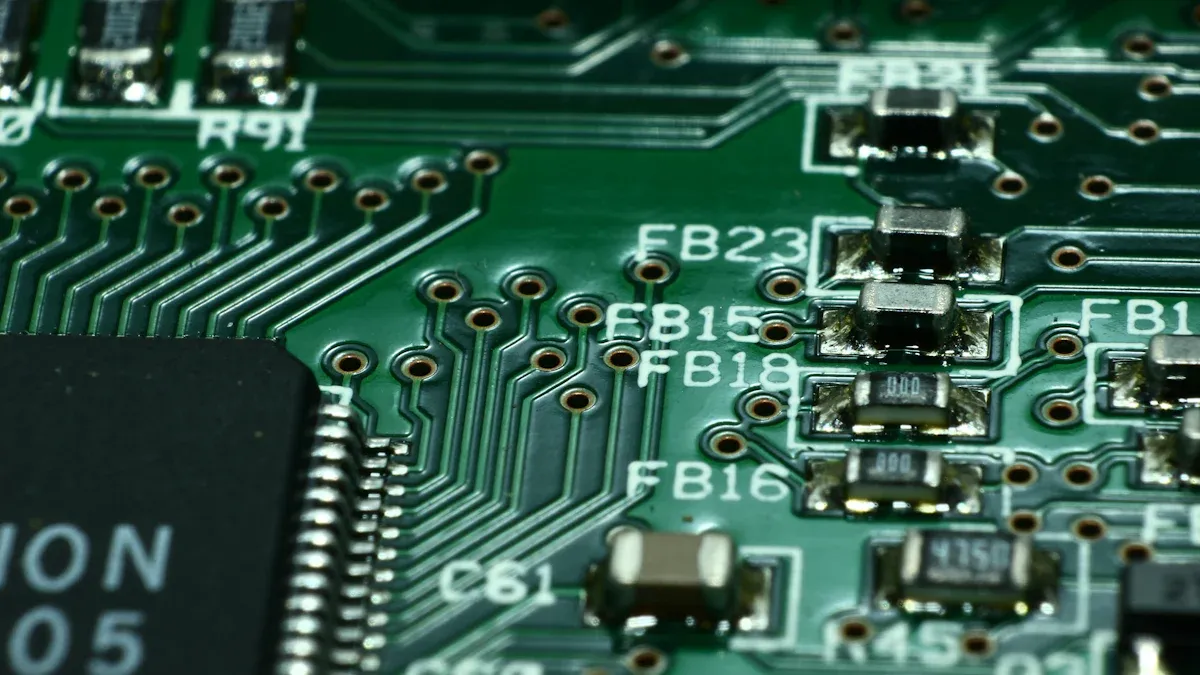

How the quality of solder paste affects the SMT soldering quality of PCB boards

The quality of solder paste is very important for good SMT soldering and strong PCB boards. It impacts how strong the solder joints are and how long the electronic parts last. Bad solder paste can cause problems, and studies show that 90% of soldering issues happen during solder paste printing. Strong connections need good solder paste and careful handling. By paying attention to these things, you can get better results and avoid expensive fixes.

Key Takeaways

Good solder paste is key for strong PCB connections. Use top-quality paste to avoid problems and make parts last longer.

Keep solder paste in a fridge at 0°C to 10°C. This helps it stay fresh for up to six months and stops it from spoiling.

Pick the right solder paste for your project. Think about things like metal type, flux, and particle size for better results.

Keep your workspace and tools clean. This stops dirt and makes soldering work better.

Watch the temperature and humidity in your workspace. The best conditions are 22°C to 26°C with 45% ± 5% humidity for solder paste to work well.

Key properties of solder paste that influence soldering quality

Viscosity and its impact on stencil printing

Viscosity shows how thick or thin solder paste is. It affects how the paste spreads during stencil printing. If the paste is too thick, it won't flow well through stencil holes. This can cause uneven or missing deposits. If the paste is too thin, it spreads too much. This can lead to smears or bridges between parts. The right viscosity helps apply the paste neatly and accurately.

Testing how solder paste holds its shape under heat is important. This is called hot slump testing. Standards like IPC TM-650 2.4.35 say solder paste should stay stable at 150°C for 10-15 minutes. This keeps the paste steady during printing and heating, lowering defect risks. Good wetting helps the paste stick better to surfaces, improving the process.

Particle size and distribution for consistent application

The size and spread of solder paste particles affect how evenly it goes on. Small, evenly spread particles make smoother application and better coverage. Uneven particle sizes can cause problems during soldering.

