PCBA Functional Test versus In-Circuit Test Key Differences and Best Applications

PCBA functional test and ICT serve distinct roles in ensuring the reliability of PCB assemblies. ICT focuses on detecting manufacturing defects such as open connections and missing components early in production. The PCBA functional test evaluates the entire assembly under simulated real-world conditions, verifying that the board performs as intended. By integrating both ICT and PCBA functional test processes, LTPCBA strengthens quality assurance, addressing both component-level and system-level issues. LTPCBA leverages advanced technology and a comprehensive approach to boost production efficiency and deliver high product reliability.

Key Takeaways

In-circuit testing (ICT) quickly finds manufacturing defects like shorts and missing parts early in production, making it ideal for high-volume runs.

Functional testing checks the whole PCBA under real-world conditions to ensure the board works as designed before shipping.

Combining ICT and functional testing gives the best quality control by catching both component-level and system-level issues.

ICT needs custom fixtures and works fast, while functional testing takes longer but does not require special fixtures.

Choosing the right test depends on production volume, design stage, and quality goals; LTPCBA helps tailor testing to meet these needs.

Test Methods

PCBA Functional Test

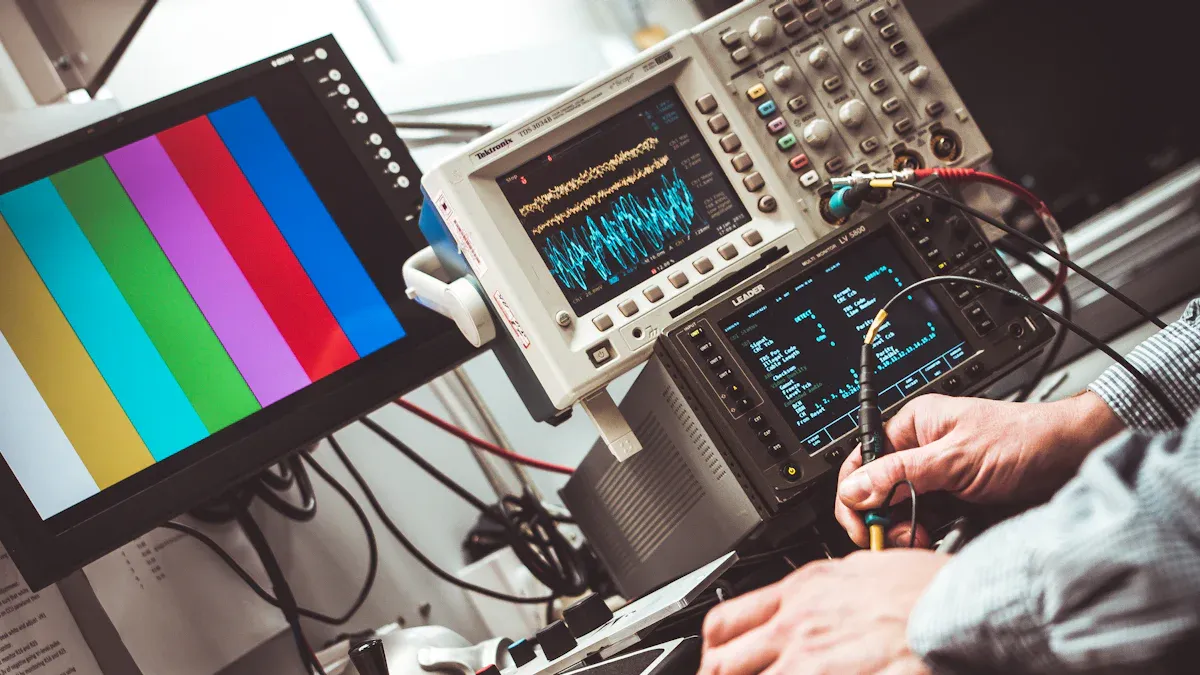

The pcba functional test serves as a comprehensive evaluation of a finished pcba. This method validates the operation of the assembly against its design specifications. During functional testing, technicians apply input test signals and analyze output responses. Specialized equipment such as signal generators, oscilloscopes, and logic analyzers play a crucial role in this process. The main goal of functional testing is to verify that the pcba performs as intended under real-world conditions.

Functional testing offers several advantages:

It checks the complete functionality of the pcba.

It tests actual performance under rated conditions.

It ensures design reliability before the product moves forward.

However, functional testing can be time-consuming because it examines the full operation of the assembly. The process requires specialized equipment and strict adherence to safety protocols, especially when handling live circuitry. LTPCBA uses advanced functional testing systems to ensure every pcba meets customer requirements and industry standards.

