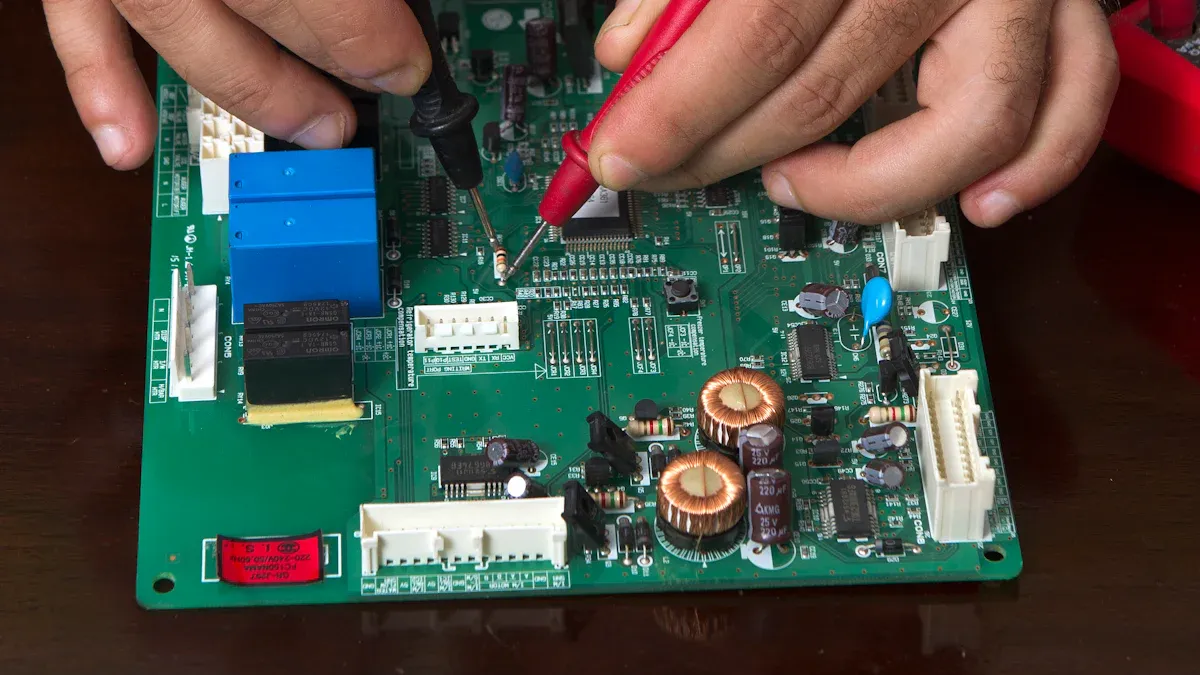

Professional PCBA Rework: When and Why You Need Professional PCBA Rework Services to Solve Common Assembly Issues

