What Is PCBA Contract Manufacturing and How Does It Work

PCBA contract manufacturing refers to the process where a specialized provider assembles electronic components onto a printed circuit board, transforming a bare PCB into a fully functional PCBA. While a PCB is simply the empty board, PCBA contract manufacturing delivers a complete board with all necessary parts installed. Companies choose pcba contract manufacturing to leverage expert knowledge, reduce costs, and ensure high-quality results.

LTPCBA is a trusted leader in pcba contract manufacturing, serving as a reliable partner in this rapidly expanding industry.

Year | Market Size (USD Billion) | Projection Year |

|---|---|---|

2022 | 515.1 | - |

2024 | 611.03 | - |

2030 | 1062.7 | - |

2034 | 1544.97 | - |

Key Takeaways

PCBA contract manufacturing changes plain circuit boards into working electronics. It does this by adding and testing all the needed parts. This helps companies save time and money.

Picking a skilled contract manufacturer like LTPCBA gives high quality. It also makes production faster and saves money. This is because they use advanced technology and strict testing.

Outsourcing PCBA assembly lets companies make more products easily. It helps them focus on their main business. They do not need to buy costly equipment or hire extra workers.

PCBA Contract Manufacturing

What Is PCBA

PCBA means printed circuit board assembly. This process turns a plain board into a working device. The PCB is the base. It gives support and paths for electricity but has no parts. A PCBA has all the needed parts, like resistors and capacitors, put on the board. This makes a circuit that can power electronics.

There are some main differences between PCB and PCBA.

PCB is just a blank board for support and connections.

PCBA has all the parts added, so it works.

Making a PCB is easier and uses steps like etching copper.

Making a PCBA is harder. It needs solder paste, machines to place parts, soldering, and testing.

These extra steps make PCBA more complex, cost more, and take longer than making a PCB.

PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) | |

|---|---|---|

Definition | Bare, unpopulated board providing electrical connections | Populated PCB with electronic components, forming a functional circuit |

Function | Mechanical support and electrical pathways for components | Performs a specific electronic function |

Components | None (empty board) | All necessary electronic components (resistors, capacitors, ICs, etc.) |

Manufacturing | Etching copper layers onto a substrate; applying solder mask | Placing and soldering components onto the PCB (SMT, through-hole) |

Testing | Continuity and short testing of copper traces | Comprehensive testing (ICT, functional testing) to ensure proper operation |

Manufacturing Complexity | Simpler fabrication process focusing on physical design | More complex due to component placement, soldering, and testing |

Cost and Lead Time | Lower cost and faster fabrication | Higher cost and longer lead time due to assembly and testing |

PCBA contract manufacturing is when a company, called a pcba manufacturer or supplier, does the whole assembly for another business. The customer gives design files. The manufacturer makes the PCB, gets the parts, puts them on the board, tests it, and ships it. This lets companies focus on research and marketing while the manufacturer handles making the product.

Role of a PCBA Manufacturer

A pcba manufacturer is very important in making electronics. The manufacturer uses their skills to build the boards and checks that each one is high quality. The jobs of a pcba manufacturer include:

Getting parts like resistors, capacitors, ICs, and connectors, making sure they are good and arrive on time.

Working with suppliers to get good parts at fair prices.

Keeping the right amount of parts in stock to save money and have what is needed.

Handling shipping so materials and finished products arrive when needed.

Making sure things are made on time to keep up with orders.

Planning production to meet what customers want and when they need it.

The assembly process has many careful steps:

Putting solder paste on the PCB to get it ready for parts.

Using machines to place parts on the board.

Soldering the parts in place with special methods.

Checking the board with machines and X-rays to find problems.

Testing the board to make sure it works right.

Doing quality checks, like looking at parts when they arrive and testing during and after making.

Offering full PCB assembly services, from design to final testing.

A pcba contract manufacturing partner like LTPCBA does more than just put parts together. LTPCBA is a full-service contract manufacturer. This means they handle everything, which makes things faster and cheaper. LTPCBA uses new technology, machines, and skilled workers to make sure each pcba is top quality. They answer quickly, have a high success rate, and care about customers. This makes them a top choice for businesses that need reliable contract manufacturing.

Note: Picking a good pcba factory like LTPCBA helps companies make more products, keep quality high, and focus on what they do best. LTPCBA’s skills in pcba manufacturing and contract work help many industries and uses.

Process Overview

Turning an idea into a finished printed circuit board assembly takes many steps. Each part of the pcb assembly process is important. These steps help make sure the final product works well and lasts long. LTPCBA uses new technology and strong quality checks. They do this from the start of the design to the end delivery.

