PCB Production and Assembly Compared for Beginners

You may wonder about the difference between pcb fabrication and pcb assembly. Fabrication creates the physical pcb, while assembly adds electronic components, making the board work. Understanding the importance of pcb fabrication and assembly helps you avoid confusion in pcb production and assembly. The pcb market keeps growing, as shown below:

Year | CAGR (%) | |

|---|---|---|

2023 | 86.76 | N/A |

2024 | 91.79 | N/A |

2033 | 152.46 | 5.8 |

Key Takeaways

PCB fabrication creates the bare board, while assembly adds electronic components to make it functional.

Understanding the differences between fabrication and assembly helps avoid confusion and ensures a smoother production process.

Choosing the right PCB manufacturing partner is crucial for quality, cost-effectiveness, and timely delivery.

Understanding PCB Assembly and Fabrication

What Is PCB Fabrication?

You start your journey with pcb fabrication when you want to create a new electronic device. This process builds the physical foundation of your project. In simple terms, pcb fabrication means making the actual board that will hold all your electronic parts. People often call this the "bare PCB" because it does not have any components attached yet.

You will see the word "fab" used as a short form for fabrication. Manufacturers use a fabrication drawing to guide the process. This drawing shows where to drill holes, the size of each hole, the shape of the board, and the materials to use. Here is a quick reference:

Term | Definition |

|---|---|

Fab | Short for fabrication. |

Fabrication Drawing | A drawing used to aid the construction of a printed board. It shows all of the locations of the holes to be drilled, their sizes and tolerances, dimensions of the board edges, and notes on the materials and methods to be used. Called 'fab drawing' for short. |

You will find several materials used in pcb fabrication. The most common ones include:

FR-4 (fiberglass-reinforced epoxy resin)

Polyimide

Rogers (polymer-ceramic composites)

Aluminum

FR-4 stands out because it offers good electrical insulation, strong mechanical support, and stability at high temperatures. Rogers materials work well for high-frequency circuits. Metal-core boards, like those made with aluminum, help manage heat. Polyimide gives you flexibility and can handle high temperatures.

The pcb fabrication process follows a series of steps. You begin with your design and select the right board material. The process continues as you transfer the design onto copper-clad material using a photoresist. Unwanted copper gets removed through chemical etching, leaving only the desired circuit pattern. For multi-layer boards, you align and laminate the layers together. Holes are drilled and plated to create connections called vias. The board receives a solder mask and protective plating on the pads. When you finish these steps, you have a bare pcb ready for the next stage.

What Is PCB Assembly?