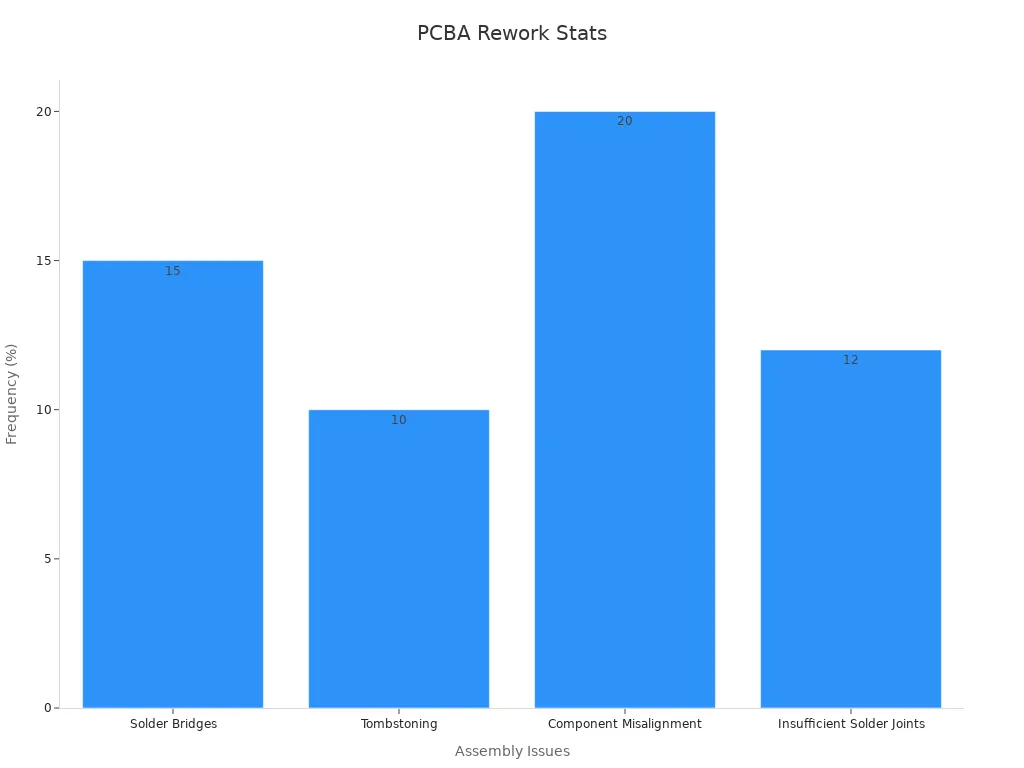

You need professional pcba rework when you have problems like solder bridges, component misalignment, or not enough solder joints. Trying to fix these yourself can make your pcb less safe and less reliable. Many people need pcba rework often, as you can see below:

Assembly Issue | Frequency of Occurrence (%) |

|---|---|

Solder Bridges | |

Tombstoning | 10 |

Component Misalignment | 20 |

Insufficient Solder Joints | 12 |

Warpage | 5-8 |

Professional pcba rework services help you stop doing the same repairs again and again. They also help you avoid paying for a new pcb. You get better quality and results that last longer. Expert engineers at LTPCBA give you special pcb repair solutions that keep your investment safe.

Key Takeaways

Professional PCBA rework helps fix problems like solder bridges and parts that are not lined up right. This keeps your circuit board safe and working well. - Experts use special tools and follow strict rules to fix PCBs. This makes them work like new and last longer. - Picking professional rework saves money. It lowers mistakes and makes products better. It also makes customers happier.

What Is Professional PCBA Rework?

PCBA Rework Defined

You might wonder how professional pcba rework is different from simple repair. Professional pcba rework is a special way to fix your pcb so it works like new. Experts use advanced tools and careful methods to make sure your pcb is high quality. Here are some ways professional pcba rework is unique:

Your pcb gets checked closely with special cameras or machines.

Technicians remove broken parts using hot air tools, keeping your board safe.

They clean off old solder and flux before adding new parts.

New parts are put on and soldered with the right heat, so the pcb does not get hurt.

The fixed pcb is tested a lot, sometimes with X-rays, to make sure it works right.

Only trained experts do this work, following strict rules for quality.

Aspect | Professional PCBA Rework | Basic Repair Methods |

|---|---|---|

Definition | Reprocessing non-complying articles using original or equivalent processing to assure full compliance with drawings/specifications (IPC-7711/7721). | Restoring functional capability without assuring compliance with original drawings/specifications. |

Timing/Context | Performed on the shop floor to fix manufacturing faults after inspection and testing. | Performed on assemblies failed in the field, often involving physical damage repair. |

Outcome | Product indistinguishable from original; meets all quality and specification requirements. | Product functions correctly but may show visible differences; form, fit, and function remain the same. |

Process Control | Uses original or equivalent processes; requires high precision, skill, specialized equipment, and strict quality control. | May use alternative methods not originally specified; often requires customer authorization and stricter controls. |

Standards & Compliance | Governed by IPC-7711/7721 and quality standards like AS9100; rework generally allowed without customer permission. | Repairs may require pre-authorization and are more strictly controlled contractually. |

LTPCBA gives you this expert service. They use the best technology and follow world standards for every pcb rework job.

