How Design Choices Impact PCBA Manufacturing and Assembly Costs

Informed design decisions in pcba manufacturing and assembly can lead to significant cost savings and improved outcomes. Every choice, from component placement to process selection, directly impacts the pcba manufacturing and assembly budget. Early use of tools like Design for Manufacturing and Assembly Report Cards helps engineers understand how design factors may alter costs by up to 30%. Companies that enhance their pcba manufacturing and assembly scores often experience fewer costly changes and improved yield. By prioritizing these factors early in the process, teams can effectively control pcba manufacturing and assembly costs and increase overall efficiency.

Key Takeaways

Choosing the right materials and simplifying board design can lower PCBA manufacturing costs by reducing waste and processing steps.

Selecting standard components and collaborating early with manufacturers like LTPCBA helps control assembly costs and improves quality.

Higher production volumes reduce unit costs through bulk purchasing and efficient processes, benefiting both prototypes and larger runs.

Following manufacturer guidelines and avoiding last-minute changes prevent costly errors and delays in the assembly process.

Using design strategies like DFM and DFA, along with clear documentation, leads to smoother production and better cost control.

PCBA Manufacturing and Assembly Cost Drivers

Material Costs

Material costs represent a major factor in pcba manufacturing and assembly. The selection of substrates, copper thickness, and surface finishes directly influences the overall budget. Industry experts identify panel fabrication costs as a primary driver, including expenses for materials, labor, plating, drilling, and lead time. LTPCBA leverages partnerships with multiple vendors to secure competitive pricing and stocks standard components to minimize material costs. Their advanced manufacturing process ensures efficient use of raw materials, reducing waste and optimizing panel utilization. By choosing appropriate materials early, designers can control pcb manufacturing costs and avoid unnecessary expenses.

Tip: Early collaboration with LTPCBA helps teams select cost-effective materials that meet performance and reliability requirements.