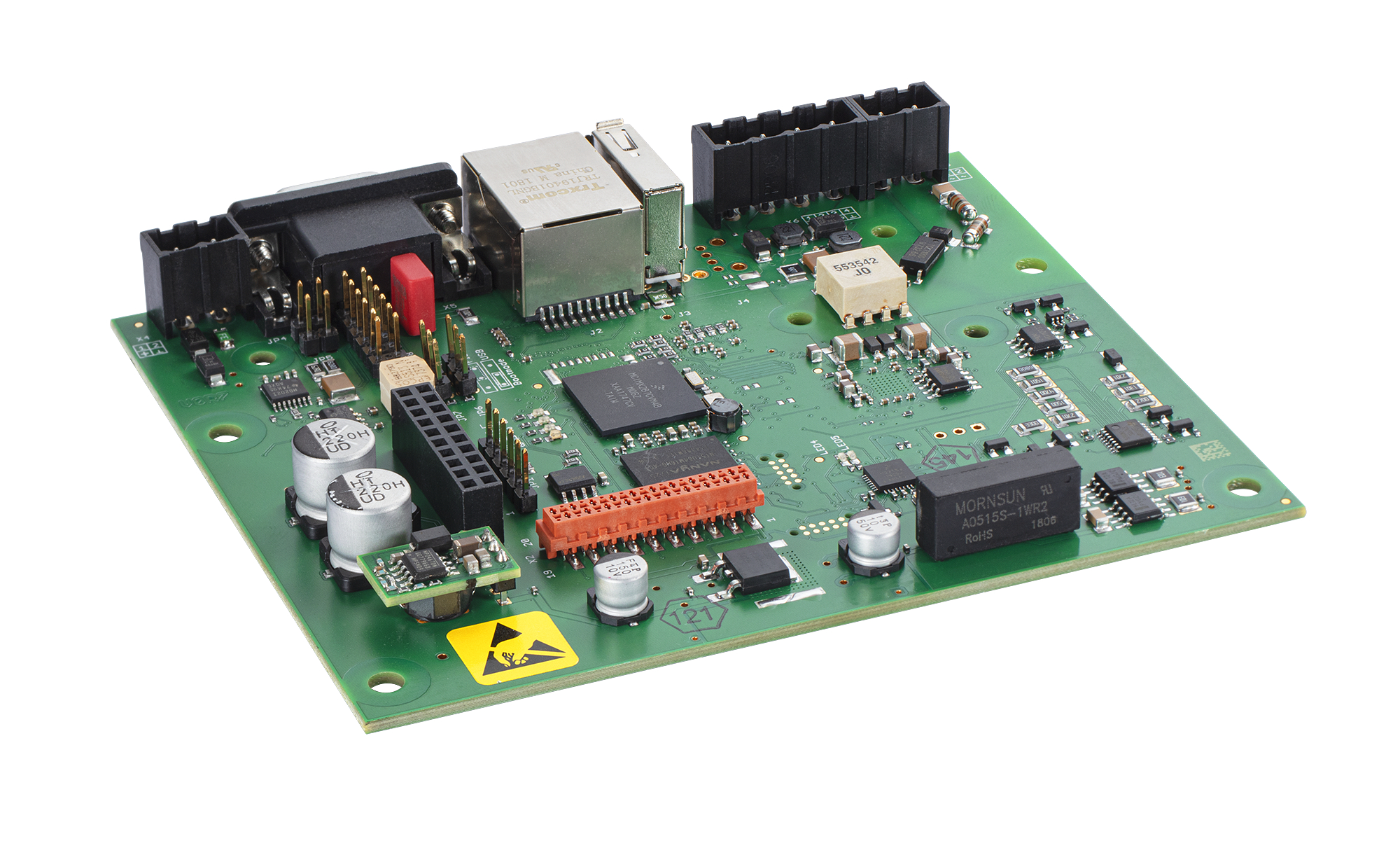

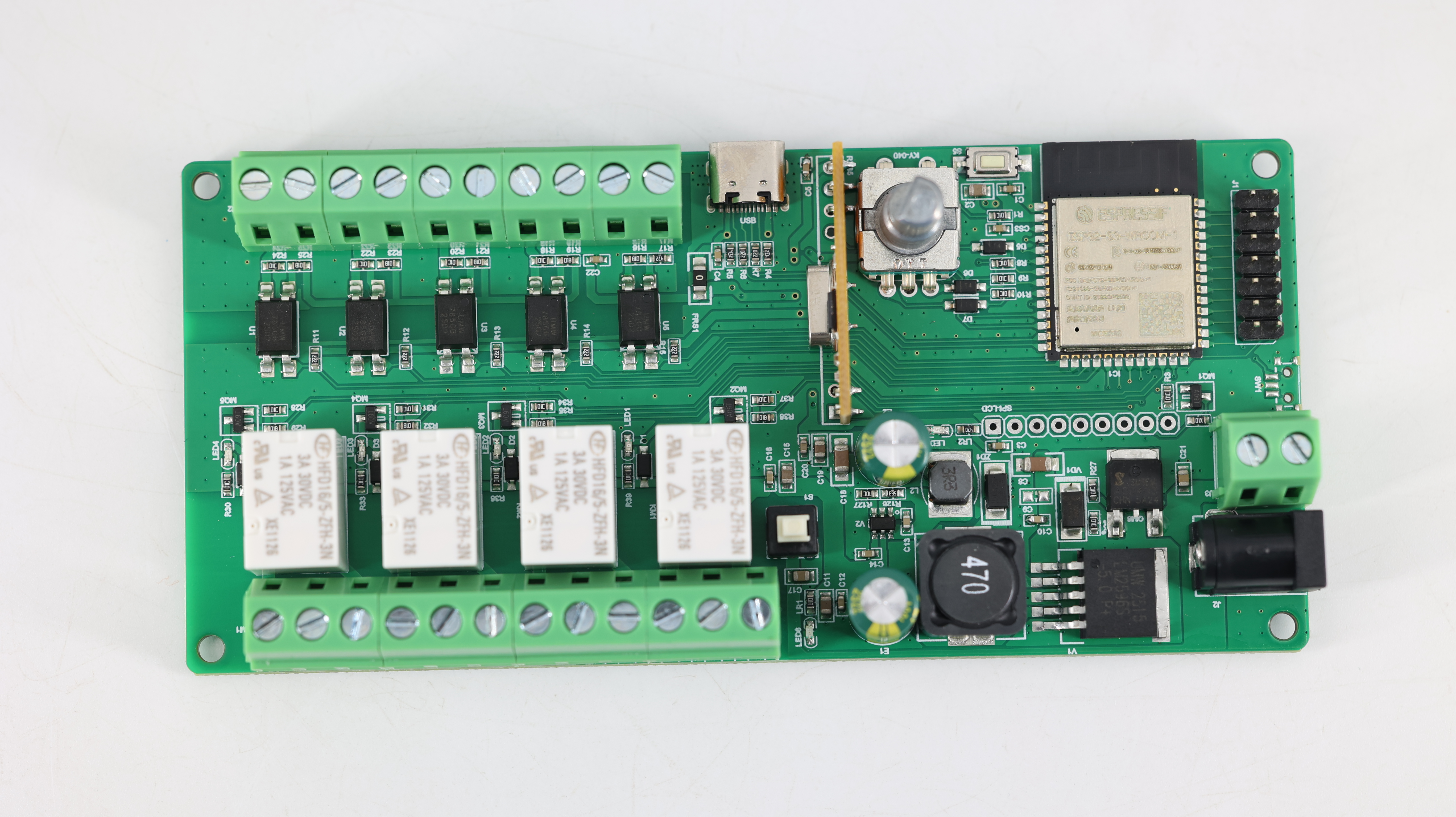

After pcb fabrication, you move to pcb assembly. This process transforms your bare pcb into a working electronic device. During pcb assembly, you add all the electronic components to the board. These components can include resistors, capacitors, chips, and switches. You may hear the term "PCBA," which stands for printed circuit board assembly. This means the board now has all its parts installed and soldered in place.

PCB assembly involves several important steps:

Design Checks: You make sure the pcb design matches the requirements before starting.

Solder Paste Application: You apply solder paste to the board using a stencil. This paste helps attach the components.

Component Placement: You place each electronic part onto the board in its correct spot.

Reflow Soldering: You heat the board in a special oven. The solder melts and forms strong connections.

Inspection Methods: You check the finished board using tools like Automated Optical Inspection (AOI) to find any mistakes.

You use different methods in pcb assembly, such as surface-mount technology (SMT) and through-hole placement. SMT places parts directly onto the surface, while through-hole parts go into drilled holes. Common components added during pcb assembly include switches, which control the flow of current. You might use push-button, toggle, or micro switches, depending on your design.

When you finish pcb assembly, you have a complete PCBA. This board uses copper pathways inside the layers to connect all the parts. The assembly process brings your circuit board to life, allowing it to perform its intended function.

Tip: Understanding pcb assembly and fabrication helps you avoid confusion. Remember, fabrication creates the board, and assembly adds the parts. Both steps are essential for building reliable electronic devices.

PCB Fabrication Process

Main Steps in Fabrication

