How Quick Turn PCB Prototyping Speeds Up Medical Device Innovation

Quick turn PCBA prototype medical solutions from LTPCBA drive enhanced innovation in product development, allowing you to move from concept to working hardware in just days. By leveraging quick turn PCBA prototype medical services, you can accelerate the iterative design process, identify risks early, and achieve your objectives faster. With rapid design iterations, flexibility, and customization, you can easily adapt to evolving requirements and support rigorous testing. LTPCBA leads the industry in quick turn PCBA prototype medical solutions, offering lightning-fast cycle times, advanced quality controls, and unmatched flexibility, empowering your iterative design process and enabling enhanced innovation throughout every stage of product development.

Key Takeaways

Quick-turn PCB prototyping lets medical device developers move from design to working hardware in just days, speeding up innovation and testing.

Using rapid prototyping helps catch design flaws early, reduces costly errors, and shortens development cycles by up to half, leading to faster product launches.

High-quality standards and strict testing ensure prototypes meet medical regulations without sacrificing speed or reliability.

Partnering with experienced manufacturers like LTPCBA provides expert support, fast delivery, and flexible small-batch production to keep projects on track.

Advanced technologies and digital tools in rapid prototyping enable smarter, smaller, and more personalized medical devices for better patient outcomes.

Quick Turn PCBA Prototype Medical Devices

What Is Quick-Turn PCB Prototyping?

