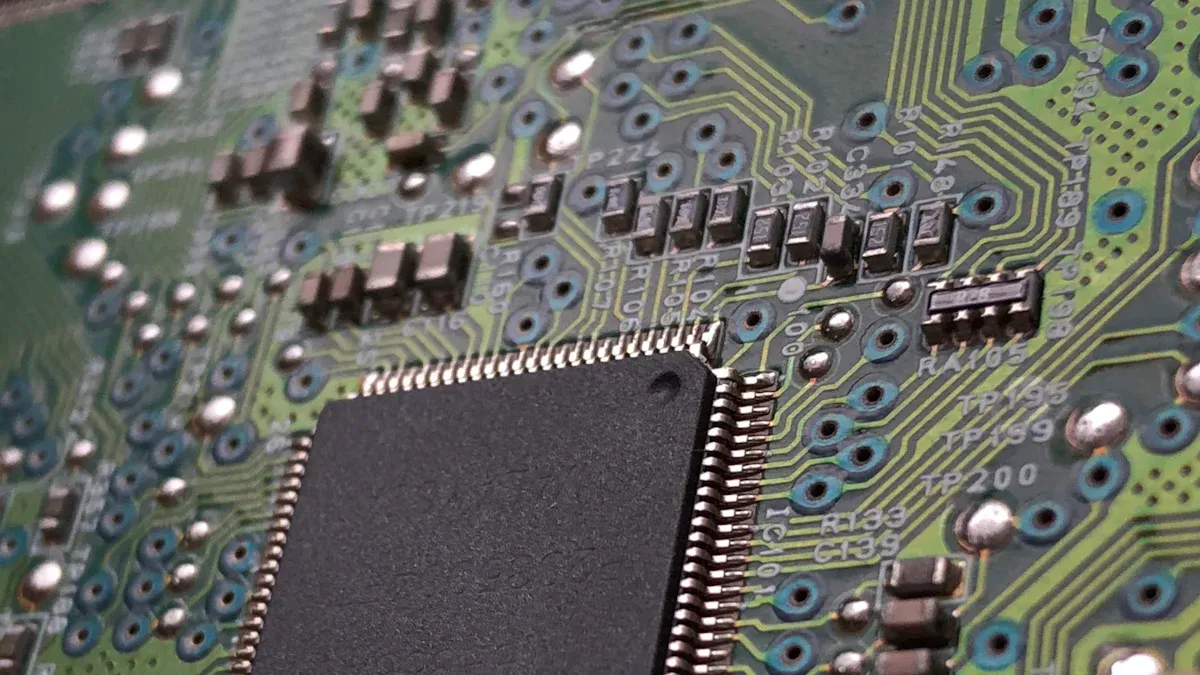

The manufacturability design of PCB boards for SMT processing requirements

Manufacturability design makes sure PCB boards fit SMT assembly needs. It boosts production speed, lowers costs, and keeps quality steady. For example, engineers may swap rare parts for common ones. This improves performance and saves money. LTPCBA helps by giving expert advice. It ensures designs follow rules and work perfectly during assembly.

Key Takeaways

A good design helps PCB boards fit SMT assembly needs. This makes production quicker, cheaper, and keeps quality steady.

Correct part placement and spacing are key for SMT assembly. Good layouts lower mistakes and make production faster.

Exact files like BOM and Gerber files are important for SMT assembly. They stop errors and make sure parts are placed right.

Understanding SMT Assembly and Its Design Needs

What is SMT assembly and why it’s useful

Surface Mount Technology (SMT) changed how PCBs are made. It uses machines to place parts on the board’s surface. This method is faster and more accurate than older ways. SMT parts are small, so boards can be compact and hold more components. It also reduces mistakes, with fewer than 10 errors per million parts. This makes it very reliable.

SMT saves money too. Faster production and better results cut costs. Industries like cars, planes, and medical tools use SMT for advanced systems. Examples include car controls, airplane electronics, and health monitors.

How SMT differs from through-hole technology

Through-hole technology (THT) puts parts with wires into drilled holes. SMT skips the holes and places parts directly on the board. This changes the size, speed, and density of the board.