Why Rework Matters

You need professional pcba rework to keep your pcba working well. Fixing problems like solder bridges or parts in the wrong place helps stop your product from breaking. It also saves you from expensive recalls. Studies show that using good rework steps, like those at LTPCBA, lowers the chance of failure and makes products better. The process follows IPC-7711/7721 rules, so your pcb meets all needs. Choosing professional pcba rework protects your money and makes your pcba last longer. You also get different types of pcb rework, each made for certain problems.

Common PCB Assembly Rework Issues

Soldering Defects

Soldering problems are a big reason for pcb rework. Open solder joints, solder bridges, and shorts can make a circuit board stop working. These soldering problems cause about 75% of all pcb assembly rework. Look at the table below to see how often these happen:

Defect Type | Failure Rate (%) |

|---|---|

Open Solder Joints | 34 |

Shorts (Solder Bridging) | 15 |

Component Shift (Misalignment) | 15 |

If you do not fix soldering problems, your pcb can get damaged or even burnt. LTPCBA uses special tools like AOI and X-ray to find these problems early. Skilled workers use careful rework steps to make your printed circuit board work again.

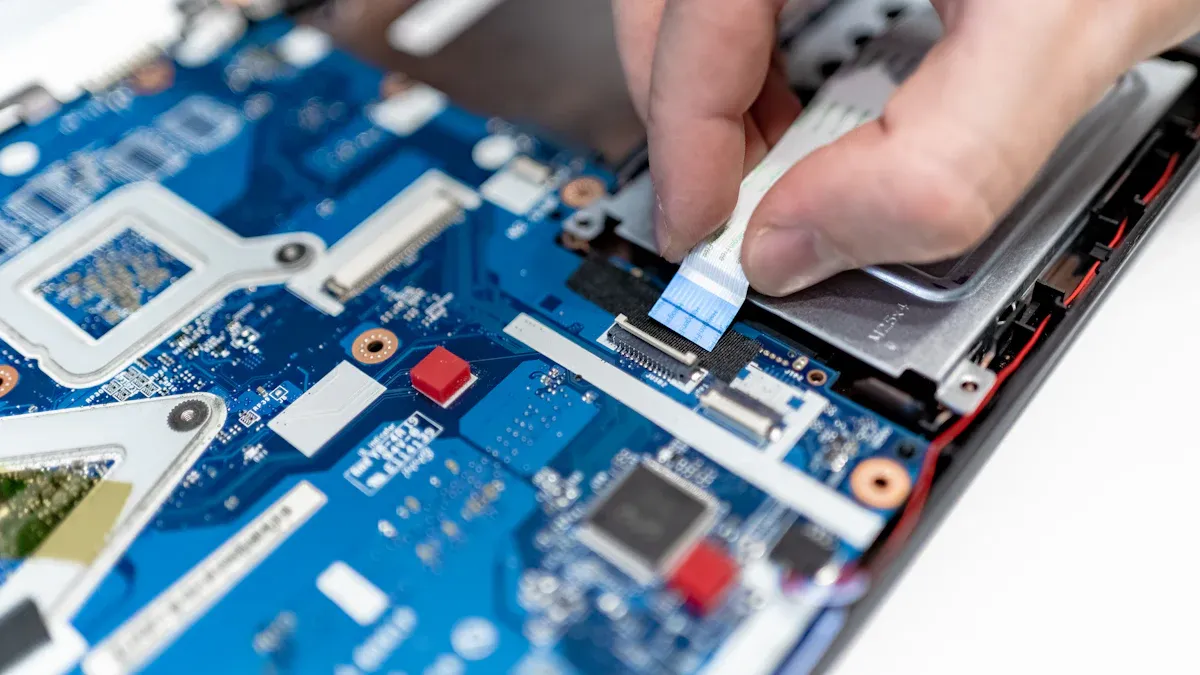

Component Problems

Problems with parts also mean you need pcb rework. Sometimes parts are missing, in the wrong place, or broken on your circuit board. AOI and ICT help find these problems fast. When you need to take out or change a part, LTPCBA’s experts make sure your pcb assembly rework is done right. This stops your pcb from getting corroded and keeps your device working well.