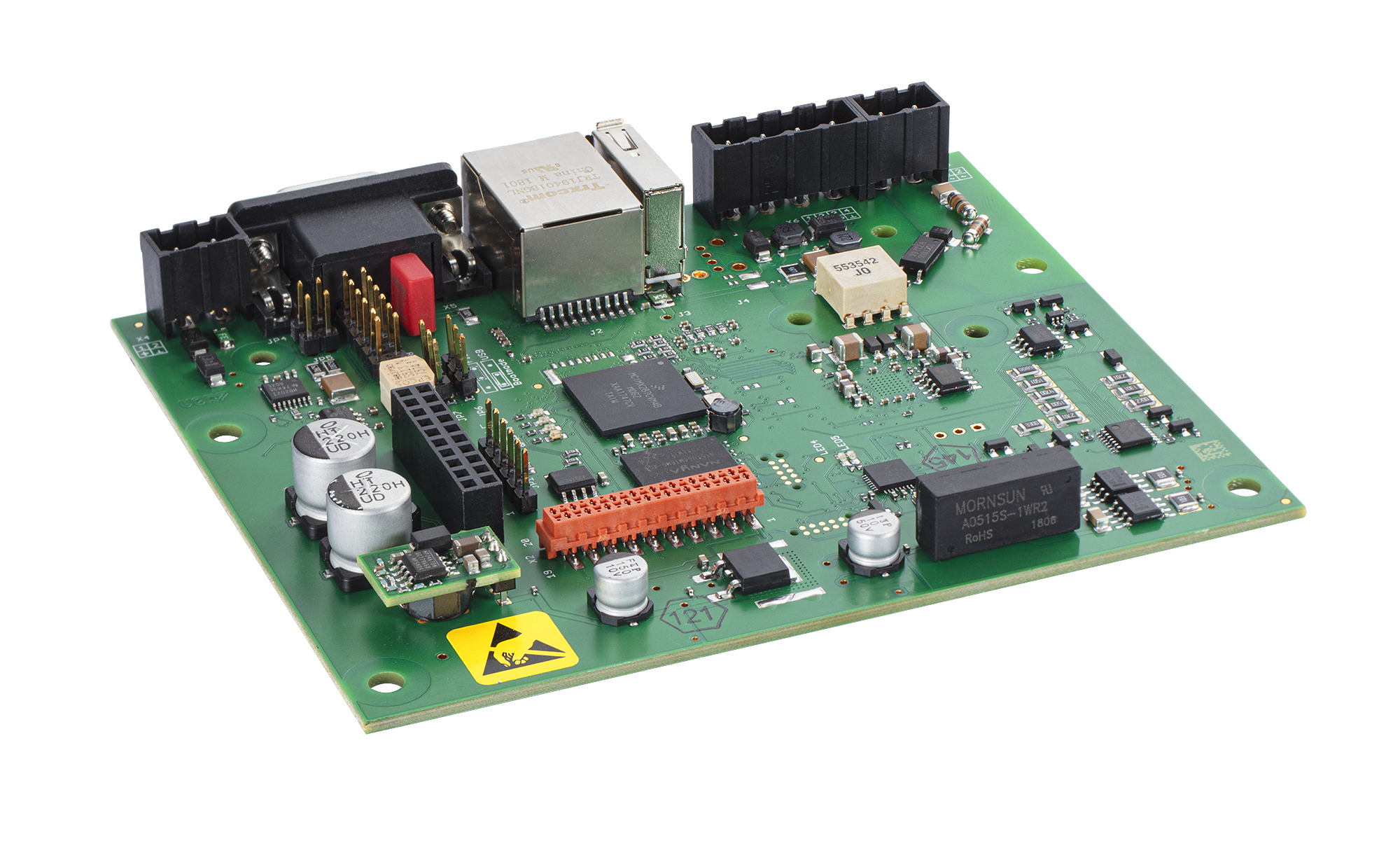

Board Complexity

Board complexity affects both fabrication and assembly costs. Factors such as layer count, board size, drill hole sizes, and routing density increase the difficulty of pcb manufacturing. Complex boards often require additional processing steps, specialized equipment, and longer lead times. LTPCBA’s expertise in handling high-layer-count and rigid flex pcb assemblies allows them to manage intricate designs without sacrificing quality. Automated optical inspection and advanced testing procedures ensure that even the most complex boards meet international standards. Simplifying board layouts and optimizing panel design can significantly reduce manufacturing costs and improve yield.

Complexity Factor | Impact on Cost | LTPCBA Solution |

|---|---|---|

Layer Count | Higher | Advanced fabrication capabilities |

Drill Sizes | Increased | Precision drilling equipment |

Routing Density | Elevated | Automated inspection systems |

Component Selection

Component selection plays a critical role in determining total assembly and component procurement costs. Prices vary widely based on specifications and availability. For example, a standard resistor costs only a few cents, while a high-precision resistor may cost ten times more. Bulk purchasing lowers per-unit cost but introduces risks if project requirements change. Components requiring manual handling or special machine setups increase labor and setup costs. LTPCBA prioritizes sourcing components compatible with automated assembly, such as standard footprints and tape-and-reel packaging, to control assembly costs. Their procurement team focuses on reliability and manufacturability, reducing rework and ensuring consistent quality.

Standard components lower assembly costs.

Specialized packaging types like BGA, LGA, and QFN increase inspection and labor costs.

Poor selection can lead to higher rework and reliability issues.

LTPCBA’s sourcing strategies minimize component procurement costs and ensure timely delivery.

Production Volume

Production volume strongly influences unit cost in pcb manufacturing and assembly. Higher volumes enable bulk purchasing of raw materials, which lowers material costs and component procurement costs. LTPCBA’s scalable manufacturing process supports both prototypes and mid-volume production runs, allowing customers to benefit from economies of scale. Simultaneous inspection and testing during production further reduce overall costs. For small batches, setup and tooling expenses can raise per-board costs, but LTPCBA’s efficient processes help mitigate these effects. By planning for appropriate production volumes, teams can achieve greater cost efficiency and maintain high quality.

Note: Increasing production volume with LTPCBA unlocks cost advantages through bulk purchasing, streamlined assembly, and reduced inspection overhead.

Cost Analysis in PCBA Assembly

PCB Assembly Cost Breakdown

A clear understanding of pcb assembly cost composition helps teams manage budgets and avoid surprises. The main cost components include raw materials, process costs, labor, tooling, and logistics. LTPCBA uses advanced systems to track each cost element, ensuring transparency and efficiency. Industry data shows that pcb manufacturing and assembly costs depend on board size, complexity, and material selection. Accurate cost analysis allows engineers to optimize designs and select the most cost-effective solutions.

Cost Component | Description |

|---|---|

Materials | Substrate, copper, solder, and surface finishes |

Labor | Assembly, inspection, and testing |

Tooling & Setup | Stencils, programming, and fixtures |

Logistics | Shipping, customs, and delivery |

BOM and Labor Costs

The bill of materials (BOM) and labor costs make up a significant portion of pcb assembly cost. BOM includes all components required for assembly, from resistors to microcontrollers. Labor costs cover the time spent on assembly, inspection, and testing. LTPCBA’s automated assembly lines reduce manual labor, lowering overall process costs. Efficient sourcing and standardization also help control BOM expenses. Teams that focus on BOM optimization and streamlined assembly processes achieve better cost control and higher quality.

