How to Estimate PCBA Cost for Your Electronics Project in 2025

To get an accurate PCBA cost estimate for 2025, it's important to consider all the factors that influence pricing. Costs typically range from $10 to $50 per board, while boards with specialized designs may reach $500 or more due to increased complexity and testing requirements. Using online calculators can provide a general PCBA cost estimate, but consulting reliable providers like LTPCBA will give you more precise figures. Always keep in mind that fluctuations in supplies and materials can impact your overall budget.

Key Takeaways

Learn about the main parts of PCBA cost. These include component costs, labor, overhead, and testing. Knowing this helps you plan your budget well.

Try online PCB cost calculators for quick price guesses. These tools show how design changes can change your costs.

Buy more boards at once to lower each board’s price. Buying in bulk can save you a lot of money on your PCBA project.

Pick standard components and make your design simple. This way, you spend less and finish faster.

Talk to trusted providers like LTPCBA for good price quotes and help. Their skills can help you avoid expensive mistakes.

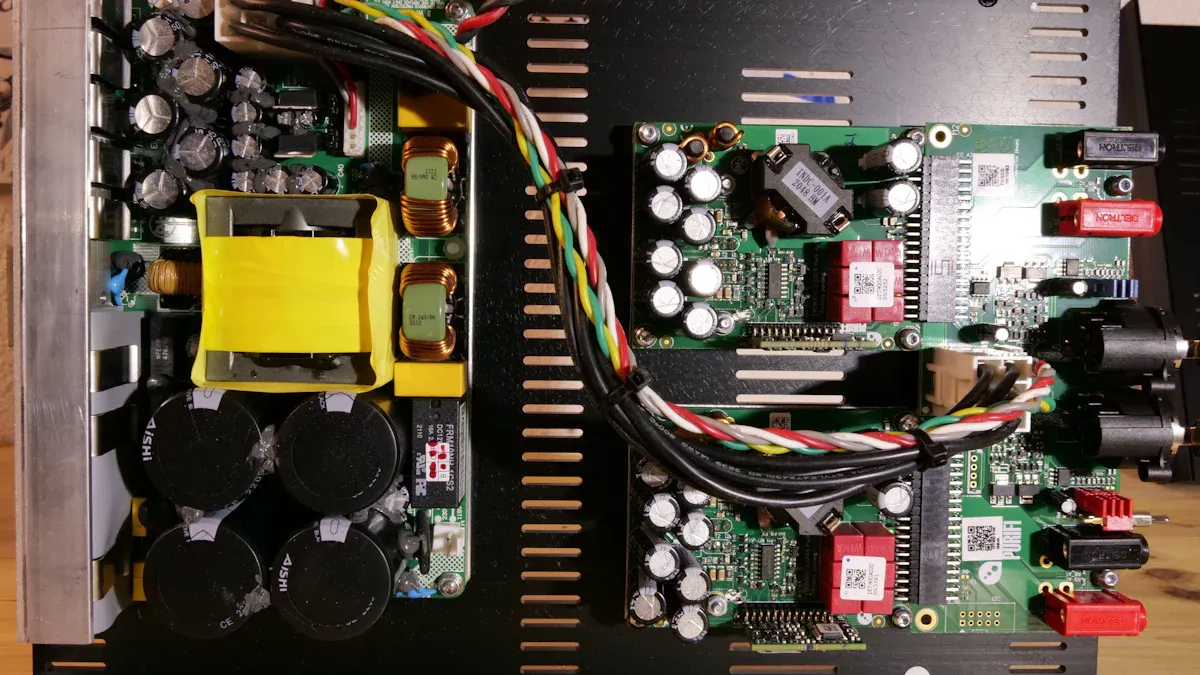

PCBA Cost Estimate Basics

When you start a new electronics project, you need to understand the main parts of a pcba cost estimate. Each part of the process adds to your total budget. Knowing the details helps you plan better and avoid surprises. Here is a simple table that shows the main cost components and what they mean for your project:

Cost Component | Description |

|---|---|

Component Cost | Cost of individual parts like resistors, chips, and connectors. |

Labor Costs | Money paid for assembly work, which depends on time and complexity. |

Overhead Costs | Expenses for factory rent, utilities, and equipment upkeep. |

Materials | Cost of the pcb itself, solder paste, and special materials. |

Testing and Inspection | Money spent on checking boards for errors and making sure they work. |

Quality Assurance | Costs for meeting industry standards and getting certifications. |

Volume | How the number of boards you order affects the price per board. |

You can use this cost breakdown to see where most of your money goes. LTPCBA gives you a full solution for all these steps. You get a quick quote, usually in 2-3 days, and support for every stage of your project.