You begin pcb fabrication by designing your circuit board with special software. This design guides every step of pcb manufacturing. The pcb fabrication process includes several important steps that turn your idea into a real board:

Design your circuit board using software.

Sand the copper plate to prepare the surface.

Clean the copper plate to remove any particles.

Transfer your design onto the copper plate.

Cool the plate in water to separate the paper.

Etch the pcb to remove extra copper.

Wash and dry the board.

Drill holes for components.

Strip away any remaining copper with nitric acid.

Apply solder resist to prevent unwanted solder.

Test the pcb to make sure it works.

Move to assembly, where you add components.

The timing for each step in pcb manufacturing can vary. Here is a table to help you understand the average time needed:

Step | Average Time |

|---|---|

Design and Prototyping | 1–3 weeks (3–5 days for simpler designs) |

Bare PCB Fabrication | 3–14 days (1–2 days for rush services) |

Assembly | 1–5 days (1–3 days for SMT; 3–5 days for THT) |

Testing and Quality Control | 1–5 days (hours for basic; 2–5 days for comprehensive) |

Role of Fabrication in Production

Pcb fabrication plays a key role in pcb manufacturing. You create the bare pcb, which acts as the foundation for all electronic devices. Without proper fabrication, you cannot move forward with pcb assembly. High-quality pcb fabrication ensures tight tolerances and reduces defects. You get better durability and longer life for your products when you use high-grade materials in pcb manufacturing. Precision in fabrication also means your boards work the same way every time, which is important for reliability.

Note: Tolerances in pcb manufacturing affect both cost and quality. If you set tolerances too tight, you may spend more money. If they are too loose, your pcb might not work well. You should always work with an experienced pcb manufacturing partner to get the best results.

