Optimizing Your SMT Assembly Line for Small to Medium Production Runs

You have some special problems with a small or medium smt assembly line. You need to change things often and make many types of products. This means you need flexible layouts and smart machines. Many factories now use real-time monitoring and data analytics. These tools help make quality and efficiency better. They help you act fast, save money, and improve each step of your smt assembly line.

Key Takeaways

Think about your SMT assembly line layout to save time and space. Try using U-shaped layouts and clear floor markings. These help workers move materials fast and stay safe.

Pick SMT machines that are not too simple or too complex. These machines can handle many product types. They help lower costs and make training easier.

Use lean process control and real-time monitoring to cut waste. These steps also help improve quality. Check and train workers often to find defects early. This keeps your line running well.

SMT Assembly Line Optimization

Line Layout Planning

You can make your smt assembly line better by planning the layout well. A smart layout helps workers move materials faster. This saves time and lowers labor costs. It also helps you make more products in less time. Machines and workstations should be set up for easy material flow. A U-shaped layout can save space. It lets workers reach stations quickly. This layout also helps you make different products easily.

Tip: Put clear signs and lines on the floor. This helps workers move materials fast and stay safe.

Check your layout often to see if it works well. Small changes, like moving a feeder closer, can help a lot. When you plan, think about how to make the process flexible. This helps you handle new products and meet customer needs.

Equipment Selection

Picking the right equipment is very important for your smt assembly line. You do not always need the newest machines. Moderate complexity SMT machines are often the best choice. They give you a good mix of automation and flexibility. These machines can make many types and sizes of products. This is great for small and medium runs.

In Kazakhstan, a factory uses moderate complexity SMT machines. They also use process optimization to make complex products. This keeps their output steady and high-quality.

In Finland, an LED line uses similar machines. The line makes up to 1,000 LED bulbs and 400 LED strips each hour. The machines work with different LED sizes. This makes the line flexible and saves money.

In Uruguay, a U-shaped smt assembly line uses advanced pick-and-place machines. The line makes up to 1,000 units each hour. It uses AI-driven quality control to lower defects.

These examples show that moderate complexity SMT machines help you work faster. They also make it easier to train workers and keep costs low.

Process Control

You can make process control better by using lean principles and standard workstations. Lean principles, like Kaizen, help you find and remove waste. This means workers move less and work faster. Standard workstations make sure everyone does the same steps. This keeps quality high.

A company used lean methods like DMAIC and Value Stream Mapping. They cut lead time by two hours. They also made process cycle efficiency over 40% better. They removed all steps that did not add value. This made the smt assembly line run smoother.

Note: Lean tools like just-in-time production and Kanban help you control inventory. They also help you react fast to changes in demand.

Studies show that lean production control systems, like CONWIP, work well in complex factories. These systems help you handle demand changes and keep your smt assembly line running well. If you focus on ergonomics and better workstations, workers stay safe and do a better job.