Feature/Aspect | Through Hole Technology | Surface Mount Technology (SMT) |

|---|---|---|

Part Size | Bigger, takes more space | Smaller, saves space |

Part Density | Fewer parts fit | More parts fit |

Build Time | Slow, done by hand | Fast, done by machines |

Cost | Costs more | Costs less |

Heat Handling | Handles heat well | Can be heat-sensitive |

SMT is great for small, fast builds. THT works better for strong, sturdy designs.

Why good design matters for SMT assembly

Good PCB design helps SMT work well and stay reliable. Planning ahead lowers costs and makes production smoother. For instance, using the right settings for solder paste printing improves quality. Following smart design tips leads to better results and fewer errors.

New markets in Latin America and Africa show why design is key. Growth in electronics and automation needs careful PCB planning. Local production programs also push for designs that fit SMT methods.

Key Principles of Easy-to-Make PCB Designs for SMT Assembly

Placing and Spacing Parts the Right Way

Putting parts in the right spots is very important. It helps machines work faster during assembly. Studies show smart layouts save time and boost efficiency. A good design also matches machine needs, cutting down on soldering mistakes.

Think about how part placement affects making the PCB. A clear and smart layout makes building easier and improves quality.

Benefits of good placement and spacing:

Faster assembly because machines move less.

Fewer soldering mistakes for better reliability.

Easier and smoother manufacturing process.

Aligning Parts for Better Assembly

Parts need to face the right way for smooth assembly. For example, placing LEDs correctly makes them last longer and work better. If parts are not aligned, it can cause electrical problems like short circuits.

When parts are aligned, assembly is quicker and has fewer errors. It also ensures parts connect properly, helping devices work well and last longer.

Routing Traces and Placing Vias for Strong Signals

How you route traces and place vias affects signal quality. Avoid sharp corners in traces; use two smaller angles instead. Keep fast and slow signals apart to reduce interference.

Tips for routing and via placement:

Don’t put vias in paired traces to avoid signal issues.

Use multi-layer boards with special layers for power and ground.

Pick the right materials based on signal speed.

For example, FR-4 works for slow signals, while Rogers RO4350 is better for fast ones. These tips keep signals strong, even in tricky designs.

Making Pads Good for Soldering

Pads need the right size, shape, and finish for good soldering. For example, keeping pad spacing at least 0.006 inches helps solder stick well.

Pad Feature | Specification |

|---|---|

Minimum Pad Spacing | 0.006 inch |

Minimum Feature Size | 0.002 inch |

Soldermask Adhesion | Depends on materials used |

Following these rules makes solder joints stronger and reduces mistakes during assembly.

LTPCBA’s Way of Making PCB Designs Easy to Build

LTPCBA focuses on what customers need for easy PCB assembly. They use advanced methods to handle different part types, like small and big BGAs.

Their quality checks are also important. The team fixes problems and prevents them from happening again. This ensures your PCB design is ready for smooth assembly.

Feature | Description |

|---|---|

Customer Focus | LTPCBA listens to customer needs for better designs. |

Quality Checks | Prevents problems and keeps high standards. |

Advanced Techniques | Handles all kinds of parts for great results. |

By working with LTPCBA, you get expert help for fast and reliable PCB assembly.

Design Checks and Process Compatibility for SMT Assembly

Keeping files accurate: Gerber files, BOM, and pick-and-place data

Accurate files are key for smooth SMT assembly. You must provide complete files like Gerber files, BOM (Bill of Materials), and pick-and-place data. Each file has a specific job in the process.

File Type | Purpose |

|---|---|

Netlists (IPC-D-350 and IPC-D-356) | Show electrical connections for correct assembly. |

Centroid File | Gives part positions and directions for machine assembly. |

BOM | Lists all parts, their numbers, and needed amounts. |

Unlike regular Gerber files, IPC-2581 combines all data into one file. This format includes layout, drilling, and placement details. It reduces errors and helps teams work better together. It ensures your PCB design fits SMT needs.

Checking design specs with SMT equipment

Checking your design specs makes sure they match SMT tools. This step tests if pad sizes, trace widths, and part placements fit machine limits.

Tests like power checks and signal quality tests confirm the design works. These tests ensure the PCB functions well and meets standards.

