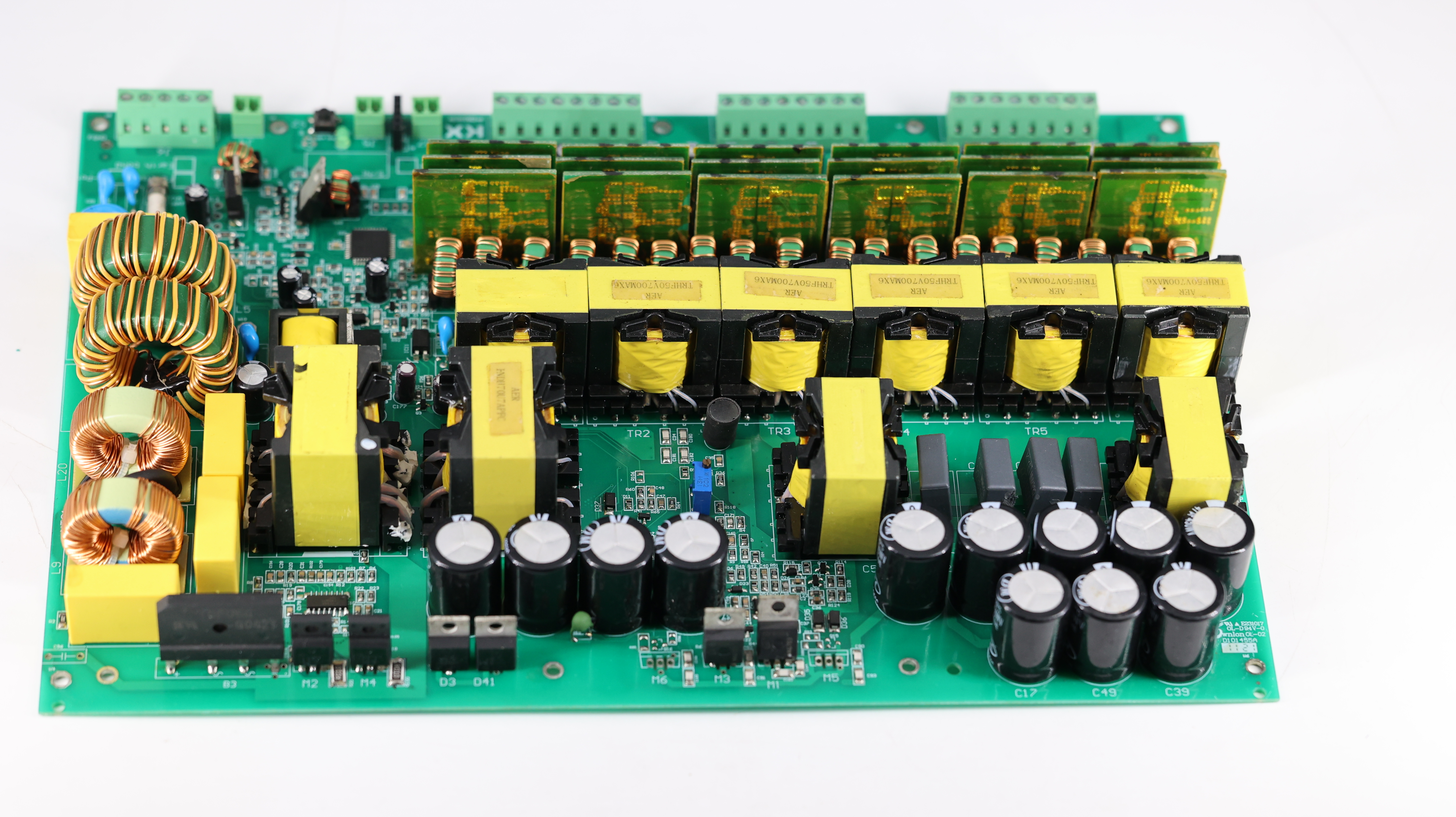

Is Outsourcing PCB Manufacturing Right for Your Business

Outsourcing pcb manufacturing and assembly can help you cut costs, access specialized expertise, and scale your operations quickly. When considering pcb manufacturing and assembly, it’s essential to focus on key factors such as cost, speed, and control. Many businesses have concerns about common challenges:

Concern Type | Description |

|---|---|

Inadequate Partner Vetting | Weak vetting in pcb manufacturing and assembly can cause costly rework and delays. |

Ignoring Total Cost of Ownership (TCO) | Hidden expenses in pcb manufacturing and assembly, like rework and warranty claims, hurt profits. |

Failing to Prioritize Effective Communication | Poor communication during pcb manufacturing and assembly leads to misunderstandings and flawed products. |

Viewing the Relationship as Transactional | Treating pcb manufacturing and assembly partnerships as transactional limits growth and innovation. |

Key Takeaways

Outsourcing PCB manufacturing can significantly reduce costs, especially for small production runs, allowing businesses to focus on their core operations.

Access to specialized expertise and advanced technology through outsourcing can enhance product quality and consistency, ensuring compliance with industry standards.

Effective communication and thorough vetting of partners are crucial to mitigate risks associated with outsourcing, such as quality control issues and delays.

Decision Factors for PCB Manufacturing and Assembly

When you consider outsourcing pcb manufacturing, you need to look at several important factors. These include your business goals, the type and amount of products you want to make, and how quickly you need to get your product to market. Each of these factors can help you decide if outsourcing pcb assembly or keeping in-house pcb manufacturing makes sense for your company.

Business Goals and Priorities

Your business goals shape your decision. If you want to use advanced technology or lower your costs, outsourcing can help. Here is a quick look at how your priorities can affect your choice:

Factor | Explanation |

|---|---|

Access to Advanced Technology | Outsourcing gives you access to expensive machines and automation without buying them yourself. |

Lower Operational Costs | You can turn fixed costs into variable costs and focus on your main business. |

Strong Supply Chain Support | Experienced partners can get parts faster and at better prices, which saves money and avoids shortages. |

Better Quality and Consistency | Trusted providers follow strict rules, so you get reliable products with fewer defects. |

Production Volume and Complexity

Think about your production volume and complexity. If you need to make thousands or even millions of units, outsourcing pcb manufacturing can handle these large orders. Many industries, like automotive and medical devices, need complex boards and strict quality checks. Outsourcing partners use advanced inspection tools and can manage both simple and complex jobs.

Time-to-Market Needs

Speed matters in today’s market. If you need to launch your product fast, outsourcing pcb assembly can help you move up to 30% quicker than doing it yourself. Contract manufacturers already have the tools and supply chains in place. They can also adjust their methods to fit your project, which helps you respond to changes and stay ahead of competitors.

Benefits of Outsourcing PCB Assembly

Cost Savings

You can achieve significant cost savings by outsourcing pcb assembly. Many companies choose this path to reduce expenses. In fact, a KPMG survey found that 94 percent of companies outsource PCB assembly primarily for cost savings. When you compare in-house pcb manufacturing with outsourcing, the numbers show a clear advantage for outsourcing, especially for small production runs.

Production Method | Total Cost | |

|---|---|---|

In-House | $200 | $200,000 |

Outsourced | $85 | $85,000 |

For small batches, outsourcing pcb manufacturing offers better cost-effectiveness and economies of scale. In-house production may only become cost-effective for very large runs, where you can spread capital costs over many units.

Access to Expertise

You gain access to advanced technologies and specialized skills when you outsource. Leading vendors employ technicians with deep, cross-disciplinary expertise. They hold certifications like IPC-A-620 and IPC-A-610, which are not always available in-house. These vendors also understand industry standards such as ISO 16750 and IEC 60947. They use advanced tools, including 3D X-ray machines and environmental chambers, to ensure high quality.

Aspect | In-House Teams | Leading PCB Assembly Vendors |

|---|---|---|

Skills | Limited cross-disciplinary skills | Deep, cross-disciplinary expertise |

Certifications | Varies, often not IPC certified | IPC-A-620/IPC-A-610 certified technicians |

Industry Knowledge | General knowledge | Specialized knowledge of ISO 16750 and IEC 60947 standards |

Tools | Basic equipment | Advanced tools like 3D X-ray and environmental chambers |

Outsourced providers keep their teams up to date by hiring skilled engineers and using the latest technology. They guarantee IPC certification, which is essential for technical standards. Many also comply with ISO 9001, AS9100D, or ISO 13485, which are crucial for industries like aerospace and medical devices.