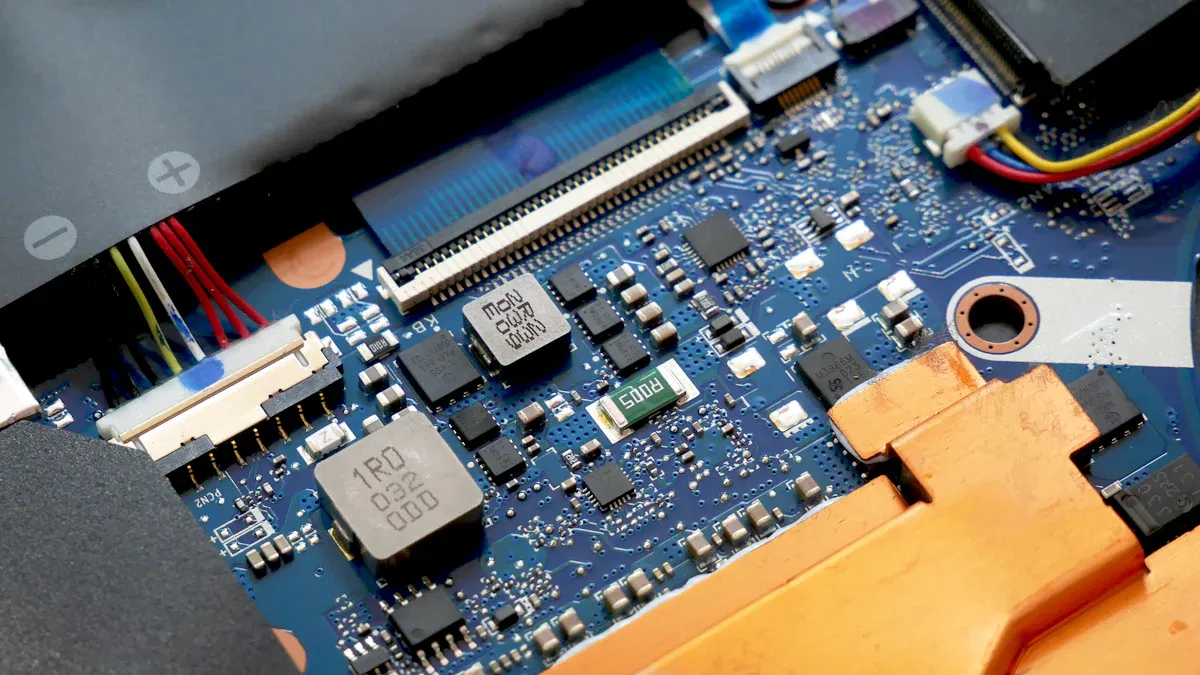

Surface Mount Technology Process

Surface mount technology lets you make electronic products fast. It also helps you keep the quality high. Every step in this process matters for your yield. It also affects how well your pcb manufacturing works. You can get better first run yield and save money. Focus on four main stages: solder paste printing, component placement, reflow soldering, and inspection & quality control.

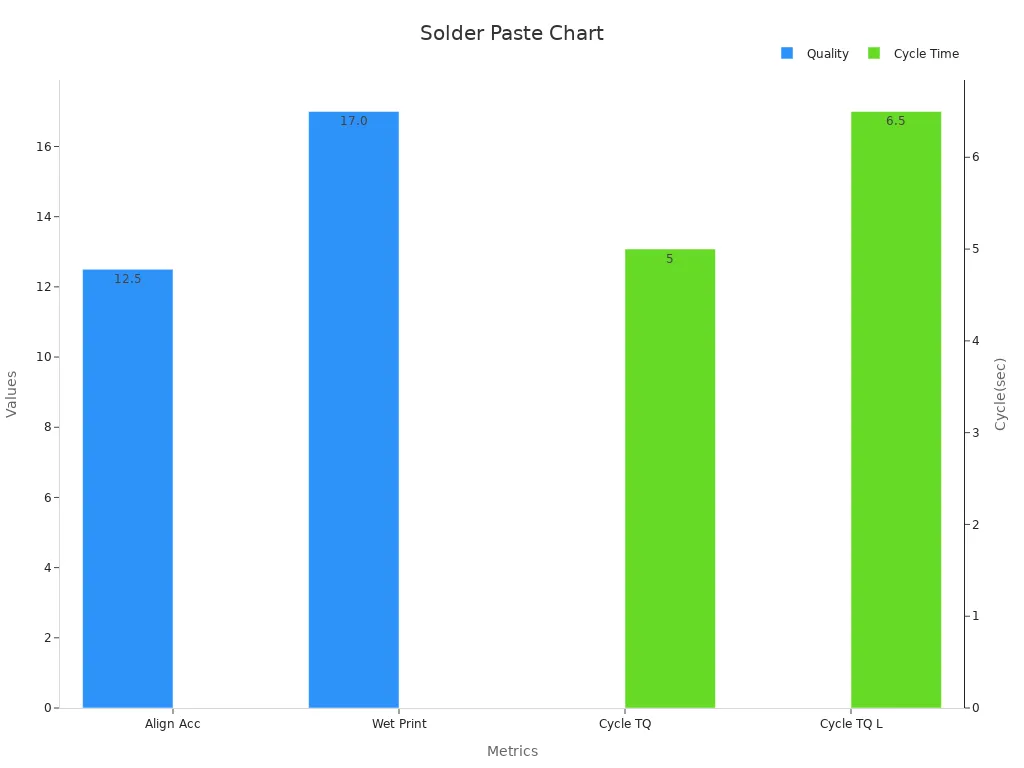

Solder Paste Printing

Solder paste printing is the first step in this process. You put solder paste on the pcb pads. This gets them ready for component placement. You need to control this step to get high yield and fewer defects.

Automated printers help you line things up and work faster. New printers have automatic stencil cleaning and real-time monitoring. These features keep the process steady. They also help when you change pcb designs. If you make solder paste printing better, you get higher first run yield and less rework.