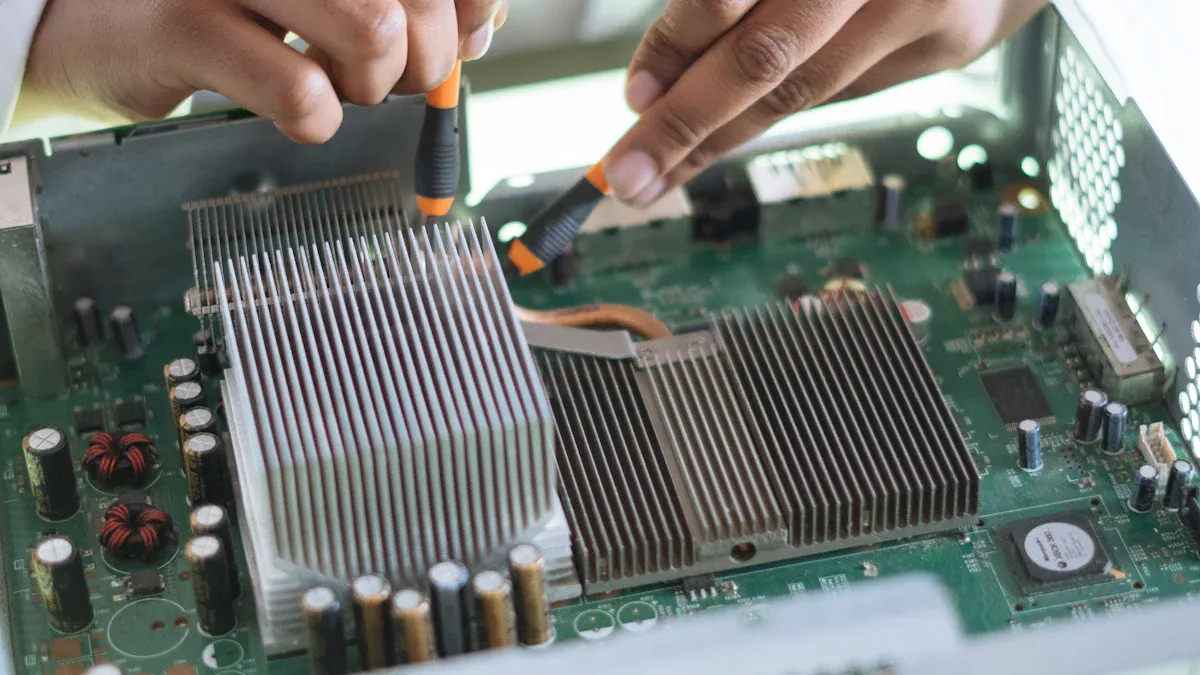

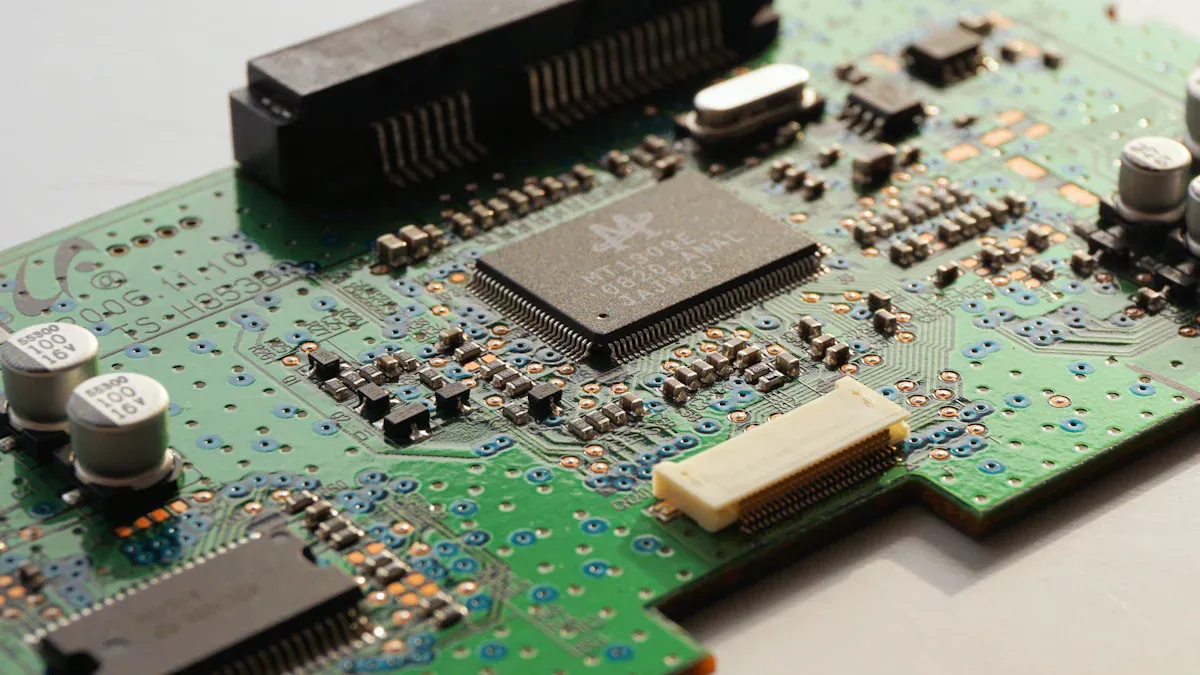

Quick-turn pcb prototypes represent a specialized approach to prototyping that allows you to move from design to physical board in record time. In the medical field, you often need to test new ideas quickly and validate designs before moving to mass production. Quick turn pcba prototype medical solutions give you the ability to create, test, and refine your concepts with speed and precision. This process uses advanced quick-turn pcb assembly methods, such as SMT and BGA assembly, to handle complex layouts and tight tolerances. You benefit from rapid prototyping cycles, which means you can identify design flaws early and reduce costly rework.

LTPCBA stands out in the quick-turn pcb assembly market by offering:

Delivery of quick-turn pcb prototypes in as little as 24 hours for urgent projects.

Advanced testing, including AOI and X-ray inspection, to ensure every prototype meets strict medical standards.

Affordable small-batch quick turn pcba prototype medical runs, so you can iterate without breaking your budget.

Dedicated engineering teams who review your designs for manufacturability, helping you avoid delays.

24/7 customer support to keep your rapid prototyping projects on track.

Why Speed Matters in Medical Devices

Speed is critical in medical device development. Rapid prototyping with quick-turn pcb assembly lets you respond to changing requirements and regulatory updates without losing momentum. You can quickly adapt your designs, test new features, and meet tight deadlines for clinical trials or product launches. Quick turn pcba prototype medical services help you stay ahead of competitors and deliver safer, more effective devices to market.

LTPCBA’s quick-turn pcb prototypes combine rapid turnaround with high quality. Their certifications, such as ISO and UL, and a 99.5% product pass rate, ensure your prototypes meet the highest standards. With robust testing and expert support, you can trust LTPCBA to help you achieve your rapid prototyping goals and accelerate your path to innovation.

