How PCBA Services Cover Every Step from Manufacturing to Testing

You can count on LTPCBA for all your PCBA services needs. They handle making, assembling, and testing PCBs with precision. LTPCBA uses the latest machines and performs quality checks at every step of the PCBA services process. The company holds worldwide certifications and boasts high test scores, ensuring their PCBA services deliver reliable and trusted products.

Metric | LTPCBA's Performance | Industry Benchmark |

|---|---|---|

On-Time Delivery Rate | 99.5% | >98% |

Failure Rate (Functional Testing) | 0.0003% | 0.03% |

Key Takeaways

LTPCBA helps with PCBA from start to finish.

They make sure your circuit boards are built well.

They use special machines and careful tests like AOI and X-ray.

These tests help find problems early and make good boards.

LTPCBA checks quality and ships fast and safely.

They promise their products work well and meet world rules.

Your boards will get to you on time.

One-Stop PCBA Services

PCBA Process Overview

LTPCBA helps you from start to finish. They guide you from design to testing. The process has many steps for strong circuit boards. Here is what happens:

First, you design your board and get files ready. EDA tools help you make the layout and files.

Next, LTPCBA finds all the parts you need. They get every part for your board.

Then, they make the board using your files. This step builds the real circuit board.

Solder paste goes on the board pads.

Machines put parts on the board.

Soldering connects the parts to the board.

Tests and checks make sure your board works well.

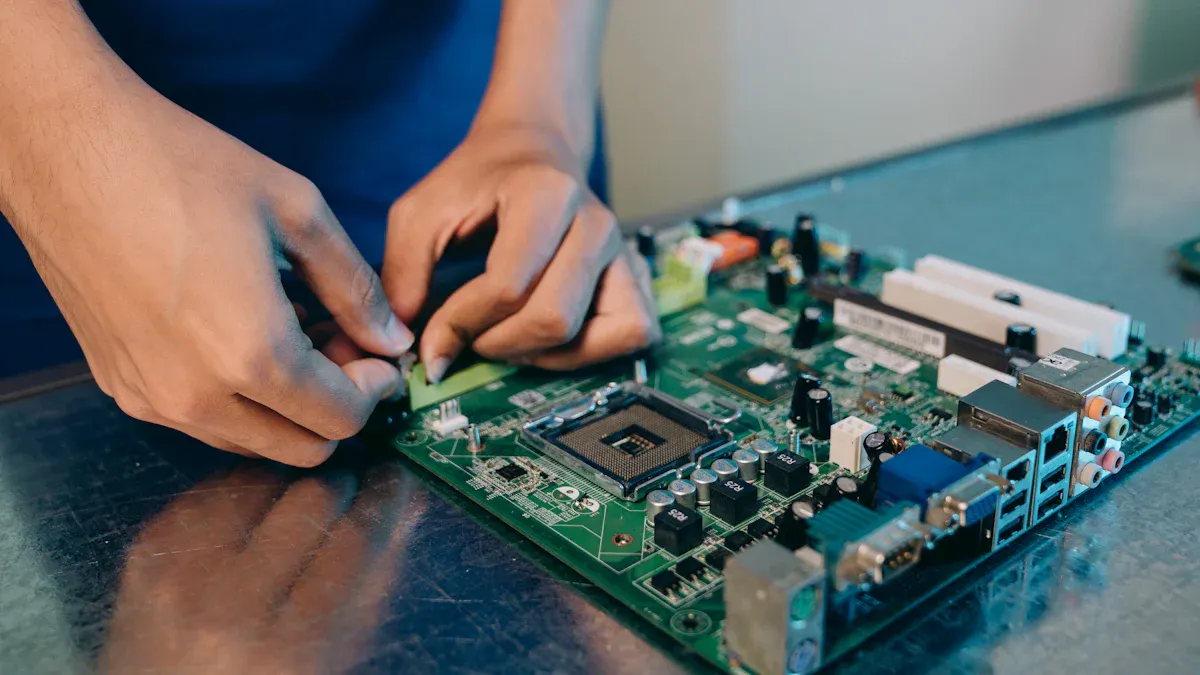

PCB Manufacturing

LTPCBA is a top choice for making circuit boards. They use smart machines and computers for each step. Laser stencils, X-ray, and AOI help them check for mistakes. You get your boards fast, even for small or medium orders. They can make many types and sizes of boards, so your project goes smoothly.

