How PCBA Manufacturing Capabilities Influence Product Quality

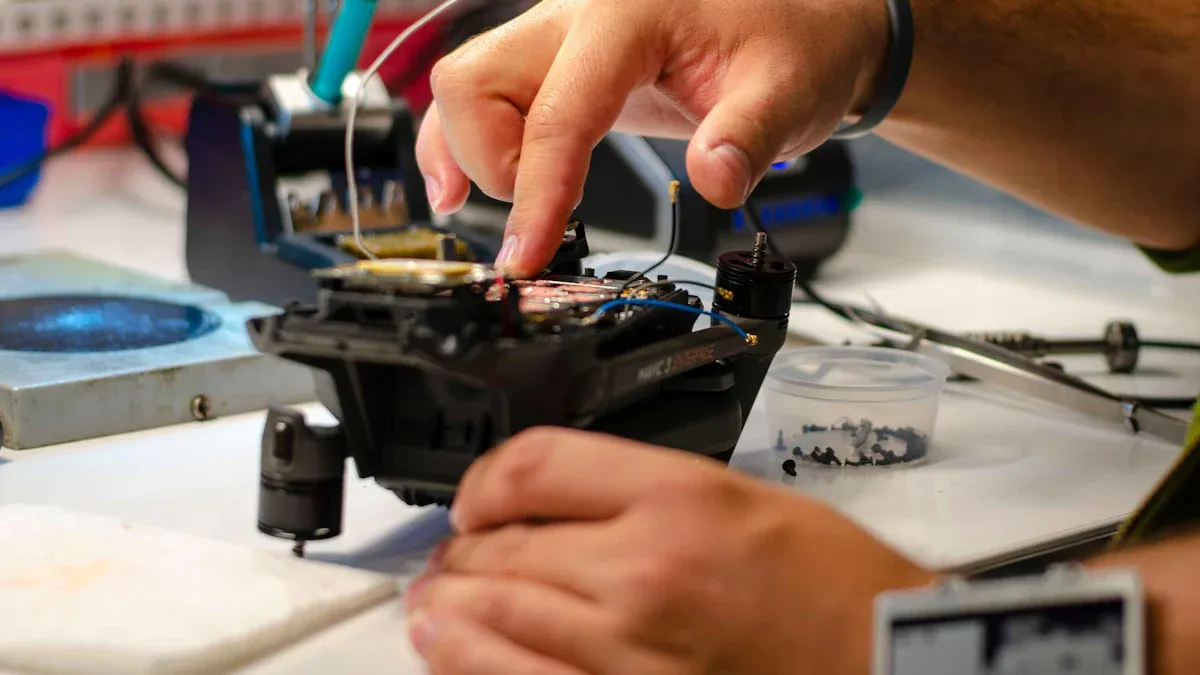

You depend on pcba manufacturing capabilities to achieve high product quality in your electronic devices. When you select a high-quality pcba manufacturer, you gain access to advanced pcb assembly equipment, strict quality controls, and robust DFM practices. LTPCBA, based in Shenzhen, showcases capabilities that include automated SMT lines, cleanroom environments, and comprehensive pcb testing. These strengths result in fewer defects, improved reliability, and longer product life.

Advanced pcb manufacturing processes and DFM standards reduce defects.

Quality certifications and pcb inspection systems ensure stable performance.

Skilled teams optimize DFM for every pcb batch.

LTPCBA’s commitment to DFM and innovation elevates pcb reliability.

Key Takeaways

Choosing a PCBA manufacturer with advanced process control and automation reduces defects and ensures consistent, reliable products.

Design for Manufacturability (DFM) reviews optimize your PCB design, lowering costs and improving assembly quality.

Strong quality assurance methods like AOI, X-ray inspection, and functional testing catch defects early and boost product reliability.

Certifications such as ISO 9001 and IPC-A-610 prove a manufacturer’s commitment to high standards and safety.

Responsive customer support and effective material management help keep your projects on track and maintain product quality.

