PCBA assembly secure choices for tough jobs

You face tough jobs that demand reliable solutions. Military-grade PCBAs offer strict standards and rugged materials. Commercial secure options focus on advanced protection and efficient design. Secure choices matter when you need durability and security. LTPCBA helps you choose the right pcba assembly secure for your project.

Key Takeaways

Military-grade PCBs offer extreme durability and strict standards, making them ideal for harsh environments like deserts and arctic zones.

Commercial secure PCBs provide strong data protection and flexibility, suitable for projects that prioritize cybersecurity and quick production scaling.

When choosing between military and commercial PCBs, assess your project's specific needs for durability, security, and compliance to make the best decision.

Tough Jobs Defined

Harsh Environments

You often work with pcbs in places where conditions push the limits. Extreme heat, cold, and rapid temperature changes challenge the performance of military and defense equipment. You need pcbs that pass harsh environment testing and deliver consistent quality. Military and defense equipment must operate in deserts, arctic zones, or high-altitude locations. These places demand materials that resist temperature swings and mechanical stress.

The table below shows how different pcb materials handle temperature extremes. High-Tg FR-4 and polyimide offer better resistance for military and defense equipment. You can see why these materials matter for defense applications.

Material Type | Glass Transition Temperature (Tg) | Coefficient of Thermal Expansion (CTE) | Maximum Temperature Resistance |

|---|---|---|---|

Standard FR-4 | 130°C | 12-14 ppm/°C | N/A |

High-Tg FR-4 | 170°C or higher | 12-14 ppm/°C | N/A |

Polyimide | Up to 260°C | N/A | N/A |

Security and Reliability

You want pcbs that protect sensitive data and ensure reliable operation. Security is critical for military and defense equipment, especially in defense communications and control systems. Military pcbs use advanced design features to block unauthorized access and prevent tampering. You rely on quality manufacturing to keep defense systems running without failure. Reliability means your pcbs perform under stress, vibration, and electrical noise. Military and defense equipment require pcbs that meet strict quality standards and deliver security in every mission.

Tip: Choose pcbs with proven reliability and security features for defense and military applications. Quality materials and design help you succeed in tough jobs.