Aspect | Details |

|---|---|

Automation | Smart lines, laser stencils, AOI, X-ray checks |

Delivery | Samples in 24 hours, small orders in 72 hours, medium in 5 days |

Capacity | SMT: 4 million parts/day, THT: 500,000 parts/day |

Board Types | Hard, bendy, metal boards; up to 400mm x 1200mm |

Component Procurement

You want only good parts in your board. LTPCBA uses a strong system to buy parts. They pick trusted sellers and use smart plans to avoid problems. You get good quality and clear prices. This keeps your project on time and costs steady.

Early checks find problems before you get the board.

Extra parts and many suppliers keep work moving.

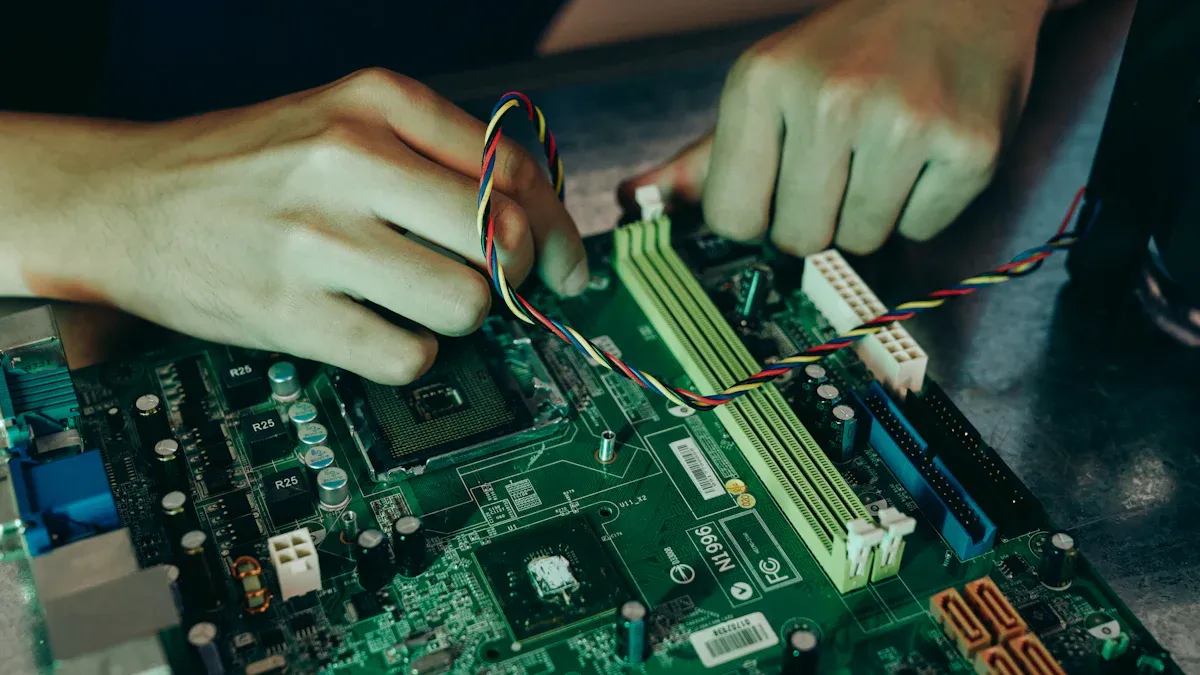

Assembly Methods (SMT, THT)

Your board can use SMT or THT ways. SMT puts small parts on top, making things smaller and lighter. Fast SMT lines help make more boards and save money. THT puts parts through holes for extra strength. Both ways together help your board work for any job. LTPCBA checks each step with AOI and X-ray to make sure it is right.

