What is PCBA Traceability and Why Does It Matter

PCBA traceability allows you to monitor every stage of the PCBA process, from sourcing raw materials to delivering finished products. This system provides enhanced quality assurance and process optimization, ensuring that each step is documented and verifiable. Comprehensive pcba traceability reports give you greater confidence in your PCBA, especially when strict industry standards must be met. At LTPCBA, pcba traceability is a core practice, guaranteeing reliable and consistent results.

Aspect | Impact on Product Quality and Customer Trust |

|---|---|

Enhanced Quality Assurance | PCBA traceability enables quick identification of defects, reducing waste and maintaining high yield rates. |

Process Optimization | PCBA traceability highlights recurring issues, driving continuous improvement in production efficiency. |

Customer Confidence | Full pcba traceability reports build trust, especially in high-reliability sectors like automotive and medical. |

Regulatory Compliance | PCBA traceability ensures adherence to global standards, supporting audits and certifications. |

Efficient Recall Management | PCBA traceability allows precise identification of affected units during recalls, minimizing costs and corrective actions. |

The significance of pcba traceability directly influences your experience of product quality and customer trust.

Key Takeaways

PCBA traceability ensures quality by tracking every step of the production process, helping to identify defects quickly and reduce waste.

Implementing traceability systems enhances customer trust by providing detailed reports that meet strict industry standards, especially in sectors like automotive and medical.

Effective traceability aids in compliance with regulations, making audits easier and minimizing risks during product recalls by allowing precise identification of affected units.

PCBA Traceability Basics

What is PCBA Traceability

You need to understand pcb traceability to appreciate how manufacturers control quality and ensure reliability in electronics. Pcb traceability means tracking every step in the lifecycle of printed circuit boards. This process starts with the concept phase and continues through design, manufacturing, testing, and even maintenance after deployment. You can see how pcb traceability helps you pinpoint the source of any issue, making repairs and quality control much easier.

PCB traceability is essential for streamlining production procedures. It enables producers to pinpoint the origin of any flaws or issues that can appear during manufacturing, enhancing quality control and guaranteeing adherence to rules and regulations. Additionally, it simplifies maintenance and repairs because personnel can find the root of problems and replace broken parts more rapidly.

Pcb traceability plays a vital role in every stage of a pcb's lifecycle. You can refer to the table below to see how each phase is tracked:

Stage | Description |

|---|---|

Concept Phase | Initial requirements for the pcb are defined based on customer needs, market trends, or technical specs. |

Design Phase | The pcb is developed, linking each element to corresponding requirements. |

Manufacturing Phase | The pcb is produced according to design specifications, ensuring quality control measures are in place. |

Testing Phase | Verification that the pcb meets specified requirements through various tests. |

Deployment and Maintenance | Tracking requirements and making updates post-deployment based on changes in needs or regulations. |

You benefit from pcb traceability because it gives you confidence in the quality and reliability of your printed circuit boards. LTPCBA uses advanced systems to ensure that every pcb meets strict standards. You can trust that each pcb is tracked from start to finish, making it easier to identify and solve any problems.

How PCBA Traceability Works

You might wonder how pcb traceability operates in a modern manufacturing environment. The process relies on several core components that work together to track every pcb and its assembly. LTPCBA uses these components to maintain high standards and deliver reliable products.

Component | Description |

|---|---|

Unique Identifiers | Each component, pcb, and assembly should have a unique identifier, such as serial numbers, barcodes, or RFID tags, enabling individual item tracking throughout its lifecycle. |

Documentation and Records | Detailed records of components, suppliers, manufacturing processes, inspections, and testing results are essential for traceability, facilitating trace-back and trace-forward capabilities. |

Data Capture and Integration | Automated data capture systems, such as Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) software, integrate data from various sources, enabling real-time visibility and analysis. |

Traceability Protocols | Establishing traceability protocols and standards, such as IPC-1782 for traceability of electronic components, ensures consistency and interoperability across the supply chain. |

LTPCBA uses real-time production dashboards and predictive maintenance alerts to keep data accurate. You can rely on end-to-end traceability, which tracks every component throughout the production process. Version-controlled documents and real-time tracking help you quickly identify defects and analyze root causes.