Rapid PCB Prototyping Benefits

Accelerating Development Cycles

You face constant pressure to innovate in medical device product development. Rapid pcb prototyping gives you the power to move from concept to functional hardware in record time. With quick-turn pcb assembly, you can test new ideas, refine designs, and implement changes without waiting weeks for each iteration. This approach transforms your development timelines, making accelerating development cycles a reality.

Rapid pcb prototyping enables you to perform multiple design iterations within days, not months.

Early detection of design flaws through prototyping helps you avoid costly redesigns and manufacturing delays.

Real-world testing of prototypes lets you analyze signal integrity, heat dissipation, and electrical behavior.

Companies using rapid pcb prototyping often see a 30-50% reduction in development cycles, leading to faster time to market.

Prototyping reduces production costs by preventing large-scale errors and expensive recalls.

Medical device companies benefit from quick-turn pcb assembly by launching products faster in response to evolving clinical needs.

Integration of PCB design services with prototyping streamlines your workflow through advanced simulation, optimized layouts, and automated error checks.

When you partner with LTPCBA, you gain access to advanced quick-turn pcb assembly technology and a team that understands the urgency of rapid prototyping. Their quick turnaround time and rapid turnaround capabilities keep your projects on schedule, helping you stay ahead in a competitive market.

Reducing Time-to-Market

Reducing time-to-market is essential for your success in the medical device industry. Rapid pcb prototyping and quick-turn pcb assembly allow you to compress your development timelines and respond quickly to regulatory changes or market demands. You can move from design to prototype in as little as 24 hours, thanks to LTPCBA’s optimized assembly processes and quick turnaround time.

LTPCBA delivers a 24-hour rapid pcb prototyping service with a 99.2% on-time delivery rate.

Optimized assembly processes reduce lead times by 30-50% compared to industry benchmarks.

Engineering DFM analysis resolves nearly 28% of manufacturing issues before production begins.

ISO 9001-certified production with a 99.97% first-pass yield ensures your prototypes are reliable and ready for testing.

Over 8,000 successful projects in medical and other industries prove LTPCBA’s ability to accelerate product development.