PCBA Manufacturing Capabilities and Product Quality

Process Control and Reliability

You rely on pcba manufacturing capabilities to achieve improved product quality and long-term reliability in your electronic products. Process control stands as one of the core competencies of pcba manufacturing. When you choose a high-quality pcba manufacturer, you benefit from strict process control systems that minimize defects and ensure consistent results.

Manufacturers like LTPCBA use advanced inspection tools and standardized operating procedures throughout the pcb manufacturing process. You see real-time monitoring of critical parameters such as soldering temperature and humidity. Automated Optical Inspection (AOI) and X-ray inspection catch defects early, allowing immediate corrective actions. Layered inspection methods combine visual checks, AOI, and X-ray at different stages, so you avoid hidden faults and ensure every pcb meets strict standards.

Tip: Look for manufacturers who implement design for manufacturability (dfm) principles. DFM helps you reduce manufacturing challenges and defect rates by optimizing your pcb design for assembly.

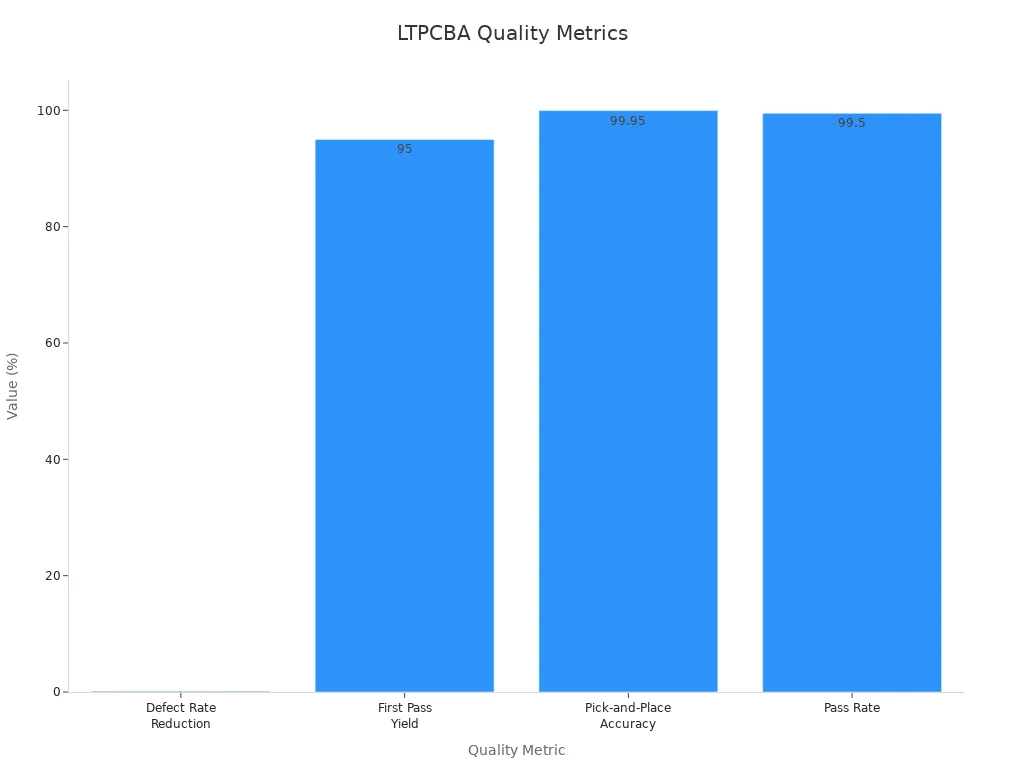

You also benefit from continuous improvement frameworks. Data-driven feedback loops analyze defect patterns and refine processes. Employee training ensures everyone follows standardized procedures, reducing human error. LTPCBA’s commitment to dfm and process control results in a 99.5% first-pass yield, which surpasses industry averages and guarantees reliability.

Key Process Control Practices:

Real-time monitoring and control using Statistical Process Control (SPC).

Root cause analysis to address defect sources.

Automation for precise component placement and immediate defect detection.

Comprehensive testing protocols, including In-Circuit Testing (ICT) and functional testing.

Continuous improvement through data analysis and employee training.