Design and Documentation

The pcb assembly process starts with good design and clear paperwork. Customers need to give full and correct files. This helps avoid mistakes and keeps things on time. The usual paperwork includes:

Bill of Material (BOM): Lists all parts, how many, part numbers, and trusted vendors.

Assembly Drawings: Shows board size, thickness, layers, and part numbers. Has Gerber files for each layer.

Custom Item Suppliers: Gives info for special parts or suppliers.

Testing and Sampling Requirements: Tells about programming, test needs, and sample products.

Special Processes: Notes about RoHS, coatings, or special tests.

Other Information: Lists order size, delivery wishes, company info, IPC class, and special needs.

Netlist File: Explains electrical links for testing after making.

Test Specifications: Gives steps for testing during and after making.

Regulatory and Compliance Information: Talks about RoHS, REACH, IPC rules, and other laws.

Keeping paperwork up-to-date and complete stops costly mistakes and delays. Working early with LTPCBA’s engineers helps set clear rules and goals.

Some problems in this step are bad heat control, signal problems, and hard-to-test designs. Missing or old paperwork can cause mix-ups, extra work, and slowdowns. LTPCBA’s team works with clients to check all paperwork is right and full. This helps move smoothly to the making stage.

Component Sourcing

Getting parts is a key step in the pcb assembly process. LTPCBA has skilled buyers who know the electronic parts market well. They only buy from trusted suppliers and brokers. This makes sure the parts are real and good quality. Every part gets checked closely, including looking at labels and packages. This stops fake or broken parts from being used.

This careful way lowers risks and makes sure every printed circuit board assembly uses strong, good parts. LTPCBA’s worldwide network and good supplier ties help find rare parts and keep work moving.

Assembly Steps

LTPCBA mixes smart machines with expert workers in the pcb assembly process. The main steps are:

Component Placement: Engineers put parts on the PCB using design files. They check the direction and how the parts face.

Inspection and Rectification: Machines check if parts are in the right place. Mistakes get fixed before soldering.

Soldering: Surface mount and through-hole parts get soldered with special tools like wave soldering and reflow ovens.

Advanced Technologies: LTPCBA uses SMT assembly, BGA assembly, flex PCB assembly, and turnkey solutions. Machines like AOI, X-ray, and 3D scanners help catch problems early.

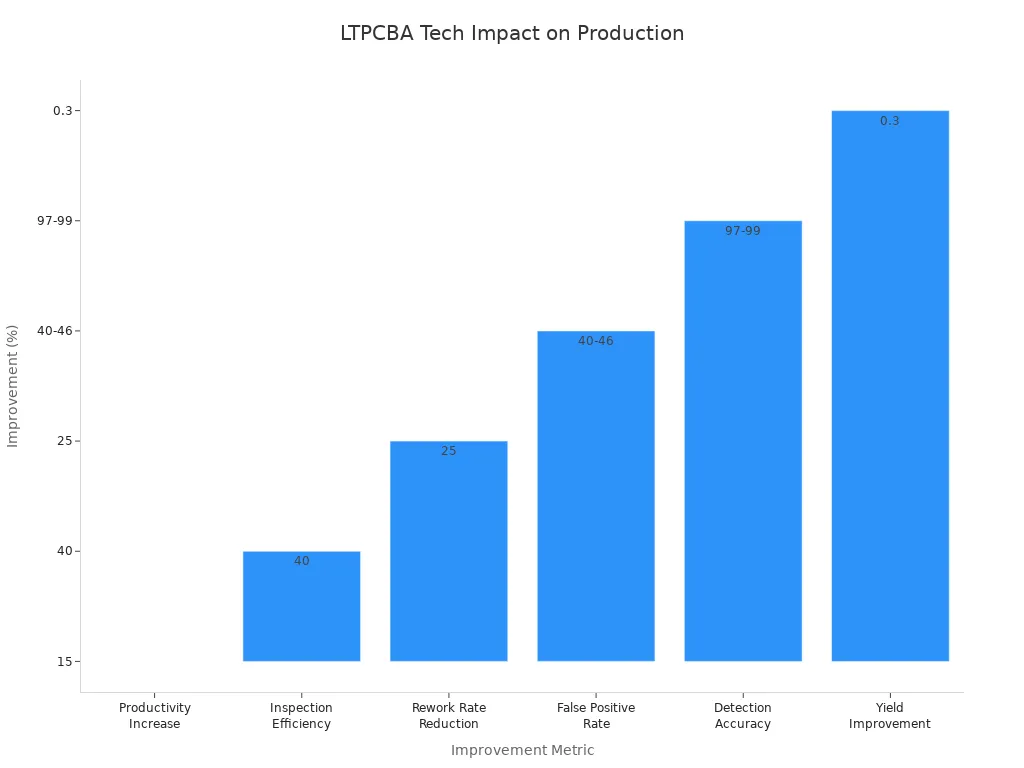

LTPCBA uses cobots, AI vision, and digital twins to speed up work and make it more exact. Cobots make placing parts 30% faster. AI cuts mistakes to just 0.05%.