In-Circuit Testing (ICT)

In-circuit testing, often referred to as ict, focuses on detecting manufacturing defects at the component and connection level. This method uses specialized ict testers equipped with multiple probes that contact key test points on the pcb. The process involves several key steps:

1. Preparation and connection of the pcb to ict equipment using probes or pins. 2. Electrical testing of components and connections by passing signals through test points to measure resistance, capacitance, and voltage. 3. Analysis of test data by comparing measured values to expected results to identify variances and defects. 4. Reporting of detected faults with precise location information for troubleshooting. 5. Correction or repair of identified defects before further production stages.

Ict provides fast, reliable, and precise detection of assembly errors and manufacturing defects. LTPCBA leverages state-of-the-art ict technology to ensure high product quality and minimize the risk of faulty assemblies reaching customers.

Test Processes

Functional Testing Steps

Functional testing serves as the final checkpoint in the PCBA manufacturing process. LTPCBA uses advanced testing equipment and strict quality assurance protocols to ensure every assembly meets design requirements. The typical testing procedures for a pcba functional test include:

1. Place the device under test (DUT) onto a Bed-of-Nails fixture to establish secure electrical connections. 2. Power the DUT and validate that all voltage rails generate correct values. 3. Program microcontrollers and memory components on the board. 4. Test communication buses to confirm proper data transfer and signal integrity. 5. Verify firmware operation and ensure the hardware responds as expected. 6. Simulate real-world application environments by connecting the PCB to similar systems or final products. 7. Document results and analyze any failures for root cause identification and process improvement.

LTPCBA’s functional testing procedures help detect power integrity issues, signal distortion, and system-level operational failures before products reach customers.

ICT Steps

In-circuit testing (ICT) focuses on identifying manufacturing defects at the component and connection level. LTPCBA’s automated ICT systems streamline the testing procedures for high efficiency and accuracy. The typical ICT steps include:

Mount the PCB onto the ICT fixture equipped with multiple probes.

Use the probes to contact test points and measure electrical parameters such as resistance, capacitance, and voltage.

Compare measured values to expected results to identify discrepancies.

Generate detailed reports highlighting the exact location and nature of detected faults.

Repair or replace faulty components before advancing to the next production stage.

ICT enables rapid, precise detection of assembly errors, ensuring only high-quality boards proceed through the manufacturing process.

Defect Detection

Functional testing and in-circuit testing each target different defect types during the testing procedures:

ICT detects:

Short circuits

Open circuits

Misaligned or missing components

Incorrect component values

Functional testing identifies:

System-level operational failures

Power integrity issues

Signal distortion

Firmware or communication bus malfunctions

LTPCBA’s dual approach with both ICT and pcba functional test ensures comprehensive defect coverage, supporting the company’s commitment to quality assurance and customer satisfaction.

Comparison: PCBA Functional Test vs. ICT

Key Differences

Manufacturers rely on both ICT and PCBA functional test methods to ensure product reliability. Each approach offers unique strengths and addresses different stages of the assembly process. ICT focuses on detecting component-level faults such as shorts, opens, and incorrect placements. This method uses a custom fixture and probes to check individual components and connections. It operates quickly, often completing tests in less than one minute per board. The process requires a significant upfront investment in fixture creation, which suits high-volume production environments.

PCBA functional testing evaluates the entire assembly under simulated operating conditions. Technicians use specialized equipment to apply input signals and monitor output responses. This method verifies that all components work together as designed. Functional testing takes longer, typically 20-30 minutes per board, but does not require a custom fixture. It provides system-level validation and can reduce the need for expensive system tests.

LTPCBA leverages both ICT and PCBA functional test processes to achieve comprehensive quality assurance. ICT ensures component integrity and correct assembly before moving to the next stage. Functional testing confirms that the assembled board performs as intended in real-world scenarios. This dual approach allows LTPCBA to deliver reliable products that meet customer expectations.

Tip: Manufacturers often use ICT for rapid defect detection in high-volume runs, while functional testing provides deeper validation for final product performance.