Here is a table that shows how better solder paste printing helps:

Metric | Value | Significance |

|---|---|---|

Alignment Accuracy | High precision in solder paste alignment | |

Wet Print Accuracy | ±17.0 micrometers at 2 Cpk | Consistent and accurate paste volume |

Core Cycle Time (DEK TQ) | 5 seconds | Fast printing process efficiency |

Core Cycle Time (DEK TQ L) | 6.5 seconds | Optimized throughput for larger pcbs |

Tip: Use in-line inspection after solder paste printing. This helps you find mistakes early and keeps your yield high.

Component Placement

Component placement is when you put parts on the pcb. Pick-and-place machines do this step. You can get better yield and first run yield with smart feeders and real-time monitoring.

Smart feeders use sensors to cut down on mistakes. They also make changeovers quicker. Software can track how well parts are placed and how fast. Training operators and doing regular maintenance keeps machines working well. These steps help you stop downtime and make more pcbs.

Here is a table that shows how you can make feeder efficiency and placement better:

Performance Aspect | Measurement / Result | Impact on Feeder Efficiency / SMT Placement |

|---|---|---|

Placement Accuracy Improvement | Reduced soldering defects by up to 15% | |

Vision System Error Rate | Below 0.001% at 50,000 CPH | High-speed placement with minimal errors |

Smart Feeders with Sensors | More reliable placement, less downtime | |

Smart Scheduling | 30% faster changeover | Higher throughput, less waiting |

Operator Training | 20% fewer programming errors | Better uptime, fewer setup mistakes |

KPIs | Key metrics for pick-and-place performance |

Note: Smart feeders and software help you track yield and first run yield. They also let you change settings fast for different pcb types.

Reflow Soldering

Reflow soldering melts the solder paste and connects parts to the pcb. You must control the temperature profile well. A good profile starts slow, then gets hotter, then cools down fast. This helps stop problems like bridging, tombstoning, and solder balling.

Forced air convection ovens give you better heat control. They work for many pcb sizes and part types. If you use good reflow profiles, you get stronger solder joints and higher yield. This is important for small and medium runs. You want every pcb to pass the first time.

Tip: Use SAC solder and watch the process with sensors. This helps you keep first run yield high and avoid rework.

Inspection & Quality Control

Inspection and quality control make sure your process gives good products. Automated optical inspection systems check each pcb for defects after reflow. In-line inspection finds problems early. You can fix them before they reach the customer.

Studies show better inspection and process changes lower defect rates. Here is a table that compares different inspection ways:

Inspection Strategy | Defect Probability (Pd) | Type I Error (α) | Type II Error (β) | Inspection Cost (€/unit) | Prevention Cost (€/unit) | External Failure Rate (EF, 10^-3) | Cost of Quality (CoQ, €) |

|---|---|---|---|---|---|---|---|

IS-0 (100% inspection) | 1.80% | 0.50% | 0.43 | 0 | 0.257 | 0.600 | |

IS-1 (Better equipment) | 5.14% | 1.00% | 0.10% | 1.00 | 0 | 0.051 | 1.194 |

IS-2 (Process improvement) | 2.5% | 1.80% | 0.50% | 0.43 | 0.40 | 0.125 | 0.921 |

Automated inspection and watching the process all the time help you get close to zero defects. Real-time data helps you see trends and make things better. You can use statistical process control to track yield and first run yield over time. This helps you balance quality and cost in your pcb manufacturing.

Tip: Design your pcb so it is easy to inspect. Use clear marks and test points. This makes it easier to find defects and improve your yield.

You can make your SMT assembly line better by picking flexible machines. Use good processes and focus on checking quality. New studies show that smart machines and software help a lot. Training workers also helps you place parts faster and make fewer mistakes. You will get more good products this way.

Use machine learning to check quality

Train workers often

Make sure everyone follows the same steps

Link systems for real-time control

You can talk to SMT experts or have someone check your factory. This can help you find even more ways to improve.

FAQ

What is the best way to reduce changeover time in SMT assembly?

You can use smart feeders and quick-release fixtures. These tools help you switch products fast and keep your line running smoothly.

Tip: Train your team to follow a clear changeover checklist.

How do you keep quality high in small to medium SMT runs?

You should use in-line inspection and real-time monitoring. These steps help you catch problems early and keep your defect rate low.

Can you optimize an SMT line without buying new machines?

Yes. You can rearrange your layout, improve process control, and train workers. These changes boost efficiency and quality without big investments.

See Also

Effective Strategies To Enhance SMT Line Performance In PCBA

Ways To Improve SMT PCB Assembly For Higher Efficiency

Fast SMT Assembly Solutions Delivering Quality Under Tight Deadlines

Top SMT Assembly Techniques For Superior Electronic Production