How PCBA Contract Manufacturing Can Boost Your Business Efficiency

Outsourcing PCBA contract manufacturing helps make your business smoother. Giving manufacturing tasks to others lets you focus on key areas. You can spend more time on marketing and supply chain work. This method helps your business grow and handle changing demands easily. It’s a great way to improve and stay ahead of others.

Key Takeaways

Hiring LTPCBA for PCBA work helps save money and time. It lets your business focus on important tasks like marketing and creating new products.

LTPCBA uses modern tools and skills to make great PCBs. This lowers mistakes and makes customers happier.

LTPCBA can change production easily to meet new needs. This helps your business launch products faster and work better.

Cost Efficiency in PCBA Contract Manufacturing

Saving money with LTPCBA

Building your own PCB assembly setup costs a lot. You need to buy machines, hire experts, and maintain a workspace. Working with LTPCBA removes these big expenses. They already have the tools, space, and skills for PCB assembly. This lets you spend money on other important things like new products or advertising.

Using LTPCBA also saves money through bulk production. Their organized systems lower costs, making it cheaper for you. Whether you need a few items or many, LTPCBA adjusts to your needs. You only pay for what you use, avoiding extra costs.

Cutting daily costs by outsourcing

Running PCB assembly yourself can get expensive fast. Bills, repairs, and upkeep can drain your funds. Outsourcing to LTPCBA reduces these costs. Their modern tools and methods ensure quality without high expenses.

Experts like LTPCBA buy parts at good prices worldwide. This lowers your costs even more. They also manage risks like delays or fake parts, saving you from surprise expenses. By outsourcing, you get a trusted partner focused on saving you money.

Reducing waste and fixing problems early

Smart PCBA manufacturing saves money and cuts waste. LTPCBA uses data to find problems like wasted energy or broken machines. They fix issues early to avoid delays. Catching quality problems early stops material waste or bad products.

With these methods, LTPCBA helps you save money while keeping quality high. They also follow eco-friendly practices, making them a great choice. LTPCBA handles the hard work, so you can focus on creating great products.

Expertise and Advanced Technology with LTPCBA

Using expert skills for better quality

Picking LTPCBA gives you access to special skills. Their team knows a lot about pcb assembly and has years of experience. This means they can check quality carefully, making sure every pcb is top-notch.

LTPCBA works hard to keep quality high. For example, their First Pass Yield (FPY) is 95%-98%, and their scrap rate is only 2%. These numbers show how much they care about great results. They also have important certifications like ISO 9001:2015 and ISO 13485:2016, proving their focus on quality and happy customers.

Metric | Value Range |

|---|---|

Order Fulfillment Rate | 90% to 95% (up to 98%) |

Scrap Rate | Below 5% (as low as 2%) |

First Pass Yield (FPY) | 95% to 98% |

On-Time Delivery Rate (OTDR) | 90% to 95% (Top performers > 98%) |

Customer Satisfaction Score | 70% to 90% (Excellent > 80%) |

Defects per Million Opportunities (DPMO) | 500 to 1000 |

With LTPCBA’s skills, your business gets reliable and high-quality pcb assembly every time.

