Top Quality Control Processes in Turnkey PCBA Manufacturing

Quality Control Processes in turnkey PCBA manufacturing use automated optical inspection, in-circuit testing, careful supplier selection, and real-time checking. - These steps help make sure products have no defects. - They also help products work well the first time and have few problems.

LTPCBA uses new technology and has international certificates. This shows it cares a lot about quality and making customers happy.

Key Takeaways

LTPCBA follows strict quality control steps and has top certifications. This helps them make PCBA products that are very reliable and have few defects. The company picks suppliers carefully and checks materials closely. This makes sure parts are high quality and arrive when needed. Real-time monitoring and advanced testing find problems early. This helps LTPCBA send out strong and good boards fast.

Quality Control Processes at LTPCBA

LTPCBA follows strict rules from around the world. The company uses advanced Quality Control Processes. It has certificates like ISO9001, TS16949, and US UL. These show LTPCBA cares about quality and trust. LTPCBA hires IPC-certified workers. They use best steps in every part of making boards. This helps every printed circuit board assembly meet top standards.

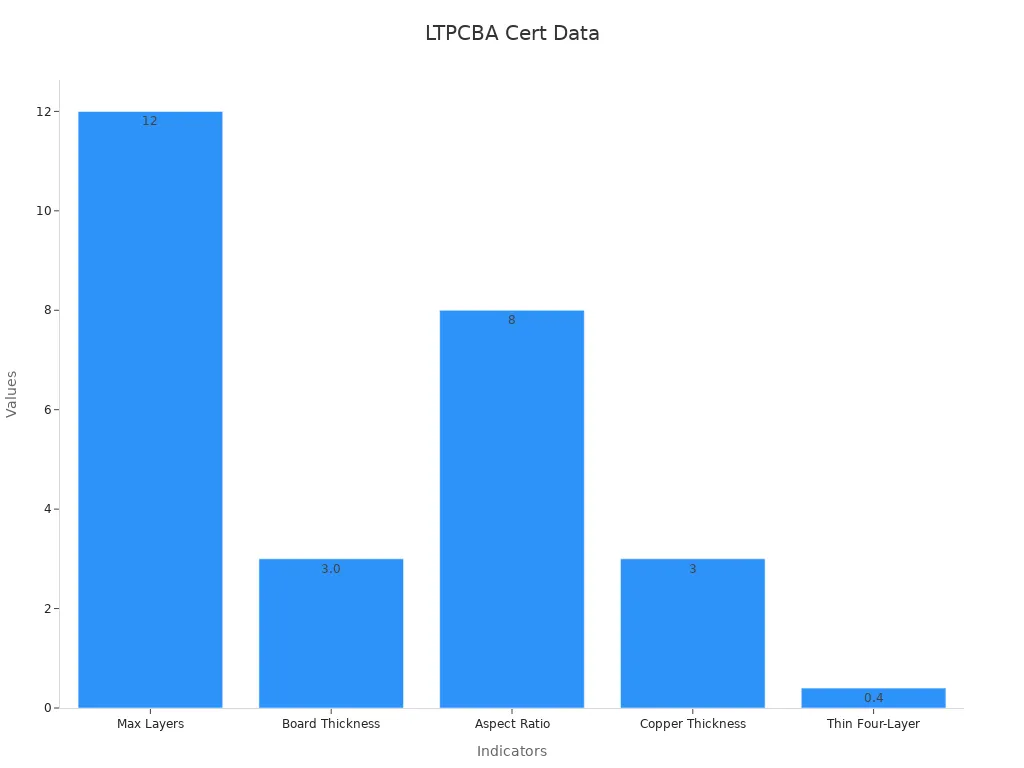

IPC Certification

LTPCBA’s team has workers with IPC-A-610D Class 3 certificates. This is the highest level for electronic assembly quality. The company can make boards with up to 12 layers. The thickest board is 3.0 mm. The copper can be as thick as 3 oz. The smallest hole is 0.1 mm. The thinnest line is 0.075 mm. These skills help LTPCBA serve tough industries.

Certification / Indicator | Details / Values |

|---|---|

Certifications | US UL, ISO9001, TS16949, CQC |

IPC Standard Compliance | IPC-A-610D Class 3 |

Maximum Number of Layers | Up to 12 layers |

Maximum Board Thickness | 3.0 mm |

Maximum Aspect Ratio | 8:1 |

Maximum Copper Thickness | 3 oz |

Maximum Working Board Size | 520 mm x 650 mm |

Thinnest Four-Layer Board | 0.4 mm |

Minimum Hole Size / Pad Size | 0.1 mm / 0.20 mm |

Minimum Line Width / Line Spacing | 0.075 mm / 0.075 mm |

These skills help LTPCBA make strong and exact boards. IPC certification means every product meets tough rules for lasting and working well.