Summary Table

Aspect | ICT (In-Circuit Testing) | PCBA Functional Test (FCT) |

|---|---|---|

Focus | Checks individual components and connections | Tests fully assembled PCBA under real conditions |

Time per board | 20-30 minutes | |

Initial Fixture Cost | $10,000 to $50,000 (average $20,000) | N/A (no custom fixture needed) |

Testing Coverage | Nearly 100% of PCB components | 50% to 100% of final product |

Testing Approach | Detects manufacturing defects | Simulates operating environment, tests overall function |

Suitability | High-volume production | Reduces need for expensive system tests |

Upfront Time | 4-6 weeks for fixture creation | N/A |

Long-term Benefit | Consistent results, reduces repair costs | Improves final product quality, error reduction |

Stage | After component placement | After assembly |

Outcome | Detects shorts, opens, incorrect placement | Validates performance and readiness |

LTPCBA combines ICT and PCBA functional testing to maximize defect coverage and product reliability. This strategy supports the company’s commitment to quality assurance and customer satisfaction.

Use Cases and Applications

When to Use Functional Testing

Functional testing works best at the final stage of the assembly process. Manufacturers use this method to confirm that the pcba operates as intended in real-world conditions. This approach suits products that require system-level validation before shipment. Companies often choose functional testing for complex assemblies with integrated firmware or communication features. LTPCBA recommends this method for projects where performance and reliability are critical, such as medical devices or advanced industrial controls. By simulating actual operating environments, functional testing helps ensure that every board meets customer expectations.

When to Use In-Circuit Testing

ICT provides rapid and thorough defect detection during the early stages of production. This method excels in high-volume manufacturing, where speed and accuracy are essential. Manufacturers rely on ict to identify issues like short circuits, open connections, and incorrect component placement before final assembly. LTPCBA uses ict to streamline production, reduce rework, and maintain high quality standards. This approach benefits industries that demand consistent output, such as automotive, consumer electronics, and telecommunications. ICT also supports quick turnaround times, making it ideal for projects with tight deadlines.

Industry Examples

Many industries depend on both ict and functional testing to guarantee the reliability of pcb assemblies. LTPCBA serves a wide range of sectors, each with unique testing requirements:

Aerospace and medical companies use burn-in testing to verify long-term performance under operational stress.

Automotive and industrial manufacturers perform peel strength and peel-back tests to ensure durability during physical stress.

Wearable electronics and automotive sectors rely on peel-back testing to confirm flexible pcba reliability under bending and twisting.

Defense and telecommunications firms apply environmental stress screening to detect early failures from temperature, humidity, or vibration.

IoT device makers use functional electrical testing to ensure connectivity, energy efficiency, and durability in challenging environments.

Wearable device manufacturers test for mechanical stress, moisture resistance, and power management to handle daily use and body movement.

Note: LTPCBA’s expertise in both ict and functional testing allows customers to select the best solution for their specific production needs.

Benefits and Limitations

Functional Testing Benefits

Functional testing provides several important advantages for PCB assembly.

It simulates real-world usage by sending signals through the fully assembled board and checking outputs.

This process helps identify integration errors and unexpected behaviors that other tests may miss.

Boards tested in this way operate as designed, which improves product reliability and performance.

Functional testing detects issues that visual or electrical tests might overlook, increasing safety and reliability.

When combined with other methods, such as AOI and ict, it contributes to early defect detection and better quality control.

These practices prevent defective products from reaching customers, which increases satisfaction and trust.

Compliance with safety and regulatory standards is ensured, which is critical for industries like medical devices and automotive electronics.

Functional testing helps manufacturers deliver products that meet strict performance and safety requirements.

ICT Benefits

ict offers a range of benefits that make it essential for modern PCB production.

Fast and accurate detection of component and continuity faults.

Simple operation with minimal user error.

Short testing time, usually 1-2 minutes per assembly, ideal for medium to high volume production.

High fault coverage, detecting up to 99% of manufacturing defects.

Test results are easy to interpret, allowing quick identification of faulty components or nodes.

Cost-effective with minimal maintenance needs.

Easily integrates into automated production lines.

Adaptable procedures for various PCB designs and technologies.

Reduces rework and repair costs, helping ensure high-quality end products with fewer field failures.

Comprehensive test coverage, including boundary scan, analog signature analysis, and parametric tests.

ict is quick, reliable, and comprehensive, making it a cornerstone of quality assurance in electronics manufacturing.

Limitations of Each

Both functional testing and ict have limitations that can impact production outcomes.

Limited test access on high-density PCBAs reduces test coverage, as placing test points on every node is impractical.

High-impedance nodes require longer test times, which slows throughput and complicates fault isolation.

Specialized components, such as supercapacitors, demand precise cycles, adding complexity to ict.

Low current measurements, important for automotive ECUs, are challenging but necessary for battery life and safety.

These limitations can increase test duration, reduce coverage, and create bottlenecks in manufacturing lines.

