What Secure PCBA Manufacturing Means and Why It Matters

PCBA manufacturing secure practices ensure your assemblies are built with rigorous controls that safeguard your products against cyber threats, physical damage, and counterfeit components. This is especially critical in industries such as defense, infrastructure, and consumer electronics, where any failure can compromise safety or national security. By choosing pcba manufacturing secure solutions, you guarantee reliability even in demanding environments. Trusted providers like LTPCBA utilize advanced materials, comprehensive quality testing, and secure packaging to keep your devices protected and dependable throughout the entire production process.

Key Takeaways

Secure PCBA manufacturing protects your products from threats like counterfeit parts, tampering, and data breaches.

Following strict standards and using advanced inspections ensure high-quality, reliable circuit boards for critical industries.

Traceability and detailed documentation help you track components and quickly fix any defects or vulnerabilities.

Choosing trusted manufacturers like LTPCBA guarantees compliance with global certifications and reduces risks.

Investing in secure PCBA saves money by preventing costly recalls, protecting your brand, and meeting future regulations.

PCBA Manufacturing Secure

What Is PCBA?

You interact with printed circuit boards every day, whether you realize it or not. PCBA stands for Printed Circuit Board Assembly. This process transforms blank pcbs into functional electronic devices by adding and soldering components. You can find pcbs in everything from smartphones to medical equipment.

The pcba process involves several key steps that ensure each board meets strict requirements for quality and performance:

Design Phase: You start with schematic development, layout, and generating design files for your printed circuit boards.

PCB Fabrication: Manufacturers transfer the circuit image, etch copper, laminate layers, drill holes, and apply solder masks and labels.

PCB Assembly: Machines place components on the board, followed by soldering and manual or automated inspection.

Testing and Quality Control: Each pcba undergoes inspection to catch any misplaced parts or poor connections.

Automation: Advanced robotics and automated systems improve speed, accuracy, and consistency.

Both Surface-Mount Technology (SMT) and Through-Hole Technology (THT) play important roles. SMT allows for smaller, faster assemblies, while THT provides extra strength for demanding applications. You benefit from both methods, depending on your product’s needs.

Security in PCBA Manufacturing

You need more than just a working board—you need pcba manufacturing secure practices that protect your products and your customers. Security in this context means safeguarding your printed circuit boards from threats like tampering, counterfeit parts, and data breaches. Secure manufacturing also ensures that your pcbs meet all regulatory and industry requirements.

To achieve pcba manufacturing secure results, you must follow strict standards and best practices:

IPC standards, such as IPC-A-610, set the bar for workmanship and reliability.

ISO 9001 and UL certifications guarantee quality management and safety.

RoHS compliance limits hazardous materials, protecting health and the environment.

ITAR compliance is essential for defense and aerospace, ensuring that sensitive technology stays protected.

Industry-specific standards, like MIL-STD, add extra layers of durability and performance.

Tip: Always choose a manufacturer that demonstrates itar compliance and meets all relevant standards. This protects your intellectual property and ensures your pcbs are safe for critical applications.

LTPCBA stands out as a leader in pcba manufacturing secure solutions. You benefit from their advanced technology, which includes automated pick-and-place machines, AOI systems, and X-ray inspections. These tools catch errors early and prevent hidden defects. LTPCBA’s AI-driven automation reduces false defect alerts, while real-time monitoring and digital twins keep production under control. Their collaborative sourcing with verified suppliers blocks counterfeit components before they reach your printed circuit boards.

You can trust LTPCBA to deliver pcba manufacturing secure assemblies that meet or exceed industry standards. Their commitment to itar compliance, ISO, and UL certifications means your pcbs are ready for even the most demanding environments. With a first-pass yield over 98.5% and defect rates as low as 0.05%, you get reliable, high-quality results every time.

Importance of Security in PCBA

Risks and Threats

You face many risks when you build or source printed circuit board assemblies. Security threats can appear at every stage of the process. If you ignore these risks, you may expose your products to hidden backdoors, counterfeit components, or tampering. These vulnerabilities can damage your reputation and put your customers at risk.