PCB Fabrication Cost

The pcb fabrication cost is one of the biggest parts of your pcba cost estimate. This cost depends on the size of your board, the number of layers, and the materials you choose. If you pick a bigger board or add more layers, the price goes up. Multi-layer pcb fabrication can make your project more expensive, but sometimes you need it for complex designs.

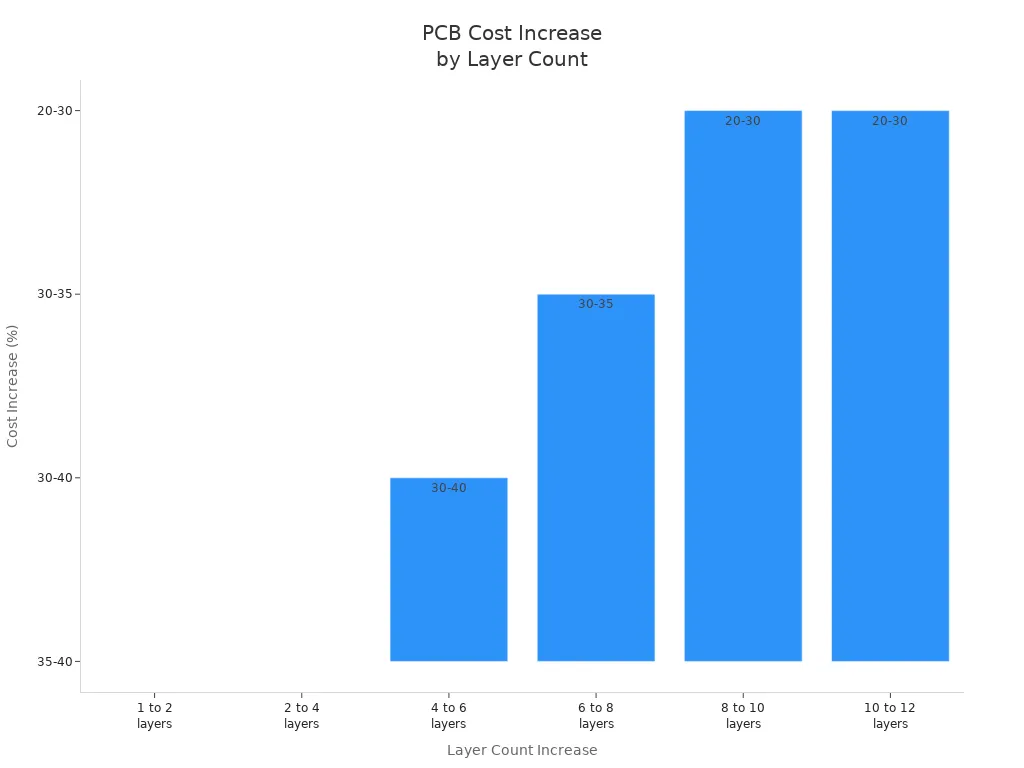

Here is a table that shows how the pcb fabrication cost increases as you add more layers:

Layer Count Increase | Cost Increase Percentage |

|---|---|

1 to 2 layers | 35 to 40% |

2 to 4 layers | 35 to 40% |

4 to 6 layers | 30 to 40% |

6 to 8 layers | 30 to 35% |

8 to 10 layers | 20 to 30% |

10 to 12 layers | 20 to 30% |

Larger pcb sizes mean higher material costs.

Complex designs with many layers or small holes also raise the pcb cost.

Thicker copper or special materials add to the pcb fabrication cost.

LTPCBA uses advanced technology to keep pcb manufacturing costs low while still giving you high quality. You can use a pcb cost calculator to get a quick idea of your pcb cost before you order.

PCB Assembly Cost

The pcb assembly cost covers the work needed to put all the parts on your board. This includes placing chips, soldering, and checking for errors. The typical cost per assembled board changes based on where you make your boards and how many you order.

Here is a table that shows the pcb assembly cost in different regions for 2025:

Region | Prototype (10 pcs) | 500 pcs | 1000+ pcs |

|---|---|---|---|

China | $60–$110 total | $0.90–$1.50/pc | $0.35–$0.75/pc |

Vietnam | $70–$130 total | $1.00–$1.60/pc | $0.40–$0.85/pc |

Germany | $120–$180 total | $2.00–$3.20/pc | $1.20–$2.20/pc |

USA | $150–$250 total | $2.50–$3.80/pc | $1.50–$3.00/pc |

If you order more boards, your typical cost per assembled board goes down. LTPCBA offers SMT, BGA, and through-hole assembly, so you can choose the best method for your project. You get a fast quote and high-quality service, which helps you stay on budget.

