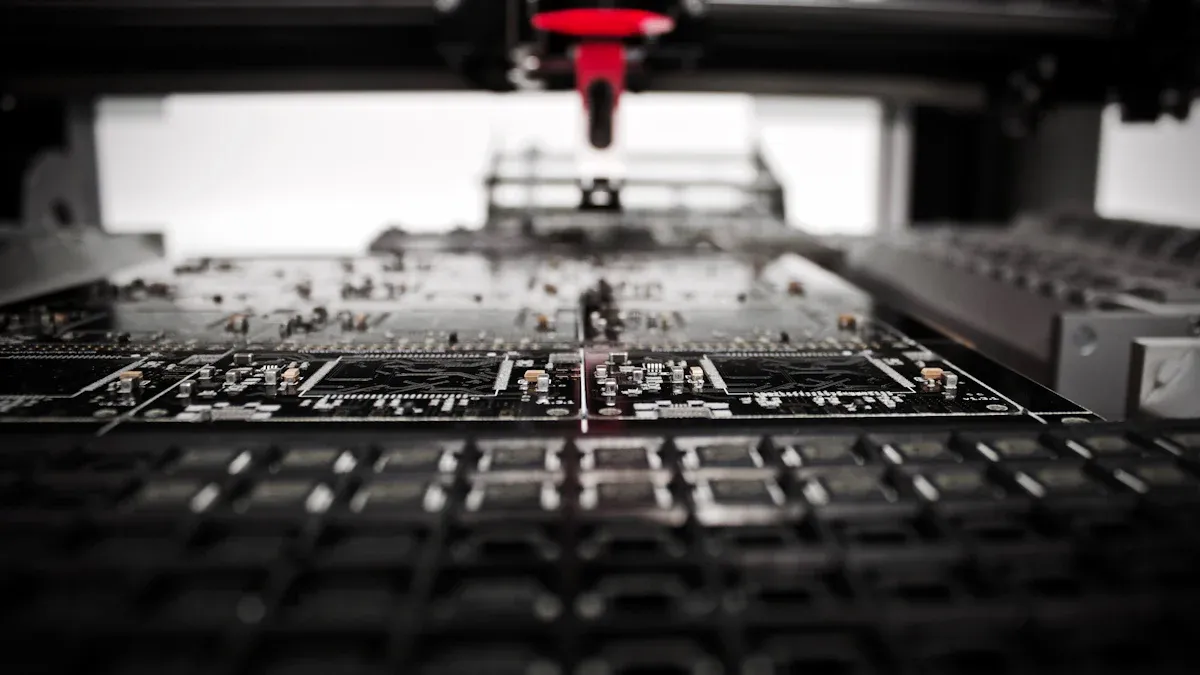

Rapid Prototype SMT Assembly lets you make and test circuit boards fast. Machines put small parts on the board with high accuracy. This helps you spot mistakes early and fix them before making lots of boards. Automation, like pick-and-place robots and inspection tools, makes things quick and steady. You can try new ideas and see what works in just a few days.

LTPCBA gives you this service with top machines and skilled workers. You get fast help, strong checks for quality, and support all the way. This lets you go from idea to working sample without waiting long.

Key Benefits

You get many good things when you use Rapid Prototype SMT Assembly:

Find problems soon so you have less risk.

Make your design better each time you try.

Save money by not making late changes.

Know how much your project will cost and how long it takes.

Get strong testing and checks for high quality.

Tip: Companies have used this process to test many designs in the same time and budget as one normal build. This lets you try more ideas and choose the best one.

When to Use It

You should use Rapid Prototype SMT Assembly if you want to:

Situation | Why It Helps |

|---|---|

Launch a new product | Get to market before others |

Test different designs | Try many layouts and features fast |

Validate ideas with real samples | Show working boards to users or investors soon |

Move from prototype to production | Fix problems early and grow your project easily |

LTPCBA helps you in all these times, making sure you get good boards on time.

Process & Best Practices

If you want to make your electronics idea real, you need a simple plan. Rapid Prototype SMT Assembly helps you go from design to working board fast. LTPCBA does most of the work for you, so you can focus on your design. Here is how you can do well at each step.

Design Prep & DFM

Begin with a good design. Make sure your files are ready for quick building. Check if your parts are easy to get and use normal board sizes. Keep your design simple by using fewer layers and following the rules for making boards. Always look over your files for mistakes before you send them.

Tip: Use Design for Manufacturability (DFM) checks. This helps you find problems early and stops delays.

LTPCBA checks your design files for any issues. Their team looks at part shapes, spacing, and hole sizes. They help you fix problems before they start building. This saves you both time and money.

Component Selection

Pick the best parts for your project. Choose parts that are easy to buy and work well with SMT assembly. Do not use rare or old parts because they can slow you down.

Here are some good tips for picking parts:

Use parts that are in stock and fit SMT assembly.

Make sure your parts fit the board and do not touch each other.