Here is a table showing common vulnerabilities at each stage of PCBA manufacturing:

Manufacturing Stage | Common Security Risks |

|---|---|

Design Stage | Hidden backdoors, toolchain exploits, insufficient design reviews leading to overlooked vulnerabilities |

Manufacturing Stage | Tampering by untrusted foundries, counterfeit components, assembly tampering |

Post-Production Stage | Firmware exploits, physical access tampering, lack of updates increasing vulnerability |

You see that vulnerabilities can appear before, during, and after production. The complexity of modern PCBs and the global supply chain make it easier for attackers to find weak points. Cyberattacks on PCBA manufacturing supply chains are frequent and growing. In 2025, the manufacturing sector made up 4% of all dark web cybercrime posts. Attackers often target smaller vendors to reach larger manufacturers. The United States alone accounted for nearly 18% of manufacturing-related cybercrime activity. These patterns show that you must stay alert to security threats at all times.

Counterfeit components also pose a major risk. If you use fake parts, your products may fail or become unsafe. Tampering during assembly or after production can introduce new vulnerabilities. These issues can lead to costly recalls, loss of trust, and even legal trouble.

Benefits of Secure PCBA

You gain many advantages when you focus on security in PCBA manufacturing. Secure processes protect your data, assets, and product integrity. You reduce vulnerabilities by using strict controls and advanced inspection methods.

Here are some ways secure PCBA manufacturing helps you prevent counterfeit components and other vulnerabilities:

You set up a dedicated quality inspection department with trained staff and professional equipment. This step blocks fake parts before they enter your products.

You work with independent third-party labs for unbiased testing. These labs catch vulnerabilities that in-house checks might miss.

You audit and monitor your suppliers regularly. This action ensures consistent quality and reduces the risk of vulnerabilities from unreliable sources.

You choose original manufacturers or authorized distributors. This choice gives you traceability and lowers the chance of vulnerabilities from unknown suppliers.

You use visual and electrical tests, including X-ray inspection, to spot defects and vulnerabilities.

You train your team to recognize counterfeit parts and vulnerabilities during assembly.

Note: Investing in secure PCBA manufacturing costs much less than dealing with the fallout from a security breach. Intellectual property theft in electronics manufacturing causes losses between $225 billion and $600 billion each year. New regulations, like the 2027 Cyber Resilience Act, will bring strict requirements and heavy fines for non-compliance. If you document your processes and use connected technology, you avoid hidden costs and reduce vulnerabilities that can disrupt your business.

Government regulations also play a big role in enforcing security. For example:

ITAR controls the export and import of defense-related PCBs. You must protect sensitive data and follow strict rules to avoid penalties.

NIST 800-171 requires you to use cybersecurity controls if you handle government contracts. You must manage access, train staff, and monitor systems to reduce vulnerabilities.

ISO 9001:2015 and other certifications require you to maintain high standards for quality and security.

LTPCBA shows a strong commitment to security and quality. The company holds certifications such as ISO 9001:2015, IATF 16949, UL, RoHS, and IPC standards. Here is a summary of LTPCBA’s certifications and quality measures:

Certification Type | Description |

|---|---|

ISO 9001:2015 | Ensures consistent quality in manufacturing processes. |

IATF 16949 | Meets automotive industry quality requirements. |

UL | Complies with electrical and fire safety standards. |

RoHS | Restricts hazardous substances in electronics. |

IPC Standards | Sets high standards for assembly and workmanship. |

LTPCBA uses advanced inspection technologies like 3D AOI, X-ray inspection, and 100% visual checks. You benefit from electrical and functional testing that verifies circuit performance and reduces vulnerabilities. Full traceability and documentation at every step help you track and resolve issues quickly. Automation and AI-driven systems lead to a 99.5% first-pass yield and a 99% on-time delivery rate. These practices ensure you receive high-quality, secure PCBA assemblies that meet the needs of critical industries.

When you choose secure PCBA manufacturing, you protect your business, your customers, and your reputation. You reduce vulnerabilities, improve quality, and meet the demands of modern regulations. LTPCBA stands ready to help you achieve these goals with proven expertise and a strong focus on security.

Best Practices for Secure PCBA

Quality Assurance

You need strong quality assurance to build reliable pcbs. Start with clear communication between you and your manufacturer. Early design validation helps you catch errors before production begins. Apply secure design practices such as Design for Manufacturability (DFM) and Design Rule Checks (DRC) to reduce complexity and improve assembly. Use standardized components to simplify procurement and speed up production. Partner with manufacturers who have proven quality control programs and trusted supply chains.

