Procurement Strategies for Electronic Components in PCB Assembly Projects

Procurement Strategies for electronics in assembly projects need good supplier relationships. You also need to buy electronic components carefully. Checking if parts match design specs is important. Supplier qualification and traceability help lower risks.

Risk Factor | Statistic / Data Point | Impact on PCB Procurement |

|---|---|---|

Extended Lead Times | 78% of distributors say lead times are over 20 weeks. Automotive-grade components can be delayed up to 52 weeks. | This causes delays in making products and planning schedules. |

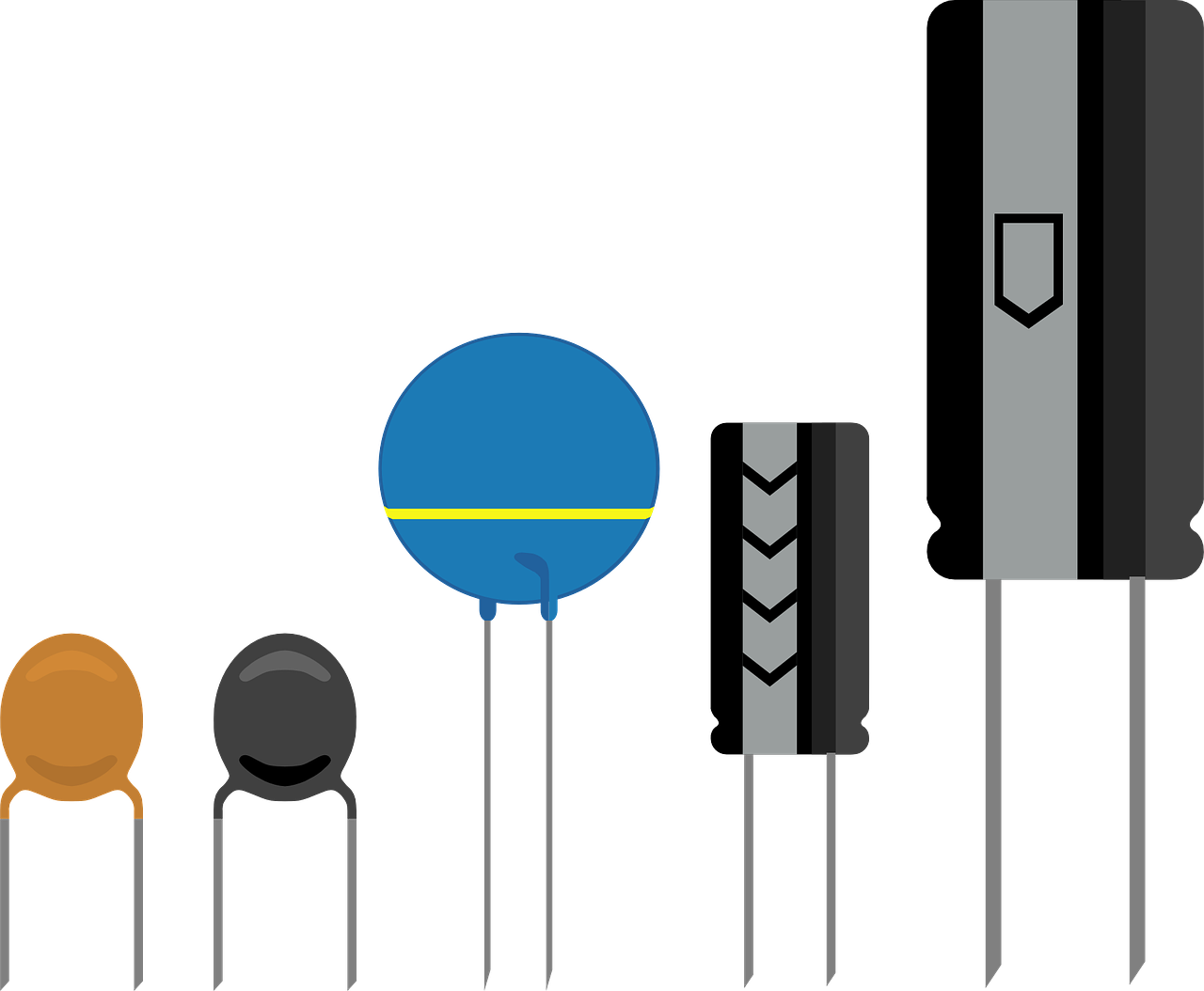

Counterfeit Incidents | There were over 12,000 incidents in 2022. 62% involved passive components like MLCCs and resistors. | This can hurt product quality and make products less reliable. |

Price Volatility | MLCC prices changed up to 300% during shortages in 2021-2022. | This makes costs hard to predict and can hurt budgets. |

Component Obsolescence | Over 15% of components in a BOM get End-of-Life notices in 18 months. | This means you must manage lifecycles and suppliers early. |

Electronics projects have problems with cost, quality, and old parts in assembly.