Feature | Contribution to Data Accuracy and Reliability |

|---|---|

Real-time production dashboards | Provides immediate feedback on production status and defect detection. |

Predictive maintenance alerts | Ensures timely equipment maintenance, reducing potential errors. |

End-to-end traceability | Tracks components throughout the production process for accountability. |

Version-controlled documents | Maintains accurate records with audit trails for changes and approvals. |

Real-time tracking of production | Enables quick identification of defects and root-cause analysis. |

You see the benefits of pcb traceability in the data collected during production. The system gathers unique identification marks for each pcb, automated data from key equipment, and operator information. All production and test data go into a central database. You can visualize and report on the entire history of each pcb, making it easy to query and analyze.

Unique identification marks for each pcb, such as bar codes or two-dimensional codes.

Automated data collection from key processing equipment, including parameters and operator information.

Central database for managing all production and test data associated with the unique ID.

Visualization and reporting functions for querying production and testing history.

LTPCBA follows strict industry standards and certifications to ensure pcb traceability meets global requirements. You can see how these standards support quality and compliance:

Certification/Standard | Key Aspects |

|---|---|

ISO 9001 | Quality management system applicable across industries, ensuring consistent quality and customer satisfaction. |

IPC-A-610 | Standards for pcb assembly and inspection, including soldering criteria and cleanliness assessment. |

ISO 13485 | Quality management for medical devices, emphasizing traceability and risk management. |

AS9100 | Quality management for aerospace, including product safety and counterfeit part prevention. |

IATF 16949 | Quality management for automotive, focusing on continuous improvement and supplier management. |

You can trust LTPCBA to deliver printed circuit boards that meet these standards. Pcb traceability ensures every pcb is tracked, documented, and verified. You gain peace of mind knowing that your pcba meets the highest levels of quality and reliability.

Importance of Traceability in Manufacturing

Quality Assurance with LTPCBA

You need to understand the importance of traceability in pcba manufacturing to see how it shapes the quality and reliability of every pcb you use. Traceability acts as a safety net, catching errors before they reach your hands. When you track each pcb from the moment it enters production to the time it leaves the factory, you gain control over every detail. This process helps you prevent defects, maintain high yield rates, and ensure that only the best products reach your customers.

Traceability in pcba manufacturing is not just about tracking numbers. It is about building a system that supports continuous improvement and learning from every production run.

You can see the impact of traceability on quality assurance in the table below:

Benefit | How Traceability Supports It |

|---|---|

Defect Reduction | You can quickly identify the root cause of defects by analyzing production data, which reduces waste and rework. |

Continuous Improvement | You can spot patterns and recurring issues, allowing you to make changes that reduce defects over time. |

Process Efficiency | By recording every process, material, and operator, you can improve production efficiency and eliminate weaknesses. |

LTPCBA uses advanced traceability systems to track every component and process in your pcb. You benefit from:

Component traceability: You can follow each part from the supplier to the finished pcb using barcodes or RFID tags. This includes batch numbers and expiration dates.

Process traceability: You know who assembled your board, when it was done, and which equipment was used. This makes it easy to find the source of any issue.