Process Standards

LTPCBA uses set steps for its Quality Control Processes. The company follows clear rules and checks important numbers. These numbers include defect rate, first pass yield, and pick-and-place accuracy. They help the team watch and improve each step.

Metric | Before Quality Control | After Quality Control | Improvement |

|---|---|---|---|

Defect Rate | 0.91% | 0.14% | Reduced by 0.77% |

Defects Observed | 366 | 58 | Decreased by 308 |

Lot Reject Rate (PPM) | 5500 | 900 | Reduced by 4600 PPM |

Process Control Metric | Target / Value | Role in Reliability and Consistency |

|---|---|---|

First Pass Yield | 95% | Minimizes rework and speeds delivery |

Pick-and-Place Accuracy | 99.95% | Ensures precise component placement, reducing defects |

Pass Rate | 99.5% | Indicates high manufacturing quality and consistency |

These numbers help LTPCBA measure and get better at making boards. By checking things like defect density and pass rates, the company finds problems early. Then they fix them fast. This means fewer mistakes, quicker delivery, and happier customers. Using set steps also helps LTPCBA reach its business goals. Every product meets what customers want.

Note: LTPCBA’s focus on set steps and certificates builds a strong base for good, reliable PCB assemblies. Customers get products that work right away and last a long time.

Component Sourcing

Supplier Selection

LTPCBA picks suppliers very carefully. The team looks at each supplier’s certificates and how much they can make. They also check if the supplier has done a good job before. Suppliers must have ISO9001 and IATF 16949 certificates. They need to show they can deliver fast and manage their supply chain well. LTPCBA checks old customer stories and tests small orders first. This helps make sure suppliers send good parts on time.

Supplier Quality Metrics / Manufacturing Capabilities | Description |

|---|---|

International Certifications | ISO9001, IATF 16949, IPC standards |

Production Capacity | Rapid delivery and stable supply chain |

BOM Cost Control | Reduces unnecessary costs |

Industry Experience | Proven solutions for different needs |

Traceability | Tracks quality data during production |

Technical Support | Fast help for product updates |

Automated Equipment | Reduces errors and boosts precision |

ESD and Cleanroom Standards | Protects sensitive components |

LTPCBA uses Altium Designer and Octopart data to check parts. They look at how long parts will last, how fast they can get them, and if they follow rules. This helps stop supply problems and keeps things steady for a long time.

Material Inspection

LTPCBA checks every batch of materials before building. The team makes sure part numbers are right and parts are good. They check if parts follow RoHS and REACH rules. They use AOI, X-ray, and ICT to find problems early. They also look at the BOM often to spot old parts and price changes fast.

Flexible sourcing helps stop shortages and delays.

Demand models help plan better.

Inventory management keeps stock just right.

Vendor checks help deliveries stay on time.

Metric | Industry Standard | LTPCBA Performance |

|---|---|---|

N/A | ||

Problem Detection Rate | N/A | 90% |

On-Time Delivery Rate | N/A | 97% |

Void Rate (BGA) | < 10% | < 5% |

First-Pass Yield | > 95% | > 99% |

Top distributors in the Americas grew by 21.9%. This shows that smart sourcing works well. LTPCBA’s careful checks keep quality high and customers happy.

Assembly Controls

SOPs

Standard Operating Procedures are step-by-step guides for workers. These instructions help everyone do the same thing each time. This keeps quality high and mistakes low. Solder paste inspection machines check the paste’s height, width, and amount. This makes sure the paste is even and in the right place. The machines also find missing paste or solder bridges. These problems can cause trouble later.

Automated pick-and-place machines put parts in the right spots. This helps make fewer mistakes and keeps boards up to standard. Design for Assembly checks make sure the bill of materials matches the design. They also check if part sizes are right and if there is enough space between parts. These checks help stop assembly problems.

SOPs help LTPCBA build good products. They make sure customers get reliable boards.

Real-Time Monitoring

LTPCBA uses real-time monitoring to find problems fast. Machine vision systems watch the assembly line all the time. They give feedback right away. If a problem shows up, workers can fix it quickly. AI-powered vision systems are very accurate. They catch up to 99% of mistakes and lower defect rates by 30%. Inspection times go from one minute to just over two seconds per board.

Control charts watch for changes and errors in the process. If things go outside safe limits, the team acts fast. This stops problems from spreading and keeps things steady. Real-time data also helps find patterns and repeated issues. This lets LTPCBA make its process better over time.

Real-time monitoring means fewer mistakes and less waste. Customers get better boards, faster.