Tooling and Setup Expenses

Setup and tooling expenses represent initial one-time costs in pcb manufacturing. These include programming pick-and-place machines, creating stencils, and building jigs or fixtures. For small production runs, these costs spread over fewer units, resulting in higher per-unit expenses. In large runs, the same setup costs become negligible per unit due to economies of scale. LTPCBA’s flexible production lines help customers minimize setup costs, regardless of batch size.

Shipping and Logistics

Shipping and logistics play a crucial role in total pcb assembly cost. International projects face higher and more unpredictable costs because of tariffs, customs delays, and expensive transportation. Domestic pcb manufacturing offers shorter supply chains, lower transportation costs, and faster delivery. Companies benefit from just-in-time production and fewer logistics complications. LTPCBA’s global logistics network ensures reliable delivery and helps customers avoid unexpected shipping expenses.

International shipping often leads to higher costs and delays.

Domestic assembly reduces logistics risks and improves supply chain stability.

Reshoring pcb manufacturing can lower shipping costs and improve project timelines.

Accurate cost estimation tools, such as manufacturer quotes and online calculators, help teams plan budgets, avoid unexpected expenses, and optimize design choices. These tools are essential for balancing cost and performance in pcb assembly projects.

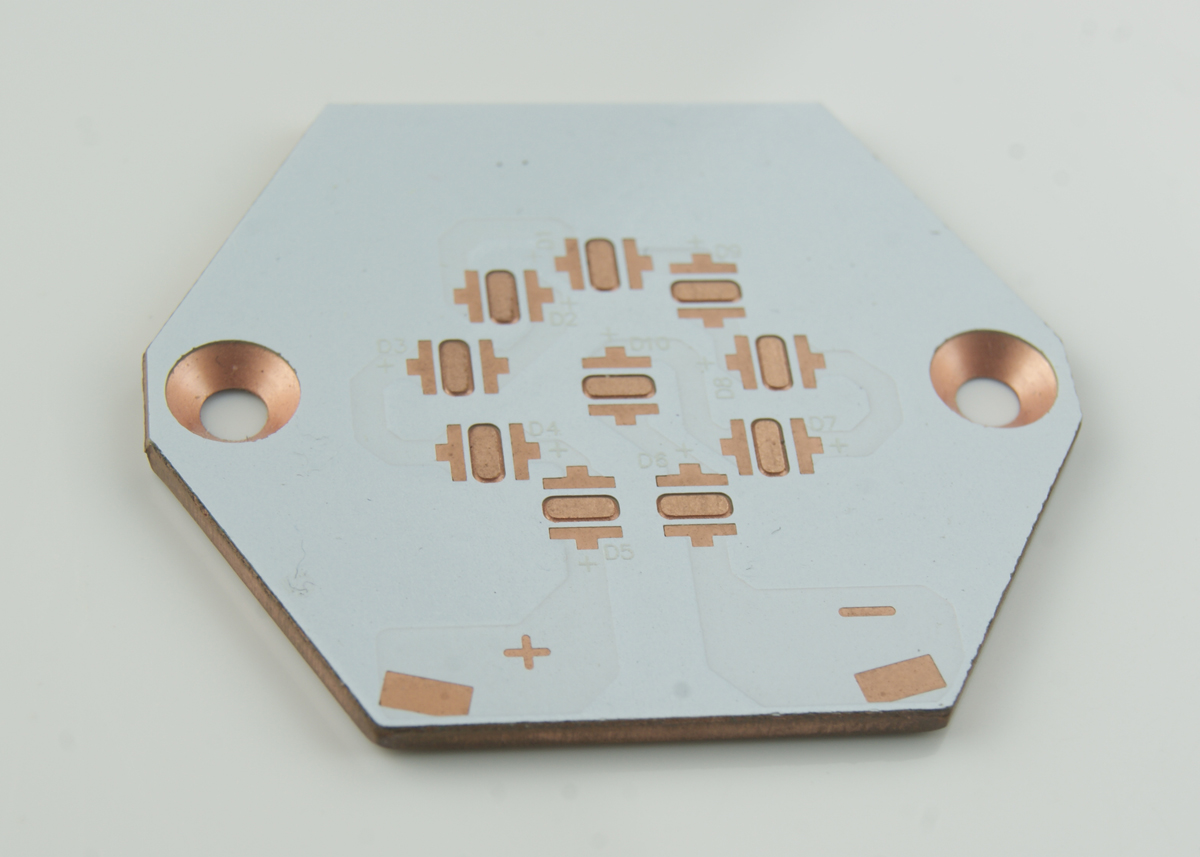

Design Choices That Impact Material Costs

Substrate Selection

Substrate selection plays a vital role in determining material costs for pcb manufacturing. Engineers often choose FR4 for standard pcbs because it offers a balance between performance and affordability. Specialized industries, such as aerospace or fuel systems, require substrates with enhanced thermal reliability, temperature resistance, and signal integrity. These advanced materials increase the overall cost due to their superior mechanical and electrical properties. Material choice stands as one of the three main factors affecting pcb manufacturing cost, alongside board size and layer count. Selecting high-performance substrates ensures operational reliability but raises material costs.

Standard FR4 substrates provide cost-effective solutions for general applications.

Advanced substrates deliver better performance but result in higher material costs.

Material selection directly influences the total cost of pcb manufacturing.

Layer Count

Layer count significantly impacts both the complexity and cost of pcb production. Adding layers requires more raw materials and introduces extra manufacturing steps, such as etching and bonding. Inspection and testing also become more challenging as each layer must meet quality standards. The most substantial cost increase occurs when moving from 2 to 4 layers, with costs rising by approximately 35-40%. Adding 4 to 6 layers leads to a 30-40% increase, while 6 to 8 layers result in a 30-35% rise. After the initial layers, the incremental cost per additional layer decreases. Designers must balance performance needs with material costs when determining layer count.

More layers require additional materials and processing.

Inspection complexity grows with each added layer.

Initial increases in layer count drive the highest cost jumps.

Board Size and Shape