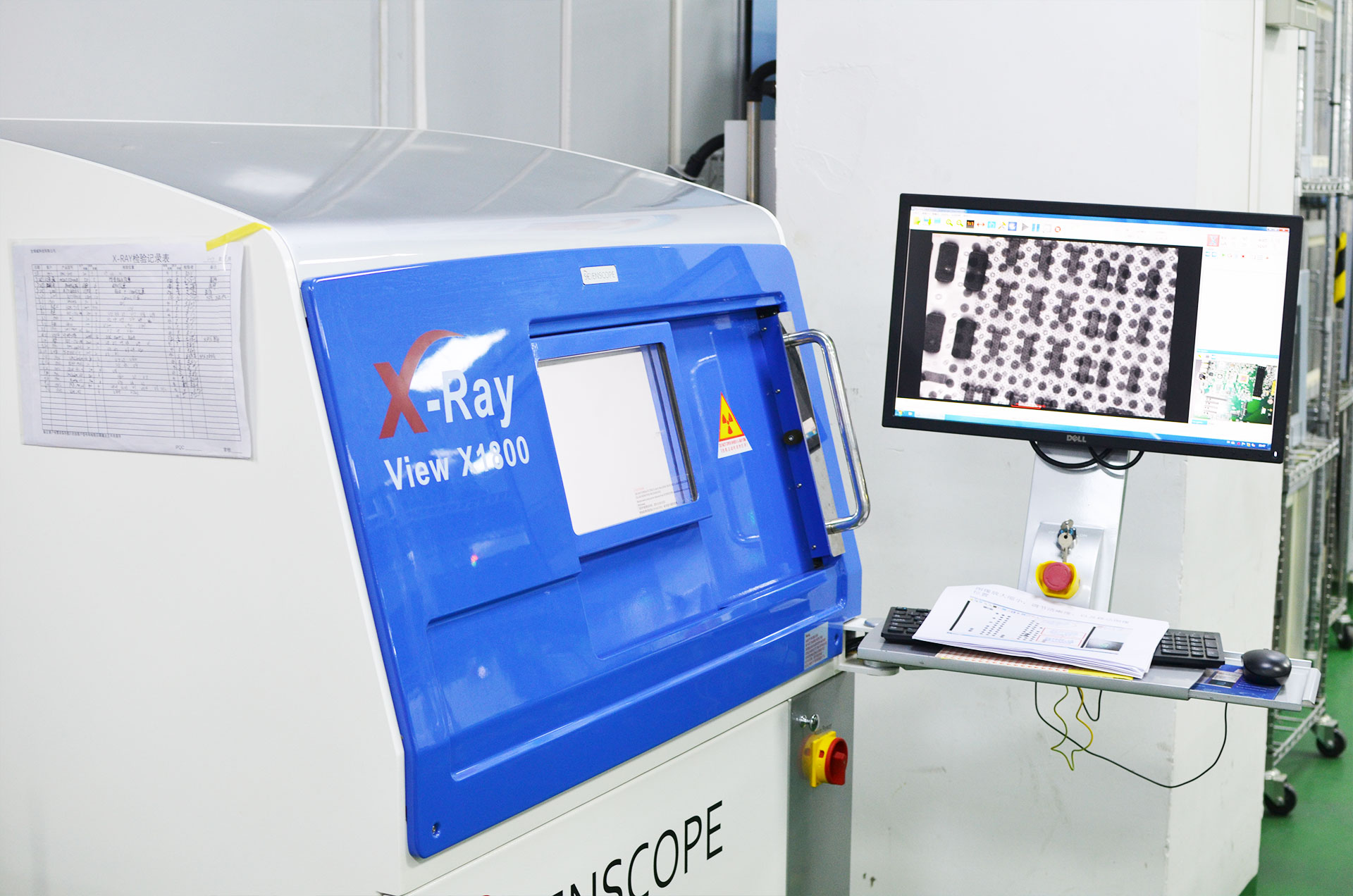

Test documentation: You have access to AOI and X-ray reports, ICT results, and functional test data for audits or customer requests.

Aspect | Description |

|---|---|

Component Traceability | Tracking every part from supplier to pcb using barcodes or RFID, including batch numbers and expiration dates. |

Process Traceability | Recording who assembled the board, when, and which equipment was used—enabling rapid root cause analysis if defects occur. |

Test Documentation | Storing AOI/X-ray reports, ICT results, and functional test data for audits or customer requests. |

You can trust LTPCBA’s commitment to quality assurance. The company holds certifications such as ISO 9001, IATF 16949, and UL, which require strict traceability and process control. These standards help you meet industry requirements and deliver reliable products to your customers.

Case studies show how traceability improves results. For example, in 5G base station pcb production, solder bridges dropped from 12 to 3 per board, saving $180,000 in rework costs each year. In medical device pcb manufacturing, zero bridge defects were found in over 5,000 units, making ISO 13485 audits easier. Automotive ADAS pcb production saw a 70% reduction in bridges, with 98% of units passing five-year field testing.

You also gain from continuous improvement. Traceability lets you learn from data, identify inefficiencies, and make informed changes. This leads to higher first-pass yield, better quality consistency, and lower manufacturing costs.

Compliance and Product Recalls

You face strict regulations in electronics manufacturing. Traceability helps you meet these requirements and manage risks. Regulations such as ISO 9001, IPC, IATF 16949, RoHS, and REACH demand detailed records of every pcb and its components. You must track hazardous substances, verify material safety, and provide documentation during audits.

Compliance Requirement | Description |

|---|---|

ISO 9001 | Quality management systems standard that emphasizes traceability in processes. |

IPC | Standards for electronics manufacturing that include traceability requirements. |

IATF 16949 | Automotive quality management standard requiring traceability for compliance. |

RoHS | Regulation that mandates traceability of hazardous substances in electronics. |

REACH | Regulation for chemical safety that requires traceability in supply chains. |

You need to keep detailed records of materials and processes to pass audits and avoid penalties. For example, RoHS and REACH require you to test and verify that your pcb contains no restricted substances. You must also provide information about any substances of very high concern.