Equipment and Automation

You gain a significant advantage when your manufacturer invests in intelligent and automated production equipment. Advanced capabilities in pcb assembly, such as pick-and-place machines and soldering robots, deliver high precision and repeatability. Automation reduces human error and increases throughput, so you receive consistent quality in every pcb batch.

LTPCBA stands out as a high-quality pcba manufacturer with cutting-edge technology. The company uses laser direct imaging (LDI) for ±25µm pattern accuracy and laser via drilling for microvias. These capabilities support fine line/space requirements down to 30µm, which is essential for modern applications like 5G and IoT. LTPCBA’s automated inspection systems, including 100% AOI and X-ray, ensure every pcb assembly meets strict quality standards.

Here’s a table summarizing the most critical pcba manufacturing capabilities that directly influence product quality and reliability:

PCBA Manufacturing Capability | Description | Impact on Product Quality and Reliability |

|---|---|---|

Automated Optical Inspection (AOI) | Uses high-resolution cameras and software to detect defects such as solder bridges, missing components, and misalignments. | Enables rapid defect detection and immediate corrective actions, reducing errors and improving assembly quality. |

X-ray Inspection | Non-destructive testing that reveals hidden solder joint defects and internal PCB issues using 3D imaging. | Detects hidden faults like voids and cracks, ensuring integrity of complex components and multilayer boards. |

Functional Testing (ICT and Final Testing) | Electrical probes and performance tests verify component functionality and overall board operation. | Confirms electrical performance and functionality, preventing faulty boards from proceeding to final assembly. |

Automation and Robotics | Automated machines precisely place components and perform soldering with minimal human intervention. | Enhances precision, throughput, and consistency, reducing human error and improving repeatability. |

Supply Chain Management | Includes supplier vetting, inventory control, forecasting, and quality management systems. | Ensures timely availability of quality components, preventing delays and defects caused by substandard parts. |

Material Innovations | Use of advanced substrates and conductive inks to improve board performance. | Improves electrical and mechanical reliability of the PCBA under operational stresses. |

You should always check for certifications when evaluating a manufacturer. LTPCBA holds ISO 9001, IATF 16949, UL 94, and ISO 13485 certifications, which prove its commitment to global standards and quality assurance. These certifications guarantee that your pcb manufacturing process meets the highest requirements for safety, reliability, and performance.

Note: DFM input from your manufacturer optimizes production efficiency and cost without sacrificing quality. LTPCBA provides turnkey pcb assembly services, rapid quoting, and real-time project tracking, so you stay informed and confident throughout the process.

When you select LTPCBA, you benefit from advanced pcb manufacturing process control, intelligent and automated production equipment, and a skilled team dedicated to dfm and quality. These capabilities ensure your pcb assembly delivers consistent, high-quality results for every project.

Technical Level Determines PCBA Quality

The technical level determines pcba quality at every stage of the pcb manufacturing process. Your choice of manufacturer directly impacts the reliability, performance, and consistency of your electronic products. When you work with a partner like LTPCBA, you benefit from advanced smt placement, strict soldering quality management, and a skilled team that understands both design for manufacturing and design for assembly principles. These strengths ensure your pcb assembly meets the highest standards.

SMT, DIP, and Assembly Expertise

You need a manufacturer with deep expertise in both SMT and DIP assembly. Advanced smt placement uses automated pick-and-place machines and precise soldering to mount millions of components daily. This process delivers high accuracy and repeatability, which is essential for modern electronics. DIP assembly complements SMT by providing strong mechanical connections through through-hole technology. This combination gives your pcb assembly both miniaturization and ruggedness.

Automated SMT lines at LTPCBA handle high-volume orders and prototypes with equal efficiency.

Parallel SMT lines boost production speed and flexibility.

Rigorous quality checks, including AOI and X-ray, verify solder joint integrity and component placement.

DIP assembly ensures your boards withstand vibration and thermal stress, making them ideal for demanding environments.

You benefit from a process where dfm is central. LTPCBA’s engineers review your pcb design for manufacturability and assembly, optimizing layouts and component choices. This approach reduces defects, improves first-pass yield, and ensures your pcb assembly performs reliably in the field.