Military-Grade PCBs

Standards and Tolerances

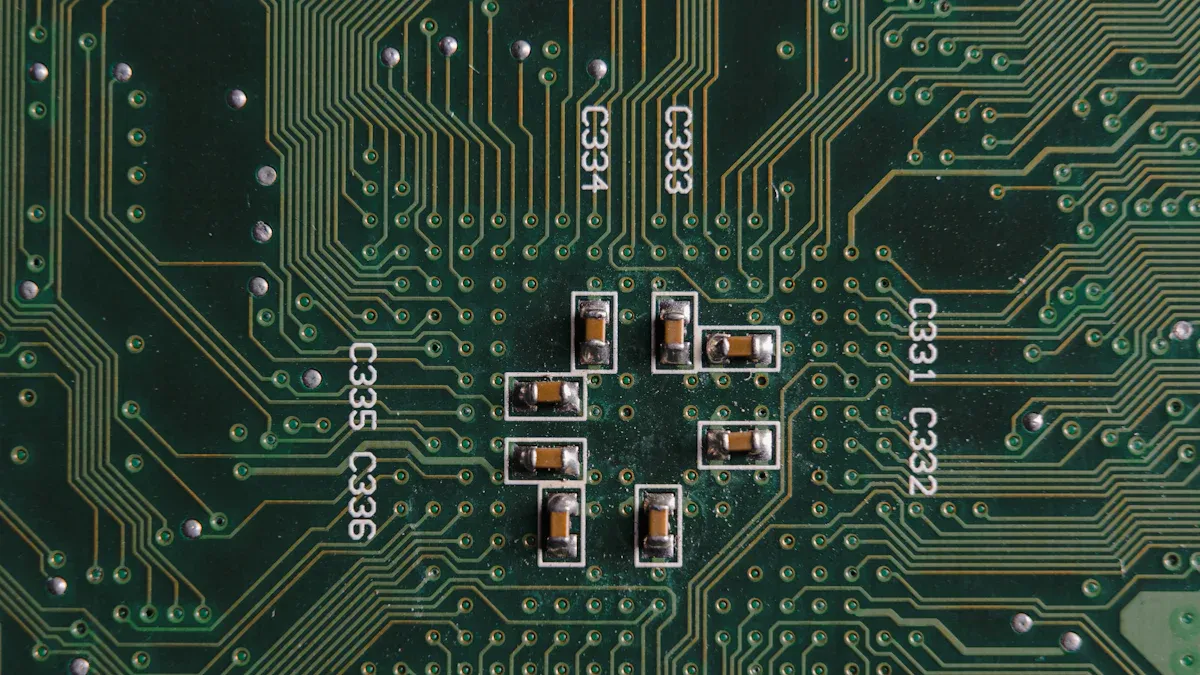

You rely on military-grade pcbs when you need strict standards and precise tolerances. Military pcb assembly follows military standards that set the bar for quality and reliability. These standards ensure that defense systems work in extreme conditions. You see military pcb manufacturers use advanced inspection methods to check every detail. Military pcb assembly services include automated optical inspection and X-ray analysis. These steps help you avoid errors and keep your defense equipment safe.

Note: Military pcb assembly partner companies must meet certifications like ISO and UL to deliver trusted results for defense projects.

Materials and Durability

You choose military pcb components for their strength and endurance. These components use materials like high-Tg FR-4 and polyimide. You find these materials resist heat, vibration, and moisture. Military pcb assembly uses soldering techniques that protect connections from stress. You see military pcb manufacturers select coatings that shield pcbs from chemicals and dust. These features help defense equipment last longer in harsh environments.

Material | Benefit for Defense |

|---|---|

High-Tg FR-4 | Heat resistance |

Polyimide | Flexibility |

Special Coatings | Moisture barrier |

Military PCB Assembly for Defense Applications

You need military pcb assembly for defense systems such as missile control platforms and weapon systems. Military pcb components support secure communication and precise control. You trust military pcb assembly services to deliver reliable pcbs for defense missions. Military pcb assembly keeps your equipment running in critical situations. You work with a military pcb assembly partner who understands the demands of defense technology. Military pcb assembly gives you confidence in every mission.

Commercial Secure PCBA Assembly

Secure PCB Design Features

You need secure pcb design when you want to protect your pcbs from tampering and cyber threats. Secure pcb design uses encryption and advanced layout techniques to block unauthorized access. You see features like shielded traces, secure boot chips, and hardware authentication. These features help you maintain the integrity and reliability of your high-reliability products. Secure pcb design also supports cybersecurity enhancements for commercial and defense applications. You rely on these designs to keep your data safe in radar and surveillance systems. Secure pcb design gives you confidence that your pcba assembly secure will meet strict security standards.

LTPCBA’s Secure PCBA Solutions

You trust LTPCBA to deliver pcba assembly secure for tough jobs. LTPCBA uses automated systems and strict quality checks to produce secure pcb design for commercial and defense needs. You benefit from quick response times and 24-hour technical support. LTPCBA follows international standards to ensure quality and reliability in every batch. You can order pcbs for military, defense, and surveillance projects. LTPCBA offers solutions for high-reliability products, including advanced encryption and cybersecurity enhancements. You get pcbs that protect your data and maintain integrity in demanding environments.

Pros and Cons

You compare commercial secure pcba assembly secure with military-grade options to find the best fit. Commercial secure pcbs offer strong security and reliable performance for most applications. You see lower equipment costs and flexible production options. Automated SMT lines help you scale up quickly, while manual DIP assembly suits small batches. The table below shows how cost and scalability differ between SMT and DIP methods:

Factor | SMT (Surface Mount Technology) | DIP (Dual In-line Package) |

|---|---|---|

Equipment Costs | Significant upfront investment in machines costing tens to hundreds of thousands of dollars. | Minimal equipment needed, lower initial costs. |

Labor and Production Costs | Lower long-term labor costs due to automation, but higher per-unit costs for small batches. | Higher labor costs for manual assembly, but lower setup fees. |

Productivity | Automated lines produce thousands of PCBs daily, ideal for scaling production. | Manual processes limit speed, suitable for small batches. |

Tip: Choose commercial secure pcba assembly secure when you need flexibility, strong security, and reliable quality for commercial, defense, and surveillance projects.