Particle sizes usually range from 2-12 µm. The best squeegee pressure is about 7 kgf, with a print speed of 20 mm/s. These settings help keep paste application even. The table below shows how particle size affects performance:

Performance Attribute | Effect of Solder Powder Size |

|---|---|

Shelf Life | Changes |

Stencil Life | Changes |

Reflow Performance | Changes |

Voiding Behavior | Changes |

Reactivity/Stability | Changes |

By controlling particle size, you can improve paste quality and avoid defects.

Metal content and its role in joint strength

Metal content in solder paste affects how strong solder joints are. More metal usually makes stronger connections. But too much metal can make the paste stiff and hard to use.

Balanced metal content gives strong joints without making the paste hard to apply. The heating profile must match the paste's makeup for good joint formation. Well-made solder paste with the right metal content avoids weak joints and voids. This helps your PCB assembly work better.

Flux composition and its role in stopping oxidation

Flux is very important for good soldering. It cleans off oxidation from metal parts on PCBs and components. Oxidation happens when metal reacts with oxygen, creating a layer that blocks solder from sticking. Flux removes this layer so solder can bond well. This makes strong connections and lowers the chance of weak joints.

The ingredients in flux decide how well it stops oxidation. Some fluxes have special chemicals like phosphorus. Phosphorus helps by reacting with oxygen on the solder's surface. This reaction stops more oxidation and keeps the solder strong. Without this, oxidation could weaken the joints and harm your PCB's performance.

You also need to pick the right flux for your project. No-clean flux leaves little residue, so it’s good for hard-to-clean assemblies. Water-soluble flux needs cleaning but works great at stopping oxidation. Picking the right flux gives better results and fewer problems.

Tip: Always make sure your flux works with your solder paste and PCB materials. This avoids surprises during assembly.

Knowing how flux works to stop oxidation helps improve soldering quality. Strong solder joints start with using the right flux.

Factors affecting the quality of solder paste

Storage conditions and their influence on paste performance

Storing solder paste the right way is very important. If stored poorly, the paste can go bad and cause problems. Keep solder paste in a fridge at 0°C to 10°C (32°F to 50°F). This keeps it good for up to six months. At room temperature (19°C to 25°C or 66°F to 77°F), it lasts about two weeks. If it gets hotter than 29°C (84°F), it goes bad quickly.

Storage Condition | Recommended Temperature | Shelf Life | Notes |

|---|---|---|---|

Long-term storage | 0-10°C (32-50°F) | 6 months | Best kept in a fridge |

Room temperature | 19-25°C (66-77°F) | 2 weeks | Okay for short-term use |

Exposure above 29°C | >29°C (84°F) | Decreases | Avoid high heat |

Cold solder paste can get wet when taken out of the fridge. This can mess up how it works. Let it warm up to room temperature before using it. As it warms, its thickness might change. You may need to adjust it for printing. Follow the maker's rules for better results.

Tip: Always keep solder paste in its original container. Make sure the lid is tight to stop moisture and dirt from getting in.