Quality checkpoints at every stage matter. You should use multiple inspection methods, including Automated Optical Inspection (AOI), X-ray, and functional testing. These steps help you find defects early and maintain high-quality production. Invest in employee training to boost technical expertise and quality awareness. Maintain certifications like ISO 9001 and IATF 16949 to meet global standards.

Early design validation and secure design practices

Standardized components for efficient assembly

Multiple inspection methods: AOI, X-ray, functional testing

Employee training and continuous improvement

Certifications for global quality standards

Traceability

Traceability gives you control over your pcbs and helps you prevent security breaches. You should keep detailed records of components, suppliers, and manufacturing processes. Use unique identifiers such as serial numbers, barcodes, or RFID tags for each pcba. Automated data capture systems like MES or ERP software help you track items in real time. Link each pcb’s identifier to its process history, including inspections and testing results.

Traceability enables you to pinpoint defective parts and prevent cascading failures. You can quickly locate and replace faulty components, reducing downtime. Integration with digital Quality Management Systems automates non-conformance logging and links corrective actions to defect records. AI-driven analytics detect quality trends and anomalies early, allowing predictive monitoring and root cause analysis.

Maintain detailed documentation for every pcb

Use automated systems for real-time tracking

Apply unique identifiers for traceability

Integrate traceability data with digital QMS

Use AI analytics for predictive quality monitoring

Choosing LTPCBA

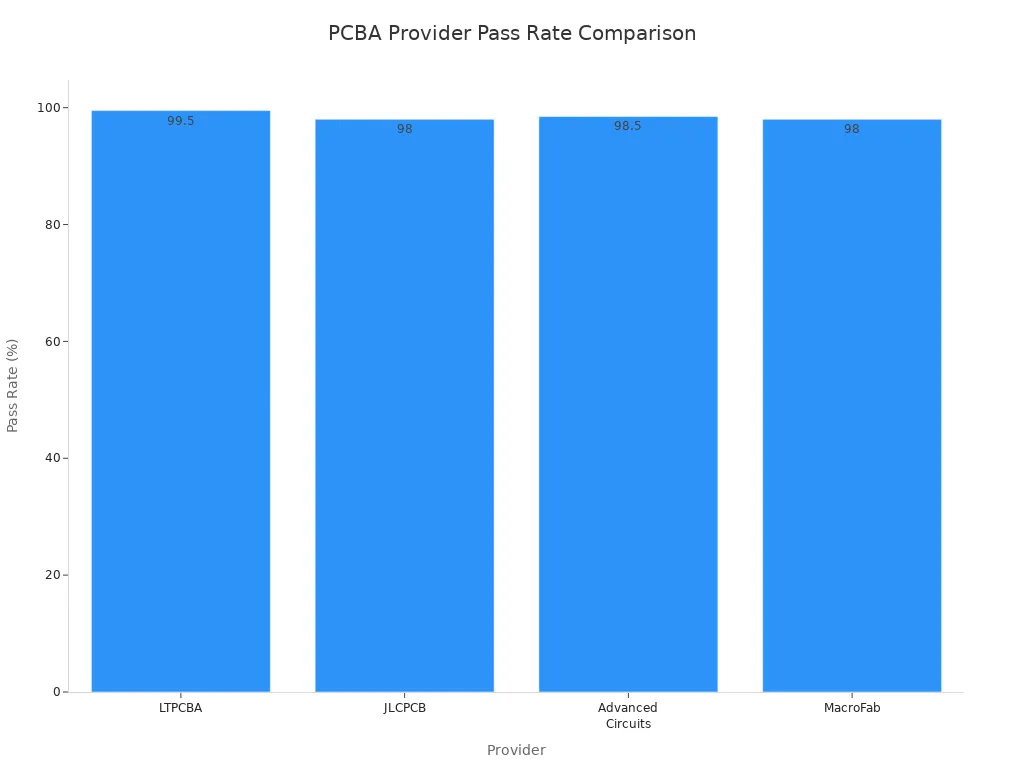

You want a secure partner for your pcba needs. LTPCBA stands out with a 99.5% pass rate, which is higher than other leading manufacturers. The company uses advanced inspection methods such as AOI, X-ray, and functional testing to ensure quality. LTPCBA holds certifications including ISO 9001, IATF 16949, UL, RoHS, and IPC standards. These achievements show a commitment to secure design practices and trusted supply chains.