Technology/Feature | Impact on Production Speed and Quality |

|---|---|

Cobots | Accelerate component placement by 30% |

AI Vision Systems | Reduce false positives by 50%, improving inspection accuracy |

Digital Twins | Shorten process setup time by 20% |

Turnkey PCBA Approach | Reduce lead times by 40%, achieve first-pass yields above 98.5% |

AI-driven Automation | Minimize errors, defect rates as low as 0.05% |

Industry 4.0 Integration | Ensure consistent quality and faster production throughput |

Testing and Quality

Testing and checking quality are very important in pcba manufacturing. LTPCBA follows strict rules like IPC-A-610, ISO 9001, RoHS, and UL. These rules make sure each board is safe, works well, and meets laws.

The quality steps include:

X-ray and 3D pictures to check hidden solder spots.

Tests to see if the board works, based on what the customer wants.

Checks for RoHS, REACH, and other rules.

LTPCBA’s smart systems get a first-pass yield over 98.5%. Their defect rate is as low as 0.05%. This is better than most companies, where defect rates are 1% to 2% after final tests. LTPCBA’s focus on quality means customers get boards they can trust.

LTPCBA gives fast help, 24-hour tech support, and a high pass rate. This makes them a top choice for companies that want strong pcba solutions.

Benefits of Contract Manufacturing

Cost and Efficiency

When companies use contract manufacturing for pcba, they save a lot of money. A contract manufacturer puts together orders from many clients. This makes each board cost less to make. Companies do not need to buy expensive machines or hire many skilled workers. Most companies save about 15-20% or even more by letting someone else do the pcba assembly. For example, a contract manufacturer can help save over $5 million every year on labor and materials.

Cost Component | In-House (OEM) | Contract Manufacturer | Savings / Notes |

|---|---|---|---|

Direct Labor Hourly Rate | $62.00 | $49.71 | $12.29 per hour savings |

Material Procurement Savings | N/A | N/A | $3,150,000 saved annually |

Total Annual Savings | N/A | N/A | Over $5 million in combined savings |

A contract manufacturer also works faster by using new machines and skilled teams. This helps companies get their products ready and shipped out sooner.

Quality Assurance

A good pcba manufacturer checks every board to make sure it works right. They use special machines like AOI and X-ray to find problems early. Skilled workers use these machines to keep quality high. The manufacturer follows rules like ISO and IPC-A-610. This means each pcba meets important world standards.

In-circuit and other tests make sure each board works.

Stress tests check if products last in hard places.

Scalability

Contract manufacturing lets companies make more or fewer boards when needed. The manufacturer can make just a few boards or thousands at once. Smart machines and robots help change how much is made very quickly. This helps companies keep up with what customers want without wasting money or time.

The manufacturer uses Industry 4.0 tools to watch work in real time.

Production plans change to fit what customers order.

Outsourcing lets companies spend more time on research and sales.

LTPCBA Advantages

LTPCBA is a top contract manufacturing partner. The company has certifications like ISO 9001:2015, IPC-A-610, RoHS, IATF 16949, and UL. These show they care about safety and quality. LTPCBA has a 99.5% first pass yield for pcba products. Customers get help any time of day and quick answers. LTPCBA’s skills and new systems make it a trusted pcba manufacturer for many kinds of businesses.

PCBA contract manufacturing lets companies spend less money and make better products. It also helps them make more products when needed. Picking a good partner like LTPCBA means you get strong quality checks, new machines, and help you can trust.

When you pick a contract manufacturer, think about these things:

Do they know the industry and have the right certificates?

Can they make what you need?

Is their supply chain strong?

Do they talk clearly and share information?

To learn more, go to LTPCBA’s website.

FAQ

What is the typical lead time for PCBA contract manufacturing?

Most jobs take about 2 to 4 weeks from start to finish. LTPCBA gives fast price quotes and can work quickly if you need boards sooner.

How does LTPCBA ensure the quality of assembled boards?

LTPCBA checks boards with AOI, X-ray, and other tests. The team follows strict rules like ISO and IPC-A-610 for every order.

Can LTPCBA handle both prototypes and large production runs?

Yes. LTPCBA can make a few boards or many at once. The company changes its team and tools to fit what each customer needs.

See Also

Understanding PCBA And Its Essential Electronic Components

Ways PCBA Contract Manufacturing Enhances Business Productivity

Defining PCBA And Its Meaning In Electronics Industry

Comprehensive PCBA Services From Production To Final Testing

Complete PCBA Manufacturing Process Guide For All Skill Levels