Key Takeaways

Make good, lasting connections with trusted suppliers. Use authorized distributors to get real, high-quality electronic components. This helps lower risks like getting fake parts.

Use smart tools to manage inventory and predict what you will need. This helps keep enough stock, stops shortages, and lets you react fast to market changes.

Be ready to change by having backup components. Check BOMs often and watch out for risks like old parts or price and quality problems. This helps projects go well.

Supplier Relationships

Qualification and Trust

Getting electronic parts means picking vendors with high standards. Companies need to find vendors who show proof of quality. They should give clear documents and records. This helps everyone trust each other.

Vendors who let you check their work, in person or online, help you see how they do things.

Testing samples in outside labs makes sure parts are good.

Checking data with groups like ERAI and SiliconExpert helps prove parts are real.

Vendors who use online tools or APIs make it easy to see records fast.

Ways to stop fake parts keep bad parts out.

These tips help teams pick vendors who give good parts and keep quality high.

Long-Term Partnerships

Working with the same vendors for a long time is helpful. It gives more than just steady parts. Working together helps you learn about costs and new ideas. Trying new parts in steps makes things safer. Vendors share new tech and give better prices to loyal buyers. Over time, these friendships help companies grow and do better. They also help companies stay ahead. Studies show strong vendor ties help money and new ideas. For example, a delivery company made 35% more money in five years by working closely with a car maker.

Performance Monitoring

Teams must check how vendors do to keep quality high. The table below shows what to watch:

Relevant Metrics and Practices | |

|---|---|

Supplier Qualification and Management | How vendors are picked, checked, and managed |

Quality Certifications | ISO certifications, IPC standards like IPC-A-610E Class 3 |

Monitoring Statistics | Defect rates, first pass yield, return rates, failure rates, process capability indices (Cp/Cpk) |

Supplier Vetting Procedures | Checking factories, picking vendors by strict rules, regular checks |

Traceability and Record Keeping | Tracking parts from vendor to assembly, keeping good records for quality |

These tips help make sure vendors meet goals and keep quality high in electronics projects.

Procurement Strategies

Authorized Distributors

Authorized distributors are very important in buying electronics. These vendors help keep the supply chain steady and clear. Companies that use them can handle surprises better when buying parts. They get parts straight from the real makers. This makes sure the parts are real and not fake.

Companies say they are happier with authorized distributors because they trust the parts more.

These vendors give the right papers and warranties.

They help stop work from slowing down by finding parts fast and having good connections.

Using authorized distributors helps companies plan better and avoid big problems or recalls.

Independent Brokers

Independent brokers help when authorized distributors do not have the parts. These vendors can find rare or old parts. But buying from brokers is more risky. The supply chain can get weak, and fake parts are more likely. Companies should check if brokers are certified and ask for proof of where parts came from. Using smart ways like random checks and outside tests can make things safer when using brokers.

Component Authenticity

Making sure parts are real is very important when buying them. Companies should check new parts when they arrive. They can use visual checks, X-rays, and tests to see if parts work.

Visual checks look for wrong marks or changes on the part.

X-rays let you see inside the part and compare it.

Working with trusted labs for hard tests gives extra safety.

Having a Counterfeit Parts Detection & Avoidance Program keeps everyone careful.

Buying from authorized distributors is still the best way to get real parts.

Inventory Management

Demand Forecasting

Demand forecasting is very important in electronics buying. Teams look at old sales numbers and market changes to guess what they will need. They also use special computer tools like AI to study lots of data. These tools help find patterns in what people buy. This helps companies change plans fast and not run out of parts.

Using smart data tools can cut mistakes in the supply chain by half.

Better guessing makes the supply chain work 65% better.

Mixing old sales with new trends helps make better guesses.

Sales, marketing, and supply teams work together to make these guesses better. They update their guessing tools often so they can keep up with the market.

Buffer Stock

Buffer stock, or safety stock, helps when there are sudden changes. It keeps companies from losing sales or stopping work when parts run out. Having the right amount of extra parts stops both too much and too little stock.

Tip: Safety stock is like a shield. It helps when the supply chain has problems, which happens a lot in electronics.

A new way to measure safety stock uses how steady the supply chain is and if there are busy seasons. This helps companies save money and not run out of parts.

Inventory Tools

Modern inventory tools help companies manage parts better. These tools watch stock all the time, warn when it is low, and order more by themselves. Special software uses smart guessing to plan for busy times and sales.

Watching data all the time helps fix shortages fast.

Planning software helps see what is in stock and keeps the right amount.

Using these tools well saves money on storage and makes sure parts are ready. This helps electronics makers handle problems in the supply chain better.

Design and Sourcing Flexibility

Alternate Components

Design teams plan for alternate components in projects. They pick parts that fit the same way as others. Teams use special tools to watch how long parts will last. This helps them act fast if there are supply chain problems. If a part might run out, they can use a backup part. They do not need to change the design much.