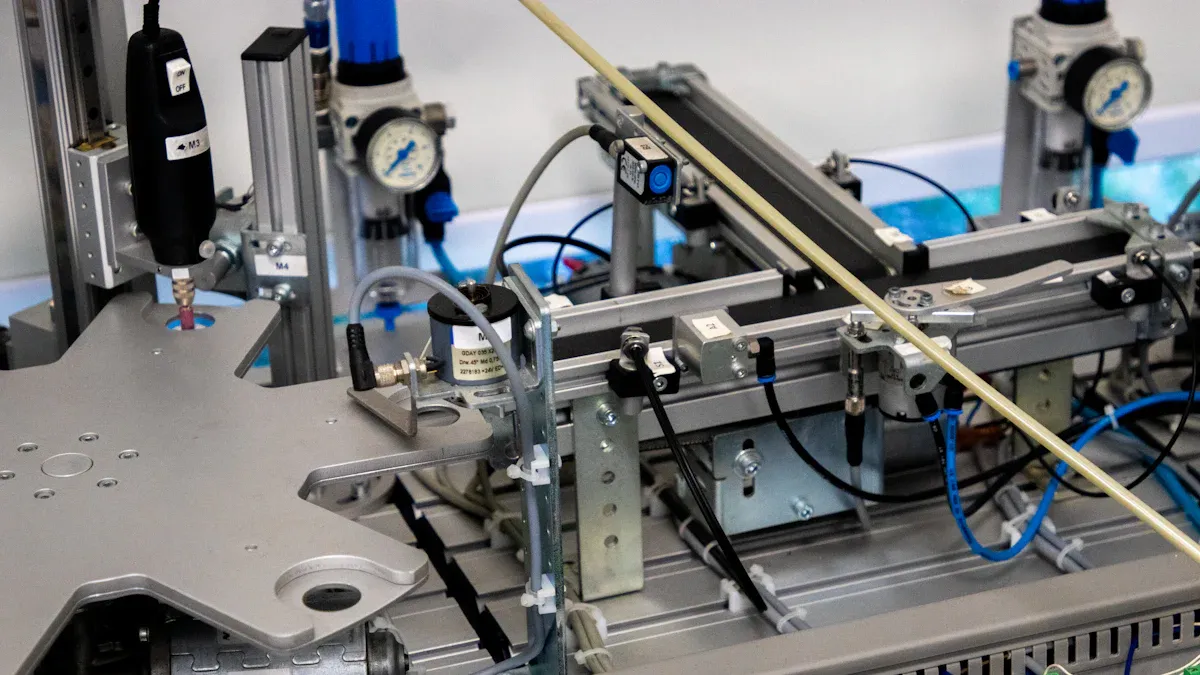

Using advanced tools for better production

LTPCBA uses the latest technology to stay ahead. They use tools like AI, machine learning, and robotics to work faster and better. For instance, AI finds problems early, so they can fix them quickly. This reduces mistakes and improves the final product.

Technological Advancement | Description | Impact on Production Efficiency |

|---|---|---|

AI and Machine Learning | Finds and fixes problems early using data. | Reduces mistakes and improves quality. |

Vision Systems | Uses lasers for accurate part placement. | Makes fewer errors and works better. |

Automation and Robotics | Speeds up tasks like soldering with precision. | Increases work time by 60%. |

Industry 4.0 Tools | Uses live data for smarter decisions. | Improves overall production quality. |

These tools help LTPCBA handle tough pcb assembly jobs with great accuracy. Robotics and automation make work 60% faster, so you get your products quicker without losing quality. This technology helps your business stay strong in a fast-moving market.

Following global rules for trust

Meeting global standards is key for trust in pcb manufacturing. LTPCBA follows rules like ISO 9001:2015 for quality and ISO 13485:2016 for safe medical devices. These rules ensure every pcb assembly meets strict global needs.

LTPCBA also uses advanced materials like polyimide and Rogers substrates for better performance. Conductive inks allow creative ways to make electronics. Choosing LTPCBA means working with a partner who values rules and innovation, helping your business succeed long-term.

Tip: Partnering with LTPCBA ensures your products meet global standards and stay high-quality every time.

Scalability and Flexibility for Business Growth

Adjusting to changing production needs

Your business must stay flexible to meet customer changes. LTPCBA’s advanced systems and pcb assembly skills make this possible. Whether you need a few prototypes or many products, LTPCBA adjusts easily. This ensures you don’t make too much or too little, saving time and money.

Outsourcing your pcb assembly to LTPCBA gives you big savings. Their smooth operations and global suppliers handle sudden demand increases. They do this without lowering quality. This flexibility helps your business stay strong, even in tough markets.