Component Sourcing

Component sourcing is another key part of your pcba cost estimate. The price of each part can change based on the supplier and how easy it is to find. Sometimes, a part looks cheap at first, but if it is hard to get or takes a long time to ship, your total pcb cost can go up. You need to think about more than just the sticker price.

Purchase Price Variance (PPV) shows the difference between what you expect to pay and what you actually pay. If you save money, PPV is positive. If you spend more, PPV is negative. Reliable suppliers help you avoid delays and extra costs. LTPCBA handles component sourcing for you, making sure you get good parts at a fair price.

Tip: Always check part availability and supplier reliability before you order. This helps you avoid delays and keeps your budget on track.

Testing and Shipping

Testing and shipping are the final steps in your pcba cost estimate. Testing makes sure your boards work as planned. This step usually costs between $0.10 and $2 per board, depending on how much checking you need. Quality assurance is important, especially if you want to meet industry standards.

Shipping costs depend on where you are and how fast you need your boards. LTPCBA offers fast and safe shipping, so you get your boards on time. You can use a pcb cost calculator to include shipping in your total pcb cost.

Note: Always include testing and shipping in your cost breakdown. These steps protect your investment and help you avoid problems later.

LTPCBA stands out because you get a complete service, from pcb fabrication cost to final delivery. You can use online pcb cost calculator tools or ask LTPCBA for a direct quote. This gives you accurate cost estimates and helps you plan your budget with confidence.

Key Cost Drivers for PCBA

When you plan a project, you should know what changes your pcba cost estimate. Each thing can make your pcb cost go up or down. LTPCBA uses smart tools to help you keep costs low. Let’s see what matters most for your total pcb cost.

Board Size and Layers

The size of your pcb and how many layers it has matter a lot. Bigger boards need more material, so your pcb cost gets higher. More layers make building harder. Each new layer adds to your pcb manufacturing costs.

Layer Increase | |

|---|---|

1L to 2L | 35 – 40% |

2L to 4L | 35 – 40% |

4L to 6L | 30 – 40% |

6L to 8L | 30 – 35% |

8L to 10L | 20 – 30% |

10L to 12L | 20 – 30% |

If you pick a board with many layers, you get more space for wires. But your pcb cost will be higher. LTPCBA helps you choose the right size and layers for your budget.

Design Complexity

How hard your design is also changes your pcba cost estimate. Hard designs need more time and work. If your pcb has lots of parts or tight spots, the pcb cost goes up. Here are some ways that happen:

Boards with lots of parts need careful drilling and routing.

Many parts close together need careful placing, which costs more.

Tiny wires and close copper need special work, so your pcb cost rises.

Try to keep your design simple. This helps you save money and stay on budget.

Volume and Economies of Scale

How many boards you order changes your pcb cost for each one. If you order just a few, setup costs make each board expensive. If you order a lot, you save money. The more you order, the less each board costs.

Production Volume | Explanation | |

|---|---|---|

Prototypes (Low) | High | Setup costs are split between fewer boards, so each costs more. |

Mass Production | Low | Fixed costs are shared by many boards, so each costs less. |

For example, if you make 1,000 boards, each one costs less than if you make only 10. LTPCBA works fast to give you good prices for big or small orders.

Material Selection

What you make your pcb from changes your pcb cost and budget. Some materials cost more but work better. Here is a table with common pcb types and their prices:

PCB Type | |

|---|---|

Basic 2-layer FR4 PCB | $0.50 – $1.00 |

4-layer PCB | $1.50 – $2.50 |

6+ layer PCB | $2.50 – $4.50 |

Ceramic or metal-core | $3.00 – $5.00+ |

Regular FR-4 is cheapest. If you need heat protection, you might pick high-Tg FR-4 or polyimide, but these cost more. RF or microwave boards need Rogers or Teflon, which are much more expensive. LTPCBA helps you pick the best material for your needs and budget.

Lead Time and Location

Where and how fast you make your pcb also changes your pcba cost estimate. Making boards in Shenzhen, China, can lower your pcb cost because there are many skilled workers. LTPCBA is in Shenzhen, so you get fast work and good shipping.

If you want your boards fast, you may pay more.

If you wait for parts or shipping, your pcb cost can go up.

Cheaper labor and strong supply chains in Shenzhen help keep pcb manufacturing costs low.

Plan your time and pick your factory location carefully. This helps you avoid extra costs.

Tip: Always remember hidden costs in your budget. Testing, fixing mistakes, and shipping can add up fast. Tests like functional testing, in-circuit testing, and burn-in tests make sure your boards work but cost more. If you need to fix boards or wait for parts, your total cost can go up quickly.