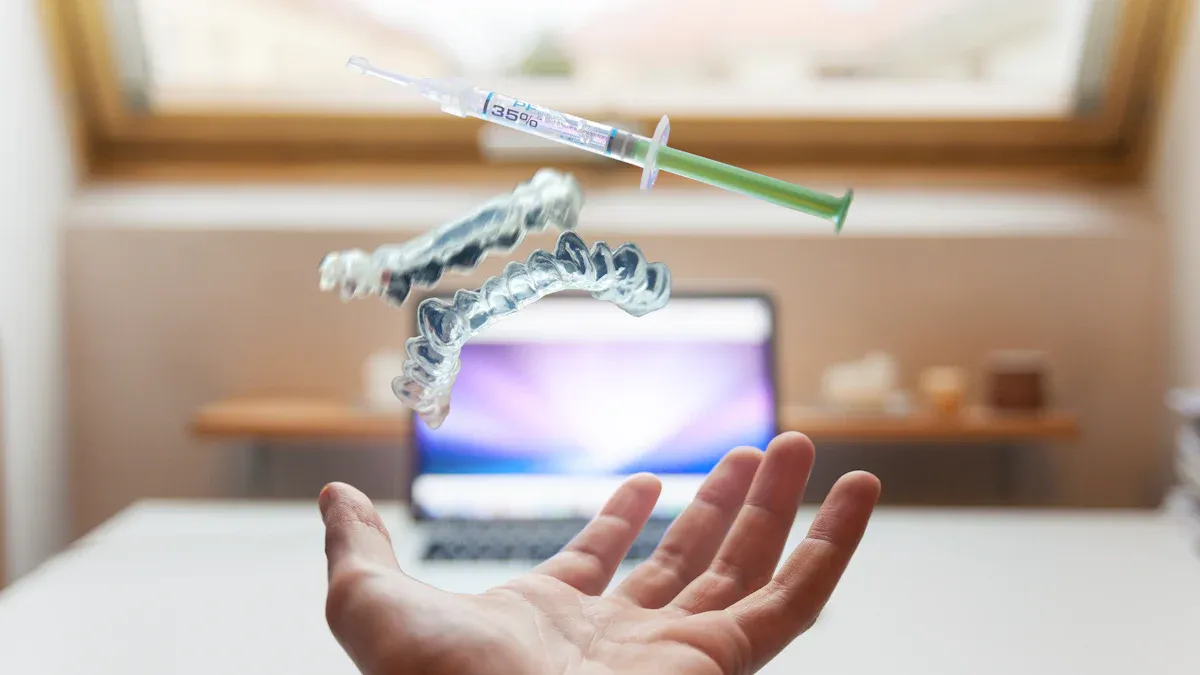

Consider the example of a client who developed an inhaler device through three rapid pcb prototyping iterations. Each cycle brought size reductions, usability improvements, and regulatory compliance adjustments. This process, powered by quick-turn pcb assembly, led to a faster time to market and a more competitive product.

Tip: Partnering with an end-to-end EMS provider like LTPCBA ensures design for manufacturability, reduces rework, and supports regulatory compliance, all of which contribute to reducing time-to-market.

Quality Assurance and Compliance

Quality assurance and compliance are non-negotiable in medical device product development. Rapid pcb prototyping with quick-turn pcb assembly does not mean sacrificing quality. Instead, you can achieve high standards through advanced testing and strict process controls.

Select a reputable manufacturer like LTPCBA, which uses industry-standard production technology.

Provide clear and accurate design files to minimize manufacturing errors.

Conduct quality inspections at multiple stages during manufacturing.

Perform comprehensive factory testing, including electrical, visual, and dimensional checks.

Utilize automated equipment such as AOI and flying probe testers to reduce human error and improve efficiency.

Maintain strong communication with your manufacturer to address issues quickly.

Adhere to industry standards such as IPC for reliability and consistency.

LTPCBA employs specialized testing solutions, including the ATE Checksum Dual-Purpose Tester and the SPEA 4060M Flying Probe Tester. These tools deliver over 95% test coverage and rapid results, making them ideal for quick-turn pcb assembly and rapid prototyping. Automated Optical Inspection and First Article Inspection further ensure that every prototype meets your specifications.

Certification | Relevance to Medical Device PCB Prototyping Compliance | Key Focus Areas |

|---|---|---|

ISO 13485:2016 | Critical for medical device PCB manufacturing compliance | Medical device QMS, risk management, traceability |

ISO 9001:2015 | General quality management framework, supports ISO 13485 | Quality management, continuous improvement |

UL, IPC Standards | Additional safety and quality assurances for PCB manufacturing | Component safety, process reliability |

You can trust LTPCBA’s quick-turn pcb assembly to deliver prototypes that meet ISO 13485, ISO 9001, and UL standards. Their commitment to quality and compliance ensures your medical devices are safe, reliable, and ready for regulatory approval.

Steps for Quick-Turn PCB Prototypes

Design File Submission

You start the quick-turn pcb prototypes process by preparing and submitting complete design documentation. This step sets the foundation for successful prototyping and small-batch production. You need to provide:

Fabrication Drawing: Include the board outline, mounting holes, stack-up details, drill locations, and any special features like slots or cut-outs. Add silkscreen, solder mask, and impedance requirements.

Assembly Drawing: Show where each component goes, using reference designators. Highlight critical assembly areas and include any special mounting instructions.

Bill of Materials (BOM): List every part with accurate descriptions, reference designators, and full manufacturer part numbers. Update the BOM to reflect any design changes.

IPC Netlist: Supply this file to verify connectivity and assembly correctness during testing.

Tip: Submitting clear and accurate files helps LTPCBA’s automated systems process your order quickly, reducing errors and delays in prototyping.

You also need to finalize your BOM and check component availability. Inventory verification ensures all materials meet required specifications and certifications, such as RoHS and UL. This step prevents delays and supports rapid small-batch production.

DFM and Material Selection

After you submit your files, LTPCBA’s engineering team reviews your design for manufacturability (DFM). This review identifies potential issues before manufacturing begins, saving you time and money during prototyping. Automation tools break your project into smaller tasks, minimizing manual errors and keeping the process efficient.