Tip: Always choose a manufacturer who integrates dfm reviews into every stage of the pcb assembly process. This step helps you avoid costly redesigns and delays.

Environmental Controls

Environmental controls play a critical role in pcb assembly quality. You must maintain strict temperature and humidity levels to prevent defects and ensure consistent results. LTPCBA keeps production areas between 20-25°C and relative humidity from 30% to 60%. These conditions protect sensitive components from electrostatic discharge and moisture damage.

Uniform temperature and humidity across the facility reduce variability in soldering and assembly.

Real-time monitoring allows immediate adjustments, keeping your pcb assembly process stable.

Proper environmental controls lower defect rates, improve reliability, and reduce warranty costs.

You see the impact of these controls in the final product. Fewer defects mean higher customer satisfaction and less time spent on repairs. LTPCBA’s commitment to environmental management supports your need for consistent, high-quality pcb assembly.

Skilled Workforce

A skilled workforce is the backbone of any successful pcb assembly operation. You rely on experienced engineers and technicians to manage complex assembly tasks, operate advanced equipment, and uphold strict quality standards. LTPCBA invests in continuous training and certification for its team, ensuring everyone understands the latest industry practices.

Technicians follow standardized procedures for every pcb assembly batch.

Engineers use dfm principles to optimize your pcb design and assembly process.

Quality inspectors use AOI, X-ray, and functional testing to catch defects early.

LTPCBA’s team holds certifications in ISO 9001, ISO 13485, and IPC Class 3 standards. These achievements reflect a strong commitment to quality assurance and regulatory compliance. You gain peace of mind knowing your pcb assembly meets international requirements for safety, reliability, and performance.

Note: LTPCBA’s quality management system covers every aspect of the pcb manufacturing process, from material control to defect management and continuous improvement. This system ensures your products remain stable and consistent across every order.

When you choose a manufacturer with advanced technical capabilities, strict environmental controls, and a skilled workforce, you secure the foundation for reliable, high-quality pcb assembly. LTPCBA’s focus on dfm, quality certifications, and process excellence positions your products for long-term success.

Quality Assurance and Testing

Inspection Methods

You need robust inspection methods to ensure every pcb meets strict quality standards. Manufacturers use a range of tests to catch defects early and guarantee reliable performance. Common pcb inspection and testing methods include:

Visual inspection to spot soldering defects, misaligned or missing components, and surface damage.

Automated Optical Inspection (AOI) for rapid, high-precision detection of surface-level defects like solder bridges and polarity errors.

X-ray inspection to reveal hidden issues in complex assemblies, such as solder voids or misaligned balls in BGA packages.

In-circuit testing (ICT) and bed of nails tests to verify electrical connections, component values, and circuit continuity.

Functional testing to confirm the pcb operates as designed under real-world conditions.

Flying probe testing for flexible, fixtureless electrical checks on low to medium volume pcb batches.

Electrical testing, including continuity and hi-pot tests, to ensure compliance with design specifications.

Accelerated life and burn-in testing to simulate long-term use and identify early failures.