Board size and shape directly affect material usage and waste in pcb manufacturing. Larger boards consume more raw materials, increasing material costs. Complex shapes and multiple cutouts generate more scrap and extend manufacturing time. Efficient panel utilization reduces waste and lowers cost. Rectangular or square boards offer better material efficiency, while irregular shapes like circles or L-shapes create more scrap. Careful design and panelization strategies help minimize waste and control material costs.

Factor | Impact on Material Usage and Waste | Design Strategy to Reduce Waste and Cost |

|---|---|---|

Board Size | Larger boards consume more raw materials, increasing material use and cost. | Keep board size to the minimum necessary for components and function. |

Board Shape Complexity | Complex shapes and multiple cutouts increase scrap and manufacturing time. | Simplify board outlines and reduce cutouts to minimize waste. |

Panel Utilization | Poor layout leads to inefficient use of panel space and more scrap. | Optimize board layout to maximize panel utilization and reduce waste. |

Tip: Engineers can reduce material costs by selecting standard substrates, limiting layer count, and optimizing board size and shape.

Optimizing PCBA Assembly with LTPCBA

DFM and DFA Strategies

Design for Manufacturing (DFM) and Design for Assembly (DFA) strategies form the foundation of effective design optimization. LTPCBA encourages engineers to consider manufacturability and assembly requirements from the earliest stages. Simple layouts, clear labeling, and standard footprints help reduce errors and speed up production. These strategies also support easier testing and quality control, which leads to fewer defects and lower rework rates. LTPCBA’s engineering team reviews each pcb design for potential improvements, ensuring that every project benefits from expert guidance and proven optimization techniques.

Standardization and Sourcing

Standardization in component sourcing drives significant cost savings and boosts optimization across projects. LTPCBA recommends using common components and materials whenever possible. This approach offers several advantages:

Reducing inventory complexity and simplifying management

Streamlining procurement processes for greater efficiency

Lowering procurement costs and improving manufacturing efficiency

By focusing on standardization, LTPCBA helps customers achieve consistent results and maintain reliable supply chains. This method also supports better testing and quality control, as standardized parts are easier to inspect and verify.

Early Manufacturer Collaboration

Early collaboration with LTPCBA’s team delivers powerful benefits for pcb assembly projects. When designers engage with manufacturing experts at the start, they gain a deeper understanding of processes like drilling, plating, and etching. Visiting fabrication facilities provides practical insights that lead to smarter design optimization. Designers who understand these constraints create more manufacturable and cost-effective pcbs. Early collaboration reduces design mistakes, improves optimization, and bridges the gap between design and manufacturing. This synergy enhances project quality, shortens turnaround times, and ensures smoother execution.

Tip: Early engagement with LTPCBA’s experts leads to better design decisions, fewer delays, and lower overall cost.