Purpose | |

|---|---|

Basic functional test | Checks if the product works as expected. |

Power measurement | Measures how much power the device uses. |

Signal quality test | Tests how clear the signals are. |

Conformance test | Ensures the design meets all rules. |

EMI pre-scan | Checks for electromagnetic interference. |

Thermal and 4 corner test | Tests heat performance in different areas. |

Basic parametric measurements | Confirms key product specifications. |

These checks find problems early, saving time and money later.

Avoiding common design mistakes in SMT assembly

Avoiding mistakes is important for good SMT assembly. Errors like wrong part direction, small pad spacing, or bad solder mask design cause problems.

Problem Description | Observations | Fixes Applied |

|---|---|---|

Parts placed incorrectly | Adjust machine temperature and do maintenance. | |

Resistance readings vary between operators | Inconsistent measurement results | Improve training and update procedures. |

Fixing these issues during design improves production and lowers defects.

How LTPCBA ensures designs work with SMT

LTPCBA uses advanced tools to check and improve PCB designs. They make sure files are correct and designs fit SMT processes.

Their performance metrics show their focus on quality:

KPI Name | Average Value |

|---|---|

12 hours | |

First Pass Yield | 95% |

On-Time Delivery Rate | 97% |

LTPCBA’s expertise reduces mistakes and boosts efficiency. They ensure your PCB assembly is smooth and reliable, giving you great results.

Getting Ready for SMT Assembly and Testing

Checking the BOM and Finding Materials

A clear BOM (Bill of Materials) helps SMT assembly go smoothly. It should have all the needed details to avoid mistakes.

Add part numbers to prevent mix-ups.

Write exact amounts for each part.

Use Reference Designators to show where parts go on the PCB.

Give detailed info to stop wrong orders.

List backup parts in case of supply problems.

A neat BOM makes quoting faster, helps buy parts quickly, and improves assembly. Double-checking every detail ensures your design works for SMT.

Setting Up SMT Machines and Stencils

SMT setup means programming machines to place parts correctly. You need to give accurate pick-and-place data for this. Stencils are also important. They control how solder paste is added to the PCB.

Use laser-cut stencils for better accuracy.

Match stencil holes to pad sizes for good solder paste application.

Pick the right stencil thickness to avoid solder problems.

Good setup and stencils make assembly easier and reduce errors.

Checking Quality: AOI, X-ray, and Tests

Quality checks make sure your PCB is built well. Different tests check different parts of the process.

Check Type | What It Does |

|---|---|

Finds problems like misplaced parts or bad solder using cameras. | |

X-ray Inspection | Looks at hidden solder joints and inside parts, like in BGA packages. |

Functional Testing | Makes sure the PCB works as it should before shipping. |

These checks catch problems early, so your PCB is reliable and ready to use.

LTPCBA’s Quality Steps for Great SMT Assembly

LTPCBA follows strict rules to make high-quality PCBs. They use IPC-A-610 for solder standards and ISO 9001 for quality management.

Rule/Method | What It Covers |

|---|---|

IPC-A-610 | Sets rules for solder joints, part placement, and cleanliness. |

Automated Optical Inspection (AOI) | Uses cameras to find issues like misplaced parts. |

X-ray Inspection | Spots hidden problems, like short circuits, with detailed images. |

By using advanced checks and strict rules, LTPCBA ensures your PCB meets top quality standards.

Making PCB designs easy to build helps SMT assembly work well. Using smart SMT design ideas saves money and improves production. LTPCBA gives expert help and uses advanced tools to prepare designs. Their focus on quality makes sure your PCB projects are reliable and successful.

FAQ

1. Why is manufacturability design important for SMT assembly?

Manufacturability design makes sure your PCB works with SMT. It speeds up production, lowers mistakes, and ensures high-quality devices.

2. How does LTPCBA support manufacturability design?

LTPCBA offers expert advice, modern tools, and strict checks. These help your PCB design match SMT needs for easy and smooth assembly.

3. What files are needed for SMT assembly?

You need Gerber files, BOM, and pick-and-place data. These files help place parts correctly and make production faster.

See Also

Essential Criteria For PCB Boards In SMT Manufacturing

Top Strategies To Enhance SMT Line Efficiency In PCBA

Choosing The Right PCB Materials For SMT Assembly