PCBA Testing and Final Assembly

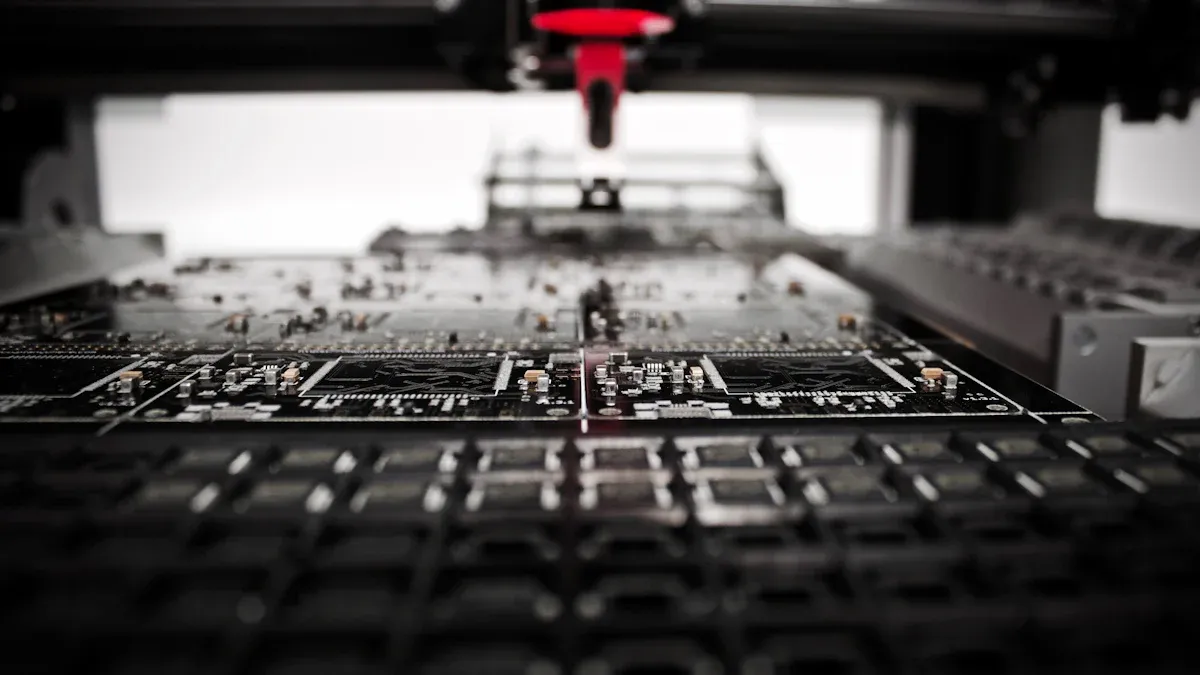

In-Process PCBA Testing

You want your board to work right away. LTPCBA checks for problems early. AOI looks for missing or wrong parts. X-ray finds hidden solder issues inside the board. ICT tests if each part works. Functional testing checks if the board does its job.

You see these steps in every test:

AOI looks for surface problems.

X-ray checks under chips and inside solder.

ICT tests wires and values.

Functional testing runs the board for real use.

Test tools include AOI, ICT, and software. Each test follows clear steps and keeps records. Machines are checked often for accuracy. If a problem shows up, teams find and fix it fast. Everyone works together to make things better.

Note: Testing during the process stops big mistakes later. Finding problems early saves time and gives better boards.