Faster Time to Market

You can bring your products to market faster with outsourcing pcb assembly. Contract manufacturers have established supply chains and production lines. This means you do not need to wait to set up your own processes. You benefit from their experience and infrastructure, which increases efficiency and reduces delays.

Outsourced providers can quickly adjust to changes in demand. They manage production capacity dynamically, so you do not need to invest in extra resources. This flexibility helps you respond to market shifts and stay competitive. You avoid the risk of holding excess inventory and can shift your focus based on trends.

Tip: Outsourcing gives you a time-to-market and flexibility advantage, helping you launch new products ahead of competitors.

Scalability and Resource Focus

Outsourcing allows you to scale production up or down as needed. You can handle projects of any size, from small prototypes to large production runs. This customization and flexibility prevent problems like overstaffing or idle equipment during slow periods. You can also manage seasonal demand changes without wasting resources.

Outsourcing enables real-time adjustments to production levels.

You can optimize resource use and avoid shortages or excess capacity.

Companies can quickly accommodate growth without large capital investments.

When you outsource, you can focus on core competencies. For example, a Western European industrial SME freed up 30% of its production floor space and several million dollars in working capital by outsourcing non-core manufacturing tasks. This allowed the company to launch new products and improve customer service. The CEO said the company felt "lighter and more focused," showing how outsourcing can help you concentrate on what matters most.

By choosing outsourcing pcb manufacturing and assembly, you gain cost savings, access to expertise, faster market entry, and the ability to scale efficiently. These benefits help you stay agile and competitive in a fast-changing industry.

Risks of Outsourcing PCB Manufacturing

When you consider outsourcing pcb manufacturing, you must weigh the potential drawbacks as carefully as the benefits. While outsourcing can boost efficiency and lower costs, it also introduces risks that can impact your product quality, timelines, and business reputation.

Loss of Control

You give up a degree of direct oversight when you outsource. This shift can lead to several challenges:

Quality control issues may arise, resulting in electrical failures or increased warranty returns.

Sharing your designs with external partners increases the risk of intellectual property leakage.

Communication barriers, such as time zone differences or language gaps, can cause misunderstandings.

Offshore manufacturing often leads to longer lead times due to shipping and customs.

Description | |

|---|---|

Wrong Contract Manufacturer | Selecting an inappropriate contract manufacturer can lead to various operational issues. |

Inadequate Communication | Poor communication can result in misunderstandings and project delays. |

Hidden Costs | Lower initial quotes may hide significant costs related to defects and corrections. |

Compliance Management Issues | Failing to ensure compliance with environmental regulations can expose companies to legal risks. |

You can lose control over processes if you do not define your requirements clearly or if you select the wrong partner. To maintain control, you should:

Define your requirements with clarity.

Evaluate the manufacturer's quality and certifications.

Visit or audit the factory when possible.

Note: You can protect your intellectual property by working with reputable companies and signing non-disclosure agreements.

Quality and Consistency Risks

Quality and consistency can suffer when you rely on external partners. You may face issues such as:

Inconsistent quality standards across different vendors.

Defects that require costly rework or lead to product failures.

Compliance problems if the manufacturer does not follow industry regulations.

Importance | |

|---|---|

Quality Control Processes | Essential for maintaining high production standards |

Certifications (ISO 9001, ISO 13485) | Ensures compliance with industry standards |

Testing Procedures | Critical for verifying product functionality and reliability |

You should insist on enhanced quality control. Ask your partner about their testing procedures, such as flying probe or in-circuit testing, functional tests under simulated conditions, X-ray inspection, and burn-in testing. These steps help catch defects early and ensure reliable products.

High-quality assurance is crucial in PCB assembly to mitigate potential risks and ensure the reliability of electronic products. By implementing robust quality control measures, manufacturers can identify and rectify defects early in the assembly process, preventing costly rework or product failures.

Quality testing is vital, especially for industries like medical, automotive, or aerospace. You should always verify that your partner holds the right certifications and follows strict quality processes.