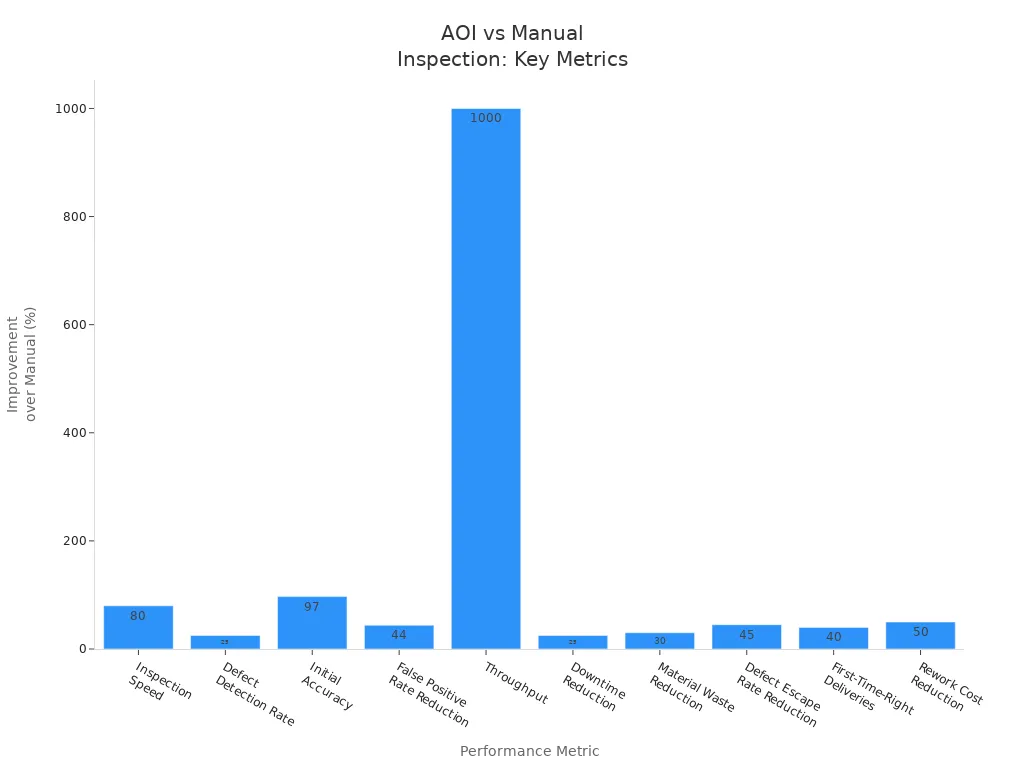

AOI and X-ray inspection systems outperform manual inspection in speed and accuracy. AOI detects 25% more defects and operates over 80 times faster, while X-ray uncovers hidden faults that surface checks miss. Combining these methods gives you comprehensive defect coverage and reduces costly rework.

Traceability and Documentation

You benefit from traceability systems that track every pcb through production. Unique identification links each pcb to its materials, operators, and test results. This approach lets you quickly pinpoint and resolve quality issues, reducing the risk of recalls and warranty claims. Traceability also supports regulatory compliance and builds customer trust.

Comprehensive documentation, including BoMs, design files, and test records, supports every stage of pcb manufacturing. Organized documentation ensures the right people access the right information, protects intellectual property, and streamlines the flow of materials and data. Automated data capture and online platforms enable real-time quality monitoring and faster response to any issues.

LTPCBA’s Quality Standards

LTPCBA sets the benchmark for pcb quality with multi-dimensional testing systems and strict process controls. The company follows IPC-A-610 (Class 3), ISO 9001, UL, and IATF standards. You see advanced inspection technologies like in-line AOI and X-ray at every stage. LTPCBA achieves a first pass yield of 99.5% and keeps defect rates below 100 DPMO.

Quality Aspect | LTPCBA Standards and Practices |

|---|---|

Quality Standards | IPC-A-610 (Class 3), ISO 9001, UL, IATF |

Inspection Technologies | In-line AOI, X-ray, functional and burn-in testing |

Process Controls | Digital tracking, AI-powered inspections, real-time quality monitoring |

Quality Metrics |

You gain confidence knowing LTPCBA uses advanced pcb inspection, documentation, and traceability to deliver consistent, high-quality results for every order.

Choosing a High-Quality PCBA Manufacturer

Certifications and Track Record

You should always start your evaluation by checking the certifications of a pcb assembly partner. Certifications like ISO 9001, UL, and IPC-A-610 show that a manufacturer follows strict quality management systems. These international quality system certifications prove that the company meets global standards for pcb assembly and safety. LTPCBA holds ISO 9001, IATF 16949, UL, and IPC-A-610D Class 3 certifications, which means you can trust their process and results.

Check for ISO 9001 to confirm a quality management system.

Look for UL and RoHS compliance for safety and environmental responsibility.

Review the manufacturer’s history, including customer reviews and years in business.

Ask for data on first pass yield and on-time delivery rates.

Confirm that certifications are current and not just for marketing.