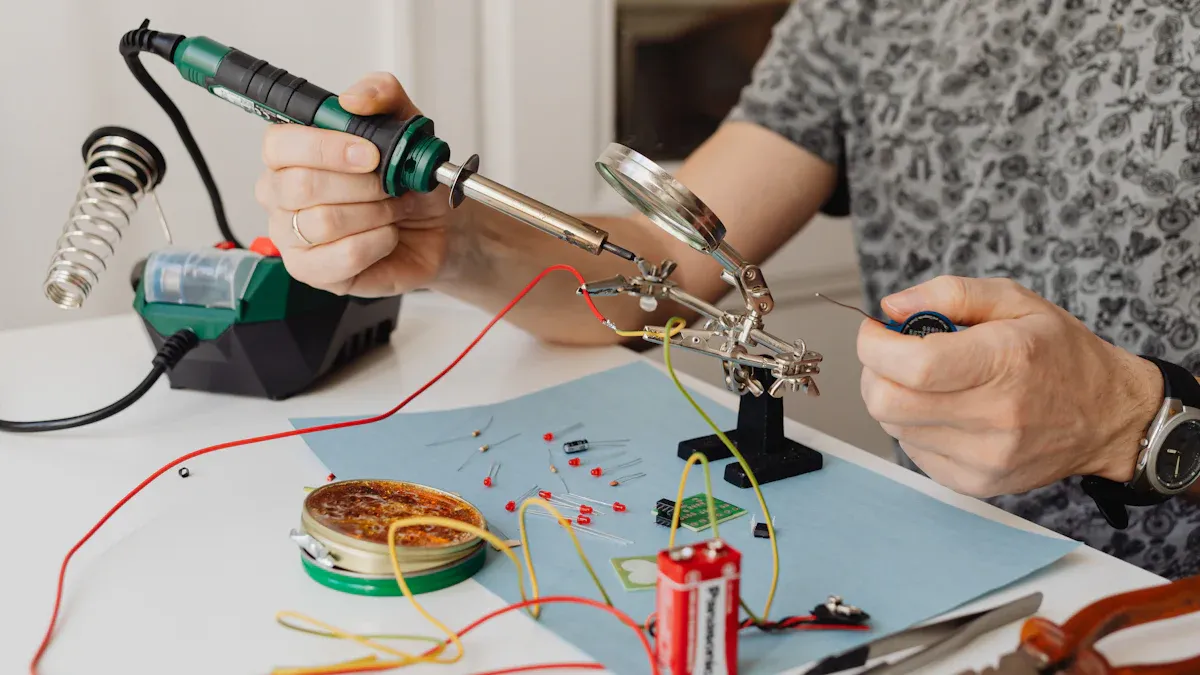

Application methods and stencil printing techniques

How you use solder paste and print it matters a lot. Stencil printing is the most common way to apply it. You need to be careful to make even layers. Use the right pressure and speed. For example, 7 kgf pressure and 20 mm/s speed work well.

Bad application can happen if the stencil is wrong or not lined up. A good stencil with the right hole size and thickness helps. Clean the stencil often to avoid clogs and smudges. This stops problems like solder bridges or not enough solder.

Note: Check your stencil for damage. A broken stencil can ruin the paste application.

Environmental factors such as temperature and humidity

The air temperature and humidity around you affect solder paste. The best conditions are 22°C to 26°C (72°F to 80°F) with 45% ± 5% humidity. Changes in these can cause problems like solder balling or bridging.

Environmental Condition | Effect on Solder Paste Performance |

|---|---|

47% Relative Humidity | Paste looks normal. |

Paste slumps, causing solder bridges. | |

Temperature Increase | Makes prints less clear, causes solder balling. |

5°C Temperature Change | Leads to more print bridges on parts. |

High humidity, like 80%, makes the paste slump and form bridges. Hotter temperatures make prints blurry and cause mid-chip beading. Many engineers forget to test paste in tough conditions. This can lead to surprises when the environment changes.

Tip: Keep an eye on temperature and humidity in your workspace. This helps keep solder paste working well.

Handling practices to keep solder paste clean

Contamination can harm solder paste and cause PCB defects. Keeping the paste clean is key for good soldering results. Follow these tips to avoid contamination:

🧴 Use clean tools and equipment

Always use clean tools with solder paste. Dirty tools like spatulas or containers can add dust or grease. Wipe tools with lint-free cloths and special cleaners before using them.

Tip: Don’t use regular cloths or paper towels. They leave fibers that can mix with the paste and ruin it.

🧤 Wear protective gear

Your hands can add oils or dirt to solder paste. Wear nitrile or latex gloves to avoid touching it directly. If gloves aren’t available, wash and dry your hands well before handling the paste.

📦 Keep the paste sealed

Air exposure dries out solder paste or adds moisture. Always close the container tightly when not in use. If moving paste to another container, make sure it has a tight lid.

Common Contaminants | Effect on Solder Paste | How to Avoid |

|---|---|---|

Dust particles | Makes solder joints uneven | Use clean tools and workspace |

Moisture | Changes paste thickness | Store in sealed containers |

Skin oils | Weakens solder connections | Wear gloves |

🧹 Keep your workspace clean

A messy workspace increases contamination risks. Keep your bench free of food, liquids, or trash. Clean the area often with anti-static wipes to remove dust.

Note: Don’t eat or drink near solder paste. Even small crumbs or spills can ruin it.

🕒 Limit how long paste is exposed

Leaving solder paste out too long can ruin it. Only take out what you need for immediate use. If left out too long, it may dry or get dirty.

🚫 Don’t mix old and new paste

Never combine old paste with fresh paste. Mixing them changes the paste and causes bad results. Use separate containers for each batch and label them clearly.

By following these steps, you can keep solder paste clean and improve soldering quality. Clean tools, proper storage, and a tidy workspace help prevent contamination.