Balance price and quality to stay on budget.

Make sure your parts can handle the stress of building and testing.

Metric Category | What to Watch For | Why It Matters |

|---|---|---|

High density for smaller boards | Saves space and supports miniaturization | |

Assembly Speed | Fast placement with automated machines | Speeds up prototyping |

Quality Inspection | High AOI pass rates, few solder defects | Ensures good assembly quality |

Electrical Testing | Passes continuity and in-circuit tests | Confirms correct part selection |

Reliability Under Stress | Survives vibration and temperature changes | Proves long-term durability |

LTPCBA uses smart machines to place tiny parts, like 01005 chips and BGAs. Their supply chain helps you get parts fast, so your project stays on time.

File Submission

Send your design files in the right way. Most companies want Gerber or ODB++ files and a Bill of Materials (BOM). Check your files for mistakes before you send them.

Good tips for sending files:

Make sure your Gerber and BOM files match your design.

Add clear labels and part numbers.

Put in fiducial markers and panelization if needed.

Use normal footprints and spacing.

Sending files the right way helps you avoid errors. LTPCBA can start building as soon as they get your files. Their team can finish prototypes in just 24 hours.

Note: You can start putting parts on or programming while the board is being made. This saves time and makes your project faster.

Assembly & Testing

When your files and parts are ready, building starts. LTPCBA uses fast pick-and-place machines to put parts on your board. They use lead-free solder and control heat for strong joints.

Testing is very important. LTPCBA uses Automated Optical Inspection (AOI), X-ray, and In-Circuit Testing (ICT) to check for problems. They also do tests to make sure your board works right.

AOI checks for missing or wrong parts on the surface.

X-ray finds hidden problems under chips like BGAs.

ICT checks for shorts, opens, and correct values.

These steps help you find problems early and fix them before making lots of boards.

Speed & Quality Tips

You can get great results by following these tips:

Keep your paperwork clear and complete.

Pick parts that are easy to find and fit your board.

Work with skilled partners like LTPCBA for fast help.

Use DFM checks to find problems before building.

Use automated inspection and testing tools.

Protect sensitive parts from static and water.

Tip: LTPCBA’s machines and strong checks help you get good boards fast. Their team helps you from start to finish, so you can keep making your design better.

By following these tips, you can use Rapid Prototype SMT Assembly to test ideas, fix problems, and get your product to market faster.

Challenges & Solutions

Cost & Supply Chain

You may notice that Rapid Prototype SMT Assembly can seem expensive at first. The global SMT equipment market reached about $5.7 billion in 2022 and is expected to grow even more. This growth shows that the machines and tools needed for assembly cost a lot. Setting up a line with pick-and-place machines, solder paste printers, and inspection systems takes a big investment. For small businesses, these costs can feel like a barrier.

Supply chain issues also affect your project. Tariffs on imports can raise prices and cause delays. Sometimes, it is hard to find the right parts because many suppliers are overseas. Companies have found ways to solve these problems:

Move production closer to where you need the boards.

Use more than one supplier to avoid shortages.

Change how you import parts to lower tariffs.

Watch trade rules and stay flexible.

LTPCBA helps you by using a strong supply chain and quick sourcing. Their team finds parts fast and keeps your project on track.

Compliance

You want your boards to meet safety and quality rules. LTPCBA follows important standards like ISO 9001 for quality and RoHS for safety. They also use IPC standards to make sure your boards work well. These certifications help your product pass tests and reach more markets. You can trust that your boards will be safe and reliable.

Note: LTPCBA’s high pass rate and international certifications show their focus on quality and compliance.

Prototype to Production

Moving from a prototype to full production can be tricky. You need to keep the same quality and fix any last issues. LTPCBA supports you at every step. Their team checks your design, tests your boards, and helps you scale up. With a 99.5% pass rate, you know your boards will work as you grow. You can move from idea to mass production with less risk and more confidence.

You can lower risk and get to market faster with LTPCBA’s expert assembly services. Industry trends say that quick assembly, getting parts nearby, and strong testing can make things up to 80% faster. If you follow good steps, work with a trusted partner, and let LTPCBA help, your next electronics project will go well.

FAQ

How fast can you get a prototype with LTPCBA?

You can get your prototype in as little as 24 hours. LTPCBA uses advanced machines and a quick process to speed up delivery.

What files do you need to start SMT assembly?

You need Gerber files, a Bill of Materials (BOM), and assembly drawings. These files help LTPCBA build your board correctly.

Can you order just one or two boards for testing?

Yes! LTPCBA supports small orders. You can test your design with just one or two boards before moving to larger production.

See Also

Accelerating Project Success With Fast PCB Assembly Prototypes

Fast SMT Assembly Services That Ensure Quality And Deadlines

Where To Obtain Fast Turnaround PCB Prototypes In America

Effective Ways To Simplify Hardware Assembly For Improved Outcomes

How Component Procurement Speeds Up Electronics Time-To-Market