Purpose/Importance | Industry/Application | |

|---|---|---|

UL Certification | Ensures safety and reliability | General electronics |

IPC Standards | Sets quality benchmarks | Electronics manufacturing |

ISO 9001 | Quality management system | All industries |

IATF 16949 | Automotive quality | Automotive |

RoHS Compliance | Restricts hazardous substances | Environmental safety |

You can avoid common pitfalls by conducting supplier audits, reviewing documentation, and checking for modern equipment. Reliable pcb assembly partners like LTPCBA maintain transparency and offer real-time tracking for your orders.

Customer Support and Responsiveness

Strong customer support and fast response times make a big difference in your pcb assembly projects. LTPCBA provides 24-hour technical support and delivers quotes within 2-3 working days. You get answers to your questions quickly, which helps you plan and manage your projects with less stress. Their customer satisfaction scores often exceed 80%, showing a commitment to service.

Efficient communication keeps you updated on project progress.

Technical support covers everything from design help to after-sales assistance.

Responsive teams handle urgent changes, pilot runs, and component updates.

Transparent pricing and clear answers build trust and confidence.

Metric | LTPCBA Performance | Industry Benchmark / Notes |

|---|---|---|

Customer Satisfaction Score | >80% | Excellent service |

Quote Response Time | 2-3 working days | Fast and reliable |

Technical Support | 24-hour availability | Immediate help |

Product Delivery Pass Rate | 99.5% | High quality and reliability |

Tip: Choose a pcb assembly partner who offers real-time support and clear communication. This ensures your dfm feedback and design for assembly needs are met quickly.

Material Management

Consistent pcb quality depends on strong material management. You want a manufacturer who uses just-in-time inventory, works with trusted suppliers, and keeps accurate traceability records. LTPCBA partners with reputable suppliers and uses electronic data tools to track every component. This approach supports dfm and ensures your pcb assembly meets high standards.

Adopt just-in-time inventory to reduce costs and keep materials fresh.

Build strong supplier relationships for reliable, high-quality components.

Use barcode and RFID tracking for full traceability.

Conduct regular supplier audits and performance checks.

Monitor the supply chain to avoid disruptions and maintain quality.

You benefit from LTPCBA’s focus on dfm, which includes reviewing your pcb design and materials for manufacturability and assembly. This reduces defects and improves the reliability of every pcb batch.

To maintain high product quality, you should:

Implement rigorous incoming inspection and testing for every pcb batch.

Conduct regular supplier audits and maintain clear communication.

Use technology like RFID to track pcb components and ensure authenticity.

Train your team to spot counterfeit pcb parts and enforce verification.

Foster long-term partnerships with your pcb supplier.

You can measure long-term reliability by:

Choosing a pcb manufacturer with a proven track record.

Verifying certifications such as ISO 9001 and IPC-A-610 for pcb quality.

Testing prototype pcb batches before large-scale production.

Reviewing customer feedback and pcb supplier reputation.

Selecting a high-quality pcb manufacturer like LTPCBA leads to fewer recalls and higher reliability.

Technical capabilities, robust quality assurance, and responsive support from your pcb partner work together to safeguard your product quality and business reputation.

FAQ

What certifications should you look for in a PCBA manufacturer?

You should check for ISO 9001, IATF 16949, UL, and IPC-A-610 certifications. These prove that the manufacturer follows strict quality and safety standards. LTPCBA holds all these certifications.

How does LTPCBA ensure consistent product quality?

LTPCBA uses advanced inspection tools like AOI and X-ray. The team follows strict process controls and maintains cleanroom environments. You benefit from a 99.5% first-pass yield.

Why is Design for Manufacturability (DFM) important?

DFM helps you avoid costly errors and delays. LTPCBA’s engineers review your design before production. This step improves assembly efficiency and reduces defects.

How quickly can you get a quote from LTPCBA?

You receive a detailed quote within 2-3 working days. LTPCBA’s team responds quickly to your requests and provides 24-hour technical support.

See Also

Ensuring Quality Output Through Advanced Turnkey PCBA Facilities

Boosting Business Efficiency With PCBA Contract Manufacturing Services

Complete PCBA Services From Production To Final Testing Process

Understanding PCBA And Its Essential Component Parts Explained

Improving PCBA Quality Control Using Advanced X-Ray Inspection