Defects caused by poor-quality solder paste

Solder bridging and its impact on circuit functionality

Solder bridging happens when too much solder connects nearby parts. This can cause electrical shorts, making devices fail or damaging parts. Bad solder paste often causes this due to uneven thickness or poor particle mix.

Solder bridging does more than cause shorts. It weakens solder joints, making them break easily. It also makes testing harder, like in-circuit testing (ICT). Hot spots can form on the PCB, causing faster wear on devices.

Impact Type | Description |

|---|---|

Electrical Shorts | Unwanted connections that damage parts or stop devices from working. |

Reduced Mechanical Integrity | Weak solder joints that can break or fall off. |

Testing and Inspection Challenges | Harder testing, leading to errors in ICT and functional tests. |

Thermal Management Problems | Poor heat control, creating hot spots on the PCB. |

Reliability and Longevity | Devices fail more often and wear out faster. |

Insufficient solder joints and their effect on reliability

Insufficient solder joints happen when there isn’t enough solder to connect parts. This often comes from low metal content or bad solder paste use. Weak joints make devices unreliable and can break under stress.

Good solder paste helps prevent weak joints. Paste with the right metal mix makes strong connections, even for tricky parts like BGAs. For example, SAC305 works well for big parts like PBGA1156. Innolot is better for smaller BGAs. Picking the right paste improves your PCB’s life and performance.

Solder Alloy | Performance in Smaller BGAs | Performance in Larger Components | Lifespan Impact by Aging | Design Influence |

|---|---|---|---|---|

Innolot | Very reliable | Less effective | Aging reduces lifespan | Important |

SnPb | Okay reliability | Not mentioned | Not mentioned | Not mentioned |

SAC305 | Less reliable | Best for PBGA1156 | Not mentioned | Not mentioned |

Voiding and its influence on thermal and electrical performance

Voiding means air bubbles or gaps inside solder joints. These gaps make joints weaker and hurt heat and electricity flow. Bad solder paste often causes voiding due to poor flux or heating issues.

Voids make heat transfer worse, causing parts to overheat and fail. They also mess up electrical signals, making circuits work poorly. To avoid voiding, use good solder paste and set heating correctly.

Impact Type | Description |

|---|---|

Gaps make joints weaker and easier to break. | |

Heat Transfer | Gaps block heat flow, causing overheating and failure. |

Electrical Signal Flow | Gaps disrupt signals, making circuits unreliable. |

By learning about these problems, you can choose better solder paste. This helps make stronger, longer-lasting PCB assemblies.

Tombstoning and alignment problems during reflow

Tombstoning happens when one side of a part lifts up. It looks like a tombstone standing upright. This often occurs with small parts like resistors or capacitors. Uneven heat or too much solder on one side causes this. If one side melts faster, it pulls the part upright due to surface tension.

Alignment problems happen when parts move or turn during reflow. This can be caused by too much solder paste, a bad stencil, or oven vibrations. Misaligned parts may not connect properly, making circuits unreliable.

Defect | Cause | Impact |

|---|---|---|

Tombstoning | Uneven heat or too much solder on one side | Open circuits or lifted parts |

Misalignment | Extra solder or bad stencil design | Weak connections or circuit failure |

To stop tombstoning, apply solder paste evenly. Use a good stencil with equal-sized holes. Check the oven’s heat settings for even heating. Slowly increasing the heat helps both sides melt at the same time.

For alignment problems, check the stencil and PCB design. Make sure stencil holes match the part pads. Use the right amount of solder paste to avoid extra deposits. During reflow, keep the PCB steady and reduce oven vibrations.

Tip: Choose solder paste with smaller particles for better accuracy. This helps avoid uneven solder and improves alignment.

Fixing these issues leads to stronger solder joints and better PCBs.

Ensuring solder paste works well

Picking the right solder paste for your project

Choosing good solder paste is very important for strong PCBs. Think about things like alloy type, flux, and what your project needs. Some projects need paste that handles heat well. Others need paste that conducts electricity better.

Things like print speed, pressure, thickness, and particle size matter too. The table below shows what to check when picking solder paste:

What to Check | Important Factors |

|---|---|

Alloy type | Print speed |

Flux type | Squeegee pressure |

Special needs | Thickness |

Particle size |

Match these to your project to get better results. This helps avoid problems during assembly.

Storing and handling solder paste the right way

How you store and handle solder paste affects its quality. Keep it in a fridge at 0°C to 10°C (32°F to 50°F). This stops it from going bad and makes it last longer. Let it warm up to room temperature before using it. This avoids water forming on the paste, which can change how it works.