PCBA Assembly Secure Comparison

Durability and Security

You need to choose between military pcb assembly and commercial secure pcbs for tough jobs. Military pcb assembly gives you high durability. You see these pcbs in military and defense equipment that face extreme heat, vibration, and moisture. Defense electronics manufacturing uses materials like high-Tg FR-4 and polyimide to protect critical system pcb from damage. You rely on military pcb assembly for missions where failure is not an option.

Commercial secure pcbs also offer strong security features. You find encryption, shielded traces, and hardware authentication in these designs. These features protect critical system pcb from cyber threats and tampering. You use commercial secure pcbs in defense pcb applications that need data protection and reliability. Both options give you security, but military pcb assembly focuses more on physical durability while commercial secure pcbs emphasize digital protection.

Tip: If you work with military and defense equipment in harsh environments, choose military pcb assembly for maximum durability. For projects where data security is your main concern, commercial secure pcbs may be the better choice.

Cost and Compliance

You must consider cost and compliance when selecting pcbs for defense electronics manufacturing. Military pcb assembly often costs more because it uses advanced materials and strict inspection methods. You pay for certifications like ISO and UL, which are required for defense pcb applications. These certifications ensure your critical system pcb meets military standards.

Commercial secure pcbs give you flexibility with production costs. You can scale up quickly using automated SMT lines or choose manual DIP assembly for small batches. You save money on equipment and labor when you use commercial secure pcbs for defense electronics manufacturing. Compliance is still important. You need to follow industry standards to protect critical system pcb and meet security requirements.

Assembly Type | Durability | Security | Cost | Compliance | Best For |

|---|---|---|---|---|---|

Military PCB Assembly | High | High | Higher | Strict (ISO, UL) | Military and defense equipment |

Commercial Secure PCBs | Medium | High | Lower | Industry (ISO) | Defense pcb applications, commercial use |

Note: Always check compliance requirements before you choose an assembly type. Military pcb assembly is best for defense pcb applications that need strict standards. Commercial secure pcbs work well for projects with flexible budgets and strong security needs.

Defense PCB Applications vs. Commercial Use

You see military pcb assembly in defense pcb applications like missile control, radar systems, and secure communications. These critical system pcb designs must survive harsh conditions and deliver reliable performance. Defense electronics manufacturing uses military pcb assembly to meet the demands of military and defense equipment.

Commercial secure pcbs fit projects that need strong security but do not face extreme environments. You use these pcbs in surveillance systems, industrial controls, and commercial electronics. Critical system pcb in these applications needs protection from cyber threats and unauthorized access. Defense electronics manufacturing supports both military and commercial needs, but you must match the assembly type to your project.

Here is a checklist to help you decide:

Do you need your pcbs to survive extreme heat, vibration, or moisture?

Does your project require strict military certifications?

Is data security your top priority?

Do you need to scale production quickly?

Are you working with military and defense equipment or commercial electronics?

If you answer yes to the first two questions, military pcb assembly is your best choice. If you focus on data security and flexible production, commercial secure pcbs will meet your needs.

You now know the strengths of both military-grade and commercial secure PCBA assemblies.

Choose military-grade for extreme durability and strict standards.

Pick commercial secure for strong data protection and flexible production.

LTPCBA supports your secure PCBA needs. Assess your project’s demands before making your final choice.

FAQ

What is the main difference between military-grade and commercial secure PCBA?

Military-grade PCBA uses tougher materials and strict standards. Commercial secure PCBA focuses on data protection and flexible production.

How do you choose the right PCBA assembly for your project?

Need | Best Choice |

|---|---|

Military-grade PCBA | |

Data security | Commercial secure PCBA |

Does LTPCBA support both military and commercial secure PCBA assembly?

You get support for both types. LTPCBA offers secure solutions for defense, surveillance, and commercial electronics.

See Also

Choosing the Right PCBA Supplier for Your Requirements

Essential PCBA Processing Standards for Medical Devices

Important Strategies to Enhance PCBA Durability Over Time