Here is a table with other things that change costs:

Description | |

|---|---|

Component Count and Type | More parts and different types mean longer setup and work time. |

Assembly Process Features | Extra steps like coating and X-ray checks make assembly cost more. |

Tooling Requirements | Things like solder stencils and test jigs add to your costs. |

Machine Time and Setup | SMD line setup and soldering steps change the final pcb cost. |

Knowing these main things helps you make smart choices for your pcba cost estimate. LTPCBA uses smart systems and quick help to keep your pcb cost low and your project running smoothly.

How to Optimize Your PCBA Cost

Design for Cost Efficiency

You can save money by making smart design choices. Use standard parts and materials. This helps you avoid high costs and long waits. Try to keep your pcb simple. Fewer layers and regular board sizes make things easier. Production is cheaper when you use these ideas. Surface mount technology (SMT) is a good choice. SMT lets you use smaller boards. It also makes assembly faster. This lowers both pcb cost and labor.

Strategy | Explanation |

|---|---|

Common parts cost less and are easy to find. | |

Minimize Layers | Less layers means cheaper and easier to make. |

Regular sizes waste less and save money. | |

Use SMT | Small boards and machines help cut costs. |

Avoid Over-Specification | Only use special stuff if you really need it. |

Tip: Make your design simple. Take out features that do not help. This makes your pcba cheaper and more reliable.

Volume Purchasing Strategies

Buying more pcba units at once saves money. Big orders often get discounts. This lowers your pcb cost for each board. Build good relationships with suppliers and makers. This can get you better prices and faster service. Combine small orders into one big order. This lowers setup costs and gives better cost estimates.

Pick suppliers who give discounts for big orders.

Plan your orders to fit your budget and schedule.

Look for the best deals for your pcba needs.

Choosing LTPCBA for Quality and Value

LTPCBA gives you high-quality pcba services. They follow ISO, UL, and IATF rules. This means you get boards you can trust. LTPCBA uses smart inspection tools like AOI and X-ray. These tools help keep defects low. You get a 99.5% first pass yield. This saves you time and money on repairs. Fast help and good support keep you on budget and on time.

Feature | Benefit |

|---|---|

International Standards Compliance | High quality and fewer mistakes. |

Less defects and lower repair costs. | |

High Pass Rate (99.5%) | More reliable boards and happy customers. |

Using PCB Cost Calculator Tools

A pcb cost calculator helps you plan your project. You enter your pcb size, layers, materials, and how many you want. The calculator gives you quick cost estimates. Many makers, like LTPCBA, have online calculators. These tools show how changes affect your budget. If your pcb cost is too high, you can change your design or order size. This helps you find ways to save money.

Always put in all the details for the best results.

Use the calculator to check different choices before you buy.

Ask LTPCBA for a full review and exact cost estimates.

Note: Using a pcb cost calculator and talking to your maker early helps you avoid mistakes. It keeps your project on track.

You can figure out your pcba cost by looking at each part, like design and shipping. Pay attention to board size, how many layers you need, and what materials you pick. These choices help you keep costs low. Try online calculators to get a quick idea of your pcba cost. Ask LTPCBA for a more exact quote. If you want your pcba project to stay on budget, follow these steps:

Recommendation | Description |

|---|---|

Use one provider for your pcba to make things easier and safer. | |

Utilize a dedicated manager | Have someone watch over your pcba build to save money and get better results. |

Leverage rapid prototyping | Test your pcba early so you do not have to fix expensive mistakes later. |

Work with trusted vendors | Pick good suppliers to get strong parts and steady pcba cost. |

FAQ

What is the difference between PCB and pcba?

A PCB is just a plain board with copper lines. A pcba has all its parts put on and soldered. You use a pcba inside your electronic device. The assembly process changes a PCB into a working pcba.

How do you calculate pcba cost for a small project?

You add up the cost for the board, parts, assembly, testing, and shipping. You can use an online calculator or ask LTPCBA for a quote. This helps you know your total pcba cost before you start.

Why does pcba cost change with order volume?

You pay less for each board if you order more. Setup and tooling costs are shared by many boards. LTPCBA gives better prices for bigger pcba orders. You save money by planning how many you need.

What testing does LTPCBA include in pcba services?

LTPCBA uses automated optical inspection, X-ray checks, and functional tests. These tests help make sure your pcba works well and meets standards. You get boards that are reliable and free from defects.

Can you use a pcba cost calculator for custom designs?

Yes, you type in your board size, layers, materials, and how many you want. The calculator gives you a quick estimate. For special pcba designs, you should ask LTPCBA for a detailed quote and advice.

See Also

Navigating Electronic Component Sourcing for PCBA Production

Choosing the Ideal Turnkey PCBA Manufacturer for Your Project

Understanding PCBA and Its Essential Components

Defining PCBA and Its Meaning in Electronics

Enhancing Business Efficiency Through PCBA Contract Manufacturing