You can see that pcb fabrication is the backbone of pcb manufacturing. Every step in the pcb fabrication process matters for the final performance of your electronic device.

PCB Assembly Process

Main Steps in Assembly

You start the pcb assembly process after pcb fabrication assembly creates the bare board. The main steps in circuit card assembly follow a clear order. Each step helps you turn a simple pcb into a working device. Here is what you do during pcb assembly:

Apply solder paste to the pcb using a stencil. This paste sticks to the spots where you will place components.

Place components on the board. Pick-and-place machines help you put each part in the right spot for circuit card assembly.

Move the board through a reflow oven. The heat melts the solder paste and connects the parts to the pcb.

Inspect the board for mistakes. Automated systems check for missing or misplaced parts during circuit card assembly.

Test the finished board. You make sure the circuit card assembly works as planned.

A pcb assembly manufacturer uses these steps to make sure your circuit card assembly meets high standards. Cleanliness matters at every stage. If you store boards wrong or handle them poorly, oxidation can build up and cause problems. Good pcb assembly services focus on quality control to avoid these issues.

Purpose of Assembly

The main goal of pcb assembly is to turn a bare pcb into a device that works. Circuit card assembly lets you mount and solder electronic parts onto the board. This process gives your device electrical connections and makes it reliable. You need pcb assembly to make sure all parts work together as a team.

A pcb assembly manufacturer plays a big role in this process. The role of a pcb assembly manufacturer is to use the right tools and skills to build strong, dependable circuit card assembly. When you choose pcb assembly services, you get expert help with mounting, soldering, and testing. This ensures your pcb fabrication assembly will last and perform well.

Tip: Treat pcb assembly as a key part of your design. Careful circuit card assembly leads to better heat control and longer life for your device.

A good pcb assembly manufacturer checks for mistakes and cleans the board well. This prevents failures and keeps your circuit card assembly working for a long time. You can trust pcb fabrication assembly to bring your ideas to life.

Key Differences Between Assembly and Fabrication

Process Comparison

You need to understand the key differences between assembly and fabrication before starting any pcb project. Fabrication creates the bare pcb. You use etching, layering, and drilling to shape the board. Assembly adds electronic components and solders them onto the fabricated pcb. This step turns the board into a working device.

Here is a table that shows how the processes differ:

Process | PCB Fabrication | PCB Assembly |

|---|---|---|

Definition | The creation of the bare PCB through etching, layering, and drilling. | The process of adding and soldering components onto the fabricated PCB. |

Sequence | This is the initial step before assembly can occur. | This follows fabrication and completes the circuit. |

Importance | Essential for creating the platform for assembly. | Necessary for making the PCB functional. |

You etch copper layers onto a substrate during pcb fabrication. You solder components onto the board during pcb assembly. You need both steps for a successful pcb manufacturing assembly. Understanding these differences helps you plan your workflow and avoid mistakes.

Time and Cost

You should know that pcb fabrication and pcb assembly have different timelines and costs. Fabrication usually takes longer if your design is complex. Assembly can be quick for prototypes but may take more time for larger production runs.

Check the table below for typical lead times:

Process | Lead Time |

|---|---|

PCB Fabrication (Standard) | 2–7 business days |

PCB Fabrication (Complex) | 7–15 business days |

Prototype Assembly | 1–5 working days |

Low-Volume Production Assembly | 5–10 working days |

You pay different amounts for each process. The average cost for pcb assembly ranges from $0.02 to $0.05 per square inch. Costs change based on design complexity and labor needs. Labor rates and overhead also affect the final price. You should compare quotes from different pcb manufacturing assembly partners to find the best value.

Tip: Plan your project timeline and budget by considering both fabrication and assembly. This helps you avoid delays and unexpected costs.

Required Files and Inputs

You need different files for pcb fabrication and pcb assembly. Each process uses specific documents to guide production and ensure quality.

For pcb fabrication, you prepare:

Fabrication drawing with board outline, drilled holes, stack-up view, and processing requirements.

ODB++ file with all data for defining circuit board layers.

Stack-up drawing showing layer thicknesses and materials.

Schematic drawings for the circuit design.

For pcb assembly, you provide:

Assembly drawing with component locations and reference designators.

Bill of materials (BOM) listing all components and their descriptions.

IPC netlist for test fixture information.

3D files for verifying component placement.

Special assembly instructions for soldering and handling.