Always keep the paste in its original container with the lid tight. Don’t mix old paste with new paste. Use clean tools and wear gloves to keep dirt and oils away.

Tip: Write down the expiration date on each paste container. Use it before it expires for the best results.

Checking solder paste often for good quality

Checking solder paste regularly helps keep it working well. Follow these steps to test the paste:

Look at it: Make sure the color is even and there are no clumps.

Check thickness: Use a tool to measure how thick the paste is.

Test metal content: Check the metal amount to ensure strong joints.

Check particle size: Use a special tool to see if particles are even.

Follow industry rules like IPC-7527 and IPC-J-STD-004 for testing. These rules help make sure the paste works as it should. The table below lists some important standards:

Standard | What It Covers |

|---|---|

IPC-7527 | Rules for solder paste printing. |

IPC-J-STD-002 | Rules for soldering materials and methods. |

IPC-J-STD-004 | Rules for soldering fluxes. |

IPC-J-STD-006 | Rules for soldering surface mount parts. |

IPC-SM-817 | Tips for putting together electronic products. |

IPC-CC-830 | Rules for protective coatings on PCBs. |

IPC-HDBK-830 | Guide for using PCB assembly standards. |

By following these steps and rules, you can keep solder paste in good shape. This helps make better PCBs with fewer problems.

Optimizing reflow parameters for reliable results

Reflow soldering is important for making strong solder joints. Adjusting reflow settings improves PCB quality and lowers defects. During reflow, solder paste melts to attach parts to the PCB. Controlling heat and time carefully gives better results.

The heating profile is a key part of reflow. It ensures solder paste heats enough without overheating or underheating. Too much heat can harm parts, while too little makes weak joints. Change the heating time (Ht) to match your solder paste and parts. The table below shows how heating affects solder joint strength:

Variable | Description |

|---|---|

Qηmin | Smallest heating factor that changes with Ht. |

Ht | Heating time adjusted based on QηL and Qηmin differences. |

α | Rate of change between Qηmin and Ht. |

QηL | Target heating factor for strong solder joints. |

Process Recipe | Made by setting Ht to reach QηL in later reflow runs. |

To improve reflow, check the heating factor (QηL) and match it to the target value. Adjust heating time (Ht) to balance this. Use the slope (α) to fine-tune the process. These steps help create a recipe for consistent reflow results.

Tip: Use a thermal profiler to check PCB temperature during reflow. This finds uneven heating and helps fix it.

Better reflow settings make solder joints stronger, reduce problems, and improve PCB performance.

The quality of solder paste is key for good SMT soldering. It helps connect electronic parts and keeps them in place. Many PCB problems happen because solder paste is not used correctly. This is even more common as devices get smaller. For instance, using over 50% solder paste for small parts lowers defects a lot. Tests show that more solder paste makes joints stronger over time. This is very important for devices that need to last long.

By learning about solder paste and storing it properly, you can avoid problems. Using good materials and careful methods improves results. This also helps devices work better and fail less often.

FAQ

What is solder paste, and why does it matter?

Solder paste is a mix of tiny metal bits and flux. It helps stick electronic parts to PCB boards during soldering. Good solder paste makes strong connections and reduces problems, making devices more reliable.

How should you store solder paste?

Keep solder paste in a fridge at 0°C to 10°C (32°F to 50°F). Always close the container tightly to keep out moisture or dirt. Let it warm to room temperature before using to stop water from forming.

Tip: Write expiration dates on containers to know when to use them.

What leads to solder bridging?

Solder bridging happens when too much solder links nearby parts. This can be caused by uneven printing, bad solder paste, or high humidity. Using the right methods and controlling the environment can stop this.

How do you pick the best solder paste?

Think about what your project needs, like alloy type, flux, and particle size. Match these to your project for better results. Testing different pastes can help you choose the right one.

Can the environment affect solder paste?

Yes, temperature and humidity can change how solder paste works. High humidity can make it spread too much, and extreme heat can change its thickness. Keep the workspace at 22°C to 26°C with 45% ± 5% humidity for the best results.

Note: Use a hygrometer to check the temperature and humidity in your workspace.

See Also

The Influence Of Reflow Soldering Zones On PCB Quality

A Comprehensive Guide To SMT And DIP Assembly Techniques

Evaluating Advantages And Disadvantages Of SMD And Through-Hole

Boosting Project Efficiency With Quick-Turn PCB Assembly Prototypes

Exploring Industrial Serial Screen PCBA Applications In Today’s Industries