Inspection Methods

Visual Inspection

Visual inspection is the first step in checking PCBA boards. Trained workers look at each board for problems they can see. They search for things like solder bridges, missing parts, or parts that are not lined up right. This step depends on how careful and skilled the worker is. Companies use numbers to see how well visual inspection works.

Metric / Case Study Aspect | Description / Result | Formula / Impact Example |

|---|---|---|

Shows what percent of problems are found by looking | (Defects Detected by VI / Total Defects) x 100 | |

False Rejection Rate (FRR) | Tells how often good boards are marked as bad | (False Rejects / Total Units Inspected) x 100 |

Escape Rate | Shows what percent of problems are missed | (Defects Missed by VI / Total Defects) x 100 |

First Pass Yield (FPY) | Tells how many boards pass the first check | (Units Passing on First Try / Total Units Inspected) x 100 |

Case Study: Consumer Electronics | AOI helped lower returns by 30% and saved $2M | Shows fewer problems and money saved |

Case Study: Automotive Electronics | Better manual checks cut complaints by 45% | Proves better checking helps customers |

Case Study: Aerospace Electronics | AI checks raised first pass yield by 20% and saved $5M | Shows how new tech helps and saves money |

Visual inspection finds many easy-to-see problems early. Good training and practice help workers miss fewer mistakes. This also helps more boards pass the first time. Companies use these results to make their Quality Control Processes better and more reliable.

AOI and X-ray

Automated Optical Inspection and X-ray use machines to check boards. AOI uses cameras and computer programs to look for problems. These machines can find up to 99% of issues, which is better than people. AOI also means one person can watch many boards at once.

AOI gives fast feedback, so problems get fixed quickly.

X-ray checks can find hidden problems under BGAs using special pictures.

AOI and X-ray together help track problems and make the process better.

These machines work for both big and small jobs, so they are useful and save money.

AOI and X-ray help companies find problems early and fix them fast. This means less rework and more good boards. These tools give clear data, so companies can keep getting better. Quality Control Processes are stronger when people and machines work together. This helps make sure products work well and have no defects.

Testing Processes

In-Circuit Testing

In-circuit testing checks each part on the board. Test probes measure things like resistance and voltage. Technicians use ICT to find open or short circuits. They also spot wrong parts on the board. Automated systems collect numbers for every board tested. Each test result matches a serial number for easy tracking. This helps teams find problems early and fix them fast.

ICT uses stress tests like thermal, mechanical, and electrical checks.

Numbers show how each board works in different situations.

Good records help teams find why boards fail and make them better.

Automated software saves test reports for later checks and audits.

These steps help keep Quality Control Processes strong. Finding problems early and using data means fewer mistakes and better boards.

Functional Testing

Functional testing acts like real use for each PCBA. The process checks if the board works as it should. Engineers use tools like oscilloscopes and multimeters. They measure signals and check firmware and communication. Automated testing makes things faster and more correct for big batches.

Test Type | Fault Found | What Happens | What the Test Shows |

|---|---|---|---|

Continuity Test | Open circuit in trace | Device will not turn on | Fault found, board gets rewired |

Solder Joint Check | Cold solder joint | Bad connection, part does not work | Reflow soldering fixes the problem |

Component Placement | Misplaced capacitor | Board does not work right | Parts moved and re-soldered |

Short Circuit Test | Short between parts | Device may not work | Fault found, parts replaced |

Functional testing finds problems like open circuits and bad solder joints. It also finds parts in the wrong place. Finding these early means less rework and fewer problems later. This makes sure every product meets what customers and rules need.

Prototyping and Validation

Early Detection

Early detection is very important in the PCBA process. LTPCBA uses prototyping to find design mistakes and big bugs early. This helps save time and money because fixing problems is easier now. Prototyping gives many good results:

Early design checks help engineers find and fix mistakes fast.

Finding bugs early makes fixing them cheaper. Fixing mistakes later costs much more.

Prototyping helps get products to market faster by solving problems before they slow things down.

Early detection stops costly recalls, waste, and having to redo tools.

First ICT can test many parts in seconds. This gives fast and correct results.

Design for Testability, like adding easy-to-reach test points, makes early tests work better.

By using these ways, LTPCBA makes sure every board is high quality from the start.

Design for Manufacturability

Design for Manufacturability (DFM) makes sure every board is made well and fast. LTPCBA works with design and factory teams to make each step better. Vertical integration lets the company use the same quality checks from start to finish. This means fewer mistakes and steady quality.

Teams working together means less errors and smoother work. Data and process checks help LTPCBA get better and make fewer mistakes over time. Important DFM steps are:

Keeping enough space between parts to stop solder bridges.

Making trace paths better for good signals and power.

Designing vias with the right rules and spots.