Product recalls are a major risk in electronics. In 2019, product recalls made up 15% of all recalls in the EU and 29% in the US. The average cost of a recall claim is over $1 million. Common causes include faulty batteries, overheating devices, and counterfeit components. The Samsung Galaxy Note 7 recall in 2016, which involved 2.5 million units, shows how costly and damaging recalls can be.

Traceability gives you the power to act quickly during a recall. You can identify affected batches and limit the recall to only those units, reducing costs by 40–50%. Real-time traceability systems provide precise timestamps and operational data, making it easy to find the source of a problem. You can respond immediately, prevent defective products from reaching the market, and protect your brand reputation.

A strong traceability system is your best defense against compliance risks and costly recalls. It helps you maintain customer trust and meet the highest standards in the industry.

You avoid risks such as non-compliance penalties, quality issues, and damage to your brand by using traceability. LTPCBA’s advanced systems and certifications ensure that your pcb meets all regulatory and quality requirements. You gain peace of mind knowing that every pcba is tracked, documented, and ready for any challenge.

PCB Traceability Technologies

Tracking Methods and Systems

You rely on advanced tracking methods to ensure every pcb in your pcba process is accounted for. Barcodes, RFID tags, and serialization stand out as the leading technologies. Barcodes offer a cost-effective way to label each pcb. You can choose from several barcode types, each with unique strengths:

Barcode Type | Description | Applications |

|---|---|---|

Code 128 | Encodes all 128 ASCII characters in a compact format. | Simple alphanumeric strings. |

DataMatrix | Stores large amounts of data in a small space. | PCBs with limited space. |

PDF417 | Encodes up to 1800 characters in a stacked format. | Complex data needs. |

QR Code | Square format, easy to scan. | Consumer products. |

RFID technology gives you real-time visibility and automatic traceability. You can track each pcb as it moves through production. RFID tags cost more than barcodes, but they provide advanced features like alerts and condition monitoring. Serialization assigns a unique number to every pcb, supporting traceability protocols and quality control.

You benefit from these systems through machine readability, data density, and supply chain efficiency. These methods help you authenticate products and manage quality at every step.

Data Management Challenges

You face challenges when you try to collect traceability data from different machines and suppliers. Each stage of pcb production may use different software or formats. This makes it hard to achieve complete traceability across your pcba process. You need a unified system that brings together data from cameras, lasers, and quality checks.

Integration issues can slow you down. Incompatible formats and software create barriers. You want real-time insights for millions of pcb units, but data silos make this difficult. LTPCBA uses automated data management systems to solve these problems. These systems speed up development, link design data with traceability protocols, and make audits easier. You can quickly identify issues and keep your records ready for compliance checks.

Automated traceability systems help you maintain up-to-date records, support regular reviews, and encourage team collaboration. You gain better control over your pcb production and meet customer requirements with confidence.

You see the benefits of pcba traceability every time you use a reliable pcb. Traceability gives you end-to-end visibility, supports design improvements, and helps you plan for the end of a pcb’s life.

Benefit | Description |

|---|---|

End-to-End Visibility | You gain insights into the entire lifecycle of pcb products. |

Reliability Enhancements | You make informed decisions that improve pcb reliability. |

Cost Optimizations | You identify cost-saving opportunities throughout the pcb lifecycle. |

LTPCBA uses advanced technologies like RFID and barcodes to track each pcb. You avoid counterfeit components and reduce the risk of recalls. You also meet industry standards and keep your supply chain strong.

You track every pcb component and process step, which is crucial for quality investigations.

You contain field issues quickly, which improves pcb reliability.

You support continuous improvement with data-driven insights for better quality control.

You should make traceability a priority in your own pcb manufacturing. This approach helps you deliver safe, high-quality products and builds customer trust.

FAQ

What is the main benefit of PCBA traceability?

You gain the ability to track every component and process. This helps you improve quality, reduce errors, and support supply chain integrity.

How does traceability help during a product recall?

You can quickly identify affected units. This lets you act fast, limit the recall, and protect your brand reputation.

Does PCBA traceability support compliance with industry standards?

You meet strict industry standards more easily. Traceability provides clear records for audits and helps you maintain high-quality production.

See Also

Understanding PCBA and Its Essential Components

Defining PCBA: Its Meaning in the Electronics Field

PCBA Processing Needs for Medical Device Manufacturing