LTPCBA addresses these challenges by integrating multiple advanced testing methods, including AOI, X-ray imaging, and ict, to detect defects early and accurately. The company follows strict industry standards and employs certified technicians who use precise rework techniques. LTPCBA’s comprehensive approach maximizes test coverage, reduces scrap rates, and enhances product reliability. Their quality management system, continuous training, and process audits ensure consistent quality and rapid turnaround. By combining multiple testing methods and professional rework, LTPCBA minimizes costly recalls and maximizes customer satisfaction.

Choosing the Right Test Method

Factors to Consider

Selecting the right testing method for PCB assembly depends on several important factors. The choice between ict and functional testing often starts with the stage of production and the specific goals for quality assurance. High-volume production benefits from ict because it offers fast, repeatable results and detects most component-level faults. For prototypes or small batches, flying probe testing provides flexibility without the need for expensive fixtures. Functional testing becomes essential as a final check before shipping, ensuring the board works as intended in real-world conditions.

Factor / Test Method | In-Circuit Test (ICT) | Flying Probe Testing (FPT) | Functional Test (FCT) |

|---|---|---|---|

High volumes of the same design | Prototype or small batch production | Used as a final quality gate before shipping | |

Design Maturity | Design is finalized | Design not finalized or expected to iterate | Tests real-world operation, firmware, power rails, protocols |

Test Coverage Needs | Maximum test coverage for shorts, opens, component values | Basic testing | Simulates real-world operation and firmware validation |

Budget for Fixtures | Budget allows for custom fixtures and programming | Avoid fixture costs and long setup times | Fixture cost varies; often combined with other methods |

Stage of Product Lifecycle | Full production | Prototype phase or early runs | Final assembly line testing |

Additional Considerations | Often combined with functional testing for reliability | Used during prototype phase before ICT transition | Validates firmware and system-level operation |

Industry experts also recommend considering PCB complexity, required test coverage, and the manufacturer’s capabilities. Reliable ict, AOI, and X-ray inspection help detect defects early and support consistent production quality.

LTPCBA Recommendations

LTPCBA advises customers to match the testing method to their production needs and product goals. For high-volume production, ict delivers rapid, detailed fault detection and process control. This method identifies up to 90% of component-level defects, making it ideal for mass production environments. Functional testing, on the other hand, verifies the complete operation of the board under real-world conditions. LTPCBA recommends functional testing as the final quality gate, especially for products where reliability and traceability matter most.

LTPCBA customizes its approach based on customer requirements. The team collaborates with clients during design reviews to select the best testing strategy. Automated optical inspection and ict are used for both prototypes and full production runs. Functional testing is tailored to the product’s intended use, ensuring that each board meets customer expectations. Certifications such as ISO, IATF, and UL support LTPCBA’s commitment to quality across different industries. Skilled engineers, 24-hour support, and flexible processes allow LTPCBA to adapt quickly as production goals change.

Tip: LTPCBA’s integrated approach combines ict, functional testing, and advanced inspection methods to maximize defect coverage and ensure reliable delivery for every production run.

Manufacturers use in-circuit testing to verify individual components and connections early in production, while functional testing checks overall board performance under simulated conditions.

ICT excels at detecting shorts, opens, and placement errors, making it ideal for high-volume runs and complex boards.

Functional testing ensures system-level reliability, especially for advanced modules.

LTPCBA delivers both solutions with advanced automated assembly, strict quality control, and industry certifications. The company offers expert guidance through direct contact, supporting customers from prototype to production.

For tailored PCB assembly testing advice, LTPCBA encourages customers to reach out via online forms, WhatsApp, or email.

FAQ

What is the main difference between ICT and functional testing?

ICT checks individual components and connections for manufacturing defects. Functional testing verifies the entire board’s operation under simulated real-world conditions. Each method targets different stages of the assembly process.

When should manufacturers use both ICT and functional testing?

Manufacturers use ICT early in production to catch assembly errors. They apply functional testing at the final stage to confirm system-level performance. LTPCBA recommends combining both for maximum reliability.

Does ICT require a custom fixture for every PCB design?

Yes. ICT needs a dedicated fixture tailored to each PCB layout. This fixture allows probes to contact specific test points. The process suits high-volume production where fixture investment is justified.

Can functional testing detect all types of defects?

Functional testing identifies system-level issues and integration errors. It may not catch every component-level fault. Combining functional testing with ICT and AOI increases defect coverage and product reliability.

See Also

Understanding PCBA And Its Essential Parts Explained

Complete PCBA Services From Production Through Final Testing

Defining The Meaning Of PCBA In Electronic Devices