Material selection plays a critical role in the performance and compliance of medical device quick-turn pcb prototypes. You must choose materials that match your application’s needs:

Material | Key Properties and Impact on Medical PCB Performance and Compliance |

|---|---|

FR-4 | Cost-effective, good electrical properties; less suitable for high-temperature sterilization and implantable devices. |

Excellent thermal stability and biocompatibility; ideal for implantable and high-reliability devices. | |

Rogers | Superior electrical performance for high-frequency applications; higher cost and complexity. |

Teflon (PTFE) | Excellent dielectric and chemical resistance; difficult to process and costly. |

You should also consider coatings like parylene for biocompatibility and moisture protection. For implantable or skin-contacting devices, select materials that are non-toxic and corrosion-resistant. LTPCBA’s experts help you choose the right materials for both prototyping and small-batch production, ensuring compliance with ISO 13485, FDA, and RoHS standards.

Prototype Manufacturing

Once you finalize your design and materials, LTPCBA’s automated workflow moves your project into manufacturing. Inline automation integrates design, fabrication, and testing into a single process. This approach reduces lead times by up to 40% compared to traditional methods, helping you achieve faster time to market.

You benefit from:

Real-time production tracking through cloud-based platforms, giving you transparency and quick issue resolution.

Automated Optical Inspection (AOI) and X-ray Inspection (AXI) with defect detection rates up to 99.99%, ensuring high reliability for your quick-turn pcb prototypes.

Modular manufacturing that supports scalability, from small-batch production of 10 units to over 100,000 units.

Reduced material waste by 15%, with 95% material utilization, lowering costs and supporting sustainability.

Note: LTPCBA’s workflow supports rapid prototyping and small-batch production, making it easy to test new designs and adapt quickly to feedback.

Testing and Delivery

Testing is a critical step in the quick-turn pcb prototypes process. LTPCBA uses advanced protocols to ensure your prototypes meet strict medical standards. You can expect:

Testing Protocol | Objective | Importance for Medical Device PCB Prototypes |

|---|---|---|

In-circuit testing using spring-loaded pins to verify electrical connections and component functionality. | Detects open/short circuits and assembly faults, ensuring reliability. | |

Flying Probe Testing | Movable probes perform electrical tests without custom fixtures. | Flexible and effective for low-volume or prototype testing. |

AOI and AXI | Automated camera and X-ray inspection for soldering and placement defects. | Achieves defect detection rates up to 99.99%, reducing rework and field failures. |

Electrical Testing | Measures continuity, resistance, and other electrical properties. | Confirms the PCB meets design specifications. |

Aging and Environmental Tests | Simulates years of operation and extreme conditions. | Predicts long-term reliability and identifies early failures. |

You also receive comprehensive documentation, including test reports, traceability records, and certificates of compliance. Inventory verification continues through this stage, with material test certificates and process control data maintained for regulatory audits.

LTPCBA’s streamlined process ensures you receive your quick-turn pcb prototypes on time, ready for early testing and further development. This approach supports rapid prototyping, small-batch production, and faster adaptation to design changes. You can move confidently from early testing to clinical trials, knowing your prototypes meet the highest standards.

Callout: By following these steps and working with LTPCBA, you streamline prototyping, reduce errors, and ensure your medical device projects stay on track for successful delivery.

Best Practices for Medical Device PCB Prototyping

Standard Design Practices

You can optimize your quick-turn pcb assembly by following best practices for rapid pcb prototyping. These guidelines help you achieve reliable, high-quality results for medical device applications:

Use surface mount components to save space and simplify assembly.

Provide accessible test points for power, clock, and control signals to streamline testing and debugging.

Allow for design modifications to support future improvements and customization.

Employ multiple testing methods, such as AOI, flying probe, and X-ray inspection, to catch defects early.

Adhere to IPC Class 3 standards for medical devices, ensuring strict design rules and reliability.

Calculate trace widths according to IPC-2152 for consistent performance.

Minimize trace lengths and keep sensitive signals short and direct.

Use power and ground planes to improve signal integrity and reduce noise.

Isolate temperature-sensitive components and verify reflow soldering profiles.