Adding test points with labels for easy checks and fixes.

These steps help LTPCBA give customers strong and good PCBAs every time.

Final Quality Checks

FQC Inspection

Final Quality Control (FQC) inspection is the last step before shipping. The FQC team checks every finished PCB. They make sure each board meets customer and industry rules. The team uses AOI, ICT, FCT, and X-ray inspection. These tests help find problems you can see and ones you cannot. Environmental stress testing checks if the board works in hard conditions. Performance Qualification (PQ) shows the process makes strong boards for real use. The team gathers data from these tests to watch for defects and keep the process steady. This way, every product meets design and reliability needs.

Key FQC activities include:

Looking for outside and inside problems

Checking how well the board works

Testing if the board lasts under stress

Making sure labels and packaging are right

FQC inspection gives the last check that every board meets strict Quality Control Processes.

Documentation

Good documentation helps every part of the final quality check. The team keeps careful records for each batch. These records include test results, compliance checks, and traceability logs. Engineers check the Bill of Materials (BOM) to make sure parts and amounts are right. They use tools to compare materials with BOM details. Special notes, like programming or installation needs, get extra care. Regular checks and clear records help find mistakes early and stop delays.

Documentation Task | Purpose |

|---|---|

BOM Verification | Makes sure parts and amounts are correct |

Traceability Records | Gives a record for each batch |

Compliance Checklists | Checks if standards are followed |

Packaging Inspection | Stops damage and checks labels |

A strong documentation system helps the team keep getting better and follow rules. It also helps fix problems fast, so the production line keeps moving.

Manufacturing Environment

ESD Protection

Electrostatic discharge can hurt electronic parts during PCB assembly. LTPCBA uses strong ESD protection to keep products safe. Workers wear special wristbands and stand on grounded mats. Boards are stored and shipped in ESD-safe bags. These steps stop static from building up. This lowers the chance of hidden problems.

In aerospace, ESD bags stopped static from hurting avionics systems.

Consumer electronics had fewer phone returns with ESD-safe packaging.

Data centers kept hardware safe and stopped data loss with ESD bags.

Factories protected controllers and had less downtime using ESD steps.

A worldwide study found ESD causes up to $9 billion in losses each year. ESD is the reason for about 27% to 33% of semiconductor failures. One Japanese company used three steps to cut ESD damage from 0.12% to 0.003%. U.S. factories had 83% fewer ESD problems after using RFID wristband alarms. These results show strong ESD controls protect quality and save money.

Clean Workspace

A clean workspace is very important for good PCB assembly. LTPCBA keeps work areas free from dust and static. The company controls temperature and humidity for steady conditions. Workers follow cleaning routines and use air filters to remove dust.

Environmental Control Aspect | Data/Parameter | Benefit/Impact on PCB Assembly |

|---|---|---|

Temperature Control | Makes soldering better and keeps the process steady | |

Humidity Control | Relative Humidity 30%-60% | Lowers ESD risk and stops moisture damage |

Uniformity of Temperature and Humidity | Even distribution | Reduces changes and keeps things the same |

Anti-dust and Anti-static Measures | Clean environment, grounding, anti-static equipment | Stops dirt and static problems |

Recording Temperature and Humidity | Continuous monitoring | Helps track and improve the process |

These controls help LTPCBA lower defects and make products last longer. Clean and steady work areas also cut repair costs and make customers happier.

Quality Control Processes help LTPCBA make good PCB assemblies. The company sets clear goals to get better. They listen to what customers say and use data to check how they are doing. Customers trust LTPCBA because there are not many defects. People are happy with the products. LTPCBA’s strong way of working helps the business grow. It also makes customers want to buy again.

Customer feedback helps LTPCBA make things better.

Performance data shows the company is improving.

Staff training keeps work at a high level.

FAQ

What certifications does LTPCBA hold for quality assurance?

LTPCBA has ISO9001, IATF 16949, and UL certificates. These show the company cares about quality. They also prove LTPCBA wants every project to be reliable.

How does LTPCBA ensure components meet quality standards?

The team checks all materials when they arrive. They use AOI and X-ray to look for problems. They also check suppliers to make sure parts are good. This helps stop defects and keeps assemblies high quality.

Why is real-time monitoring important in PCBA manufacturing?

Real-time monitoring finds problems right away. The team can fix issues fast. This means less waste and better products.

See Also

Ensuring High Quality In Modern Turnkey PCBA Factories

Comprehensive PCBA Services From Production Through Final Testing

Improving PCBA Quality Control With Advanced X-Ray Inspection

Through-Hole DIP PCBA: Process, Quality, And Practical Uses

Choosing The Best Turnkey PCBA Manufacturer For Electronics Projects