Final Assembly

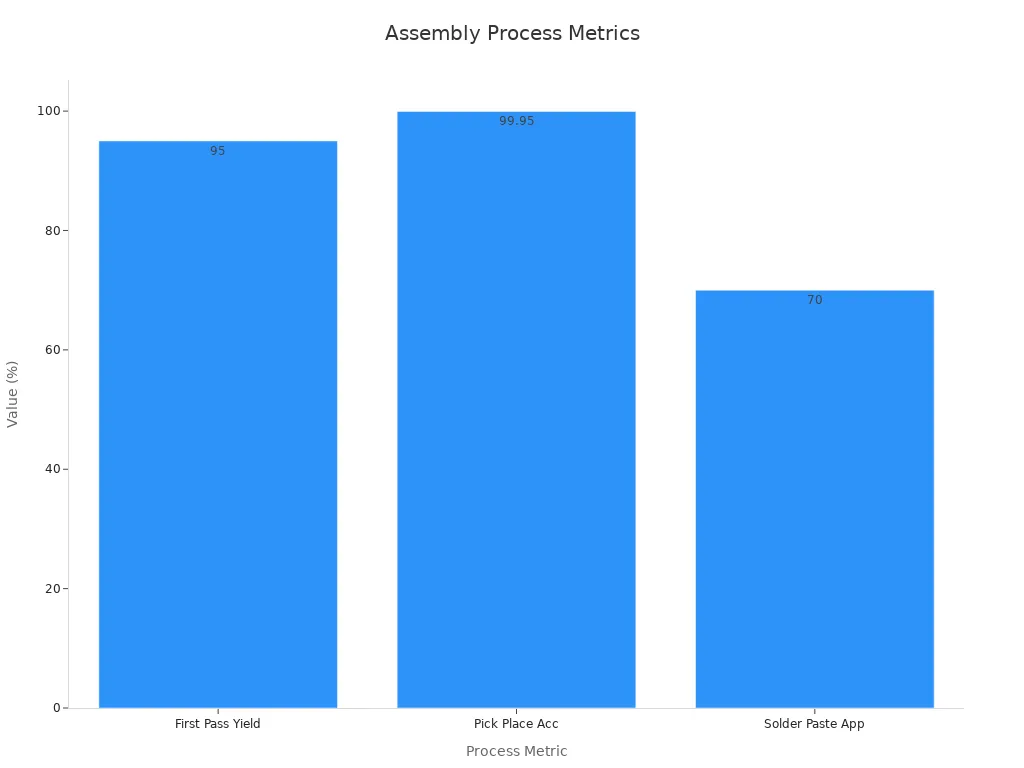

After tests, your board goes to final assembly. LTPCBA puts all parts together and checks each one. Machines place parts with almost perfect accuracy. Automated systems handle paste, placement, and soldering. This lowers mistakes and speeds up work.

Metric/Process Aspect | Description/Value | Impact on Quality and Reliability |

|---|---|---|

First Pass Yield | 95% target | Less rework, faster delivery |

Pick-and-Place Accuracy | 99.95% | Precise placement, fewer defects |

AOI and ICT | Used at every step | Early defect detection |

Inspection Time | Much shorter with automation | Faster quality control |

Solder Paste Application | Controlled by stencil and thickness | Over 70% of welding success depends here |

Reflow Soldering | Precise temperature control | Consistent solder joints |

Final Testing | Confirms reliability before shipment | |

Statistical Process Control | Data-driven quality control | Consistent quality, process improvement |

Final assembly is more than just putting parts together. You get more tests for function, electricity, and strength. These steps make sure your board lasts and works well. LTPCBA tracks every step with data. Machines are kept in good shape for smooth work.

Quality Assurance

Quality checks are very important at LTPCBA. You get strong testing at every step. AOI, x-ray, ICT, and other tests catch any problem. LTPCBA follows world rules like ISO and UL. This makes you trust every board you get.

LTPCBA uses many tools for quality:

AOI and x-ray find visible and hidden problems.

ICT and flying probe check the electric parts.

Functional tests show if the board works in real life.

Solder paste and burn-in tests add extra checks.

The company keeps records for every test. If a problem happens, teams fix it and stop it from coming back. LTPCBA’s 99.5% pass rate proves their quality. You get boards that meet tough rules.

Tip: Quality checks happen all the time, not just at the end. Every step matters, from start to finish.

Packaging & Delivery

When your board passes all tests, LTPCBA gets it ready to ship. They use special packaging to save money and protect your board. Anti-static bags and foam stop water, static, and bumps. Clear labels help avoid mistakes.

Anti-static and foam stop damage.

Labels make sure your order goes to the right place.

You can trust your board will arrive safe and on time. Good management and smart buying help LTPCBA keep this promise. Packaging and delivery are the last steps, but still very important. Your board comes ready to use, with all checks done.

Remember: Good packaging and fast shipping mean you get perfect boards every time.

You get full help from LTPCBA for your boards.

UL and ISO show the boards are safe and good.

Machines and trained workers check each board for problems.

You get quick shipping, strong boards, and service you can trust.

FAQ

What types of PCB assemblies can you order from LTPCBA?

You can order SMT, THT, mixed assembly, and rigid-flex PCBs. LTPCBA handles both simple and complex boards for many uses.

How does LTPCBA ensure your boards meet quality standards?

LTPCBA uses AOI, X-ray, and ICT testing. You get boards that meet ISO, IATF, and UL standards.

Can you get help if you have questions during your project?

Yes! You can contact LTPCBA’s 24-hour support team. They answer questions and help you solve problems fast.

See Also

Complete PCBA Solutions Covering Manufacturing Through Final Testing

Understanding PCBA And Its Key Electronic Components Explained

In-Depth PCBA Production Process Guide For Novices And Pros

Explaining The Meaning Of PCBA In Electronic Industry

Ways Modern Turnkey PCBA Plants Maintain High Quality Standards