Maintain 100% inspection and testing to ensure zero defects.

By applying these best practices for rapid pcb prototyping, you reduce errors, speed up validation, and support customization for your medical device projects.

Collaboration with LTPCBA

When you collaborate with a reliable pcb manufacturer like LTPCBA, you gain a partner dedicated to your success. LTPCBA’s quick-turn pcb assembly services start from a single piece, enabling rapid prototyping and early design validation. Their advanced equipment, including AOI and X-ray inspection, ensures high precision and quality. You benefit from comprehensive parts sourcing, fast delivery, and cost-efficient development, all of which support customization and improved collaboration.

LTPCBA’s team provides thorough DFM feedback and 24/7 technical support, helping you meet tight deadlines and reduce risks. Their experience in mission-critical industries guarantees compliance with strict standards. Customer testimonials highlight LTPCBA’s punctuality, responsiveness, and ability to deliver on urgent projects, making them an ideal partner for best practices for rapid pcb prototyping.

Metric | Value/Description |

|---|---|

Product Pass Rate | 99.5% |

On-Time Delivery Rate | >97% |

Quote Turnaround Time | 2–3 days |

Customer Support | 24/7 availability |

Certifications | ISO 9001, IATF, UL, IPC, RoHS |

Testing Protocols | AOI, X-ray, functional testing, SPC, Six Sigma |

Prototype Turnaround | 2–14 days depending on complexity |

Pricing | Competitive, transparent, cost-effective |

Project Support | Dedicated guidance, reduced bottlenecks |

Supply Chain Agility

You can strengthen your quick-turn pcb assembly process by building an agile supply chain. Outsourcing non-core functions to specialized partners like LTPCBA reduces overhead and increases flexibility. This approach allows you to focus on core competencies and respond quickly to changes in demand or supply disruptions. Agile manufacturing supports rapid changeovers and design modifications, helping you maintain on-time delivery and cost control.

Effective component sourcing with trusted global suppliers ensures you have the right parts at the right time, reducing risks such as shortages or counterfeit components. Data-driven forecasting and continuous improvement further enhance your supply chain agility. By adopting these best practices for rapid pcb prototyping, you achieve faster onboarding, risk reduction, and greater customization for your medical device projects.

Overcoming Challenges in Quick-Turn PCB Prototyping

Ensuring Quality Under Tight Deadlines

You often face pressure to deliver medical device prototypes quickly without sacrificing quality. Quick-turn PCB manufacturing services, like those from LTPCBA, help you meet tight deadlines by delivering prototypes within 24-48 hours. You benefit from advanced manufacturing techniques such as automated fabrication and High-Density Interconnect (HDI), which improve precision and reduce errors. Rigorous quality assurance processes, including Automated Optical Inspection (AOI), X-ray inspection, and functional testing, ensure your prototypes remain reliable. Design-for-manufacturability (DFM) reviews align your designs with fabrication constraints, reducing rework and extra cost. When you partner with a manufacturer certified in medical technology standards, you gain confidence that your prototypes meet strict requirements. If you encounter component shortages, using substitute parts or modular PCB designs can keep your project on schedule and control cost. For example, one medical device company used quick-turn services to receive boards in 48 hours, catching design flaws early and avoiding expensive delays.

Regulatory Compliance

You must follow strict regulatory standards during rapid PCB prototyping for medical devices. Key standards include FDA regulations (21 CFR Part 820), ISO 13485, IEC 60601, and IPC Class 3. These standards require cleanroom environments, process validation, and equipment calibration. You also need to maintain documentation and traceability, such as Design History Files and Change Control Logs, to support regulatory audits. Testing protocols like functional testing, environmental stress screening, and biocompatibility validation are essential. Compliance with these standards ensures your prototypes are safe, reliable, and ready for market approval. LTPCBA’s adherence to ISO and IPC standards helps you avoid compliance issues and unexpected cost increases.