You must check each file for accuracy before sending them to your pcb manufacturing assembly partner. Mistakes in these files can cause delays or defects.

Common Misunderstandings

Many people confuse pcb fabrication with pcb assembly. You might think they are the same process, but they serve different purposes. Fabrication creates the structure of the board. Assembly activates the board by adding functionality.

Here is a table that highlights common misunderstandings:

Aspect | PCB Fabrication | PCB Assembly |

|---|---|---|

Definition | Manufacturing of the bare circuit board without components | Process of placing and soldering components onto the PCB |

Purpose | Creates the structure of the board | Activates the board by adding functionality |

Quality Control | Electrical tests, AOI scans, X-rays | Functional testing, in-circuit tests, visual inspections |

Common Issues | Misaligned layers, over-etched copper | Misplacement, cold solder joints, incorrect parts |

Importance | Essential for creating a functional board | Essential for the board to operate as intended |

You may see the term "PWB assembly" in some industries. This can lead to confusion with pcb assembly. You need to use the correct terms to avoid errors in technical communication.

Experts recommend that you learn the physics and engineering principles behind pcb behavior. You should engage with manufacturing capabilities early in your design process. You must plan ahead and use rigorous quality controls in pcb fabrication. Strong partnerships with your pcb manufacturing assembly provider help reduce errors and improve reliability.

Note: Always double-check your files and instructions. Early communication with your pcb manufacturing assembly partner prevents costly mistakes and ensures your board works as intended.

PCB Production and Assembly Workflow

How Fabrication and Assembly Work Together

You need to understand how pcb production and assembly connect in a real-world setting. The workflow from fabrication to assembly follows a clear path. Each step builds on the last, making sure your project moves smoothly from idea to finished product. Here is a typical sequence:

Engineers design the pcb layout using special software.

The pcb is manufactured by printing copper traces and drilling holes.

Solder paste is printed onto the board to prepare for components.

Automated machines place components onto the pcb.

The board goes through reflow soldering, which melts the solder and secures the parts.

Inspection and testing check for quality and function.

Final assembly adds any last parts and prepares the board for shipment.

Many factories use conveyor systems to move boards between these steps. These systems help automate pcb production and assembly, reduce mistakes, and keep the process safe.

Choosing the Right Service

When you look for pcb production and assembly services, you should focus on several important factors. Quality assurance stands out as a top priority. You want a provider with experience and strong customer support. Cost matters, but you should balance price with value. Location can affect delivery times and communication. Industry certifications, like ISO 9001, show a provider meets high standards.

Some companies, such as Bittele Electronics and Unit Circuits, offer services that help beginners. Bittele Electronics is known for low-volume assembly and great customer service. Unit Circuits provides fast prototyping with no minimum order.

Specialization | |

|---|---|

Bittele Electronics | Low-volume PCB assembly with strong customer service |

Unit Circuits | Quick-turn PCB assembly for startups and industrial applications |

You should always match your needs to the provider’s strengths. Choosing the right service ensures your pcb production and assembly project succeeds.

You can see the main differences between PCB fabrication and assembly in the table below:

Aspect | PCB Fabrication | PCB Assembly |

|---|---|---|

Focus | Material selection, design | Component placement, soldering |

Cost | Usually less expensive | Often higher due to labor |

Timeline | Multiple steps, can take time | Focuses on assembly steps |

Quality Control | Protocols at each stage | Special checks for assemblies |

To get started, follow these steps:

Create a schematic diagram.

Design your PCB layout.

Test your design before production.

If you want to learn more, check out these resources:

Mastering Manual Assembly: A Beginner’s Guide to Electronics Projects

Essential Tools for Manual Assembly

DIY Electronics Projects

If you feel unsure, ask for help. Learning these basics gives you confidence and helps you build better projects.

FAQ

What files do you need for PCB fabrication and assembly?

Process | Required Files |

|---|---|

Fabrication | Gerber files, fab drawing |

Assembly | BOM, assembly drawing |

Can you assemble a PCB without fabrication?

You cannot assemble a PCB without fabrication. You need a bare board first. Assembly adds components to the fabricated board.

How do you choose between SMT and through-hole assembly?

Choose through-hole for strong mechanical support or larger components.

See Also

Essential Insights Into PCBA Manufacturing For All Skill Levels

Key Materials Required for Effective PCBA Production

Expert Strategies for Successful BGA Assembly Techniques

Understanding SMT and DIP Assembly for PCBA Uses

An Overview of Complete Turn-Key PCB Manufacturing Solutions