Provider | Quality Certifications | Inspection Methods | Pass Rate | Notable Strengths |

|---|---|---|---|---|

LTPCBA | ISO 9001, IATF, UL, RoHS, IPC-A-610, IPC-6012 | AOI, X-ray, Functional Testing | 99.5% | Fast turn pcb, customer support |

JLCPCB | ISO, UL | AOI, X-ray | 98% | Low pricing, fast turnaround |

Advanced Circuits | ISO, UL | AOI, In-house QC | 98.5% | North American fast turn pcb manufacturers, reliability |

MacroFab | ISO | AOI, Digital Monitoring | 98% | Flexible production, digital platform |

LTPCBA’s secure design practices, high-quality production, and trusted supply chains make it a top choice for your pcba projects. You benefit from fast response times, strong customer support, and reliable pcbs that meet strict standards.

Common PCBA Security Threats

Printed circuit board assemblies face many threats that can affect their reliability and safety. You need to understand these risks to protect your pcbs from vulnerabilities at every stage of manufacturing.

Counterfeit Components

Counterfeit parts are one of the biggest dangers in pcbs. You might find low-spec components that look like high-spec ones, defective parts sold as qualified, or used components repackaged as new. These parts often enter the supply chain through unauthorized sellers. Some common types include:

Semiconductors and integrated circuits that have been cloned or recycled.

Passive components and connectors from unqualified sources.

Components with altered markings or hidden defects.

These vulnerabilities can cause your pcbs to fail or behave unpredictably. Secure processes help you avoid these risks. You should use rigorous inspections, such as visual checks, X-ray imaging, and electrical testing, to spot irregularities. Sourcing from trusted suppliers and training your team to recognize counterfeit signs also reduces vulnerabilities in your pcbs.

Tampering

Tampering happens when someone tries to change or probe your pcbs during or after manufacturing. Attackers may use methods like epoxy sealing, washing off IC markings, or hiding connections with blind vias. They might even reverse engineer your design or install malicious software. These vulnerabilities can lead to loss of control over your pcbs or leaks of sensitive information.

You can fight tampering by using secure design techniques. Place critical components inside the board, use tamper detection circuits, and encrypt firmware. Regular inspections and matching your defenses to specific threats help you catch vulnerabilities early. Combining physical and digital protections increases the cost and difficulty for attackers.

Data Breaches

Data breaches are a growing threat as more pcbs rely on digital systems. Attackers may target your files, intellectual property, or production data. Vulnerabilities can appear if you lack strong access controls, encryption, or secure communication channels. Phishing, ransomware, and supply chain attacks can all expose your pcbs to risks.

To prevent data breaches, you need a strong information security plan. Limit access to sensitive data, use encryption for storage and transfer, and train employees about data protection. Secure your supply chain with trusted partners and regular audits. These steps help you close vulnerabilities and keep your pcbs safe from digital threats.

Secure PCBA manufacturing protects your products, brand, and customers. When you choose a trusted provider like LTPCBA, you gain:

Fewer defects and recalls, which extends product life and lowers costs.

Safer, eco-friendly materials that support recycling and reduce health risks.

Strong supplier relationships and compliance with global standards.

To keep your products safe, you should:

Use strict access controls and regular audits.

Train your team on security best practices.

Work closely with reliable partners who value quality and safety.

Your commitment to security builds trust and strengthens your brand for the future.

FAQ

What does secure PCBA manufacturing mean for you?

Secure PCBA manufacturing means you get assemblies built with strict controls. You avoid risks like counterfeit parts and tampering. Your products meet industry standards and stay reliable in critical applications.

How does LTPCBA ensure the security of your PCBA orders?

LTPCBA uses advanced inspection methods, certified supply chains, and automated systems. You benefit from ISO, IATF, and UL certifications. These steps help you receive safe, high-quality assemblies.

Why should you care about counterfeit components in PCBA?

Counterfeit components can cause failures and safety issues. You protect your products by choosing manufacturers who use trusted suppliers and thorough inspections. This reduces risks and improves reliability.

What are the main benefits of secure PCBA manufacturing?

Benefit | Description |

|---|---|

Reliability | Your products work as expected. |

Safety | You avoid dangerous failures. |

Compliance | You meet global standards. |

Traceability | You track every component easily. |

See Also

Understanding PCBA And Its Key Electronic Components

Explaining The Meaning Of PCBA In Electronics

PCBA Services Explained From Production To Final Testing

Comprehensive PCBA Manufacturing Guide For Beginners And Experts

Boosting Business Efficiency With PCBA Contract Manufacturing