Planning ahead for alternates keeps work going. This is true even when parts are hard to find or not made anymore.

Teams make backup plans and work with many suppliers. These steps help them fix problems fast. They can keep making products in big assembly jobs.

Standardization

Making parts the same helps quality and makes things work better. Teams follow IPC standards like IPC-A-610 and IPC-J-STD-001. These rules tell how to solder, check, and write down what they do.

Making things the same way means fewer mistakes.

It helps different makers use the same parts.

It helps customers trust the products.

Using the same rules makes buying parts easier. Teams can use the same parts for many projects. This makes buying simpler and saves money.

BOM Reviews

Checking the BOM often helps teams save money and buy better. When BOMs are up to date, there are fewer mistakes and delays.

BOM checks show what parts are needed and help get better prices.

They help teams talk better with suppliers.

New BOM tools let teams see and study parts right away.

When design and buying teams work together on BOMs, they make better choices. This teamwork means fewer problems and better results for assembly projects.

Global Supply Chain

Compliance

Companies that buy electronics from around the world must follow many rules. Every country has its own rules for bringing in and sending out parts. Teams check themselves often to make sure they follow rules like ITAR. Many use traceability tools to watch every change in design files. Cloud platforms with special logins help keep important data safe. Most top companies use these systems to avoid fines and earn customer trust. Teaching workers and keeping good records also help with following the rules.

Financial Considerations

Saving money in global supply chains takes smart planning. Teams use digital tools to watch spending and find risks early. Automation and AI help spot problems fast and make data better. Companies check if suppliers are strong by looking at credit scores and cash flow. Some share money details with suppliers to build trust. For example, a telecom company used early warning tools to find supplier problems during the pandemic. This stopped expensive delays. Open-book policies and finance programs help suppliers stay strong and deliver on time.

Resilience

A strong supply chain can handle surprises well. Companies watch for changes in orders and how long parts stay in storage. These steps help them act fast when needs or supplies change. Inventory turnover ratios show if stock matches what is needed. Teams also check profits to see if costs change quickly. Many companies use more than one supplier in different places to avoid big problems. They use AI and blockchain to see better and change fast when rules or markets shift. These actions help electronics projects keep going, even when there are big world problems.

Risk Management

Obsolescence

Obsolescence is a big problem in PCB assembly projects. Technology changes fast, and market needs change too. This makes many parts become end-of-life quickly. In 2022, almost 750,000 parts were not made anymore. Fast innovation was the main reason, said 36% of workers. Teams use a decision tree to manage this risk. They watch how long parts will last with special tools. They buy extra important parts before they are gone. Sometimes, they change the product and test new parts. They also use more than one supplier to stop problems. A medical device company used special software to help with this. These steps save money and keep production going.

Counterfeit Prevention

Fake electronic parts can hurt safety and cost money. The AS5553 aerospace standard helps companies stop fake parts. Teams only buy from trusted OEMs or authorized distributors. They keep records for every part they get. Workers learn to spot problems and check parts by looking at them. They use certificates and special tests too. If a part looks fake, it is set aside and reported. The Department of Defense uses strong rules and trusted programs to stop fakes. Companies that do these things keep parts good and avoid big problems.

Cost vs. Quality

Teams must plan well to save money and keep quality high. They use cost-effectiveness analysis to compare choices. Teams look at the total cost, not just the first price. They check if suppliers have good quality systems and certifications. Automated tools and smart data help make better choices. Good planning stops rushed orders that could hurt quality. Only thinking about cost can mean bad service. Not saving money can hurt budgets. Clear rules and checking suppliers often help balance cost and quality.

Tip: Checking and reviewing often keeps risk management working well and helps improve over time.

Working together with good suppliers, smart buying, and flexible design helps projects do well in assembly. Top companies like Bosch and Cisco use computers and data to make projects better. Teams need to check their assembly plans often. Always trying to get better keeps projects strong and makes assembly work well.

KPI Metric | Benchmark/Target | Review Frequency |

|---|---|---|

Production Efficiency | ≥ 85% | Daily |

On-Time Delivery | ≥ 95-98% | Daily |

FAQ

What is the best way to avoid counterfeit electronic components?

Companies need to buy parts from trusted suppliers or authorized distributors. They should look at the parts closely to check for problems. Using outside labs for testing helps make sure the parts are real.

How can teams handle sudden shortages of critical components?

Teams keep extra parts in stock to help with shortages. They use special tools to watch their inventory. They also plan for backup parts and work with more than one supplier to lower risk.

Why do regular BOM reviews matter in PCB assembly projects?

Checking the BOM often helps teams find old or risky parts. It also helps them talk better with suppliers and control costs.

See Also

Sourcing Electronic Parts Efficiently For PCBA Production

How To Find The Ideal One-Stop PCB Assembly Provider

Essential Tips For Beginners Sourcing BOM In PCBA

How Component Procurement Services Accelerate Electronics Time-To-Market