LTPCBA’s Quality and Efficiency

LTPCBA stands out for its commitment to quality, speed, and customer support. The company uses advanced automation and strict testing and quality control protocols to ensure every pcb meets international standards. Automated inspection systems catch defects early, while skilled technicians oversee each step of the assembly process. LTPCBA’s focus on optimization means customers receive reliable, high-quality pcb assembly services with fast turnaround and competitive pricing. Their dedication to continuous improvement and design optimization helps clients achieve the best possible results for every project.

Common Pitfalls in PCBA Manufacturing and Assembly

Over-Specification

Over-specification often leads to inflated costs in pcb assembly projects. Engineers sometimes select components or materials that exceed the actual requirements of the application. This practice increases both material and process costs. For example, choosing a high-grade substrate when a standard FR4 would suffice drives up the budget without adding value. Over-specification can also complicate the manufacturing process, causing delays and unnecessary expenses. Teams should match specifications to real-world needs to maintain cost efficiency.

Unnecessary Complexity

Unnecessary complexity in pcb design creates several financial challenges. Complex assemblies often introduce hidden fees and surprise markups, which reduce profit margins. Unforeseen manufacturability issues can cause costly rework. Ordering errors may result in warehousing and holding costs or project delays. The risk of obsolescence increases, raising financial risk for the entire project. Lack of transparency in manufacturing costs can derail projects before they start. By simplifying designs and focusing on essential features, teams can avoid these pitfalls and keep the manufacturing process efficient.

Hidden fees and markups lower profits.

Manufacturability issues lead to expensive rework.

Ordering mistakes cause extra storage costs or delays.

Obsolescence risk grows with complexity.

Poor cost transparency threatens project success.

Last-Minute Changes

Last-minute changes disrupt the assembly workflow and increase overall cost. When teams introduce modifications late in the process, suppliers may need to reorder components or adjust production schedules. These changes often result in additional process costs and longer lead times. Consistent communication and thorough planning help prevent last-minute surprises. Early design optimization and collaboration with the manufacturer ensure smoother project execution.

Ignoring Manufacturer Guidelines

Ignoring manufacturer guidelines can lead to costly errors and production setbacks. Each pcb manufacturer provides specific rules for layout, component placement, and assembly techniques. Disregarding these guidelines may cause compatibility issues, failed quality checks, or even complete redesigns. Following established standards supports a smoother manufacturing process and reduces the risk of expensive mistakes. Teams should always consult with their assembly partner to align design choices with proven manufacturing practices.

Thoughtful design choices and early cost analysis shape the success of every PCBA project. Teams achieve better budget control and cost optimization by following industry-recommended steps, such as maintaining a clear BOM, developing accurate component footprints, and ensuring proper spacing. LTPCBA delivers quality, efficiency, and support throughout the pcb assembly process. By applying proven optimization strategies and avoiding common pitfalls, engineers maximize project outcomes. For expert guidance and reliable optimization, LTPCBA stands ready to help.

Actionable Steps for PCBA Optimization:

Maintain a consistently formatted BOM.

Develop component footprints according to datasheets.

Mark polarity and orientation indicators clearly.

Assign independent pads for each connection.

Use ODB++ format for design data.

Organize component delivery with extra quantities.

Ensure adequate component spacing.

Avoid mixing technologies and select proper package sizes.

Communicate early with manufacturers.

Consider heat and wash requirements for components.

FAQ

What is the most effective way to reduce PCBA assembly costs?

Designers can reduce costs by selecting standard components, minimizing board complexity, and collaborating early with manufacturers like LTPCBA. Early design reviews and clear documentation help prevent costly errors.

How does LTPCBA ensure high-quality PCB assembly?

LTPCBA uses automated inspection systems, strict quality control protocols, and skilled technicians. The company follows international standards such as ISO, IATF, and UL to guarantee reliable results.

Why does production volume affect unit cost in PCBA manufacturing?

Higher production volumes allow bulk purchasing of materials and components. This approach lowers per-unit costs and improves manufacturing efficiency. LTPCBA’s scalable processes support both prototypes and mid-volume runs.

Can LTPCBA handle complex or custom PCB designs?

Yes. LTPCBA specializes in complex assemblies, including high-layer-count boards and advanced packages like BGA and QFN. The engineering team provides support from design to delivery, ensuring quality and performance.

See Also

Essential Materials Required For Successful PCBA Manufacturing

Choosing The Right PCBA Supplier To Fit Your Requirements

Designing PCB Boards For Optimal SMT Manufacturability Standards