Design and Trace Errors

Mistakes in design, like broken traces or bad layout, can hurt your pcb or even burn it. These problems often need pcb rework to fix connections and make the board work again. LTPCBA’s team uses X-ray and tests to find hidden problems. You get a circuit board that works right and does not have corroded pcb risks.

Tip: Fixing these common pcb rework problems early saves time and money. Let professionals do your pcb assembly rework for the best results.

Benefits and Rework Process

Why Choose Professional Services

You want your printed circuit board to work well from the start. Professional pcb rework services do more than just fix things fast. You save money, get better reliability, and meet the ipc standard for pcb rework. Experts help you avoid mistakes that could hurt your pcb or cause safety risks.

Professional teams use special inspection tools like AOI and X-ray. These tools find problems early and help your pcb meet high standards. Companies using these tools see big changes:

More defects are found, so fewer problems reach customers.

More boards work right the first time.

Field returns can drop by 30%, saving money on repairs.

Some companies save millions each year with better inspection and rework steps.

You also get happier customers. Studies show 73% of people care more about service than price or features. Fast repairs, clear updates, and good support make customers loyal. You can cut repair costs by up to 30% with a professional pcb rework provider.

Note: Picking a service like LTPCBA means you get a team that follows the ipc standard for pcb rework and uses the newest technology to keep your products safe and reliable.

Rework Process Steps

A good rework process uses clear steps to fix your pcb and stop future problems. LTPCBA uses a proven method that meets all industry rules. Here’s what happens:

Inspection: Experts use AOI, X-ray, and other tools to find problems.

Diagnosis: The team checks what is wrong and plans how to fix it.

Component Removal: Technicians take out bad parts without hurting the board.

Site Preparation: They clean the spot and get it ready for new parts.

Replacement: New parts are put in and soldered with the right heat.

Testing: The pcb is tested again with AOI and other checks to make sure it works.

Final Review: The team checks the board with the ipc standard for pcb rework before sending it back.

This process keeps your pcb safe and helps stop the same problems from coming back. You get a board that works like new, with fewer problems and better reliability.

Tip: Always ask your provider about their rework steps and how they follow the ipc standard for pcb rework. This helps you get the best results.

LTPCBA’s Quality Standards

LTPCBA has high standards for every pcb rework job. The company follows ISO, IATF, and UL rules, so your boards meet strict world standards. The team uses advanced inspection and tracks things like defect detection and first pass yield. This helps LTPCBA improve quality and lower costs for you.

You get:

Regular checks and audits to find problems early.

Skilled technicians who know the latest rework and repair methods.

Fast help and 24-hour support.

Full compliance with the ipc standard for pcb rework, so your products stay safe and reliable.

LTPCBA cares about quality, safety, and making customers happy. You can trust your boards will last longer and work better.

You keep your circuit board safe when you pick professional PCBA rework. Trained engineers fix hard problems, like changing parts and testing them. Top companies also make circuit board designs better and add new features. They help your product last longer. You can trust experts to make sure your circuit board works well and stays safe.

FAQ

What is the difference between rework and repair?

Rework makes your PCB just like it was before. Repair only makes it work again. Professional rework gives you better quality and more trust in your board.

How do I know if my PCB needs professional rework?

You might see solder bridges, missing parts, or broken lines. If you want your board to work well, pick professional rework.

Can LTPCBA handle urgent rework requests?

Yes. LTPCBA can help fast and is open all day. You get quick answers and expert help when you need your PCB fixed soon.

Tip: Ask LTPCBA for a free talk if you have questions about your PCB assembly.

See Also

Techniques For Double-Sided Reflow Soldering In PCBA Manufacturing

Essential Strategies To Enhance PCBA Durability Over Time

Complete PCBA Solutions Covering Manufacturing Through Final Testing

Ways Contract PCBA Manufacturing Enhances Your Business Productivity

Guide To Choosing The Right PCBA Supplier For Your Requirements