Growing production with ease using LTPCBA

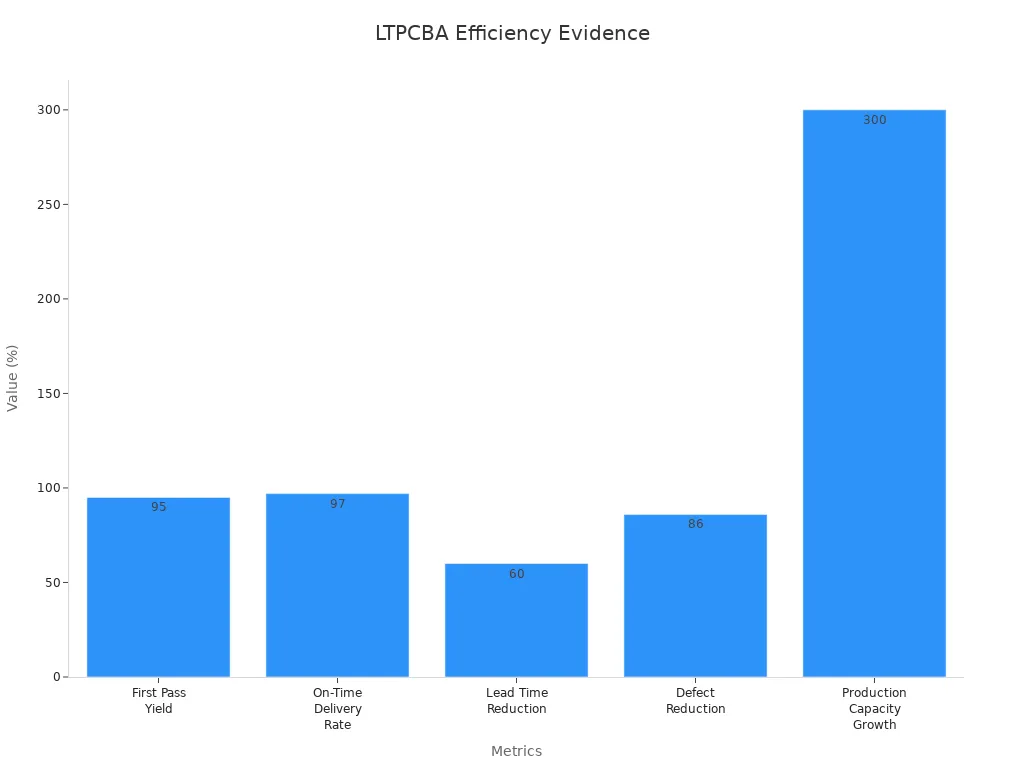

Growing production can be hard, but LTPCBA makes it simple. Their modern tools and automated systems speed up work and increase capacity. For example, LTPCBA finishes production in 12 hours and delivers 97% on time. These numbers show they grow production while keeping high standards.

Metric | Value |

|---|---|

12 hrs | |

First Pass Yield | 95% |

On-Time Delivery Rate | 97% |

Lead Time Reduction | 60% |

Defect Reduction | 86% |

Production Capacity Growth | 300% |

With LTPCBA, you can grow production smoothly. This saves money and gets your products ready faster.

Launching new products faster

Speed matters when releasing new products. LTPCBA’s pcb assembly skills help you work faster. Their supply chains and expert teams move designs to production quickly. This is great for businesses with tight deadlines.

For example, a medical device company worked with LTPCBA to meet a launch date. Using LTPCBA’s advanced methods, they delivered quality products on time. This avoided costly delays. This shows how LTPCBA speeds up launches, giving your business an edge.

Note: Faster production and delivery let you focus on new ideas while LTPCBA handles the hard work of pcb manufacturing.

Focusing on Core Competencies with Outsourcing

Freeing up resources for new ideas

Outsourcing PCB assembly to LTPCBA lets you focus on innovation. Instead of handling tough manufacturing tasks, you can work on new products. LTPCBA takes care of the technical work, giving you more freedom.

You won’t need to buy costly machines or hire experts. This saves money and energy for creating better products. Your team can now focus on designing the next big thing in your field.

Improving products and making customers happy

Outsourcing saves time and makes your products better. LTPCBA uses advanced tools and strict checks to ensure top quality. This means fewer mistakes and more reliable products for your customers.

For example, businesses working with LTPCBA see 20% fewer defects. They also grow production by 30% in the first year. Faster deliveries and great quality make customers happier.

Evidence Type | Details |

|---|---|

Production Capacity Improvement | 30% more production capacity |

Defect Reduction | 20% fewer defects in the first year |

Customer Satisfaction Improvement | Better due to faster delivery and quality |

When customers get good products on time, they trust your brand more. This trust helps your business succeed for a long time.

Making management easier

Managing PCB manufacturing yourself can be hard. You need to buy parts and follow strict rules. Outsourcing to LTPCBA makes this process simple.

LTPCBA handles everything, from buying parts to final assembly. Their smooth system means you don’t need to check every step. This gives you time to focus on big decisions for your business.

By outsourcing, you get a partner who delivers great results. They also help your business stay efficient and ready for challenges. This keeps you strong in a fast-changing market.

Working with LTPCBA changes your business for the better. Their services help you save money and make better products. They also make it easy to produce more when needed. This gives you extra time to create new ideas and grow. Choosing LTPCBA means your business runs smoothly and stays successful. Check out their services now to improve your business.

Visit LTPCBA's official website to learn more.

FAQ

What does PCBA contract manufacturing mean?

PCBA contract manufacturing means hiring experts like LTPCBA to build your PCBs. They take care of making them, so you can focus on growing your business.

Why pick LTPCBA for your PCBA needs?

LTPCBA uses smart tools, follows global rules, and saves money. Their skills ensure good results, keeping your business strong and efficient.

How can outsourcing PCBA help your business?

Outsourcing lowers costs, saves time, and improves product quality. It lets you focus on new ideas and happy customers while experts handle the hard work.

See Also

Understanding PCBA And Its Essential Components

Choosing The Right PCBA Supplier For Your Requirements

The Impact Of Quick-Turn PCB Prototypes On Efficiency