Managing Costs and Resources

Managing cost and resources efficiently is crucial in quick-turn PCB prototyping. Rapid turnaround times, sometimes as short as 24 hours, allow you to validate designs quickly and reduce time-to-market. Early error detection through inspections like AOI and Flying Probe Testing helps you avoid manufacturing delays and extra cost. LTPCBA supports complex PCB types and provides transparent pricing based on urgency and complexity, so you can plan your budget. Following Design for Assembly (DFA) guidelines, submitting accurate BOMs, and providing clear assembly drawings prevent costly mistakes. Choosing a certified manufacturer with IPC, ISO, and UL certifications reduces rework cost and supports cost savings. Local fabrication partners can also lower logistics cost and speed up delivery. Consistent communication with your manufacturer keeps your project on track and avoids hidden cost. By using these strategies, you achieve significant cost savings while maintaining high quality and fast delivery.

Future Trends in Rapid PCB Prototyping

Advanced Technologies

You will see rapid pcb prototyping transform as new technologies emerge in the medical device industry. Flexible and wearable electronics now enable you to design personalized healthcare solutions that fit the body and adapt to patient needs. Miniaturized PCB technology lets you create compact, portable devices without sacrificing performance. High-Density Interconnect (HDI) boards and rigid-flex PCBs support smaller, denser layouts, which are essential for advanced sensors and implantable devices.

Innovations such as Lab-on-PCB and medical-grade protective coatings like FDA-approved Parylene film improve both biocompatibility and device reliability. The integration of AI and machine learning with smart circuits allows real-time data analysis and predictive diagnostics, making your devices smarter and more responsive. These advancements in rapid pcb prototyping help you achieve faster turnaround, higher accuracy, and greater design flexibility.

As you adopt these technologies, you can expect improved patient outcomes and more reliable medical devices.

Digital Tools and Automation

Digital tools and automation now play a key role in rapid pcb prototyping. You can use advanced design software to simulate and optimize your circuits before manufacturing begins. Automated manufacturing lines and inspection systems, such as AOI and X-ray testing, ensure high quality even when you need rapid delivery. These tools reduce errors, speed up production, and help you meet strict medical standards.

Collaboration platforms allow you to work closely with your manufacturer, sharing feedback and making changes in real time. Automated quoting and order systems give you instant pricing and status updates, streamlining your workflow. With these digital advancements, you can move from concept to prototype in days, not weeks.

LTPCBA stands ready to support your innovation journey. Their rapid pcb prototyping services offer 24-hour delivery, advanced inspection, and small-batch flexibility. You benefit from their industry certifications and commitment to quality, making them a trusted partner as you embrace the future of rapid medical device development.

Quick-turn PCB prototyping with LTPCBA helps you deliver safer, more innovative medical devices faster. By following best practices, you:

Prioritize reliability and safety through lifecycle testing and high-quality components.

Accelerate certification by integrating regulatory compliance from the start.

Enhance device longevity with biocompatible materials and early power integrity design.

Support audits and continuous improvement with detailed documentation.

Leverage LTPCBA’s expertise and advanced technology to streamline your prototyping process and drive continuous improvement in every project.

FAQ

What is the typical turnaround time for quick-turn PCB prototypes at LTPCBA?

You can receive your quick-turn PCB prototypes in as little as 24 hours. Most standard projects take between 2 and 14 days, depending on complexity and material availability.

How does LTPCBA ensure quality for medical device PCB prototypes?

LTPCBA uses advanced inspection methods, such as AOI and X-ray testing. You benefit from strict process controls, ISO and UL certifications, and a 99.5% product pass rate.

Can I order just one prototype for my medical device project?

Yes, you can order a single prototype. LTPCBA supports low-volume and single-piece orders, which helps you validate your design before moving to larger production runs.

What documents do I need to submit for a quick-turn PCB prototype order?

You should provide a fabrication drawing, assembly drawing, BOM, and IPC netlist. Clear documentation helps LTPCBA process your order quickly and accurately.

Does LTPCBA offer technical support during the prototyping process?

You have access to 24/7 technical support from LTPCBA’s engineering team. They help you resolve design issues, answer questions, and keep your project on track.

See Also

Accelerating Project Success With Rapid PCB Assembly Prototypes

Where To Obtain Fast Turnaround PCB Prototypes Stateside

Ways EMS Providers Improve Efficiency In PCB Production

Key Processing Standards For Medical Equipment PCBA Assembly

Boosting Business Performance Through PCBA Contract Manufacturing