Communication and Delays

Communication breakdowns and delays are common risks in outsourcing pcb assembly. You may work with multiple vendors, which increases the chance of misunderstandings and shipment delays.

Description | |

|---|---|

Communication breakdowns | Occur due to multiple vendors handling different steps of the process. |

Shipment delays | Result from the involvement of various contractors and logistics issues. |

Quality inconsistencies | Arise from inconsistent QA standards across different vendors. |

You can minimize these risks by:

Providing feedback quickly on design iterations.

Tracking versions and changes with digital tools.

Centralizing communication and documentation to create a single source of truth.

Using integrated platforms like Flux for real-time collaboration.

Tip: Effective communication and clear documentation help you avoid costly delays and ensure everyone stays on the same page.

You should also plan logistics carefully and understand lead times. This approach helps you take advantage of rapid production capabilities while avoiding unexpected delays.

If you compare outsourcing with in-house pcb manufacturing, you will see that in-house teams often have fewer communication barriers and more direct control. However, outsourcing can still succeed if you use strong vendor management and quality assurance practices.

By understanding these risks and taking proactive steps, you can make outsourcing pcb manufacturing and assembly a successful part of your business strategy.

Making the Right Choice

When you decide if outsourcing pcb assembly fits your business, you need a clear process. Start by looking at your technical requirements and quality standards. Make sure your partner can handle your product’s complexity and industry needs.

Assessing Technical Requirements

You should check if your project needs special skills or equipment. Use this table to guide your review:

Requirement | Description |

|---|---|

Manufacturing Capabilities | Does the partner have experience with your type of pcb manufacturing and assembly? |

Do they follow strict quality checks and testing? | |

Supply Chain Management | Can they source reliable parts quickly and cost-effectively? |

A dependable supplier network and efficient sourcing help you achieve rapid prototyping and iteration. Ask if the partner has experience in your industry and what technologies they use to ensure quality.

Evaluating Vendors

Choose vendors who meet your technical requirements and quality standards. Look for:

Certifications like IPC-A-610 and RoHS compliance

Watch for red flags such as poor communication, lack of expertise, or weak quality control. These issues can lead to delays and extra costs.

Calculating Total Costs

Compare in-house pcb manufacturing with outsourcing by listing all expenses. Include engineering fees, expedited charges, and small batch surcharges. Add hidden costs like delays, quality issues, and communication barriers. Use these steps:

Define your project scope.

List all in-house costs.

Get quotes from vendors.

Subtract in-house costs from vendor quotes.

Add risk and long-term costs.

This approach gives you a full picture of your investment.

Aligning with Long-Term Strategy

Think about how outsourcing fits your business goals. Outsourcing lets you focus on core competencies and access to advanced technologies. You gain customization and flexibility, which helps you scale and adapt. Over time, you reduce capital investment and keep up with industry changes.

Tip: Align your outsourcing decision with your growth plans to stay competitive and efficient.

Outsourcing PCB manufacturing offers cost savings, expertise, and scalability, but you must weigh these against risks like less control. Align your choice with business goals. Compare outsourcing with in-house pcb manufacturing. Start with a pilot project, review vendor quality, and use advanced cost estimation to improve your results.

FAQ

What is the main difference between outsourcing and in-house pcb manufacturing?

You control every step with in-house pcb manufacturing. Outsourcing lets you use external expertise and resources. Each approach offers unique benefits for your business goals.

How do you choose a reliable PCB manufacturing partner?

Check certifications, review customer feedback, and ask about quality control. Visit the facility if possible. Strong communication and clear expectations help you avoid common issues.

Can outsourcing help you scale production quickly?

Yes. Outsourcing allows you to increase or decrease production fast. You avoid large investments in equipment and staff. This flexibility supports rapid business growth.

See Also

Tips for Choosing the Ideal Turnkey PCBA Manufacturer

Enhancing Business Efficiency Through PCBA Contract Manufacturing

Finding the Perfect PCBA Supplier for Your Requirements

Sourcing Electronic Components for Effective PCBA Manufacturing

Selecting the Top Comprehensive PCB Assembly Service Provider